How to engineer porosity gradients in HE ceramics for thermal insulation with mechanical load

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Porosity Gradient Ceramics: Background and Objectives

Porosity gradient ceramics represent a significant advancement in materials science, particularly for high-entropy (HE) ceramic systems designed for extreme environments. The evolution of these materials traces back to the early 2000s when researchers began exploring heterogeneous ceramic structures with controlled porosity distributions. This technological trajectory has accelerated in recent years due to increasing demands for materials that can withstand both thermal and mechanical stresses in aerospace, energy generation, and advanced manufacturing sectors.

The fundamental concept behind porosity gradient ceramics involves the strategic engineering of void spaces within the ceramic matrix, creating a graduated structure that transitions from high porosity regions (optimized for thermal insulation) to denser regions (providing mechanical strength). This gradient approach represents a paradigm shift from traditional homogeneous ceramics, which typically force engineers to compromise between thermal and mechanical properties.

High-entropy ceramics, characterized by their incorporation of multiple principal elements in near-equimolar ratios, have emerged as particularly promising candidates for porosity gradient engineering. These materials exhibit exceptional phase stability, resistance to grain growth, and superior mechanical properties compared to conventional ceramics. The combination of the HE concept with porosity gradients creates a powerful synergy that addresses the longstanding challenge of achieving both thermal insulation and mechanical load-bearing capabilities.

Current technological trends indicate a growing focus on precise control of porosity architecture at multiple length scales, from nanometer to millimeter dimensions. This multi-scale approach enables tailored performance across different regions of a single component. Advances in manufacturing techniques, particularly additive manufacturing and freeze-casting methods, have been instrumental in realizing these complex structures with unprecedented precision.

The primary objective of research in this field is to develop systematic methodologies for engineering porosity gradients in HE ceramics that optimize the trade-off between thermal insulation and mechanical integrity. This includes establishing quantitative relationships between processing parameters, resultant microstructures, and functional properties. Additionally, researchers aim to create predictive models that can guide the design of gradient structures for specific application requirements.

Another critical goal is to enhance the scalability and reproducibility of manufacturing processes for these advanced ceramics, transitioning from laboratory demonstrations to industrially viable production methods. This technological evolution is expected to enable next-generation thermal management solutions for hypersonic vehicles, nuclear fusion reactors, and concentrated solar power systems, where the combination of extreme temperatures and mechanical loads presents unique materials challenges.

The fundamental concept behind porosity gradient ceramics involves the strategic engineering of void spaces within the ceramic matrix, creating a graduated structure that transitions from high porosity regions (optimized for thermal insulation) to denser regions (providing mechanical strength). This gradient approach represents a paradigm shift from traditional homogeneous ceramics, which typically force engineers to compromise between thermal and mechanical properties.

High-entropy ceramics, characterized by their incorporation of multiple principal elements in near-equimolar ratios, have emerged as particularly promising candidates for porosity gradient engineering. These materials exhibit exceptional phase stability, resistance to grain growth, and superior mechanical properties compared to conventional ceramics. The combination of the HE concept with porosity gradients creates a powerful synergy that addresses the longstanding challenge of achieving both thermal insulation and mechanical load-bearing capabilities.

Current technological trends indicate a growing focus on precise control of porosity architecture at multiple length scales, from nanometer to millimeter dimensions. This multi-scale approach enables tailored performance across different regions of a single component. Advances in manufacturing techniques, particularly additive manufacturing and freeze-casting methods, have been instrumental in realizing these complex structures with unprecedented precision.

The primary objective of research in this field is to develop systematic methodologies for engineering porosity gradients in HE ceramics that optimize the trade-off between thermal insulation and mechanical integrity. This includes establishing quantitative relationships between processing parameters, resultant microstructures, and functional properties. Additionally, researchers aim to create predictive models that can guide the design of gradient structures for specific application requirements.

Another critical goal is to enhance the scalability and reproducibility of manufacturing processes for these advanced ceramics, transitioning from laboratory demonstrations to industrially viable production methods. This technological evolution is expected to enable next-generation thermal management solutions for hypersonic vehicles, nuclear fusion reactors, and concentrated solar power systems, where the combination of extreme temperatures and mechanical loads presents unique materials challenges.

Market Analysis for High-Entropy Ceramic Thermal Insulators

The global market for high-entropy ceramic thermal insulators is experiencing significant growth, driven by increasing demands in aerospace, energy, and advanced manufacturing sectors. Current market valuations indicate that the thermal insulation materials market reached approximately $27 billion in 2022, with high-performance ceramics representing a growing segment estimated at $3.5 billion. Industry analysts project a compound annual growth rate of 6.8% for specialized ceramic thermal insulators through 2030.

The aerospace and defense sectors constitute the largest market segment, accounting for nearly 35% of high-entropy ceramic applications. These industries require materials that can withstand extreme temperatures while maintaining structural integrity under mechanical stress. The energy sector follows closely, with applications in gas turbines, nuclear reactors, and concentrated solar power systems demanding approximately 28% of market share.

Regional analysis reveals North America and Europe as current market leaders, collectively holding 58% of the global market. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is demonstrating the fastest growth rate at 8.2% annually, fueled by expanding industrial bases and increased R&D investments in advanced materials.

Customer needs assessment indicates five primary market requirements: superior thermal insulation performance, mechanical durability under load, weight reduction capabilities, extended service life in extreme environments, and cost-effectiveness compared to traditional solutions. The engineered porosity gradient technology directly addresses these requirements by enabling customizable thermal-mechanical property profiles.

Market barriers include high production costs, with current manufacturing processes for high-entropy ceramics with controlled porosity gradients being 2.5-3 times more expensive than conventional ceramics. Technical complexity in achieving consistent porosity control at industrial scales also limits widespread adoption. Additionally, conservative industry adoption cycles, particularly in safety-critical applications, slow market penetration.

Emerging opportunities exist in the renewable energy sector, where high-temperature thermal energy storage systems could benefit from porosity-engineered high-entropy ceramics. The electric vehicle market also presents potential applications in battery thermal management systems, where materials with tailored thermal conductivity gradients could enhance safety and performance.

Consumer willingness to pay premium prices for high-entropy ceramic insulators varies by sector, with aerospace and defense demonstrating highest price tolerance (30-40% premium), followed by energy (20-25% premium) and industrial manufacturing (15-20% premium). This price sensitivity directly correlates with application criticality and performance requirements.

The aerospace and defense sectors constitute the largest market segment, accounting for nearly 35% of high-entropy ceramic applications. These industries require materials that can withstand extreme temperatures while maintaining structural integrity under mechanical stress. The energy sector follows closely, with applications in gas turbines, nuclear reactors, and concentrated solar power systems demanding approximately 28% of market share.

Regional analysis reveals North America and Europe as current market leaders, collectively holding 58% of the global market. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is demonstrating the fastest growth rate at 8.2% annually, fueled by expanding industrial bases and increased R&D investments in advanced materials.

Customer needs assessment indicates five primary market requirements: superior thermal insulation performance, mechanical durability under load, weight reduction capabilities, extended service life in extreme environments, and cost-effectiveness compared to traditional solutions. The engineered porosity gradient technology directly addresses these requirements by enabling customizable thermal-mechanical property profiles.

Market barriers include high production costs, with current manufacturing processes for high-entropy ceramics with controlled porosity gradients being 2.5-3 times more expensive than conventional ceramics. Technical complexity in achieving consistent porosity control at industrial scales also limits widespread adoption. Additionally, conservative industry adoption cycles, particularly in safety-critical applications, slow market penetration.

Emerging opportunities exist in the renewable energy sector, where high-temperature thermal energy storage systems could benefit from porosity-engineered high-entropy ceramics. The electric vehicle market also presents potential applications in battery thermal management systems, where materials with tailored thermal conductivity gradients could enhance safety and performance.

Consumer willingness to pay premium prices for high-entropy ceramic insulators varies by sector, with aerospace and defense demonstrating highest price tolerance (30-40% premium), followed by energy (20-25% premium) and industrial manufacturing (15-20% premium). This price sensitivity directly correlates with application criticality and performance requirements.

Technical Challenges in HE Ceramic Porosity Engineering

Engineering porosity gradients in High Entropy (HE) ceramics presents several significant technical challenges that must be overcome to achieve optimal thermal insulation properties while maintaining mechanical integrity. The fundamental difficulty lies in the inherent trade-off between porosity and mechanical strength - as porosity increases to enhance thermal insulation, mechanical properties typically deteriorate.

Precise control of pore size distribution and morphology across the ceramic body represents a primary challenge. Current manufacturing techniques struggle to create consistent, predictable gradients where pore size, shape, and interconnectivity can be precisely engineered from one region to another. This control is essential for tailoring thermal conductivity pathways while preserving structural integrity in load-bearing areas.

Material homogeneity presents another significant obstacle. High entropy ceramics, by definition, contain multiple principal elements in near-equimolar ratios, making uniform distribution of these elements throughout the porous structure difficult to achieve. Segregation or clustering of certain elements during processing can create weak points or thermal bridges that compromise overall performance.

Processing temperature management poses particular difficulties for HE ceramics. The multi-element composition typically results in complex sintering behavior with varying densification rates across the material. Creating controlled porosity gradients requires precise thermal profiles that can simultaneously accommodate the different sintering kinetics of multiple elements while preventing unwanted grain growth or phase separation.

Interface stability between regions of different porosity levels represents another critical challenge. Sharp transitions between areas of different porosity can create stress concentration points that become failure initiation sites under mechanical loading. Engineering gradual transitions while maintaining distinct functional zones requires sophisticated processing approaches not yet fully developed.

Characterization and modeling of these complex structures present additional technical hurdles. Current analytical techniques struggle to accurately map three-dimensional porosity distributions within ceramic bodies, particularly at the microscale. Similarly, computational models that can simultaneously predict both thermal and mechanical behavior across porosity gradients remain limited in their predictive capabilities.

Long-term stability under thermal cycling and mechanical loading conditions represents perhaps the most significant challenge for practical applications. Differential thermal expansion between regions of varying porosity can lead to progressive microcrack formation and eventual failure. Developing compositions and structures that maintain stable porosity gradients throughout the service life of the component remains an ongoing research challenge.

Precise control of pore size distribution and morphology across the ceramic body represents a primary challenge. Current manufacturing techniques struggle to create consistent, predictable gradients where pore size, shape, and interconnectivity can be precisely engineered from one region to another. This control is essential for tailoring thermal conductivity pathways while preserving structural integrity in load-bearing areas.

Material homogeneity presents another significant obstacle. High entropy ceramics, by definition, contain multiple principal elements in near-equimolar ratios, making uniform distribution of these elements throughout the porous structure difficult to achieve. Segregation or clustering of certain elements during processing can create weak points or thermal bridges that compromise overall performance.

Processing temperature management poses particular difficulties for HE ceramics. The multi-element composition typically results in complex sintering behavior with varying densification rates across the material. Creating controlled porosity gradients requires precise thermal profiles that can simultaneously accommodate the different sintering kinetics of multiple elements while preventing unwanted grain growth or phase separation.

Interface stability between regions of different porosity levels represents another critical challenge. Sharp transitions between areas of different porosity can create stress concentration points that become failure initiation sites under mechanical loading. Engineering gradual transitions while maintaining distinct functional zones requires sophisticated processing approaches not yet fully developed.

Characterization and modeling of these complex structures present additional technical hurdles. Current analytical techniques struggle to accurately map three-dimensional porosity distributions within ceramic bodies, particularly at the microscale. Similarly, computational models that can simultaneously predict both thermal and mechanical behavior across porosity gradients remain limited in their predictive capabilities.

Long-term stability under thermal cycling and mechanical loading conditions represents perhaps the most significant challenge for practical applications. Differential thermal expansion between regions of varying porosity can lead to progressive microcrack formation and eventual failure. Developing compositions and structures that maintain stable porosity gradients throughout the service life of the component remains an ongoing research challenge.

Current Porosity Gradient Engineering Approaches

01 Composition and structure of HE ceramics with porosity gradients

High entropy (HE) ceramics with porosity gradients are composed of multiple principal elements in near-equiatomic ratios, creating a complex crystal structure with high configurational entropy. These ceramics feature controlled porosity distribution that gradually changes across the material, allowing for customized thermal insulation properties. The gradient structure can be designed to have varying pore sizes, shapes, and distributions, which significantly affects the thermal conductivity and mechanical stability of the material.- High entropy ceramic compositions for thermal insulation: High entropy ceramics (HECs) are advanced materials composed of multiple elements in near-equimolar ratios, creating unique crystal structures with enhanced thermal insulation properties. These ceramics exhibit low thermal conductivity due to lattice distortion and phonon scattering effects. The multi-element composition creates atomic disorder that impedes heat transfer, making them excellent candidates for thermal barrier applications. Various compositions including rare earth elements, transition metals, and non-metals can be formulated to optimize thermal resistance properties.

- Porosity gradient design in high entropy ceramics: Engineered porosity gradients in high entropy ceramics provide enhanced thermal insulation performance by creating controlled void structures throughout the material. These gradients can be designed to transition from high porosity regions that minimize heat transfer to denser regions that maintain structural integrity. The controlled distribution of pores at different scales (micro, meso, and macro) creates tortuous heat flow paths that effectively reduce thermal conductivity while maintaining adequate mechanical properties. This approach allows for customization of thermal resistance based on specific application requirements.

- Manufacturing methods for porous high entropy ceramics: Various manufacturing techniques can be employed to create high entropy ceramics with controlled porosity gradients for thermal insulation applications. These include freeze casting, template-assisted methods, additive manufacturing, and selective sintering processes. Precursor selection and processing parameters significantly influence the final pore architecture and distribution. Post-processing treatments such as controlled oxidation or chemical etching can further refine the porosity characteristics. These manufacturing approaches enable precise control over pore size, shape, orientation, and interconnectivity to optimize thermal insulation performance.

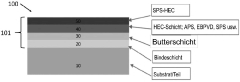

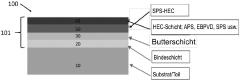

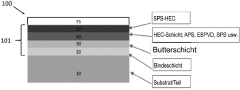

- Thermal barrier coatings using high entropy ceramics: High entropy ceramic coatings with engineered porosity gradients provide exceptional thermal barrier protection for high-temperature applications. These coatings can be applied to metal substrates in aerospace, energy generation, and industrial equipment to extend component lifespans under extreme thermal conditions. The multi-element composition of high entropy ceramics creates phase stability at elevated temperatures, while the porosity gradient optimizes the balance between thermal insulation and coating durability. Advanced deposition techniques allow for precise control of coating microstructure and porosity distribution to maximize thermal protection.

- Performance enhancement strategies for HE ceramic thermal insulators: Various strategies can enhance the thermal insulation performance of high entropy ceramics with porosity gradients. These include incorporating secondary phases, designing hierarchical pore structures, optimizing element selection for maximum phonon scattering, and creating compositional gradients that complement porosity gradients. Surface treatments and interface engineering can further improve thermal resistance by reducing radiative heat transfer. Computational modeling and machine learning approaches help predict optimal compositions and structures for specific thermal insulation requirements, accelerating the development of high-performance materials for extreme environments.

02 Manufacturing methods for porous HE ceramics

Various manufacturing techniques are employed to create HE ceramics with porosity gradients, including freeze casting, template-assisted methods, additive manufacturing, and controlled sintering processes. These methods allow precise control over pore structure, size distribution, and gradient formation. Specific processing parameters such as temperature profiles, pressure conditions, and cooling rates are critical in achieving the desired porosity gradients while maintaining the high entropy phase stability and structural integrity of the ceramic material.Expand Specific Solutions03 Thermal insulation properties and mechanisms

HE ceramics with porosity gradients exhibit exceptional thermal insulation properties due to the combined effects of phonon scattering in the high entropy crystal lattice and the presence of porosity that impedes heat transfer. The gradient structure allows for tailored thermal resistance across the material, with more porous regions providing greater insulation. These materials can maintain their insulating properties at extreme temperatures, making them suitable for applications in harsh environments. The thermal conductivity can be further optimized by controlling the composition, pore size, and gradient design.Expand Specific Solutions04 Mechanical properties and stability

Despite their porous structure, HE ceramics with porosity gradients can maintain good mechanical properties through careful design of the gradient architecture. The high entropy phase contributes to enhanced hardness and strength, while the porosity gradient can be engineered to optimize the balance between thermal insulation and mechanical performance. These materials often exhibit improved fracture toughness compared to conventional ceramics due to crack deflection mechanisms in the heterogeneous structure. Additionally, they demonstrate excellent thermal shock resistance and structural stability at high temperatures.Expand Specific Solutions05 Applications in extreme environments

HE ceramics with porosity gradients are particularly valuable for thermal insulation in extreme environments, such as aerospace components, high-temperature industrial furnaces, and energy systems. Their ability to withstand high temperatures while providing effective thermal insulation makes them suitable for thermal barrier coatings in gas turbines and rocket engines. These materials are also being explored for use in concentrated solar power systems, nuclear reactors, and hypersonic vehicles where thermal management under extreme conditions is critical. The customizable nature of the porosity gradient allows for application-specific optimization of thermal and mechanical properties.Expand Specific Solutions

Leading Research Groups and Industrial Players

The engineering of porosity gradients in high-entropy (HE) ceramics for thermal insulation with mechanical load is currently in an emerging development stage, with the market expected to grow significantly as thermal management solutions become critical in aerospace, energy, and industrial applications. The global market for advanced ceramics is projected to reach $75 billion by 2025, with thermal insulation applications representing a substantial segment. Technologically, research institutions like Harbin Institute of Technology, Wuhan University of Technology, and Northwestern Polytechnical University are leading academic innovation, while industrial players including Siemens AG, NGK Insulators, and SCHOTT AG are advancing commercial applications. Siemens Energy and Air Liquide are developing solutions for energy applications, while research centers like CSIC and CEA are bridging fundamental research with industrial implementation through collaborative projects focusing on microstructure control and manufacturing processes.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed advanced porosity-engineered ceramics with controlled gradient structures specifically for high-entropy (HE) ceramic applications requiring thermal insulation under mechanical load. Their proprietary manufacturing process utilizes freeze-casting techniques combined with controlled sintering to create directional porosity gradients. The company employs multi-component oxide systems (typically containing 5+ elements in near-equimolar ratios) to form high-entropy ceramic matrices with inherently low thermal conductivity. NGK's gradient porosity engineering involves creating a transition from higher density layers (30-40% porosity) at load-bearing surfaces to highly porous regions (60-80% porosity) in thermally insulating zones. This gradual transition minimizes thermal stress concentration while maintaining structural integrity. The company has successfully implemented this technology in industrial furnace components and high-temperature gas filtration systems where both thermal insulation and mechanical stability are critical requirements.

Strengths: Superior thermal shock resistance due to gradual porosity transitions; excellent mechanical load distribution while maintaining thermal barrier properties; established manufacturing infrastructure for large-scale production. Weaknesses: Higher production costs compared to conventional ceramics; limited flexibility in creating complex three-dimensional porosity patterns; potential challenges in quality control across large production batches.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has pioneered innovative approaches to engineering porosity gradients in high-entropy ceramics through their advanced materials research division. Their technique combines freeze-casting with template-directed assembly to create highly controlled porosity distributions in HE ceramic structures. The institute has developed a multi-step process where ceramic slurries containing high-entropy compositions (typically incorporating elements like Zr, Hf, Ti, Ta, and Nb) are subjected to directional freezing with precisely controlled temperature gradients. This creates ice crystal formations that, when sublimated, leave behind directional pore channels. By manipulating freezing parameters and slurry compositions across different layers, researchers have achieved porosity gradients ranging from 20% to 75% within a single structure. Their most recent innovation involves incorporating sacrificial polymer microspheres of varying sizes at different concentrations throughout the ceramic matrix, which decompose during sintering to create additional controlled porosity. This dual-mechanism approach allows for unprecedented control over both pore size distribution and orientation throughout the material structure, resulting in optimized thermal insulation properties while maintaining mechanical integrity under load conditions.

Strengths: Exceptional control over pore architecture and distribution; ability to create complex three-dimensional porosity patterns; strong theoretical foundation based on extensive research. Weaknesses: Laboratory-scale processes that may face challenges in industrial scaling; longer processing times compared to conventional methods; potential inconsistencies in large-format production.

Key Patents and Innovations in HE Ceramic Processing

Heat stable formed ceramic, apparatus and method of using the same

PatentInactiveEP2384316A2

Innovation

- Development of ceramic components with a multimodal grain distribution, comprising at least 50 wt% coarse grains of stabilized zirconia and 1 wt% fine grains, providing a porosity range of 5 to 45 vol%, resulting in enhanced flexural strength and normalized thermal shock resistance, suitable for high-temperature applications exceeding 1500°C.

high entropy ceramic thermal insulation layer

PatentPendingDE102022103080A1

Innovation

- A high entropy ceramic (HEC) composition comprising equimolar fractions of at least three different rare earth oxides and hafnia or zirconia, formulated to provide a thermal barrier coating with low thermal conductivity and improved toughness, stability, and erosion resistance, achieved through a layered structure using deposition techniques like suspension plasma spray.

Material Characterization and Testing Methodologies

Comprehensive material characterization and rigorous testing methodologies are essential for developing high-entropy (HE) ceramics with engineered porosity gradients that can simultaneously provide thermal insulation and withstand mechanical loads. X-ray diffraction (XRD) and neutron diffraction techniques serve as primary tools for analyzing the crystalline structure and phase composition of these advanced ceramics, providing critical insights into how porosity gradients affect the material's structural integrity at different temperatures.

Scanning Electron Microscopy (SEM) coupled with Energy Dispersive X-ray Spectroscopy (EDS) enables detailed examination of pore morphology, distribution, and interconnectivity throughout the ceramic matrix. This visualization is crucial for validating the successful implementation of designed porosity gradients. Complementary techniques such as Mercury Intrusion Porosimetry (MIP) and Brunauer-Emmett-Teller (BET) analysis provide quantitative measurements of pore size distribution, specific surface area, and total porosity volume, which directly correlate with thermal insulation performance.

Thermal conductivity measurements using laser flash analysis and steady-state heat flow methods are fundamental for evaluating the insulation effectiveness of porosity-engineered HE ceramics. These tests must be conducted across the intended operational temperature range, typically from room temperature to above 1000°C, to ensure performance stability under thermal cycling conditions. Thermal expansion coefficient measurements are equally important to assess dimensional stability and potential thermal stress development within the gradient structure.

Mechanical property evaluation requires specialized testing protocols adapted for porous ceramics. Compressive strength, flexural strength, and fracture toughness tests must be performed with careful consideration of the porosity gradient orientation relative to the applied load. Nanoindentation mapping across the gradient provides valuable information about local elastic modulus and hardness variations that conventional bulk testing cannot reveal.

Acoustic emission testing during mechanical loading offers insights into crack initiation and propagation behavior within the porosity gradient structure. This non-destructive technique helps identify failure mechanisms and validate computational models. Additionally, thermomechanical testing under simultaneous thermal gradients and mechanical loads is essential to simulate real-world operating conditions and evaluate the synergistic performance of these multifunctional ceramics.

Advanced imaging techniques such as X-ray computed tomography (CT) and 3D reconstruction algorithms enable non-destructive visualization of the internal porosity architecture before and after thermal or mechanical testing. This capability is invaluable for monitoring microstructural evolution and potential degradation mechanisms during service. Standardized testing protocols must be established specifically for gradient materials, as conventional homogeneous material testing standards may not adequately characterize these complex structures.

Scanning Electron Microscopy (SEM) coupled with Energy Dispersive X-ray Spectroscopy (EDS) enables detailed examination of pore morphology, distribution, and interconnectivity throughout the ceramic matrix. This visualization is crucial for validating the successful implementation of designed porosity gradients. Complementary techniques such as Mercury Intrusion Porosimetry (MIP) and Brunauer-Emmett-Teller (BET) analysis provide quantitative measurements of pore size distribution, specific surface area, and total porosity volume, which directly correlate with thermal insulation performance.

Thermal conductivity measurements using laser flash analysis and steady-state heat flow methods are fundamental for evaluating the insulation effectiveness of porosity-engineered HE ceramics. These tests must be conducted across the intended operational temperature range, typically from room temperature to above 1000°C, to ensure performance stability under thermal cycling conditions. Thermal expansion coefficient measurements are equally important to assess dimensional stability and potential thermal stress development within the gradient structure.

Mechanical property evaluation requires specialized testing protocols adapted for porous ceramics. Compressive strength, flexural strength, and fracture toughness tests must be performed with careful consideration of the porosity gradient orientation relative to the applied load. Nanoindentation mapping across the gradient provides valuable information about local elastic modulus and hardness variations that conventional bulk testing cannot reveal.

Acoustic emission testing during mechanical loading offers insights into crack initiation and propagation behavior within the porosity gradient structure. This non-destructive technique helps identify failure mechanisms and validate computational models. Additionally, thermomechanical testing under simultaneous thermal gradients and mechanical loads is essential to simulate real-world operating conditions and evaluate the synergistic performance of these multifunctional ceramics.

Advanced imaging techniques such as X-ray computed tomography (CT) and 3D reconstruction algorithms enable non-destructive visualization of the internal porosity architecture before and after thermal or mechanical testing. This capability is invaluable for monitoring microstructural evolution and potential degradation mechanisms during service. Standardized testing protocols must be established specifically for gradient materials, as conventional homogeneous material testing standards may not adequately characterize these complex structures.

Environmental Impact and Sustainability Considerations

The development of porosity-graded high-entropy (HE) ceramics for thermal insulation under mechanical load carries significant environmental implications that must be carefully considered. The manufacturing processes for these advanced ceramics typically involve high-temperature sintering, which consumes substantial energy and generates considerable carbon emissions. Traditional ceramic production methods can require temperatures exceeding 1600°C maintained for extended periods, resulting in a substantial carbon footprint. However, the engineered porosity gradients in HE ceramics may allow for reduced sintering temperatures or times, potentially decreasing the overall energy consumption during manufacturing.

Raw material extraction for HE ceramics presents another environmental concern. These materials often incorporate multiple elements, some of which may be rare earth metals or other critical materials with environmentally intensive mining processes. The environmental degradation associated with mining these elements includes habitat destruction, water pollution, and soil contamination. Implementing sustainable sourcing practices and exploring alternative, more abundant elements in HE ceramic formulations could mitigate these impacts.

The extended service life of porosity-graded HE ceramics offers a positive environmental contribution. Their superior thermal insulation properties combined with mechanical load-bearing capabilities mean these materials can function effectively in extreme environments for longer periods, reducing the frequency of replacement and associated material consumption. This longevity directly translates to resource conservation and waste reduction over the product lifecycle.

End-of-life considerations for HE ceramics present both challenges and opportunities. While ceramics are generally not biodegradable, their chemical stability means they don't leach harmful substances into the environment. Developing effective recycling methods for these advanced ceramics could significantly enhance their sustainability profile. Research into crushing and repurposing spent HE ceramics as aggregates or precursors for new ceramic formulations shows promise for closing the material loop.

Water usage in the manufacturing process represents another environmental consideration. Traditional ceramic processing often requires substantial amounts of water for mixing and forming operations. Developing dry processing techniques specifically tailored for porosity-graded HE ceramics could substantially reduce water consumption and associated wastewater treatment needs, contributing to more sustainable manufacturing practices.

The thermal insulation properties of these materials also contribute to energy efficiency in their applications, whether in industrial furnaces, aerospace components, or energy systems. This operational energy saving must be factored into comprehensive lifecycle assessments when evaluating the overall environmental impact of porosity-graded HE ceramics against conventional alternatives.

Raw material extraction for HE ceramics presents another environmental concern. These materials often incorporate multiple elements, some of which may be rare earth metals or other critical materials with environmentally intensive mining processes. The environmental degradation associated with mining these elements includes habitat destruction, water pollution, and soil contamination. Implementing sustainable sourcing practices and exploring alternative, more abundant elements in HE ceramic formulations could mitigate these impacts.

The extended service life of porosity-graded HE ceramics offers a positive environmental contribution. Their superior thermal insulation properties combined with mechanical load-bearing capabilities mean these materials can function effectively in extreme environments for longer periods, reducing the frequency of replacement and associated material consumption. This longevity directly translates to resource conservation and waste reduction over the product lifecycle.

End-of-life considerations for HE ceramics present both challenges and opportunities. While ceramics are generally not biodegradable, their chemical stability means they don't leach harmful substances into the environment. Developing effective recycling methods for these advanced ceramics could significantly enhance their sustainability profile. Research into crushing and repurposing spent HE ceramics as aggregates or precursors for new ceramic formulations shows promise for closing the material loop.

Water usage in the manufacturing process represents another environmental consideration. Traditional ceramic processing often requires substantial amounts of water for mixing and forming operations. Developing dry processing techniques specifically tailored for porosity-graded HE ceramics could substantially reduce water consumption and associated wastewater treatment needs, contributing to more sustainable manufacturing practices.

The thermal insulation properties of these materials also contribute to energy efficiency in their applications, whether in industrial furnaces, aerospace components, or energy systems. This operational energy saving must be factored into comprehensive lifecycle assessments when evaluating the overall environmental impact of porosity-graded HE ceramics against conventional alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!