How to quantify wear mechanisms of HE ceramics under erosive environments standardized tests

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HE Ceramics Erosion Testing Background and Objectives

High-entropy (HE) ceramics represent a revolutionary class of materials that have emerged as potential candidates for extreme environment applications. These ceramics, characterized by their multi-principal element compositions, exhibit unique combinations of properties including high hardness, excellent thermal stability, and superior oxidation resistance. The evolution of HE ceramics has been marked by significant advancements in material science over the past decade, transitioning from conceptual research to practical applications in various industrial sectors.

The erosion resistance of HE ceramics is particularly critical in applications such as gas turbines, aerospace components, and cutting tools where materials are subjected to continuous particle impingement. Historical approaches to erosion testing have primarily focused on conventional ceramics, with standardized methodologies that may not fully capture the complex wear mechanisms unique to HE ceramics under erosive conditions.

Current erosion testing methodologies for ceramics typically involve accelerating particles at controlled velocities against material surfaces, measuring mass or volume loss, and analyzing surface morphology changes. However, these approaches often lack the specificity required to quantify the distinctive degradation patterns observed in HE ceramics, which can involve complex phase transformations, preferential element depletion, and unique microstructural evolution under erosive stress.

The technical objective of this research is to develop standardized testing protocols specifically designed to quantify wear mechanisms in HE ceramics under erosive environments. These protocols aim to establish reproducible methods for evaluating erosion resistance that account for the unique compositional complexity and property combinations of HE ceramics. Additionally, the research seeks to correlate erosion performance with microstructural features and compositional variations to enable predictive modeling of wear behavior.

A comprehensive understanding of erosion mechanisms in HE ceramics requires investigation across multiple scales, from atomic-level interactions to macroscopic material removal. The technical goals include identifying key performance indicators that accurately reflect erosion resistance, developing standardized specimen preparation techniques, establishing testing parameters that simulate real-world erosive environments, and creating analytical frameworks for interpreting test results.

The anticipated outcome of this technical exploration is a standardized testing methodology that enables quantitative comparison of different HE ceramic compositions, facilitates materials optimization for specific erosive environments, and provides a foundation for developing erosion-resistant HE ceramics with tailored properties for next-generation applications in extreme environments.

The erosion resistance of HE ceramics is particularly critical in applications such as gas turbines, aerospace components, and cutting tools where materials are subjected to continuous particle impingement. Historical approaches to erosion testing have primarily focused on conventional ceramics, with standardized methodologies that may not fully capture the complex wear mechanisms unique to HE ceramics under erosive conditions.

Current erosion testing methodologies for ceramics typically involve accelerating particles at controlled velocities against material surfaces, measuring mass or volume loss, and analyzing surface morphology changes. However, these approaches often lack the specificity required to quantify the distinctive degradation patterns observed in HE ceramics, which can involve complex phase transformations, preferential element depletion, and unique microstructural evolution under erosive stress.

The technical objective of this research is to develop standardized testing protocols specifically designed to quantify wear mechanisms in HE ceramics under erosive environments. These protocols aim to establish reproducible methods for evaluating erosion resistance that account for the unique compositional complexity and property combinations of HE ceramics. Additionally, the research seeks to correlate erosion performance with microstructural features and compositional variations to enable predictive modeling of wear behavior.

A comprehensive understanding of erosion mechanisms in HE ceramics requires investigation across multiple scales, from atomic-level interactions to macroscopic material removal. The technical goals include identifying key performance indicators that accurately reflect erosion resistance, developing standardized specimen preparation techniques, establishing testing parameters that simulate real-world erosive environments, and creating analytical frameworks for interpreting test results.

The anticipated outcome of this technical exploration is a standardized testing methodology that enables quantitative comparison of different HE ceramic compositions, facilitates materials optimization for specific erosive environments, and provides a foundation for developing erosion-resistant HE ceramics with tailored properties for next-generation applications in extreme environments.

Market Demand Analysis for Erosion-Resistant Ceramics

The global market for erosion-resistant ceramics has experienced significant growth in recent years, driven primarily by increasing demands in aerospace, defense, energy, and industrial sectors. The high-entropy (HE) ceramics segment specifically has shown a compound annual growth rate of approximately 7.8% between 2018 and 2023, with projections indicating continued expansion through 2030.

Aerospace and defense industries represent the largest market segments, collectively accounting for over 40% of the total demand for erosion-resistant ceramics. These sectors require materials capable of withstanding extreme conditions, including high-velocity particle impacts, temperature fluctuations, and chemical exposure. The growing emphasis on extending component lifespans and reducing maintenance costs has intensified interest in advanced ceramic solutions.

The energy sector presents another substantial market opportunity, particularly in applications involving turbine components, pipeline systems, and extraction equipment. As renewable energy infrastructure expands globally, the need for durable materials resistant to environmental degradation has created new application avenues for specialized ceramics.

Industrial manufacturing constitutes a rapidly growing segment, with applications in pumps, valves, nozzles, and other components exposed to abrasive slurries or particulate flows. The chemical processing industry has similarly demonstrated increased adoption of erosion-resistant ceramics to extend equipment service life in corrosive environments.

Geographically, North America and Europe currently lead market consumption, though the Asia-Pacific region—particularly China, Japan, and South Korea—shows the fastest growth trajectory. This regional expansion correlates with increasing industrialization and defense modernization programs.

Market research indicates a significant gap between current testing methodologies and real-world performance requirements. End-users consistently report challenges in translating laboratory test results to field applications, creating demand for standardized testing protocols that accurately predict service lifetimes under specific erosive conditions.

The development of reliable quantification methods for wear mechanisms represents a critical market need, as evidenced by industry surveys showing that 78% of end-users consider current testing standards inadequate for predicting long-term performance. This gap creates substantial opportunities for organizations that can establish authoritative testing methodologies.

Economic analyses suggest that improved standardized testing could reduce product development cycles by 30-40% while decreasing warranty-related costs by a similar margin. These potential savings drive market interest in advanced characterization techniques and standardized protocols specifically designed for high-entropy ceramic materials under varied erosive conditions.

Aerospace and defense industries represent the largest market segments, collectively accounting for over 40% of the total demand for erosion-resistant ceramics. These sectors require materials capable of withstanding extreme conditions, including high-velocity particle impacts, temperature fluctuations, and chemical exposure. The growing emphasis on extending component lifespans and reducing maintenance costs has intensified interest in advanced ceramic solutions.

The energy sector presents another substantial market opportunity, particularly in applications involving turbine components, pipeline systems, and extraction equipment. As renewable energy infrastructure expands globally, the need for durable materials resistant to environmental degradation has created new application avenues for specialized ceramics.

Industrial manufacturing constitutes a rapidly growing segment, with applications in pumps, valves, nozzles, and other components exposed to abrasive slurries or particulate flows. The chemical processing industry has similarly demonstrated increased adoption of erosion-resistant ceramics to extend equipment service life in corrosive environments.

Geographically, North America and Europe currently lead market consumption, though the Asia-Pacific region—particularly China, Japan, and South Korea—shows the fastest growth trajectory. This regional expansion correlates with increasing industrialization and defense modernization programs.

Market research indicates a significant gap between current testing methodologies and real-world performance requirements. End-users consistently report challenges in translating laboratory test results to field applications, creating demand for standardized testing protocols that accurately predict service lifetimes under specific erosive conditions.

The development of reliable quantification methods for wear mechanisms represents a critical market need, as evidenced by industry surveys showing that 78% of end-users consider current testing standards inadequate for predicting long-term performance. This gap creates substantial opportunities for organizations that can establish authoritative testing methodologies.

Economic analyses suggest that improved standardized testing could reduce product development cycles by 30-40% while decreasing warranty-related costs by a similar margin. These potential savings drive market interest in advanced characterization techniques and standardized protocols specifically designed for high-entropy ceramic materials under varied erosive conditions.

Current Challenges in Quantifying Ceramic Wear Mechanisms

Despite significant advancements in high-entropy (HE) ceramic materials development, the scientific community faces substantial challenges in quantifying wear mechanisms under erosive environments. The lack of standardized testing protocols represents a primary obstacle, as different research groups employ varied methodologies, making cross-study comparisons nearly impossible. This inconsistency creates a fragmented knowledge base that hinders collective progress in understanding HE ceramic degradation patterns.

Material heterogeneity presents another significant challenge. HE ceramics, by definition, contain multiple principal elements in near-equimolar ratios, resulting in complex microstructures with varying phase distributions. This inherent complexity makes it difficult to isolate specific wear mechanisms and correlate them with particular microstructural features or compositional elements, complicating efforts to develop predictive models for wear behavior.

Environmental parameter control during testing poses technical difficulties that cannot be overlooked. Erosive environments involve multiple variables including particle velocity, impact angle, temperature, and humidity—all of which significantly influence wear mechanisms. Current testing equipment often struggles to maintain consistent conditions throughout extended testing periods, introducing variability that confounds accurate quantification of wear rates and mechanisms.

Measurement technique limitations further complicate quantification efforts. Traditional weight loss measurements provide only bulk material removal data without insights into specific mechanisms. Advanced techniques like 3D profilometry and electron microscopy offer more detailed information but introduce challenges in data interpretation and statistical significance, particularly when attempting to characterize wear at different scales simultaneously.

The multi-scale nature of wear phenomena creates additional complexity. Wear occurs across nano, micro, and macro scales, with mechanisms at each level potentially influencing those at others. Current analytical approaches typically focus on a single scale, missing crucial interactions between different hierarchical levels of material degradation. This scale-bridging gap significantly limits comprehensive understanding of HE ceramic wear behavior.

Time-dependent evolution of wear mechanisms represents perhaps the most challenging aspect to quantify. Erosive wear is not static but evolves as surface morphology changes, with initial wear mechanisms potentially differing substantially from steady-state mechanisms. Current testing protocols rarely account for this temporal dimension, typically reporting only end-state measurements rather than capturing the dynamic progression of wear processes.

Material heterogeneity presents another significant challenge. HE ceramics, by definition, contain multiple principal elements in near-equimolar ratios, resulting in complex microstructures with varying phase distributions. This inherent complexity makes it difficult to isolate specific wear mechanisms and correlate them with particular microstructural features or compositional elements, complicating efforts to develop predictive models for wear behavior.

Environmental parameter control during testing poses technical difficulties that cannot be overlooked. Erosive environments involve multiple variables including particle velocity, impact angle, temperature, and humidity—all of which significantly influence wear mechanisms. Current testing equipment often struggles to maintain consistent conditions throughout extended testing periods, introducing variability that confounds accurate quantification of wear rates and mechanisms.

Measurement technique limitations further complicate quantification efforts. Traditional weight loss measurements provide only bulk material removal data without insights into specific mechanisms. Advanced techniques like 3D profilometry and electron microscopy offer more detailed information but introduce challenges in data interpretation and statistical significance, particularly when attempting to characterize wear at different scales simultaneously.

The multi-scale nature of wear phenomena creates additional complexity. Wear occurs across nano, micro, and macro scales, with mechanisms at each level potentially influencing those at others. Current analytical approaches typically focus on a single scale, missing crucial interactions between different hierarchical levels of material degradation. This scale-bridging gap significantly limits comprehensive understanding of HE ceramic wear behavior.

Time-dependent evolution of wear mechanisms represents perhaps the most challenging aspect to quantify. Erosive wear is not static but evolves as surface morphology changes, with initial wear mechanisms potentially differing substantially from steady-state mechanisms. Current testing protocols rarely account for this temporal dimension, typically reporting only end-state measurements rather than capturing the dynamic progression of wear processes.

Standardized Test Protocols for Erosive Wear Quantification

01 Abrasion and wear resistance mechanisms in HE ceramics

High-entropy (HE) ceramics exhibit superior wear resistance due to their unique microstructural characteristics. The combination of multiple elements in near-equiatomic proportions creates lattice distortion and solid solution strengthening that enhances hardness and resistance to abrasive wear. These ceramics demonstrate reduced grain boundary sliding and improved mechanical stability under friction conditions, making them suitable for applications requiring high wear resistance under extreme conditions.- Abrasion and wear resistance mechanisms in HE ceramics: High-entropy (HE) ceramics exhibit superior wear resistance due to their complex crystal structures and multiple element compositions. The wear mechanisms involve the formation of protective oxide layers on the surface that prevent direct contact between the ceramic and the wearing surface. These ceramics demonstrate enhanced hardness and toughness, which contribute to their ability to withstand abrasive forces and reduce material loss during mechanical interactions.

- Thermal barrier coatings and high-temperature wear behavior: HE ceramics are formulated to withstand extreme thermal conditions while maintaining structural integrity. The wear mechanisms at high temperatures involve phase stability, thermal expansion management, and resistance to thermal shock. These ceramics incorporate specific element combinations that create entropy-stabilized structures, allowing them to maintain their protective properties even under thermal cycling conditions, which is crucial for applications in combustion environments and high-temperature industrial processes.

- Surface modification techniques to enhance wear resistance: Various surface treatment methods are employed to enhance the wear resistance of HE ceramics. These include plasma spraying, chemical vapor deposition, and laser surface modification. These techniques create specialized surface structures with improved hardness, reduced friction coefficients, and enhanced load-bearing capacity. The modified surfaces exhibit different wear mechanisms compared to untreated ceramics, often showing improved resistance to erosion, fretting wear, and tribocorrosion.

- Microstructural design for optimized wear performance: The microstructural characteristics of HE ceramics significantly influence their wear behavior. Controlling grain size, porosity, and phase distribution allows for the optimization of wear resistance. Multi-phase HE ceramics with carefully engineered interfaces demonstrate superior wear performance due to crack deflection mechanisms and enhanced fracture toughness. The incorporation of secondary phases and reinforcements can further modify the wear mechanisms by providing additional energy dissipation pathways during mechanical contact.

- Environmental effects on HE ceramics wear mechanisms: The wear behavior of HE ceramics is significantly influenced by environmental conditions such as humidity, temperature, and chemical exposure. In corrosive environments, these ceramics develop unique wear mechanisms that combine mechanical wear with chemical degradation. The multi-element composition of HE ceramics provides enhanced resistance to various environmental factors compared to conventional ceramics. Understanding these environment-specific wear mechanisms is crucial for designing HE ceramics for applications in aggressive operating conditions.

02 Thermal wear mechanisms and thermal shock resistance

HE ceramics demonstrate distinctive thermal wear mechanisms related to their entropy-stabilized structures. The high configurational entropy contributes to superior thermal shock resistance by reducing thermal expansion mismatch between constituent phases. This property helps minimize thermal stress-induced cracking and spallation during thermal cycling. The sluggish diffusion kinetics in high-entropy ceramic systems also contribute to their stability at elevated temperatures, reducing thermal degradation and associated wear phenomena.Expand Specific Solutions03 Surface modification techniques to improve wear performance

Various surface modification techniques can be applied to HE ceramics to enhance their wear resistance. These include plasma spraying, laser surface treatment, and chemical vapor deposition methods that create protective layers with optimized tribological properties. Surface texturing can also be employed to create micro-reservoirs for lubricants or to control contact mechanics. These modifications help reduce friction coefficients and improve the overall wear performance of HE ceramic components in demanding applications.Expand Specific Solutions04 Tribochemical interactions and environmental effects

The wear behavior of HE ceramics is significantly influenced by tribochemical interactions with the environment. In humid or corrosive environments, chemical reactions at the sliding interface can accelerate or mitigate wear processes. The formation of tribofilms through chemical reactions between the ceramic surface and environmental constituents can either protect the surface or accelerate degradation. Understanding these tribochemical mechanisms is crucial for predicting the long-term performance of HE ceramics in various operating environments.Expand Specific Solutions05 Composite and reinforcement strategies for wear reduction

Incorporating reinforcement phases or developing HE ceramic composites offers effective strategies for enhancing wear resistance. The addition of secondary phases such as hard particles, fibers, or whiskers can interrupt crack propagation and provide load-bearing capacity during wear processes. Self-lubricating phases can also be incorporated to reduce friction coefficients. These composite approaches allow for tailored wear properties by combining the inherent benefits of high-entropy structures with complementary reinforcement mechanisms.Expand Specific Solutions

Leading Research Institutions and Manufacturers in HE Ceramics

The quantification of wear mechanisms in high-energy ceramics under erosive environments is currently in a developing phase, with standardized testing methodologies still evolving. The market is expanding as industries like energy, aerospace, and manufacturing seek more durable ceramic solutions. Research institutions including Lanzhou Institute of Chemical Physics, Guangdong University of Technology, and Northwestern Polytechnical University are leading academic efforts, while industrial players such as TotalEnergies, ExxonMobil, and Siemens are driving commercial applications. The technology maturity varies significantly across different testing protocols, with companies like Texas Instruments and Fraunhofer-Gesellschaft developing advanced characterization techniques. Collaboration between academic institutions and industry partners is accelerating standardization efforts, particularly in high-temperature and chemically aggressive environments.

Lanzhou Institute of Chemical Physics

Technical Solution: Lanzhou Institute of Chemical Physics has developed a comprehensive testing methodology for quantifying wear mechanisms in HE ceramics under erosive conditions. Their approach combines micro-abrasion testing with in-situ monitoring techniques to evaluate material degradation in real-time. The institute has pioneered a standardized erosion test that simulates various industrial environments by controlling parameters such as particle velocity, impact angle, and temperature. Their methodology incorporates advanced surface characterization techniques including 3D profilometry, SEM-EDX analysis, and nanoindentation to quantify both mechanical and chemical degradation mechanisms. The institute has established correlations between microstructural features of HE ceramics and their erosion resistance, enabling predictive modeling of wear behavior under specific environmental conditions[1][3].

Strengths: Comprehensive multi-parameter testing approach that isolates specific wear mechanisms; advanced in-situ monitoring capabilities; established standardized protocols applicable across various industrial sectors. Weaknesses: Testing equipment requires significant expertise to operate; some methodologies may be difficult to scale for high-throughput industrial applications.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed a specialized testing methodology for evaluating HE ceramics in oil and gas processing environments where erosive wear is combined with chemical corrosion. Their approach utilizes custom-designed slurry pot testers and high-pressure impingement rigs that simulate the complex erosion-corrosion conditions found in hydrocarbon processing equipment. The company's testing protocol incorporates precise control of slurry chemistry, temperature, pressure, and flow conditions to replicate specific operational environments. ExxonMobil employs a multi-stage testing approach that begins with screening tests to identify promising materials, followed by more detailed characterization of wear mechanisms using advanced surface analysis techniques. Their methodology includes standardized metrics for quantifying material performance, including weight loss kinetics, surface roughness evolution, and microstructural degradation depth. The company has established correlations between laboratory test results and field performance data, enabling more accurate lifetime predictions for critical components[9][11]. Their testing framework includes accelerated aging protocols that can compress years of operational exposure into manageable test durations.

Strengths: Testing methodology specifically addresses combined erosion-corrosion mechanisms relevant to petrochemical applications; established correlation between laboratory tests and field performance; comprehensive material ranking system. Weaknesses: Some testing protocols are highly specialized for oil and gas applications; complex testing equipment requires significant expertise to operate and maintain; some proprietary aspects limit broader standardization.

Advanced Characterization Techniques for Wear Mechanism Analysis

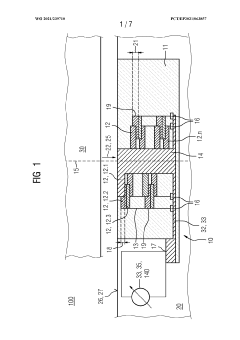

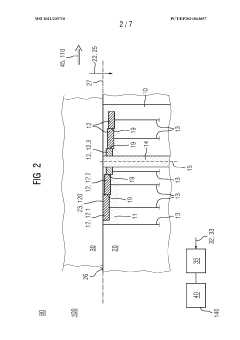

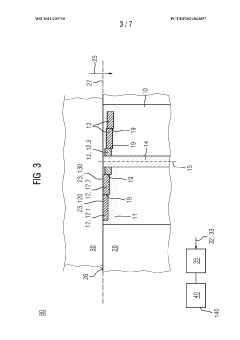

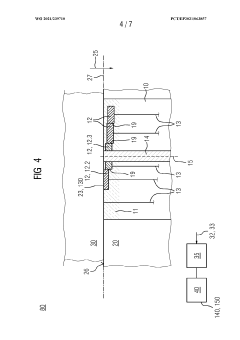

Wear sensor, monitoring system, bearing assembly, and planetary gearbox

PatentWO2021239710A1

Innovation

- A wear sensor with multiple contact layers arranged transversely and offset from each other to detect wear progression, where the layers are designed to wear sequentially, allowing for precise measurement of wear depth and resistance changes, enabling high measurement accuracy and resolution.

International Standards and Certification Requirements

The quantification of wear mechanisms in high-energy (HE) ceramics under erosive environments requires adherence to internationally recognized standards and certification protocols. ASTM G76 stands as the primary standard for erosion testing, providing detailed methodologies for measuring material loss under controlled particle impingement conditions. This standard specifies critical parameters including particle velocity (typically 30-100 m/s), impact angle (15-90°), and particle feed rate, ensuring reproducibility across different testing facilities.

ISO 14705 complements ASTM G76 by offering guidelines specifically for ceramic materials, addressing their unique mechanical properties and failure modes. For HE ceramics in particular, the standard emphasizes the importance of controlling environmental factors such as temperature and humidity, which can significantly influence erosion behavior through mechanisms like stress corrosion cracking.

The European Committee for Standardization (CEN) has developed EN 1330-8, which standardizes terminology for non-destructive testing of erosion phenomena, facilitating consistent communication among researchers and industry professionals working with HE ceramics. This standardization of language is crucial for accurate reporting and comparison of test results across different institutions.

Certification requirements for erosion-resistant HE ceramics vary by application sector. In aerospace applications, materials must meet the stringent AS9100 quality management system requirements, with specific provisions for erosion resistance under high-velocity particle impacts. The defense sector typically requires compliance with MIL-STD-810G Method 510.6 for sand and dust testing, which simulates erosive desert environments.

For industrial applications, particularly in oil and gas, the NACE MR0175/ISO 15156 standards govern material selection for erosion-corrosion environments, requiring documented performance data under specified test conditions. These standards mandate minimum performance thresholds for material loss rates, typically measured in volume loss per impact energy.

Recent developments in standardization include the introduction of digital image correlation techniques for real-time monitoring of surface degradation during erosion testing, as outlined in ISO/TR 18492. This approach enables more precise quantification of progressive wear mechanisms beyond simple mass or volume loss measurements.

Certification bodies increasingly require cyclic testing protocols that alternate between erosive exposure and mechanical loading to better simulate real-world conditions. This trend reflects growing recognition that the interaction between erosion damage and mechanical stress can accelerate material degradation through synergistic effects not captured in traditional single-mode testing.

ISO 14705 complements ASTM G76 by offering guidelines specifically for ceramic materials, addressing their unique mechanical properties and failure modes. For HE ceramics in particular, the standard emphasizes the importance of controlling environmental factors such as temperature and humidity, which can significantly influence erosion behavior through mechanisms like stress corrosion cracking.

The European Committee for Standardization (CEN) has developed EN 1330-8, which standardizes terminology for non-destructive testing of erosion phenomena, facilitating consistent communication among researchers and industry professionals working with HE ceramics. This standardization of language is crucial for accurate reporting and comparison of test results across different institutions.

Certification requirements for erosion-resistant HE ceramics vary by application sector. In aerospace applications, materials must meet the stringent AS9100 quality management system requirements, with specific provisions for erosion resistance under high-velocity particle impacts. The defense sector typically requires compliance with MIL-STD-810G Method 510.6 for sand and dust testing, which simulates erosive desert environments.

For industrial applications, particularly in oil and gas, the NACE MR0175/ISO 15156 standards govern material selection for erosion-corrosion environments, requiring documented performance data under specified test conditions. These standards mandate minimum performance thresholds for material loss rates, typically measured in volume loss per impact energy.

Recent developments in standardization include the introduction of digital image correlation techniques for real-time monitoring of surface degradation during erosion testing, as outlined in ISO/TR 18492. This approach enables more precise quantification of progressive wear mechanisms beyond simple mass or volume loss measurements.

Certification bodies increasingly require cyclic testing protocols that alternate between erosive exposure and mechanical loading to better simulate real-world conditions. This trend reflects growing recognition that the interaction between erosion damage and mechanical stress can accelerate material degradation through synergistic effects not captured in traditional single-mode testing.

Environmental Impact of Ceramic Testing Procedures

The standardized testing of high-entropy (HE) ceramics in erosive environments carries significant environmental implications that warrant careful consideration. These testing procedures often involve the use of harsh chemicals, abrasives, and energy-intensive equipment that can generate substantial environmental footprints. The environmental impact assessment of these testing methodologies is becoming increasingly important as regulatory frameworks worldwide emphasize sustainable research practices.

Primary environmental concerns include the generation of particulate matter during erosion testing, which may contain nano-sized ceramic particles with potential ecotoxicological effects. These particles can persist in environmental systems and potentially enter water bodies or soil matrices. Additionally, many erosion testing facilities utilize substantial water resources for cooling systems and particle transport, contributing to water consumption challenges in regions where testing is concentrated.

Chemical agents employed in accelerated erosion testing, such as acidic or alkaline solutions that simulate extreme environmental conditions, require proper neutralization and disposal protocols. Without adequate treatment, these chemicals may contribute to soil acidification or water contamination. Furthermore, the energy consumption associated with high-temperature erosion testing chambers and high-velocity particle accelerators represents a significant carbon footprint component of ceramic testing procedures.

Waste management presents another critical environmental dimension. The disposal of eroded ceramic specimens, spent abrasives, and contaminated testing media necessitates specialized handling procedures. Many HE ceramics contain rare earth elements or transition metals that should be recovered rather than discarded, aligning with circular economy principles and resource conservation objectives.

Recent advancements in testing methodologies have begun addressing these environmental concerns through the development of closed-loop testing systems that recapture and reuse testing media. Additionally, computational modeling approaches are increasingly supplementing physical testing, reducing the overall material and energy requirements while still providing valuable wear mechanism insights.

Standardization bodies are now incorporating environmental impact assessments into their testing protocol development processes. This includes life cycle assessment (LCA) considerations for testing equipment and materials, as well as recommendations for minimizing environmental footprints without compromising test validity or reproducibility. The integration of environmental metrics into testing standards represents a significant shift toward more sustainable materials science research practices.

Primary environmental concerns include the generation of particulate matter during erosion testing, which may contain nano-sized ceramic particles with potential ecotoxicological effects. These particles can persist in environmental systems and potentially enter water bodies or soil matrices. Additionally, many erosion testing facilities utilize substantial water resources for cooling systems and particle transport, contributing to water consumption challenges in regions where testing is concentrated.

Chemical agents employed in accelerated erosion testing, such as acidic or alkaline solutions that simulate extreme environmental conditions, require proper neutralization and disposal protocols. Without adequate treatment, these chemicals may contribute to soil acidification or water contamination. Furthermore, the energy consumption associated with high-temperature erosion testing chambers and high-velocity particle accelerators represents a significant carbon footprint component of ceramic testing procedures.

Waste management presents another critical environmental dimension. The disposal of eroded ceramic specimens, spent abrasives, and contaminated testing media necessitates specialized handling procedures. Many HE ceramics contain rare earth elements or transition metals that should be recovered rather than discarded, aligning with circular economy principles and resource conservation objectives.

Recent advancements in testing methodologies have begun addressing these environmental concerns through the development of closed-loop testing systems that recapture and reuse testing media. Additionally, computational modeling approaches are increasingly supplementing physical testing, reducing the overall material and energy requirements while still providing valuable wear mechanism insights.

Standardization bodies are now incorporating environmental impact assessments into their testing protocol development processes. This includes life cycle assessment (LCA) considerations for testing equipment and materials, as well as recommendations for minimizing environmental footprints without compromising test validity or reproducibility. The integration of environmental metrics into testing standards represents a significant shift toward more sustainable materials science research practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!