How to Process High-Entropy Carbides by Spark Plasma Sintering: Densification and grain control parameters

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEC Processing Background and Objectives

High-Entropy Carbides (HECs) represent a revolutionary class of ultra-high temperature ceramics that have emerged from the broader family of high-entropy materials. These multi-principal element compounds typically consist of five or more metal carbides in near-equiatomic proportions, creating unique crystal structures with exceptional properties. The concept of high-entropy materials was first introduced in the metallurgical field around 2004, but the extension to carbide systems only gained significant attention after 2016.

The evolution of HECs has been driven by the increasing demands in extreme environment applications, particularly in aerospace, nuclear, and defense sectors where materials must withstand temperatures exceeding 2000°C while maintaining structural integrity. Traditional single-phase carbides, despite their high melting points, often suffer from poor oxidation resistance and inadequate mechanical properties at elevated temperatures.

The technological trajectory of HECs has been marked by significant breakthroughs in compositional design and processing techniques. Early research focused primarily on establishing the formation criteria for single-phase solid solutions, while recent efforts have shifted toward optimizing processing parameters to achieve fully dense structures with controlled microstructures.

Spark Plasma Sintering (SPS) has emerged as a preferred consolidation method for HECs due to its ability to achieve rapid densification at relatively lower temperatures compared to conventional sintering techniques. This process utilizes pulsed direct current to generate localized heating at particle interfaces, facilitating mass transport and densification while minimizing grain growth.

The primary technical objectives in HEC processing via SPS include achieving near-theoretical density (>99%) while maintaining nanocrystalline or fine-grained microstructures. This combination is crucial for optimizing mechanical properties such as hardness, fracture toughness, and high-temperature strength. Additionally, researchers aim to establish reproducible processing-structure-property relationships that can guide the design of tailored HECs for specific applications.

Current research goals also encompass understanding the fundamental mechanisms governing densification and grain growth during SPS of HECs, particularly how the high configurational entropy affects diffusion kinetics and microstructural evolution. This knowledge is essential for developing predictive models that can accelerate the optimization of processing parameters and reduce the empirical nature of current approaches.

The field is now moving toward establishing standardized processing protocols that can ensure consistent quality and properties across different HEC compositions, a necessary step for industrial adoption and commercialization of these promising materials.

The evolution of HECs has been driven by the increasing demands in extreme environment applications, particularly in aerospace, nuclear, and defense sectors where materials must withstand temperatures exceeding 2000°C while maintaining structural integrity. Traditional single-phase carbides, despite their high melting points, often suffer from poor oxidation resistance and inadequate mechanical properties at elevated temperatures.

The technological trajectory of HECs has been marked by significant breakthroughs in compositional design and processing techniques. Early research focused primarily on establishing the formation criteria for single-phase solid solutions, while recent efforts have shifted toward optimizing processing parameters to achieve fully dense structures with controlled microstructures.

Spark Plasma Sintering (SPS) has emerged as a preferred consolidation method for HECs due to its ability to achieve rapid densification at relatively lower temperatures compared to conventional sintering techniques. This process utilizes pulsed direct current to generate localized heating at particle interfaces, facilitating mass transport and densification while minimizing grain growth.

The primary technical objectives in HEC processing via SPS include achieving near-theoretical density (>99%) while maintaining nanocrystalline or fine-grained microstructures. This combination is crucial for optimizing mechanical properties such as hardness, fracture toughness, and high-temperature strength. Additionally, researchers aim to establish reproducible processing-structure-property relationships that can guide the design of tailored HECs for specific applications.

Current research goals also encompass understanding the fundamental mechanisms governing densification and grain growth during SPS of HECs, particularly how the high configurational entropy affects diffusion kinetics and microstructural evolution. This knowledge is essential for developing predictive models that can accelerate the optimization of processing parameters and reduce the empirical nature of current approaches.

The field is now moving toward establishing standardized processing protocols that can ensure consistent quality and properties across different HEC compositions, a necessary step for industrial adoption and commercialization of these promising materials.

Market Applications for High-Entropy Carbides

High-entropy carbides (HECs) represent a revolutionary class of ultra-high temperature ceramics with exceptional properties that make them highly valuable across multiple industrial sectors. The aerospace industry stands as a primary beneficiary, where HECs can be utilized in thermal protection systems for hypersonic vehicles, rocket nozzles, and leading edges of reentry vehicles. Their remarkable thermal stability at temperatures exceeding 3000°C, coupled with excellent oxidation resistance, positions them as ideal candidates for these extreme environment applications.

The cutting tool industry presents another significant market opportunity. HECs processed through spark plasma sintering demonstrate superior hardness, wear resistance, and thermal stability compared to conventional carbide tools. These properties translate to extended tool life and improved machining performance, particularly in high-speed cutting operations for difficult-to-machine materials like superalloys and hardened steels.

Nuclear energy applications represent a growing market segment for HECs. Their exceptional radiation resistance, dimensional stability, and high-temperature performance make them promising candidates for next-generation nuclear reactor components, including fuel cladding and structural materials. The controlled grain structure achievable through optimized spark plasma sintering parameters directly enhances their radiation tolerance.

The defense sector increasingly demands advanced materials for armor applications. HECs offer an attractive combination of hardness, toughness, and lightweight properties that could revolutionize ballistic protection systems. The ability to precisely control densification during spark plasma sintering enables the production of HEC components with tailored porosity profiles for optimized ballistic performance.

Energy generation and storage systems benefit from HECs' unique properties as well. Their excellent electrical conductivity, electrochemical stability, and catalytic activity make them valuable for applications in solid oxide fuel cells, hydrogen production systems, and advanced battery technologies. The microstructural control afforded by spark plasma sintering directly influences these functional properties.

Industrial furnace components represent another practical application area. HECs can withstand extreme temperatures while maintaining structural integrity, making them ideal for heating elements, crucibles, and other high-temperature processing equipment. Their superior thermal shock resistance, achievable through controlled grain size distribution during sintering, extends component lifespan in cyclic heating applications.

The electronics industry may also benefit from HECs in specialized applications requiring materials with exceptional thermal management capabilities, such as heat spreaders for high-power electronic devices and substrates for power electronics operating in extreme environments.

The cutting tool industry presents another significant market opportunity. HECs processed through spark plasma sintering demonstrate superior hardness, wear resistance, and thermal stability compared to conventional carbide tools. These properties translate to extended tool life and improved machining performance, particularly in high-speed cutting operations for difficult-to-machine materials like superalloys and hardened steels.

Nuclear energy applications represent a growing market segment for HECs. Their exceptional radiation resistance, dimensional stability, and high-temperature performance make them promising candidates for next-generation nuclear reactor components, including fuel cladding and structural materials. The controlled grain structure achievable through optimized spark plasma sintering parameters directly enhances their radiation tolerance.

The defense sector increasingly demands advanced materials for armor applications. HECs offer an attractive combination of hardness, toughness, and lightweight properties that could revolutionize ballistic protection systems. The ability to precisely control densification during spark plasma sintering enables the production of HEC components with tailored porosity profiles for optimized ballistic performance.

Energy generation and storage systems benefit from HECs' unique properties as well. Their excellent electrical conductivity, electrochemical stability, and catalytic activity make them valuable for applications in solid oxide fuel cells, hydrogen production systems, and advanced battery technologies. The microstructural control afforded by spark plasma sintering directly influences these functional properties.

Industrial furnace components represent another practical application area. HECs can withstand extreme temperatures while maintaining structural integrity, making them ideal for heating elements, crucibles, and other high-temperature processing equipment. Their superior thermal shock resistance, achievable through controlled grain size distribution during sintering, extends component lifespan in cyclic heating applications.

The electronics industry may also benefit from HECs in specialized applications requiring materials with exceptional thermal management capabilities, such as heat spreaders for high-power electronic devices and substrates for power electronics operating in extreme environments.

Current Challenges in SPS Densification

Despite significant advancements in Spark Plasma Sintering (SPS) technology for processing high-entropy carbides (HECs), several critical challenges persist in achieving optimal densification. The primary obstacle lies in the inherent trade-off between densification and grain growth control. When processing temperatures are increased to enhance densification, excessive grain growth often occurs, compromising the mechanical properties and performance of the final material.

The heterogeneous nature of high-entropy carbides presents unique challenges during SPS processing. The varying melting points, thermal expansion coefficients, and diffusion rates among constituent elements lead to non-uniform sintering behavior. This heterogeneity results in differential shrinkage rates across the material, creating internal stresses that can cause microcracking and residual porosity, ultimately limiting achievable densification levels.

Pressure distribution uniformity during SPS remains problematic, particularly for complex geometries and larger sample sizes. The current die designs and pressure application mechanisms often create pressure gradients within the sample, leading to density variations and inconsistent microstructural development. These variations become more pronounced when processing multi-component systems like HECs, where compositional fluctuations can exacerbate non-uniform sintering.

Temperature control and measurement accuracy represent another significant challenge. The rapid heating rates characteristic of SPS create steep thermal gradients, and current temperature monitoring systems (typically pyrometers or thermocouples) often fail to accurately capture the true temperature at the core of the sample. This discrepancy between measured and actual temperatures leads to processing inconsistencies and reproducibility issues.

The formation of secondary phases and carbide precipitation at grain boundaries during SPS processing of HECs frequently impedes complete densification. These phases can inhibit grain boundary migration and pore elimination mechanisms, resulting in entrapped porosity that persists even at elevated processing temperatures and pressures.

Scaling challenges further complicate industrial adoption of SPS for HEC production. Current SPS equipment has limitations in sample size and throughput, making large-scale production economically unfeasible. Additionally, the high energy consumption associated with SPS processing of ultra-high temperature ceramics like HECs raises sustainability concerns that must be addressed for broader implementation.

The lack of standardized processing parameters for specific HEC compositions represents a fundamental barrier to consistent densification. The complex interactions between multiple carbide phases in HECs create a vast parameter space that remains largely unexplored, necessitating extensive trial-and-error approaches that impede systematic optimization of densification protocols.

The heterogeneous nature of high-entropy carbides presents unique challenges during SPS processing. The varying melting points, thermal expansion coefficients, and diffusion rates among constituent elements lead to non-uniform sintering behavior. This heterogeneity results in differential shrinkage rates across the material, creating internal stresses that can cause microcracking and residual porosity, ultimately limiting achievable densification levels.

Pressure distribution uniformity during SPS remains problematic, particularly for complex geometries and larger sample sizes. The current die designs and pressure application mechanisms often create pressure gradients within the sample, leading to density variations and inconsistent microstructural development. These variations become more pronounced when processing multi-component systems like HECs, where compositional fluctuations can exacerbate non-uniform sintering.

Temperature control and measurement accuracy represent another significant challenge. The rapid heating rates characteristic of SPS create steep thermal gradients, and current temperature monitoring systems (typically pyrometers or thermocouples) often fail to accurately capture the true temperature at the core of the sample. This discrepancy between measured and actual temperatures leads to processing inconsistencies and reproducibility issues.

The formation of secondary phases and carbide precipitation at grain boundaries during SPS processing of HECs frequently impedes complete densification. These phases can inhibit grain boundary migration and pore elimination mechanisms, resulting in entrapped porosity that persists even at elevated processing temperatures and pressures.

Scaling challenges further complicate industrial adoption of SPS for HEC production. Current SPS equipment has limitations in sample size and throughput, making large-scale production economically unfeasible. Additionally, the high energy consumption associated with SPS processing of ultra-high temperature ceramics like HECs raises sustainability concerns that must be addressed for broader implementation.

The lack of standardized processing parameters for specific HEC compositions represents a fundamental barrier to consistent densification. The complex interactions between multiple carbide phases in HECs create a vast parameter space that remains largely unexplored, necessitating extensive trial-and-error approaches that impede systematic optimization of densification protocols.

Current SPS Processing Parameters

01 Sintering techniques for high-entropy carbides densification

Various sintering techniques can be employed to achieve high densification of high-entropy carbides. These include spark plasma sintering (SPS), hot pressing, and pressureless sintering. These methods apply different combinations of temperature, pressure, and time to consolidate high-entropy carbide powders into dense structures while controlling grain growth. The selection of appropriate sintering parameters is crucial for achieving optimal densification without excessive grain growth.- Sintering techniques for high-entropy carbides densification: Various sintering techniques can be employed to achieve high densification of high-entropy carbides. These include spark plasma sintering (SPS), hot pressing, and pressureless sintering. These methods apply different combinations of temperature, pressure, and time to consolidate high-entropy carbide powders into dense structures while controlling grain growth. The selection of appropriate sintering parameters is crucial for achieving optimal densification without excessive grain growth.

- Grain size control through processing parameters: Controlling grain size in high-entropy carbides can be achieved through careful manipulation of processing parameters. These include milling time, sintering temperature, holding time, heating rate, and cooling rate. Lower sintering temperatures and shorter holding times typically result in finer grain structures, while higher temperatures promote densification but may lead to grain coarsening. Rapid heating and cooling rates can also help maintain fine grain structures by limiting the time available for grain growth.

- Additives and dopants for enhanced densification: The addition of specific dopants and sintering aids can significantly improve the densification behavior of high-entropy carbides while inhibiting grain growth. Common additives include transition metals, rare earth elements, and other carbide formers that can create liquid phases during sintering or pin grain boundaries. These additives can lower the sintering temperature required for full densification, enhance diffusion processes, and restrict grain boundary movement during thermal processing.

- Microstructure engineering for grain refinement: Microstructure engineering approaches can be employed to achieve refined grain structures in high-entropy carbides. These include the introduction of secondary phases at grain boundaries, creation of core-shell structures, and development of nanocomposites. By designing heterogeneous microstructures with multiple phases or compositional gradients, grain growth can be effectively inhibited during densification processes, resulting in materials with enhanced mechanical properties and thermal stability.

- Advanced powder processing for uniform densification: Advanced powder processing techniques are essential for achieving uniform densification and controlled grain growth in high-entropy carbides. These include high-energy ball milling, mechanical alloying, solution-based synthesis, and spray drying. These methods can produce homogeneous powder mixtures with fine particle sizes and uniform distribution of constituent elements, which facilitates subsequent densification processes and helps maintain uniform grain structures throughout the material.

02 Grain size control through processing parameters

Controlling grain size in high-entropy carbides can be achieved through careful manipulation of processing parameters. These include milling time during powder preparation, heating rate, sintering temperature, holding time, and cooling rate. Lower sintering temperatures and shorter holding times typically result in finer grain structures, while rapid cooling can prevent excessive grain growth. Additionally, the application of pressure during sintering can enhance densification while limiting grain growth.Expand Specific Solutions03 Dopants and additives for grain boundary engineering

The addition of dopants and secondary phases can effectively control grain growth in high-entropy carbides. Elements such as boron, silicon, and rare earth metals can segregate to grain boundaries, inhibiting grain boundary migration during sintering. Additionally, nano-sized particles of stable compounds can be incorporated to pin grain boundaries through Zener pinning mechanisms. These approaches allow for simultaneous achievement of high densification and controlled grain structure.Expand Specific Solutions04 Microstructural evolution during densification

Understanding the microstructural evolution during densification of high-entropy carbides is essential for grain control. The formation of solid solutions, phase transformations, and grain boundary migration mechanisms all influence the final microstructure. Monitoring and controlling these processes through advanced characterization techniques allows for the development of optimized processing routes. The unique characteristics of high-entropy systems, including sluggish diffusion and lattice distortion, can be leveraged to achieve desired microstructures.Expand Specific Solutions05 Novel processing routes for enhanced densification

Novel processing routes have been developed to enhance the densification of high-entropy carbides while maintaining fine grain structures. These include two-step sintering processes, field-assisted sintering techniques, and reactive sintering approaches. Additionally, the use of precursor-derived ceramics and solution-based synthesis methods can produce nano-sized powders that facilitate densification at lower temperatures. These innovative approaches offer pathways to achieve near-theoretical density while preserving nanoscale or ultrafine grain structures.Expand Specific Solutions

Leading Research Groups and Manufacturers

The high-entropy carbides processing via Spark Plasma Sintering market is in its early growth phase, characterized by intensive R&D activities and emerging commercial applications. The global market for advanced ceramics and refractory materials is expanding, with high-entropy carbides representing a promising segment due to their exceptional high-temperature properties. Leading research institutions like Commissariat à l'énergie atomique, Central South University, and National University of Defense Technology are advancing fundamental understanding, while companies including Plansee SE, Evonik Operations, and SINTERmat SAS are developing commercial applications. The technology maturity varies significantly across players, with established materials companies like Toyo Tanso and Oerlikon Surface Solutions leveraging existing expertise in related materials processing, while newer entrants focus on specialized applications in aerospace and defense sectors.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: CEA has developed a comprehensive approach to high-entropy carbide processing via SPS that focuses on precursor powder preparation and manipulation of sintering atmospheres. Their method involves controlled mechanical alloying of carbide precursors under inert conditions to create homogeneous powder mixtures with optimized particle size distributions (typically 0.1-1 μm). During SPS processing, they employ a controlled atmosphere system that allows precise regulation of carbon activity and oxygen partial pressure, which significantly influences densification behavior and final stoichiometry. CEA's research has established correlations between applied pressure profiles (typically using 30-80 MPa with programmed pressure ramps) and resultant grain boundary migration rates. Their process achieves densification exceeding 99% at relatively lower temperatures (1700-1900°C) compared to conventional methods, while maintaining average grain sizes below 2 μm through careful control of dwell times and heating rates.

Strengths: Exceptional control over stoichiometry and phase purity; lower processing temperatures than conventional methods; excellent integration of powder preparation and sintering parameters. Weaknesses: Complex process requiring sophisticated atmosphere control systems; higher sensitivity to starting powder characteristics; longer processing times compared to some competing methods.

Central South University

Technical Solution: Central South University has developed a multi-stage SPS protocol specifically for high-entropy carbides that focuses on controlling grain boundary mobility through precise thermal management. Their approach involves an initial rapid heating phase (200-300°C/min) to approximately 70% of the final sintering temperature, followed by a controlled rate heating regime with synchronized pressure application. The university's research has established critical relationships between current density distribution and resultant microstructural evolution in HECs, particularly for (Ti,Zr,Hf,Nb,Ta)C and (Ti,Zr,Hf,V,Nb)C systems. Their process incorporates specialized graphite die designs with tailored thermal conductivity gradients that help manage heat distribution during sintering. This approach has demonstrated the ability to achieve densities exceeding 99% while maintaining average grain sizes below 1 μm through careful control of dwell times (typically 5-15 minutes) at peak temperatures (1900-2100°C). The university has also pioneered the use of electric field orientation effects to influence grain growth direction in HECs, allowing for microstructural anisotropy when desired for specific applications.

Strengths: Excellent control over grain size and orientation; ability to create tailored microstructural anisotropy; high densification rates with minimal dwell times. Weaknesses: Requires specialized die designs that increase processing costs; high sensitivity to sample geometry and size; limited data on scalability to larger components.

Key Densification Mechanisms Analysis

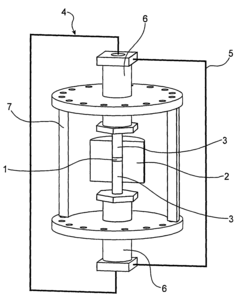

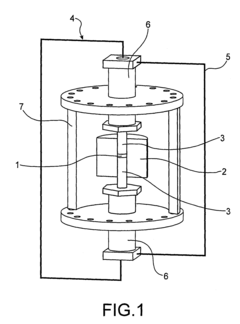

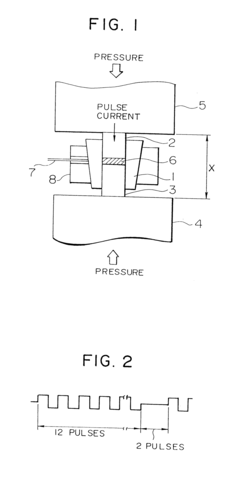

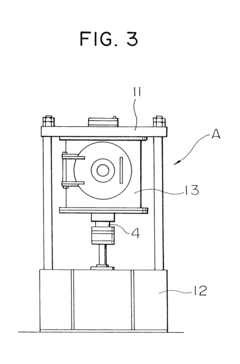

Process for joining refractory ceramic parts by spark plasma sintering (SPS)

PatentInactiveUS8956478B2

Innovation

- A process using spark plasma sintering that applies a pressure of 1 to 200 MPa and a pulsed electric current of 500 to 8000 A to raise the temperature of refractory ceramic parts to at least 1300°C, achieving a permanent, strong bond without additional materials or heat treatments, by gradually increasing pressure and temperature to avoid thermal shock.

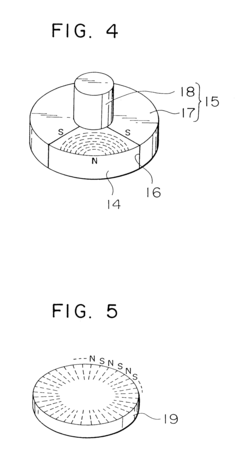

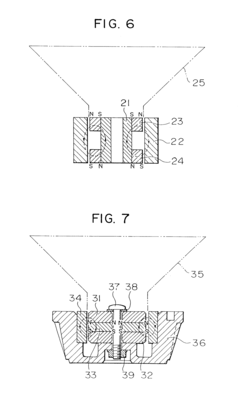

Hard magnetic alloy, hard magnetic alloy compact and method for producing the same

PatentInactiveUS6692582B1

Innovation

- A hard magnetic alloy comprising Fe, Co, Ni, rare earth elements, and B, with a specific composition and production method that includes quenching and annealing to achieve a nano-crystalline structure, resulting in a material with improved coercive force, thermal stability, and mechanical strength.

Material Characterization Techniques

Material characterization techniques play a crucial role in the development and optimization of high-entropy carbides (HECs) processed via spark plasma sintering (SPS). These advanced analytical methods enable researchers to evaluate densification levels, grain structure, phase composition, and other critical parameters that determine the final properties of sintered HEC components.

X-ray diffraction (XRD) serves as a primary technique for phase identification and crystallographic analysis of HECs. Through XRD patterns, researchers can confirm the formation of single-phase solid solutions or identify secondary phases that may emerge during the sintering process. Lattice parameter measurements derived from XRD data also provide insights into lattice distortion caused by the incorporation of multiple metal elements into the carbide structure.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) offers detailed microstructural examination and elemental distribution analysis. SEM imaging reveals grain morphology, size distribution, and porosity characteristics, which directly correlate with the densification parameters used during SPS. EDS mapping further confirms the homogeneity of elemental distribution within the HEC matrix, a critical factor for achieving consistent mechanical properties.

Transmission electron microscopy (TEM) provides atomic-scale characterization of grain boundaries, dislocations, and other microstructural features in HECs. High-resolution TEM can reveal lattice distortions and atomic arrangements that influence the unique properties of these multi-principal element carbides. Selected area electron diffraction (SAED) patterns complement TEM imaging by providing crystallographic information at the nanoscale.

Density measurements using Archimedes' principle or helium pycnometry quantitatively assess the effectiveness of SPS densification parameters. The relative density values obtained through these methods serve as direct indicators of processing optimization, with values approaching theoretical density signifying successful consolidation of HEC powders.

Mechanical property characterization through nanoindentation, microhardness testing, and fracture toughness measurements provides functional validation of the processing-structure relationships in SPS-processed HECs. These techniques allow researchers to correlate grain size control parameters with resulting mechanical performance, establishing process-property relationships essential for application-specific material design.

Advanced spectroscopic techniques such as Raman spectroscopy and X-ray photoelectron spectroscopy (XPS) offer complementary information about bonding states and surface chemistry of HECs. These insights are particularly valuable for understanding the role of carbon stoichiometry and vacancy concentrations in determining the final properties of spark plasma sintered high-entropy carbides.

X-ray diffraction (XRD) serves as a primary technique for phase identification and crystallographic analysis of HECs. Through XRD patterns, researchers can confirm the formation of single-phase solid solutions or identify secondary phases that may emerge during the sintering process. Lattice parameter measurements derived from XRD data also provide insights into lattice distortion caused by the incorporation of multiple metal elements into the carbide structure.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) offers detailed microstructural examination and elemental distribution analysis. SEM imaging reveals grain morphology, size distribution, and porosity characteristics, which directly correlate with the densification parameters used during SPS. EDS mapping further confirms the homogeneity of elemental distribution within the HEC matrix, a critical factor for achieving consistent mechanical properties.

Transmission electron microscopy (TEM) provides atomic-scale characterization of grain boundaries, dislocations, and other microstructural features in HECs. High-resolution TEM can reveal lattice distortions and atomic arrangements that influence the unique properties of these multi-principal element carbides. Selected area electron diffraction (SAED) patterns complement TEM imaging by providing crystallographic information at the nanoscale.

Density measurements using Archimedes' principle or helium pycnometry quantitatively assess the effectiveness of SPS densification parameters. The relative density values obtained through these methods serve as direct indicators of processing optimization, with values approaching theoretical density signifying successful consolidation of HEC powders.

Mechanical property characterization through nanoindentation, microhardness testing, and fracture toughness measurements provides functional validation of the processing-structure relationships in SPS-processed HECs. These techniques allow researchers to correlate grain size control parameters with resulting mechanical performance, establishing process-property relationships essential for application-specific material design.

Advanced spectroscopic techniques such as Raman spectroscopy and X-ray photoelectron spectroscopy (XPS) offer complementary information about bonding states and surface chemistry of HECs. These insights are particularly valuable for understanding the role of carbon stoichiometry and vacancy concentrations in determining the final properties of spark plasma sintered high-entropy carbides.

Sustainability in HEC Processing

Sustainability in High-Entropy Carbide (HEC) processing represents a critical frontier in advanced materials manufacturing. The environmental impact of traditional ceramic processing methods has raised significant concerns, particularly regarding energy consumption and resource utilization. Spark Plasma Sintering (SPS), as an emerging consolidation technique for HECs, offers substantial sustainability advantages compared to conventional sintering approaches.

The energy efficiency of SPS for HEC processing stems from its rapid heating rates and shorter processing times. Traditional sintering methods typically require hours or even days at elevated temperatures, whereas SPS can achieve full densification of HECs in minutes to tens of minutes. This dramatic reduction in processing time translates to energy savings of 60-80% compared to hot pressing or pressureless sintering techniques, significantly reducing the carbon footprint of HEC manufacturing.

Material utilization represents another sustainability dimension where SPS excels. The precise control over densification parameters enables near-net-shape manufacturing capabilities, minimizing post-processing requirements and associated material waste. Studies indicate that SPS can achieve material utilization rates exceeding 95% for complex HEC compositions, compared to 70-85% for conventional processing routes.

The reduced processing temperatures in SPS also contribute to sustainability through extended equipment lifespans. While conventional sintering of ultra-high temperature ceramics like HECs often requires temperatures exceeding 2000°C, SPS can achieve comparable densification at temperatures 200-300°C lower. This temperature reduction significantly extends the operational life of processing equipment and reduces maintenance frequency.

From a circular economy perspective, SPS offers promising pathways for recycling and reprocessing HEC materials. The technique's ability to consolidate fine powders without significant grain growth makes it particularly suitable for processing recycled HEC materials, which often present challenges in particle size distribution and homogeneity. Recent research demonstrates that recycled HEC powders can achieve up to 98% of the mechanical properties of virgin materials when processed via SPS.

Water consumption represents another environmental advantage of SPS for HEC processing. Unlike wet chemical processing routes that may require substantial water volumes for synthesis and cleaning, SPS is essentially a dry processing technique. This characteristic becomes increasingly valuable as water scarcity concerns intensify globally, particularly in regions with concentrated advanced materials manufacturing.

The energy efficiency of SPS for HEC processing stems from its rapid heating rates and shorter processing times. Traditional sintering methods typically require hours or even days at elevated temperatures, whereas SPS can achieve full densification of HECs in minutes to tens of minutes. This dramatic reduction in processing time translates to energy savings of 60-80% compared to hot pressing or pressureless sintering techniques, significantly reducing the carbon footprint of HEC manufacturing.

Material utilization represents another sustainability dimension where SPS excels. The precise control over densification parameters enables near-net-shape manufacturing capabilities, minimizing post-processing requirements and associated material waste. Studies indicate that SPS can achieve material utilization rates exceeding 95% for complex HEC compositions, compared to 70-85% for conventional processing routes.

The reduced processing temperatures in SPS also contribute to sustainability through extended equipment lifespans. While conventional sintering of ultra-high temperature ceramics like HECs often requires temperatures exceeding 2000°C, SPS can achieve comparable densification at temperatures 200-300°C lower. This temperature reduction significantly extends the operational life of processing equipment and reduces maintenance frequency.

From a circular economy perspective, SPS offers promising pathways for recycling and reprocessing HEC materials. The technique's ability to consolidate fine powders without significant grain growth makes it particularly suitable for processing recycled HEC materials, which often present challenges in particle size distribution and homogeneity. Recent research demonstrates that recycled HEC powders can achieve up to 98% of the mechanical properties of virgin materials when processed via SPS.

Water consumption represents another environmental advantage of SPS for HEC processing. Unlike wet chemical processing routes that may require substantial water volumes for synthesis and cleaning, SPS is essentially a dry processing technique. This characteristic becomes increasingly valuable as water scarcity concerns intensify globally, particularly in regions with concentrated advanced materials manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!