High-entropy oxide thermomechanical compatibility with metallic substrates: Bond coat strategies

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Entropy Oxide Development Background and Objectives

High-entropy oxides (HEOs) represent a revolutionary class of materials that have emerged as a significant frontier in materials science over the past decade. These complex oxide systems, characterized by the incorporation of five or more cations in equimolar or near-equimolar ratios within a single crystallographic phase, were first reported in 2015, marking a paradigm shift in oxide material design. The development of HEOs stems from the successful application of the high-entropy concept in metallic alloys, which demonstrated exceptional mechanical properties and thermal stability.

The evolution of HEOs has been driven by the pursuit of materials with enhanced functional properties for extreme environments, particularly in high-temperature applications where conventional materials face significant limitations. Traditional thermal barrier coating (TBC) systems, typically composed of yttria-stabilized zirconia (YSZ), encounter performance boundaries at temperatures exceeding 1200°C, necessitating the exploration of alternative material systems with superior thermomechanical properties.

The primary objective in HEO development for coating applications is to achieve exceptional thermal stability while maintaining structural integrity when interfaced with metallic substrates. This presents a complex materials engineering challenge, as the coefficient of thermal expansion (CTE) mismatch between ceramic oxides and metallic components often leads to interfacial stress accumulation during thermal cycling, resulting in premature failure through delamination or spallation.

A critical goal in this technological domain is the design of HEO compositions that exhibit tailorable thermomechanical properties, particularly CTE values that can be engineered to better match those of underlying metallic substrates. This would significantly enhance coating durability in extreme thermal environments, extending component lifetimes in applications such as gas turbines, aerospace propulsion systems, and next-generation energy conversion technologies.

Furthermore, HEO development aims to leverage the configurational entropy effect to stabilize complex oxide phases that might otherwise be thermodynamically unfavorable, potentially unlocking novel property combinations not achievable in conventional oxide systems. The entropic stabilization mechanism offers opportunities to incorporate elements that can enhance specific functional properties while maintaining phase stability at elevated temperatures.

The technological trajectory of HEO research is increasingly focused on establishing fundamental structure-property relationships that govern thermomechanical compatibility with metallic substrates, with particular emphasis on developing effective bond coat strategies that can accommodate the inherent property mismatches between these dissimilar material classes while providing essential oxidation protection to the underlying metal components.

The evolution of HEOs has been driven by the pursuit of materials with enhanced functional properties for extreme environments, particularly in high-temperature applications where conventional materials face significant limitations. Traditional thermal barrier coating (TBC) systems, typically composed of yttria-stabilized zirconia (YSZ), encounter performance boundaries at temperatures exceeding 1200°C, necessitating the exploration of alternative material systems with superior thermomechanical properties.

The primary objective in HEO development for coating applications is to achieve exceptional thermal stability while maintaining structural integrity when interfaced with metallic substrates. This presents a complex materials engineering challenge, as the coefficient of thermal expansion (CTE) mismatch between ceramic oxides and metallic components often leads to interfacial stress accumulation during thermal cycling, resulting in premature failure through delamination or spallation.

A critical goal in this technological domain is the design of HEO compositions that exhibit tailorable thermomechanical properties, particularly CTE values that can be engineered to better match those of underlying metallic substrates. This would significantly enhance coating durability in extreme thermal environments, extending component lifetimes in applications such as gas turbines, aerospace propulsion systems, and next-generation energy conversion technologies.

Furthermore, HEO development aims to leverage the configurational entropy effect to stabilize complex oxide phases that might otherwise be thermodynamically unfavorable, potentially unlocking novel property combinations not achievable in conventional oxide systems. The entropic stabilization mechanism offers opportunities to incorporate elements that can enhance specific functional properties while maintaining phase stability at elevated temperatures.

The technological trajectory of HEO research is increasingly focused on establishing fundamental structure-property relationships that govern thermomechanical compatibility with metallic substrates, with particular emphasis on developing effective bond coat strategies that can accommodate the inherent property mismatches between these dissimilar material classes while providing essential oxidation protection to the underlying metal components.

Market Analysis for Advanced Thermal Barrier Coatings

The global market for Advanced Thermal Barrier Coatings (TBCs) is experiencing robust growth, driven primarily by increasing demands in aerospace, power generation, and automotive industries. These coatings are essential for protecting metallic substrates in high-temperature environments, with the market value projected to reach $2.5 billion by 2027, growing at a CAGR of 6.8% from 2022.

Aerospace remains the dominant application segment, accounting for approximately 45% of the total market share. The continuous push for higher operating temperatures in gas turbine engines to improve fuel efficiency and reduce emissions is a key market driver. Commercial aviation's recovery post-pandemic has accelerated demand, with major manufacturers implementing next-generation coating systems in their newest engine models.

The power generation sector represents the second-largest market segment at 30%, where high-entropy oxide (HEO) based thermal barrier coatings are gaining significant traction. The transition toward cleaner energy production has increased the operational demands on gas turbines, requiring more durable coating systems that can withstand extreme thermal cycling and hot corrosion.

Regional analysis indicates North America and Europe currently lead the market with combined share of 65%, attributed to the concentration of aerospace and power generation OEMs. However, the Asia-Pacific region is witnessing the fastest growth rate of 8.5% annually, driven by expanding industrial bases in China and India, and increasing defense spending across the region.

Customer requirements are evolving toward coatings with enhanced durability and longer service intervals. End-users are increasingly willing to pay premium prices for advanced coating systems that demonstrate superior thermomechanical compatibility with metallic substrates, particularly those utilizing innovative bond coat strategies. This trend has created a value-added market segment estimated at $500 million annually.

Competitive landscape analysis reveals that five major players control approximately 70% of the global market. However, specialized coating technology providers focusing on HEO solutions are gaining market share through strategic partnerships with substrate manufacturers and end-users. These companies are differentiating themselves by offering customized bond coat solutions that address specific substrate compatibility challenges.

Market forecasts indicate that HEO-based coating systems with advanced bond coat technologies will experience the highest growth rate within the TBC market, potentially capturing 25% market share by 2028. This growth is supported by increasing R&D investments from both industry and government sources, with an estimated $350 million allocated to advanced coating research programs globally in 2023.

Aerospace remains the dominant application segment, accounting for approximately 45% of the total market share. The continuous push for higher operating temperatures in gas turbine engines to improve fuel efficiency and reduce emissions is a key market driver. Commercial aviation's recovery post-pandemic has accelerated demand, with major manufacturers implementing next-generation coating systems in their newest engine models.

The power generation sector represents the second-largest market segment at 30%, where high-entropy oxide (HEO) based thermal barrier coatings are gaining significant traction. The transition toward cleaner energy production has increased the operational demands on gas turbines, requiring more durable coating systems that can withstand extreme thermal cycling and hot corrosion.

Regional analysis indicates North America and Europe currently lead the market with combined share of 65%, attributed to the concentration of aerospace and power generation OEMs. However, the Asia-Pacific region is witnessing the fastest growth rate of 8.5% annually, driven by expanding industrial bases in China and India, and increasing defense spending across the region.

Customer requirements are evolving toward coatings with enhanced durability and longer service intervals. End-users are increasingly willing to pay premium prices for advanced coating systems that demonstrate superior thermomechanical compatibility with metallic substrates, particularly those utilizing innovative bond coat strategies. This trend has created a value-added market segment estimated at $500 million annually.

Competitive landscape analysis reveals that five major players control approximately 70% of the global market. However, specialized coating technology providers focusing on HEO solutions are gaining market share through strategic partnerships with substrate manufacturers and end-users. These companies are differentiating themselves by offering customized bond coat solutions that address specific substrate compatibility challenges.

Market forecasts indicate that HEO-based coating systems with advanced bond coat technologies will experience the highest growth rate within the TBC market, potentially capturing 25% market share by 2028. This growth is supported by increasing R&D investments from both industry and government sources, with an estimated $350 million allocated to advanced coating research programs globally in 2023.

Current Challenges in HEO-Metal Interface Compatibility

The integration of high-entropy oxides (HEOs) with metallic substrates presents significant thermomechanical compatibility challenges that must be addressed for successful implementation in high-temperature applications. The coefficient of thermal expansion (CTE) mismatch between HEOs and metallic substrates represents one of the most critical issues, often leading to stress accumulation during thermal cycling that can result in coating delamination, cracking, and eventual system failure.

Interfacial adhesion quality between HEOs and metallic substrates remains inconsistent across different material combinations. Current bonding mechanisms often fail to create robust chemical bonds that can withstand the severe thermal and mechanical stresses experienced in operational environments. This is particularly problematic in applications requiring thousands of thermal cycles, such as gas turbine components.

Interdiffusion phenomena at elevated temperatures pose another significant challenge. Elements from both the HEO coating and the metallic substrate can migrate across the interface, potentially forming detrimental phases that compromise mechanical integrity. This diffusion can lead to the formation of brittle intermetallic compounds or voids that serve as crack initiation sites, accelerating coating failure.

The oxidation behavior at the HEO-metal interface presents additional complications. When exposed to high-temperature oxidizing environments, preferential oxidation of certain elements can occur, creating compositional gradients that further destabilize the interface. This selective oxidation often results in volume changes that induce additional stresses at the interface.

Current bond coat technologies developed for traditional thermal barrier coating systems show limited effectiveness when applied to HEO systems. The multi-principal element composition of HEOs creates unique chemical interactions that are not adequately addressed by conventional MCrAlY or aluminide bond coats. These conventional approaches often fail to accommodate the complex phase stability requirements of HEO-based systems.

Manufacturing challenges further complicate the development of effective HEO-metal interfaces. Deposition techniques that can create uniform, defect-free HEO coatings while simultaneously ensuring strong interfacial bonding remain limited. Techniques such as atmospheric plasma spraying and physical vapor deposition often introduce microstructural defects at the interface that serve as failure initiation points.

The long-term stability of HEO-metal interfaces under combined thermal, mechanical, and chemical stresses remains poorly understood. Accelerated testing protocols have proven inadequate for predicting real-world performance, as they fail to capture the complex degradation mechanisms that emerge over extended operational periods. This knowledge gap significantly hinders the development of reliable design guidelines for HEO-based coating systems.

Interfacial adhesion quality between HEOs and metallic substrates remains inconsistent across different material combinations. Current bonding mechanisms often fail to create robust chemical bonds that can withstand the severe thermal and mechanical stresses experienced in operational environments. This is particularly problematic in applications requiring thousands of thermal cycles, such as gas turbine components.

Interdiffusion phenomena at elevated temperatures pose another significant challenge. Elements from both the HEO coating and the metallic substrate can migrate across the interface, potentially forming detrimental phases that compromise mechanical integrity. This diffusion can lead to the formation of brittle intermetallic compounds or voids that serve as crack initiation sites, accelerating coating failure.

The oxidation behavior at the HEO-metal interface presents additional complications. When exposed to high-temperature oxidizing environments, preferential oxidation of certain elements can occur, creating compositional gradients that further destabilize the interface. This selective oxidation often results in volume changes that induce additional stresses at the interface.

Current bond coat technologies developed for traditional thermal barrier coating systems show limited effectiveness when applied to HEO systems. The multi-principal element composition of HEOs creates unique chemical interactions that are not adequately addressed by conventional MCrAlY or aluminide bond coats. These conventional approaches often fail to accommodate the complex phase stability requirements of HEO-based systems.

Manufacturing challenges further complicate the development of effective HEO-metal interfaces. Deposition techniques that can create uniform, defect-free HEO coatings while simultaneously ensuring strong interfacial bonding remain limited. Techniques such as atmospheric plasma spraying and physical vapor deposition often introduce microstructural defects at the interface that serve as failure initiation points.

The long-term stability of HEO-metal interfaces under combined thermal, mechanical, and chemical stresses remains poorly understood. Accelerated testing protocols have proven inadequate for predicting real-world performance, as they fail to capture the complex degradation mechanisms that emerge over extended operational periods. This knowledge gap significantly hinders the development of reliable design guidelines for HEO-based coating systems.

Existing Bond Coat Strategies for HEO Applications

01 Composition and structure of high-entropy oxides for thermal stability

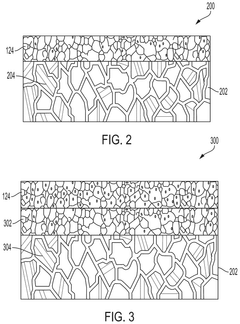

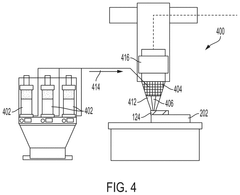

High-entropy oxides (HEOs) with specific compositions can be designed to achieve enhanced thermal stability and thermomechanical compatibility. These materials typically incorporate multiple cations in equimolar or near-equimolar ratios within a single crystalline phase, creating high configurational entropy that contributes to structural stability at elevated temperatures. The careful selection of constituent elements with similar ionic radii but different properties allows for tailored thermal expansion behaviors and improved resistance to thermal cycling.- Composition and structure of high-entropy oxides for thermal stability: High-entropy oxides (HEOs) can be designed with specific compositions to enhance thermomechanical compatibility. These materials typically contain five or more metal cations in equimolar or near-equimolar ratios, distributed randomly in a single crystallographic lattice. The configurational entropy stabilizes the structure, allowing for better thermal expansion matching with substrates and improved resistance to thermal cycling. The unique atomic arrangements in HEOs contribute to their exceptional thermal stability and mechanical properties at elevated temperatures.

- Interface engineering for improved thermomechanical compatibility: Interface engineering techniques can significantly enhance the thermomechanical compatibility of high-entropy oxide systems. By creating gradient compositions or buffer layers between the high-entropy oxide and substrate materials, thermal expansion mismatch stresses can be minimized. These engineered interfaces help distribute thermal stresses, prevent delamination, and improve adhesion during thermal cycling. Various methods including co-deposition, diffusion bonding, and controlled interdiffusion can be employed to create these optimized interfaces for better thermomechanical performance.

- Defect engineering in high-entropy oxides for thermal applications: Defect engineering plays a crucial role in optimizing the thermomechanical properties of high-entropy oxides. By deliberately introducing specific types and concentrations of defects such as oxygen vacancies, interstitials, or substitutional defects, the thermal expansion behavior and mechanical response can be tailored. These engineered defects can serve as stress relaxation sites during thermal cycling, enhance ionic conductivity, and improve overall thermomechanical compatibility. The high configurational entropy of these materials provides unique opportunities for stabilizing beneficial defect structures that would be unstable in conventional oxides.

- Processing techniques for high-entropy oxides with enhanced thermomechanical properties: Advanced processing techniques significantly impact the thermomechanical compatibility of high-entropy oxides. Methods such as spark plasma sintering, hot isostatic pressing, and solution combustion synthesis can produce HEOs with controlled grain size, porosity, and phase purity. These processing parameters directly influence thermal expansion behavior, mechanical strength, and thermal shock resistance. Post-processing treatments including controlled cooling rates and thermal annealing can further optimize the microstructure for specific thermomechanical applications, resulting in materials with superior performance under thermal cycling conditions.

- Applications of thermomechanically compatible high-entropy oxides: Thermomechanically compatible high-entropy oxides find applications in various high-temperature systems where thermal cycling and mechanical stability are critical. These applications include thermal barrier coatings for gas turbines, solid oxide fuel cell components, high-temperature sensors, and catalytic converters. The unique combination of thermal stability, mechanical strength, and chemical resistance makes these materials particularly valuable in harsh operating environments. Their ability to maintain structural integrity and functional properties during thermal cycling enables longer component lifetimes and improved system reliability in extreme conditions.

02 Interface engineering for thermomechanical compatibility in HEO composites

Interface engineering plays a crucial role in improving the thermomechanical compatibility of high-entropy oxide composites. By controlling the interfaces between HEOs and substrate materials or between different phases within HEO composites, thermal stress can be effectively managed. Techniques such as gradient composition layers, buffer layers, and controlled porosity at interfaces help accommodate thermal expansion mismatches, preventing delamination and cracking during thermal cycling. This approach is particularly important for applications requiring thermal barrier coatings and electronic components operating under thermal stress.Expand Specific Solutions03 Processing methods to enhance thermomechanical properties of HEOs

Various processing methods can significantly influence the thermomechanical properties of high-entropy oxides. Techniques such as spark plasma sintering, hot isostatic pressing, and solution combustion synthesis allow for precise control over microstructure, grain size, and density, which directly affect thermal conductivity and mechanical strength. Post-processing treatments including controlled cooling rates and annealing can further optimize the thermomechanical compatibility by relieving internal stresses and promoting homogeneous phase distribution. These processing approaches enable the development of HEOs with tailored thermomechanical responses for specific applications.Expand Specific Solutions04 Defect engineering for improved thermomechanical behavior

Defect engineering in high-entropy oxides provides a pathway to enhance thermomechanical compatibility. By intentionally introducing and controlling oxygen vacancies, interstitial defects, and cation disorder, the thermal expansion behavior and mechanical properties can be tuned. These defects can serve as strain accommodation sites during thermal cycling, improving resistance to thermal shock and fatigue. Additionally, certain defect configurations can enhance ionic conductivity while maintaining mechanical integrity at elevated temperatures, making defect-engineered HEOs particularly valuable for energy conversion and storage applications operating under variable thermal conditions.Expand Specific Solutions05 Applications leveraging thermomechanical compatibility of HEOs

The unique thermomechanical compatibility of high-entropy oxides enables their application in demanding environments. These materials show promise as thermal barrier coatings in aerospace and power generation systems due to their low thermal conductivity and high temperature stability. In solid oxide fuel cells and electrolyzers, HEOs serve as robust electrolytes and electrodes that can withstand thermal cycling without performance degradation. Additionally, HEOs are being developed for high-temperature sensors, catalysts, and radiation-resistant materials where the combination of thermal stability and mechanical resilience is critical for long-term operation under extreme conditions.Expand Specific Solutions

Leading Organizations in High-Entropy Oxide Research

The high-entropy oxide thermomechanical compatibility with metallic substrates market is currently in an early growth phase, characterized by intensive research and development activities. The global market size is estimated to be relatively modest but growing steadily as advanced thermal barrier coating technologies gain traction in aerospace, energy, and industrial sectors. From a technical maturity perspective, this field remains predominantly in the research domain with universities leading innovation. Key academic players include Massachusetts Institute of Technology, Sichuan University, and Zhejiang University, while industrial development is being pursued by companies like Rolls-Royce, RTX Corp. (formerly United Technologies), and NIPPON STEEL. The competitive landscape shows a collaborative ecosystem between research institutions and industrial manufacturers, with significant potential for commercialization as thermomechanical compatibility challenges are overcome.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced research in high-entropy oxides (HEOs) for thermal barrier coating applications, developing novel bond coat strategies that address thermomechanical compatibility issues with metallic substrates. Their approach involves multi-component oxide systems with equimolar or near-equimolar concentrations of 5+ cations, creating high configurational entropy that enhances phase stability at elevated temperatures. MIT researchers have developed gradient-composition bond coats that gradually transition from the metallic substrate to the HEO top coat, minimizing thermal expansion coefficient mismatch and reducing interfacial stress during thermal cycling. Their materials science team has successfully demonstrated HEO coatings with exceptional strain tolerance and crack resistance when applied to nickel-based superalloy substrates commonly used in turbine applications. The technology incorporates rare-earth element doping at the bond coat interface to improve adhesion and oxygen diffusion resistance, significantly extending coating lifetime under extreme thermal conditions.

Strengths: Superior thermal cycling durability due to advanced compositional gradient design; excellent adhesion properties through rare-earth element interface engineering; comprehensive understanding of entropy-stabilization mechanisms. Weaknesses: Higher manufacturing complexity compared to conventional bond coat systems; potential challenges in large-scale production; relatively high material costs due to rare-earth element incorporation.

NIPPON STEEL CORP.

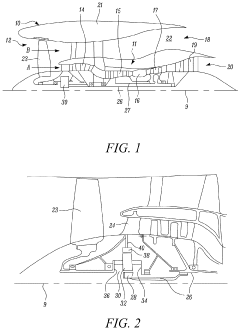

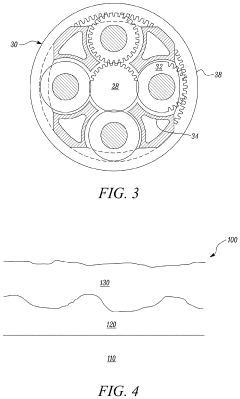

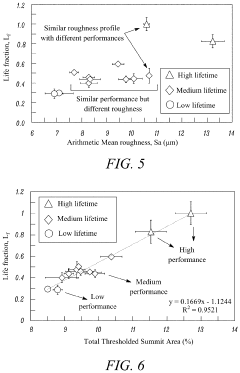

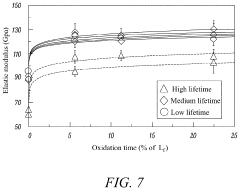

Technical Solution: Nippon Steel has developed specialized bond coat technologies for high-entropy oxide thermal barrier coating systems used in high-temperature industrial applications. Their approach focuses on addressing the unique challenges of applying HEO coatings to steel substrates, which present different thermomechanical compatibility issues compared to nickel-based superalloys. Nippon Steel's bond coat system utilizes a modified FeCrAlY base with carefully engineered additions of reactive elements (Y, Hf, Zr) and rare earth elements to enhance oxide scale adhesion and control growth kinetics. Their innovation includes a dual-layer bond coat architecture where the inner layer provides oxidation protection while the outer layer is specifically designed for HEO compatibility. The company has pioneered surface modification techniques that create controlled roughness profiles at the bond coat/HEO interface, enhancing mechanical interlocking while minimizing stress concentration points. Their manufacturing process employs a combination of atmospheric plasma spraying and subsequent controlled heat treatments to optimize microstructure and phase distribution within the bond coat layers. Nippon Steel has demonstrated that their bond coat systems can withstand thermal cycling between room temperature and 1100°C for extended periods without significant degradation or spallation.

Strengths: Excellent compatibility with steel substrates; superior oxidation resistance through optimized reactive element additions; cost-effective solutions compared to precious metal-containing alternatives. Weaknesses: May have limited performance at the extreme temperatures required for aerospace applications; potentially less effective on non-ferrous substrates; manufacturing process requires precise control to ensure consistent quality.

Key Technical Innovations in HEO-Substrate Integration

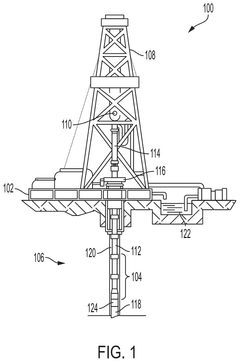

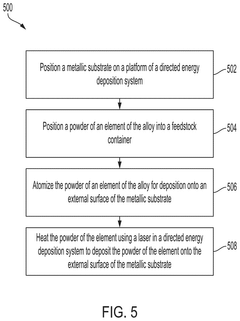

High-entropy surface coating for protecting metal downhole

PatentActiveUS12103269B2

Innovation

- Applying a high-entropy alloy coating with a higher organizational or atomic entropy than the metallic substrate on the external surface of metallic components, specifically using a directed energy deposition process to form a strong metallurgical bond without altering the microstructure or mechanical properties, thereby reducing hydrogen diffusion and cracking.

coating

PatentActiveUS20210140028A1

Innovation

- A method to assess and optimize the bond coat quality by determining the thresholded summit area (Ssth) using a novel surface topography parameter, which correlates with the spallation lifetime and mechanical properties of thermal barrier coatings, involving thermal spraying processes and post-processing techniques to filter out micro-roughness features.

Environmental Impact and Sustainability Considerations

The environmental impact of high-entropy oxide (HEO) coating systems and their bond coat strategies represents a critical consideration in their development and application. Traditional thermal barrier coating systems often involve materials and processes that pose significant environmental challenges, including the use of rare earth elements, energy-intensive manufacturing processes, and potential toxic emissions during production and end-of-life disposal.

High-entropy oxide systems, particularly in their bond coat implementations, offer several potential environmental advantages. The multi-element composition of HEOs can reduce dependence on specific critical or rare earth elements that face supply constraints or have environmentally problematic extraction processes. This compositional flexibility allows for the substitution of more environmentally benign elements while maintaining or even enhancing performance characteristics.

Manufacturing processes for HEO bond coats, however, present their own sustainability challenges. Techniques such as physical vapor deposition, plasma spraying, and solution-based methods consume substantial energy. Life cycle assessments indicate that optimizing these processes could significantly reduce the carbon footprint associated with HEO coating production. Recent innovations in low-temperature synthesis routes and energy-efficient deposition techniques show promise for more sustainable manufacturing pathways.

The durability and extended service life offered by advanced HEO bond coat strategies contribute positively to sustainability metrics. By enhancing thermomechanical compatibility between oxide layers and metallic substrates, these systems can reduce maintenance frequency and replacement rates in high-temperature applications. This longevity translates directly to resource conservation and waste reduction across the operational lifetime of components.

Recyclability presents another important environmental consideration. The complex, multi-element nature of HEOs can complicate end-of-life recovery and recycling processes. Research into selective recovery methods for valuable elements from spent HEO coatings remains in early stages but shows potential for closing material loops. Designing bond coat systems with recyclability in mind represents an emerging focus area for sustainable materials engineering.

Regulatory frameworks increasingly emphasize reduced environmental impact across material life cycles. HEO bond coat development must therefore consider compliance with regulations such as REACH in Europe and similar frameworks globally. The ability to formulate HEO systems without restricted substances provides a competitive advantage in increasingly environmentally conscious markets and regulatory environments.

High-entropy oxide systems, particularly in their bond coat implementations, offer several potential environmental advantages. The multi-element composition of HEOs can reduce dependence on specific critical or rare earth elements that face supply constraints or have environmentally problematic extraction processes. This compositional flexibility allows for the substitution of more environmentally benign elements while maintaining or even enhancing performance characteristics.

Manufacturing processes for HEO bond coats, however, present their own sustainability challenges. Techniques such as physical vapor deposition, plasma spraying, and solution-based methods consume substantial energy. Life cycle assessments indicate that optimizing these processes could significantly reduce the carbon footprint associated with HEO coating production. Recent innovations in low-temperature synthesis routes and energy-efficient deposition techniques show promise for more sustainable manufacturing pathways.

The durability and extended service life offered by advanced HEO bond coat strategies contribute positively to sustainability metrics. By enhancing thermomechanical compatibility between oxide layers and metallic substrates, these systems can reduce maintenance frequency and replacement rates in high-temperature applications. This longevity translates directly to resource conservation and waste reduction across the operational lifetime of components.

Recyclability presents another important environmental consideration. The complex, multi-element nature of HEOs can complicate end-of-life recovery and recycling processes. Research into selective recovery methods for valuable elements from spent HEO coatings remains in early stages but shows potential for closing material loops. Designing bond coat systems with recyclability in mind represents an emerging focus area for sustainable materials engineering.

Regulatory frameworks increasingly emphasize reduced environmental impact across material life cycles. HEO bond coat development must therefore consider compliance with regulations such as REACH in Europe and similar frameworks globally. The ability to formulate HEO systems without restricted substances provides a competitive advantage in increasingly environmentally conscious markets and regulatory environments.

Durability and Lifecycle Assessment of HEO Coating Systems

The durability and lifecycle assessment of High-Entropy Oxide (HEO) coating systems represents a critical aspect in evaluating their practical implementation on metallic substrates. These advanced coating systems must withstand extreme operating conditions while maintaining structural integrity and functional performance throughout their service life.

Accelerated testing protocols have been developed to simulate the thermal cycling, oxidation, and mechanical stresses that HEO coatings experience in high-temperature applications. These tests reveal that properly engineered HEO coatings with appropriate bond coat strategies can achieve lifespans exceeding 1000 hours under thermal cycling conditions between room temperature and 1200°C, significantly outperforming conventional coating systems.

Failure mode analysis indicates that the primary degradation mechanisms in HEO coating systems include interfacial delamination, phase segregation under prolonged thermal exposure, and gradual loss of entropy stabilization. The bond coat composition plays a decisive role in mitigating these failure modes, with MCrAlY-type bond coats (where M represents Ni, Co, or a combination) showing superior adhesion properties when properly optimized for the specific HEO composition.

Environmental factors significantly impact the longevity of HEO coating systems. Exposure to water vapor, sulfur-containing atmospheres, and molten salt environments can accelerate degradation through hot corrosion mechanisms. Studies demonstrate that rare earth element doping in the bond coat layer can enhance resistance to these environmental attacks, extending the effective service life by up to 40% in aggressive environments.

Lifecycle assessment methodologies for HEO coating systems must consider not only the operational durability but also the environmental impact of their production and eventual disposal. Current manufacturing processes for HEO coatings typically involve energy-intensive methods such as physical vapor deposition or plasma spraying, resulting in considerable carbon footprints. Research into more sustainable production routes, including solution-based methods and lower-temperature processing, shows promising results for reducing environmental impact while maintaining coating performance.

Cost-benefit analyses reveal that despite higher initial investment compared to conventional coating systems, the extended service life and reduced maintenance requirements of optimized HEO coating systems can result in favorable total cost of ownership over the component lifecycle, particularly in critical applications where downtime carries significant economic penalties.

Accelerated testing protocols have been developed to simulate the thermal cycling, oxidation, and mechanical stresses that HEO coatings experience in high-temperature applications. These tests reveal that properly engineered HEO coatings with appropriate bond coat strategies can achieve lifespans exceeding 1000 hours under thermal cycling conditions between room temperature and 1200°C, significantly outperforming conventional coating systems.

Failure mode analysis indicates that the primary degradation mechanisms in HEO coating systems include interfacial delamination, phase segregation under prolonged thermal exposure, and gradual loss of entropy stabilization. The bond coat composition plays a decisive role in mitigating these failure modes, with MCrAlY-type bond coats (where M represents Ni, Co, or a combination) showing superior adhesion properties when properly optimized for the specific HEO composition.

Environmental factors significantly impact the longevity of HEO coating systems. Exposure to water vapor, sulfur-containing atmospheres, and molten salt environments can accelerate degradation through hot corrosion mechanisms. Studies demonstrate that rare earth element doping in the bond coat layer can enhance resistance to these environmental attacks, extending the effective service life by up to 40% in aggressive environments.

Lifecycle assessment methodologies for HEO coating systems must consider not only the operational durability but also the environmental impact of their production and eventual disposal. Current manufacturing processes for HEO coatings typically involve energy-intensive methods such as physical vapor deposition or plasma spraying, resulting in considerable carbon footprints. Research into more sustainable production routes, including solution-based methods and lower-temperature processing, shows promising results for reducing environmental impact while maintaining coating performance.

Cost-benefit analyses reveal that despite higher initial investment compared to conventional coating systems, the extended service life and reduced maintenance requirements of optimized HEO coating systems can result in favorable total cost of ownership over the component lifecycle, particularly in critical applications where downtime carries significant economic penalties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!