How acoustic engineering is influenced by mild hybrid systems

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Challenges in Mild Hybrid Systems

The integration of mild hybrid systems in vehicles has introduced new acoustic challenges that require innovative engineering solutions. These systems, which combine traditional internal combustion engines with small electric motors, have significantly altered the acoustic landscape of modern automobiles. The primary challenge lies in managing the noise and vibration characteristics associated with the frequent transitions between electric and combustion power sources.

One of the most prominent acoustic issues in mild hybrid systems is the sudden change in noise levels during engine start-stop events. As the vehicle switches between electric and combustion power, passengers may experience abrupt changes in cabin noise, potentially leading to discomfort and a perceived reduction in vehicle quality. This necessitates the development of advanced noise cancellation and sound design techniques to ensure a seamless auditory experience.

Vibration management presents another significant challenge in mild hybrid systems. The addition of electric motors and associated components can introduce new vibration sources and alter the vehicle's overall NVH (Noise, Vibration, and Harshness) profile. Engineers must develop sophisticated isolation systems and optimize the placement of hybrid components to minimize unwanted vibrations and maintain ride comfort.

The reduced masking effect of engine noise in electric mode exposes previously unnoticed sounds, such as road noise, wind noise, and auxiliary system operations. This phenomenon, known as "sound unmasking," requires a holistic approach to vehicle acoustics, including enhanced sound insulation and the strategic use of active noise control systems.

Furthermore, the unique characteristics of electric motors in mild hybrid systems present their own set of acoustic challenges. High-frequency whine and electromagnetic noise from these motors can be particularly noticeable and potentially irritating to occupants, especially during low-speed operation or in quiet environments. Addressing these issues demands innovative motor design and encapsulation techniques.

Regulatory compliance adds another layer of complexity to acoustic engineering in mild hybrid vehicles. With increasingly stringent noise emission standards, engineers must balance the need for pedestrian safety (through artificial sound generation for electric operation) with the desire for a quiet and comfortable in-cabin experience. This often requires the implementation of sophisticated exterior sound design strategies that are both effective and aesthetically pleasing.

In response to these challenges, acoustic engineers are developing new methodologies and tools for sound quality assessment and optimization. Advanced simulation techniques, such as psychoacoustic modeling and virtual reality auralizations, are becoming essential in the design process, allowing engineers to predict and refine the acoustic performance of mild hybrid systems before physical prototypes are built.

One of the most prominent acoustic issues in mild hybrid systems is the sudden change in noise levels during engine start-stop events. As the vehicle switches between electric and combustion power, passengers may experience abrupt changes in cabin noise, potentially leading to discomfort and a perceived reduction in vehicle quality. This necessitates the development of advanced noise cancellation and sound design techniques to ensure a seamless auditory experience.

Vibration management presents another significant challenge in mild hybrid systems. The addition of electric motors and associated components can introduce new vibration sources and alter the vehicle's overall NVH (Noise, Vibration, and Harshness) profile. Engineers must develop sophisticated isolation systems and optimize the placement of hybrid components to minimize unwanted vibrations and maintain ride comfort.

The reduced masking effect of engine noise in electric mode exposes previously unnoticed sounds, such as road noise, wind noise, and auxiliary system operations. This phenomenon, known as "sound unmasking," requires a holistic approach to vehicle acoustics, including enhanced sound insulation and the strategic use of active noise control systems.

Furthermore, the unique characteristics of electric motors in mild hybrid systems present their own set of acoustic challenges. High-frequency whine and electromagnetic noise from these motors can be particularly noticeable and potentially irritating to occupants, especially during low-speed operation or in quiet environments. Addressing these issues demands innovative motor design and encapsulation techniques.

Regulatory compliance adds another layer of complexity to acoustic engineering in mild hybrid vehicles. With increasingly stringent noise emission standards, engineers must balance the need for pedestrian safety (through artificial sound generation for electric operation) with the desire for a quiet and comfortable in-cabin experience. This often requires the implementation of sophisticated exterior sound design strategies that are both effective and aesthetically pleasing.

In response to these challenges, acoustic engineers are developing new methodologies and tools for sound quality assessment and optimization. Advanced simulation techniques, such as psychoacoustic modeling and virtual reality auralizations, are becoming essential in the design process, allowing engineers to predict and refine the acoustic performance of mild hybrid systems before physical prototypes are built.

Market Trends in Hybrid Vehicle Acoustics

The market for hybrid vehicle acoustics has been experiencing significant growth and transformation in recent years, driven by the increasing adoption of mild hybrid systems in the automotive industry. As consumers become more environmentally conscious and governments implement stricter emissions regulations, the demand for hybrid vehicles has surged, consequently impacting the acoustic engineering sector.

One of the primary market trends in hybrid vehicle acoustics is the focus on noise reduction and sound quality enhancement. Mild hybrid systems introduce new sound sources and vibrations that were not present in traditional internal combustion engine vehicles. This has created a need for innovative acoustic solutions to mitigate unwanted noise and vibrations while maintaining a pleasant driving experience. As a result, there has been a growing demand for advanced sound insulation materials, active noise control systems, and sophisticated sound design techniques.

Another notable trend is the development of artificial sound generation systems for hybrid vehicles. Due to the quieter operation of electric motors in mild hybrid systems, there is an increased risk of pedestrian accidents, especially at low speeds. To address this safety concern, many automotive manufacturers are investing in the development and implementation of acoustic vehicle alerting systems (AVAS). These systems generate artificial sounds to alert pedestrians and other road users of the vehicle's presence, creating new opportunities for acoustic engineering firms specializing in sound design and synthesis.

The market for hybrid vehicle acoustics has also seen a shift towards lightweight acoustic materials. As automakers strive to improve fuel efficiency and reduce overall vehicle weight, there is a growing demand for acoustic solutions that offer excellent sound insulation properties without adding significant mass to the vehicle. This trend has led to increased research and development in advanced composite materials and innovative acoustic foam technologies.

Furthermore, the integration of acoustic engineering with other vehicle systems has become a prominent market trend. Mild hybrid systems often require sophisticated control algorithms to manage the interaction between the internal combustion engine and electric motor. This has created opportunities for acoustic engineers to collaborate with powertrain and control system specialists to optimize the overall vehicle performance and sound characteristics.

Lastly, the market for hybrid vehicle acoustics has witnessed a rise in the adoption of virtual acoustic prototyping and simulation tools. As automotive development cycles become shorter and more cost-sensitive, manufacturers are increasingly relying on advanced simulation software to predict and optimize vehicle acoustics before physical prototypes are built. This trend has led to the growth of specialized acoustic simulation software providers and increased demand for engineers skilled in virtual acoustic analysis and optimization.

One of the primary market trends in hybrid vehicle acoustics is the focus on noise reduction and sound quality enhancement. Mild hybrid systems introduce new sound sources and vibrations that were not present in traditional internal combustion engine vehicles. This has created a need for innovative acoustic solutions to mitigate unwanted noise and vibrations while maintaining a pleasant driving experience. As a result, there has been a growing demand for advanced sound insulation materials, active noise control systems, and sophisticated sound design techniques.

Another notable trend is the development of artificial sound generation systems for hybrid vehicles. Due to the quieter operation of electric motors in mild hybrid systems, there is an increased risk of pedestrian accidents, especially at low speeds. To address this safety concern, many automotive manufacturers are investing in the development and implementation of acoustic vehicle alerting systems (AVAS). These systems generate artificial sounds to alert pedestrians and other road users of the vehicle's presence, creating new opportunities for acoustic engineering firms specializing in sound design and synthesis.

The market for hybrid vehicle acoustics has also seen a shift towards lightweight acoustic materials. As automakers strive to improve fuel efficiency and reduce overall vehicle weight, there is a growing demand for acoustic solutions that offer excellent sound insulation properties without adding significant mass to the vehicle. This trend has led to increased research and development in advanced composite materials and innovative acoustic foam technologies.

Furthermore, the integration of acoustic engineering with other vehicle systems has become a prominent market trend. Mild hybrid systems often require sophisticated control algorithms to manage the interaction between the internal combustion engine and electric motor. This has created opportunities for acoustic engineers to collaborate with powertrain and control system specialists to optimize the overall vehicle performance and sound characteristics.

Lastly, the market for hybrid vehicle acoustics has witnessed a rise in the adoption of virtual acoustic prototyping and simulation tools. As automotive development cycles become shorter and more cost-sensitive, manufacturers are increasingly relying on advanced simulation software to predict and optimize vehicle acoustics before physical prototypes are built. This trend has led to the growth of specialized acoustic simulation software providers and increased demand for engineers skilled in virtual acoustic analysis and optimization.

Current Acoustic Engineering State in Mild Hybrids

Acoustic engineering in mild hybrid systems has evolved significantly in recent years, addressing unique challenges posed by the integration of electric motors with traditional internal combustion engines. The current state of acoustic engineering in mild hybrids focuses on managing the complex interplay between multiple noise sources and vibration patterns.

One of the primary concerns is the noise generated by the electric motor during start-stop operations and energy recuperation. Engineers have developed advanced active noise control systems that use strategically placed microphones and speakers to cancel out unwanted frequencies. These systems are particularly effective in mitigating the high-frequency whine often associated with electric motors.

Vibration damping has also seen considerable advancements. Mild hybrid powertrains introduce new vibration patterns due to the interaction between the electric motor and the combustion engine. To address this, engineers have implemented adaptive engine mounts that adjust their stiffness based on operating conditions, effectively isolating the powertrain from the vehicle body.

The integration of regenerative braking systems in mild hybrids has led to the development of new acoustic solutions for brake noise reduction. Traditional friction brakes are used less frequently, leading to potential issues with brake squeal when they are engaged. Acoustic engineers have responded by redesigning brake pad materials and implementing electronic brake noise suppression systems.

Another area of focus is the refinement of the transition between electric and combustion power. Acoustic engineers have developed sophisticated control algorithms that manage the engagement and disengagement of the electric motor to ensure a smooth and quiet transition. This often involves precise timing of engine start-up and shutdown in conjunction with electric motor operation.

The reduction of low-speed driving noise has become increasingly important, as mild hybrids often operate in electric-only mode at low speeds. This has led to the development of pedestrian alert systems that generate artificial sounds to warn pedestrians of the vehicle's approach, while maintaining a pleasant acoustic environment for occupants.

Cabin noise reduction techniques have also evolved to address the unique acoustic signature of mild hybrid vehicles. Sound insulation materials and designs have been optimized to attenuate both traditional engine noise and the new sounds introduced by the hybrid system. Additionally, active sound design technologies are being employed to enhance the perceived quality of the powertrain sound, creating a more engaging driving experience.

One of the primary concerns is the noise generated by the electric motor during start-stop operations and energy recuperation. Engineers have developed advanced active noise control systems that use strategically placed microphones and speakers to cancel out unwanted frequencies. These systems are particularly effective in mitigating the high-frequency whine often associated with electric motors.

Vibration damping has also seen considerable advancements. Mild hybrid powertrains introduce new vibration patterns due to the interaction between the electric motor and the combustion engine. To address this, engineers have implemented adaptive engine mounts that adjust their stiffness based on operating conditions, effectively isolating the powertrain from the vehicle body.

The integration of regenerative braking systems in mild hybrids has led to the development of new acoustic solutions for brake noise reduction. Traditional friction brakes are used less frequently, leading to potential issues with brake squeal when they are engaged. Acoustic engineers have responded by redesigning brake pad materials and implementing electronic brake noise suppression systems.

Another area of focus is the refinement of the transition between electric and combustion power. Acoustic engineers have developed sophisticated control algorithms that manage the engagement and disengagement of the electric motor to ensure a smooth and quiet transition. This often involves precise timing of engine start-up and shutdown in conjunction with electric motor operation.

The reduction of low-speed driving noise has become increasingly important, as mild hybrids often operate in electric-only mode at low speeds. This has led to the development of pedestrian alert systems that generate artificial sounds to warn pedestrians of the vehicle's approach, while maintaining a pleasant acoustic environment for occupants.

Cabin noise reduction techniques have also evolved to address the unique acoustic signature of mild hybrid vehicles. Sound insulation materials and designs have been optimized to attenuate both traditional engine noise and the new sounds introduced by the hybrid system. Additionally, active sound design technologies are being employed to enhance the perceived quality of the powertrain sound, creating a more engaging driving experience.

Existing Noise Mitigation Strategies for Mild Hybrids

01 Acoustic measurement and analysis techniques

Advanced techniques for measuring and analyzing acoustic properties, including methods for sound wave propagation, frequency analysis, and noise level assessment. These techniques are crucial for understanding and optimizing acoustic environments in various applications.- Acoustic measurement and analysis techniques: Advanced techniques for measuring and analyzing acoustic properties, including methods for sound wave propagation, frequency analysis, and noise level assessment. These techniques are crucial for understanding and improving acoustic environments in various applications.

- Acoustic materials and structures: Development of innovative materials and structures designed to enhance acoustic performance, such as sound-absorbing panels, acoustic metamaterials, and noise-reducing barriers. These advancements contribute to improved sound insulation and acoustic comfort in various settings.

- Acoustic modeling and simulation: Utilization of advanced computational methods and software tools for modeling and simulating acoustic phenomena. These techniques allow for the prediction and optimization of acoustic performance in complex environments, aiding in the design of acoustic systems and spaces.

- Acoustic transducers and sensors: Design and development of acoustic transducers and sensors for various applications, including microphones, speakers, and ultrasonic devices. These components are essential for capturing, reproducing, and analyzing sound in acoustic engineering applications.

- Noise control and soundproofing techniques: Implementation of strategies and technologies for reducing unwanted noise and improving sound isolation in various environments. This includes active noise control systems, passive noise reduction methods, and innovative soundproofing solutions for buildings, vehicles, and industrial settings.

02 Acoustic materials and structures

Development of innovative materials and structures for acoustic applications, such as sound-absorbing panels, acoustic metamaterials, and vibration damping systems. These advancements aim to improve sound insulation, reduce noise, and enhance acoustic performance in various settings.Expand Specific Solutions03 Acoustic modeling and simulation

Utilization of computational methods and software tools for modeling and simulating acoustic phenomena. This includes finite element analysis, boundary element methods, and ray tracing techniques to predict and optimize acoustic behavior in complex environments.Expand Specific Solutions04 Acoustic transducers and sensors

Design and development of advanced acoustic transducers and sensors for various applications, including microphones, loudspeakers, and ultrasonic devices. These innovations focus on improving sensitivity, frequency response, and overall performance in acoustic signal generation and detection.Expand Specific Solutions05 Acoustic testing and quality control

Methods and systems for acoustic testing and quality control in manufacturing and product development. This includes techniques for assessing sound quality, identifying defects through acoustic analysis, and ensuring compliance with acoustic standards and regulations.Expand Specific Solutions

Key Players in Automotive Acoustic Engineering

The acoustic engineering landscape in mild hybrid systems is evolving rapidly, reflecting the industry's transition towards more sustainable automotive technologies. The market is experiencing significant growth, driven by increasing demand for fuel-efficient vehicles and stricter emissions regulations. While the technology is maturing, it's still in a relatively early stage of development. Key players like Robert Bosch GmbH, Safran SA, and Siemens Energy Global GmbH & Co. KG are leading innovation in this field, leveraging their expertise in automotive and energy systems. Other companies such as Tenneco GmbH and Valeo Thermal Systems Japan Corp. are also contributing to advancements in noise reduction and thermal management for mild hybrid systems, indicating a competitive and diverse market landscape.

Freudenberg-Nok Sealing Technologies

Technical Solution: Freudenberg-Nok Sealing Technologies has developed specialized sealing and vibration control solutions for mild hybrid systems, focusing on the interface between electric and combustion components. Their approach combines advanced elastomer compounds with innovative design techniques to manage noise and vibration transmission. The company has created a range of hybrid-specific gaskets and seals that effectively dampen vibrations across a wide frequency spectrum [10]. Additionally, Freudenberg-Nok has developed micro-cellular polyurethane components that provide both acoustic insulation and structural support for hybrid powertrain mounts, significantly reducing structure-borne noise [11].

Strengths: Specialized expertise in sealing and vibration control for hybrid interfaces; Innovative material solutions for acoustic insulation. Weaknesses: Focus primarily on component-level solutions may require integration with broader acoustic management systems; Potential challenges in scaling solutions across diverse vehicle platforms.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced acoustic engineering solutions for mild hybrid systems, focusing on noise reduction and vibration control. Their approach integrates active noise cancellation technology with passive damping materials to minimize the impact of hybrid powertrains on vehicle acoustics. The company has implemented a multi-layer insulation system that effectively absorbs and dissipates sound energy generated by the electric motor and internal combustion engine [1]. Additionally, Bosch has developed smart algorithms that predict and counteract noise patterns in real-time, ensuring a smooth and quiet driving experience across various operating modes of the mild hybrid system [3].

Strengths: Comprehensive noise reduction approach combining active and passive technologies; Advanced predictive algorithms for real-time noise control. Weaknesses: Potential increased complexity and cost of implementation; May require frequent updates to maintain effectiveness across different vehicle models.

Innovative Acoustic Materials and Technologies

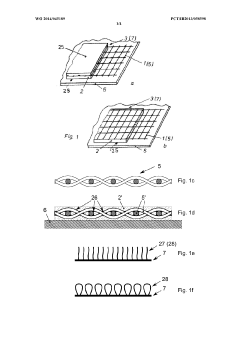

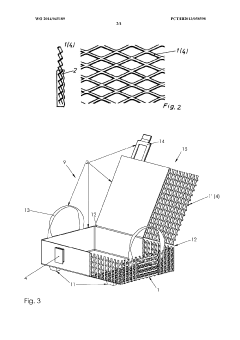

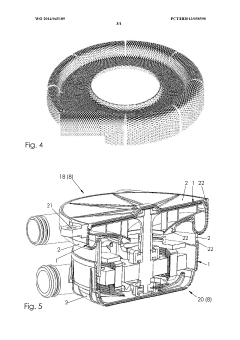

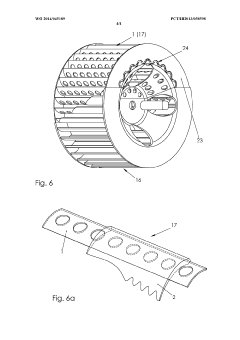

Hybrid noise-insulating structures and applications thereof

PatentWO2014045189A2

Innovation

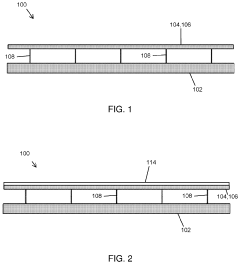

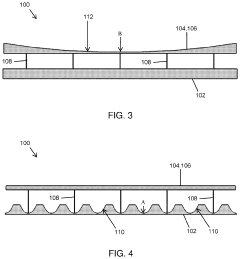

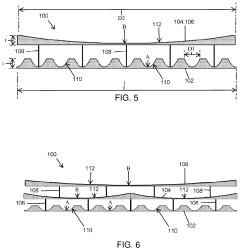

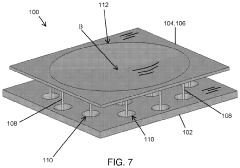

- The use of hybrid structures comprising a stiff support grid made of materials like metal, embedded in a viscoelastic sound-absorbing filling compound, which acts as a skeleton for housings and noise-suppressing adhesive tapes, forming a thin, efficient noise-blocking layer.

Vibration attenuation via tailored metastructures

PatentPendingUS20240003403A1

Innovation

- A nonlocal acoustic black hole metastructure system is introduced, comprising a load bearing layer, a non-load bearing layer, and a rigid beam connector, which provides a nonlocal connection to transfer energy and utilize viscoelastic damping for broadband low-frequency vibration attenuation.

Environmental Regulations Impact on NVH

Environmental regulations have significantly impacted the development of Noise, Vibration, and Harshness (NVH) technologies in mild hybrid systems. As governments worldwide implement stricter emissions standards and noise pollution regulations, automotive manufacturers are compelled to adapt their designs to meet these requirements. This has led to a shift in focus towards more efficient and quieter powertrains, with mild hybrid systems playing a crucial role in this transition.

The introduction of mild hybrid systems has presented both challenges and opportunities for NVH engineers. On one hand, the integration of electric motors and batteries into traditional internal combustion engine (ICE) vehicles has introduced new sources of noise and vibration. The electric motor's high-frequency whine and the additional weight of the battery pack can alter the vehicle's acoustic profile. Engineers must now consider the complex interactions between the ICE, electric motor, and transmission system to optimize NVH performance.

Conversely, mild hybrid systems offer unique advantages in NVH management. The electric motor's ability to provide instant torque allows for smoother acceleration and deceleration, reducing engine vibrations during these transitional phases. Additionally, the start-stop functionality of mild hybrid systems enables the ICE to be shut off during idle periods, significantly reducing noise and vibration at low speeds or in stationary traffic.

Environmental regulations have also pushed manufacturers to focus on lightweight materials and aerodynamic designs to improve fuel efficiency. While these changes benefit emissions reduction, they can negatively impact NVH characteristics by reducing the vehicle's sound insulation and altering its aeroacoustic properties. As a result, NVH engineers must develop innovative solutions to maintain or improve acoustic comfort while adhering to these new design constraints.

The pursuit of lower emissions has led to the development of advanced exhaust systems, including particulate filters and catalytic converters. These components can affect the exhaust note and overall sound character of the vehicle. NVH engineers must work closely with powertrain developers to ensure that the exhaust system design not only meets emissions standards but also contributes to a desirable acoustic signature.

As urban areas implement stricter noise regulations, particularly for low-speed driving, mild hybrid systems offer a potential solution. The ability to operate in electric-only mode at low speeds can significantly reduce noise pollution in city centers. This has prompted NVH engineers to focus on optimizing the transition between electric and ICE operation, ensuring a seamless and quiet driving experience across all speed ranges.

In conclusion, environmental regulations have fundamentally altered the landscape of NVH engineering in mild hybrid systems. The challenge lies in balancing the need for reduced emissions and noise pollution with the desire for a engaging and comfortable driving experience. As regulations continue to evolve, NVH engineers must remain at the forefront of innovation, developing new technologies and methodologies to meet these ever-increasing demands.

The introduction of mild hybrid systems has presented both challenges and opportunities for NVH engineers. On one hand, the integration of electric motors and batteries into traditional internal combustion engine (ICE) vehicles has introduced new sources of noise and vibration. The electric motor's high-frequency whine and the additional weight of the battery pack can alter the vehicle's acoustic profile. Engineers must now consider the complex interactions between the ICE, electric motor, and transmission system to optimize NVH performance.

Conversely, mild hybrid systems offer unique advantages in NVH management. The electric motor's ability to provide instant torque allows for smoother acceleration and deceleration, reducing engine vibrations during these transitional phases. Additionally, the start-stop functionality of mild hybrid systems enables the ICE to be shut off during idle periods, significantly reducing noise and vibration at low speeds or in stationary traffic.

Environmental regulations have also pushed manufacturers to focus on lightweight materials and aerodynamic designs to improve fuel efficiency. While these changes benefit emissions reduction, they can negatively impact NVH characteristics by reducing the vehicle's sound insulation and altering its aeroacoustic properties. As a result, NVH engineers must develop innovative solutions to maintain or improve acoustic comfort while adhering to these new design constraints.

The pursuit of lower emissions has led to the development of advanced exhaust systems, including particulate filters and catalytic converters. These components can affect the exhaust note and overall sound character of the vehicle. NVH engineers must work closely with powertrain developers to ensure that the exhaust system design not only meets emissions standards but also contributes to a desirable acoustic signature.

As urban areas implement stricter noise regulations, particularly for low-speed driving, mild hybrid systems offer a potential solution. The ability to operate in electric-only mode at low speeds can significantly reduce noise pollution in city centers. This has prompted NVH engineers to focus on optimizing the transition between electric and ICE operation, ensuring a seamless and quiet driving experience across all speed ranges.

In conclusion, environmental regulations have fundamentally altered the landscape of NVH engineering in mild hybrid systems. The challenge lies in balancing the need for reduced emissions and noise pollution with the desire for a engaging and comfortable driving experience. As regulations continue to evolve, NVH engineers must remain at the forefront of innovation, developing new technologies and methodologies to meet these ever-increasing demands.

Consumer Perception of Hybrid Vehicle Sound

Consumer perception of hybrid vehicle sound plays a crucial role in the acceptance and market success of these environmentally friendly vehicles. As mild hybrid systems become more prevalent, their impact on acoustic engineering has become a significant area of focus for automotive manufacturers and researchers.

Traditionally, consumers have associated the sound of a vehicle with its power, performance, and overall quality. The introduction of hybrid technology, particularly mild hybrid systems, has challenged these long-held perceptions. The quieter operation of hybrid vehicles, especially at low speeds or when running on electric power alone, has led to a range of consumer reactions.

Many consumers appreciate the reduced noise levels of hybrid vehicles, associating them with a more refined and luxurious driving experience. The quieter operation is often perceived as a sign of advanced technology and environmental consciousness. This positive perception has been a driving factor in the adoption of hybrid vehicles among environmentally aware consumers and those seeking a more serene driving environment.

However, the lack of traditional engine noise has also raised concerns among some consumers. The absence of familiar auditory cues can lead to a perception of reduced power or performance, even when this is not the case. This perception challenge has prompted automotive engineers to develop innovative solutions to address these concerns while maintaining the benefits of hybrid technology.

Safety considerations have also influenced consumer perceptions of hybrid vehicle sound. The quieter operation of these vehicles, particularly at low speeds, has led to concerns about pedestrian safety. This has resulted in the development and implementation of artificial sound generators in many hybrid models, designed to alert pedestrians to the vehicle's presence.

The automotive industry has responded to these varied consumer perceptions by focusing on creating a balanced acoustic profile for hybrid vehicles. This involves carefully engineering the sound of the vehicle to maintain a sense of power and performance while showcasing the unique benefits of hybrid technology. Manufacturers are increasingly using active sound design techniques to create signature engine sounds that blend traditional expectations with the modern, eco-friendly image of hybrid vehicles.

Consumer education has become a key component in shaping perceptions of hybrid vehicle sound. As more drivers experience these vehicles, there is a growing understanding and appreciation of their unique acoustic characteristics. This shift in perception is gradually redefining what consumers expect from a vehicle in terms of sound, with quieter operation increasingly being associated with advanced technology and environmental responsibility.

Traditionally, consumers have associated the sound of a vehicle with its power, performance, and overall quality. The introduction of hybrid technology, particularly mild hybrid systems, has challenged these long-held perceptions. The quieter operation of hybrid vehicles, especially at low speeds or when running on electric power alone, has led to a range of consumer reactions.

Many consumers appreciate the reduced noise levels of hybrid vehicles, associating them with a more refined and luxurious driving experience. The quieter operation is often perceived as a sign of advanced technology and environmental consciousness. This positive perception has been a driving factor in the adoption of hybrid vehicles among environmentally aware consumers and those seeking a more serene driving environment.

However, the lack of traditional engine noise has also raised concerns among some consumers. The absence of familiar auditory cues can lead to a perception of reduced power or performance, even when this is not the case. This perception challenge has prompted automotive engineers to develop innovative solutions to address these concerns while maintaining the benefits of hybrid technology.

Safety considerations have also influenced consumer perceptions of hybrid vehicle sound. The quieter operation of these vehicles, particularly at low speeds, has led to concerns about pedestrian safety. This has resulted in the development and implementation of artificial sound generators in many hybrid models, designed to alert pedestrians to the vehicle's presence.

The automotive industry has responded to these varied consumer perceptions by focusing on creating a balanced acoustic profile for hybrid vehicles. This involves carefully engineering the sound of the vehicle to maintain a sense of power and performance while showcasing the unique benefits of hybrid technology. Manufacturers are increasingly using active sound design techniques to create signature engine sounds that blend traditional expectations with the modern, eco-friendly image of hybrid vehicles.

Consumer education has become a key component in shaping perceptions of hybrid vehicle sound. As more drivers experience these vehicles, there is a growing understanding and appreciation of their unique acoustic characteristics. This shift in perception is gradually redefining what consumers expect from a vehicle in terms of sound, with quieter operation increasingly being associated with advanced technology and environmental responsibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!