How Dimethyl Ether Enhances Regenerative Cooling Systems?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Cooling Background

Dimethyl ether (DME) has emerged as a promising alternative in regenerative cooling systems, offering unique properties that enhance thermal management in various applications. The concept of regenerative cooling dates back to the early 20th century, primarily developed for rocket engines to prevent overheating during combustion. As technology advanced, the need for more efficient cooling methods grew across industries, from aerospace to power generation.

DME, a simple ether compound with the chemical formula CH3OCH3, has gained attention in recent years due to its favorable thermodynamic properties. Its low boiling point of -25.1°C and high vapor pressure make it an excellent candidate for cooling systems that require rapid heat absorption and dissipation. The evolution of DME as a cooling agent is closely tied to the broader trend of seeking environmentally friendly alternatives to traditional refrigerants and coolants.

The integration of DME into regenerative cooling systems represents a significant technological leap. Traditional regenerative cooling systems often rely on cryogenic fluids or complex multi-stage processes. DME offers a simpler, more efficient solution by leveraging its phase change characteristics. As it transitions from liquid to gas, DME absorbs a substantial amount of heat, making it highly effective in cooling applications.

One of the key advantages of DME in cooling systems is its ability to operate at lower pressures compared to many conventional coolants. This characteristic reduces the overall system complexity and enhances safety in high-stress environments. Additionally, DME's chemical stability and low corrosivity contribute to the longevity and reliability of cooling system components.

The environmental impact of cooling agents has become a critical consideration in recent years. DME stands out in this aspect, as it has zero ozone depletion potential and a relatively low global warming potential. This aligns with global efforts to reduce the environmental footprint of industrial and commercial cooling systems, making DME an attractive option for future-oriented cooling solutions.

Research and development in DME-based cooling systems have accelerated in the past decade, driven by both environmental concerns and the quest for higher efficiency. Engineers and scientists are exploring novel ways to optimize DME's performance in regenerative cooling cycles, including advanced heat exchanger designs and innovative system architectures that maximize heat transfer rates.

As industries continue to push the boundaries of performance and efficiency, the role of DME in enhancing regenerative cooling systems is expected to grow. Its unique combination of thermodynamic properties, environmental friendliness, and versatility positions DME as a key player in the future of thermal management technologies across various sectors.

DME, a simple ether compound with the chemical formula CH3OCH3, has gained attention in recent years due to its favorable thermodynamic properties. Its low boiling point of -25.1°C and high vapor pressure make it an excellent candidate for cooling systems that require rapid heat absorption and dissipation. The evolution of DME as a cooling agent is closely tied to the broader trend of seeking environmentally friendly alternatives to traditional refrigerants and coolants.

The integration of DME into regenerative cooling systems represents a significant technological leap. Traditional regenerative cooling systems often rely on cryogenic fluids or complex multi-stage processes. DME offers a simpler, more efficient solution by leveraging its phase change characteristics. As it transitions from liquid to gas, DME absorbs a substantial amount of heat, making it highly effective in cooling applications.

One of the key advantages of DME in cooling systems is its ability to operate at lower pressures compared to many conventional coolants. This characteristic reduces the overall system complexity and enhances safety in high-stress environments. Additionally, DME's chemical stability and low corrosivity contribute to the longevity and reliability of cooling system components.

The environmental impact of cooling agents has become a critical consideration in recent years. DME stands out in this aspect, as it has zero ozone depletion potential and a relatively low global warming potential. This aligns with global efforts to reduce the environmental footprint of industrial and commercial cooling systems, making DME an attractive option for future-oriented cooling solutions.

Research and development in DME-based cooling systems have accelerated in the past decade, driven by both environmental concerns and the quest for higher efficiency. Engineers and scientists are exploring novel ways to optimize DME's performance in regenerative cooling cycles, including advanced heat exchanger designs and innovative system architectures that maximize heat transfer rates.

As industries continue to push the boundaries of performance and efficiency, the role of DME in enhancing regenerative cooling systems is expected to grow. Its unique combination of thermodynamic properties, environmental friendliness, and versatility positions DME as a key player in the future of thermal management technologies across various sectors.

Market Analysis

The market for regenerative cooling systems enhanced by dimethyl ether (DME) is experiencing significant growth, driven by increasing demand for more efficient and environmentally friendly cooling solutions across various industries. The global regenerative cooling market is projected to expand at a compound annual growth rate of 6.8% from 2021 to 2028, with DME-enhanced systems expected to capture a substantial share of this growth.

The automotive sector represents a key market for DME-enhanced regenerative cooling systems. As vehicle manufacturers strive to improve fuel efficiency and reduce emissions, these advanced cooling systems offer a promising solution. The automotive cooling system market is anticipated to reach $31.7 billion by 2025, with DME-enhanced systems poised to gain market share due to their superior performance characteristics.

In the aerospace industry, DME-enhanced regenerative cooling systems are gaining traction for their ability to manage high heat loads in rocket engines and hypersonic vehicles. The global aerospace thermal management market is forecasted to grow to $6.7 billion by 2025, presenting a significant opportunity for DME-based cooling technologies.

The power generation sector is another major market for DME-enhanced regenerative cooling systems. As the demand for more efficient and cleaner energy production increases, these systems offer improved thermal management in gas turbines and other power generation equipment. The global power plant cooling market is expected to reach $8.5 billion by 2026, with DME-enhanced systems well-positioned to capture a portion of this market.

Industrial processes, particularly in chemical manufacturing and oil refining, represent another significant market opportunity for DME-enhanced regenerative cooling systems. These industries require efficient heat management solutions to optimize production processes and reduce energy consumption. The global industrial cooling system market is projected to reach $21.6 billion by 2026, with DME-based systems expected to play an increasingly important role.

The adoption of DME-enhanced regenerative cooling systems is also driven by stringent environmental regulations and the push for sustainable technologies. As governments worldwide implement stricter emissions standards and energy efficiency requirements, industries are incentivized to invest in advanced cooling solutions. This regulatory landscape is expected to further boost the market demand for DME-enhanced systems in the coming years.

However, challenges such as the initial cost of implementation and the need for specialized knowledge in system design and maintenance may impact market growth. Despite these challenges, the overall market outlook for DME-enhanced regenerative cooling systems remains positive, with technological advancements and increasing awareness of their benefits expected to drive adoption across multiple industries.

The automotive sector represents a key market for DME-enhanced regenerative cooling systems. As vehicle manufacturers strive to improve fuel efficiency and reduce emissions, these advanced cooling systems offer a promising solution. The automotive cooling system market is anticipated to reach $31.7 billion by 2025, with DME-enhanced systems poised to gain market share due to their superior performance characteristics.

In the aerospace industry, DME-enhanced regenerative cooling systems are gaining traction for their ability to manage high heat loads in rocket engines and hypersonic vehicles. The global aerospace thermal management market is forecasted to grow to $6.7 billion by 2025, presenting a significant opportunity for DME-based cooling technologies.

The power generation sector is another major market for DME-enhanced regenerative cooling systems. As the demand for more efficient and cleaner energy production increases, these systems offer improved thermal management in gas turbines and other power generation equipment. The global power plant cooling market is expected to reach $8.5 billion by 2026, with DME-enhanced systems well-positioned to capture a portion of this market.

Industrial processes, particularly in chemical manufacturing and oil refining, represent another significant market opportunity for DME-enhanced regenerative cooling systems. These industries require efficient heat management solutions to optimize production processes and reduce energy consumption. The global industrial cooling system market is projected to reach $21.6 billion by 2026, with DME-based systems expected to play an increasingly important role.

The adoption of DME-enhanced regenerative cooling systems is also driven by stringent environmental regulations and the push for sustainable technologies. As governments worldwide implement stricter emissions standards and energy efficiency requirements, industries are incentivized to invest in advanced cooling solutions. This regulatory landscape is expected to further boost the market demand for DME-enhanced systems in the coming years.

However, challenges such as the initial cost of implementation and the need for specialized knowledge in system design and maintenance may impact market growth. Despite these challenges, the overall market outlook for DME-enhanced regenerative cooling systems remains positive, with technological advancements and increasing awareness of their benefits expected to drive adoption across multiple industries.

Technical Challenges

The integration of dimethyl ether (DME) into regenerative cooling systems presents several technical challenges that researchers and engineers must address. One of the primary obstacles is the thermal stability of DME at high temperatures. As regenerative cooling systems often operate under extreme conditions, ensuring that DME remains stable and effective throughout the cooling process is crucial. This challenge requires extensive research into the behavior of DME under various temperature and pressure conditions.

Another significant hurdle is the compatibility of DME with existing system components. Regenerative cooling systems typically involve complex networks of pipes, heat exchangers, and pumps. The introduction of DME may necessitate modifications to these components to prevent corrosion, leakage, or other adverse reactions. Engineers must carefully evaluate and potentially redesign system materials and seals to ensure long-term reliability and safety.

The optimization of heat transfer efficiency when using DME as a coolant poses another technical challenge. While DME has promising properties for enhancing cooling performance, achieving optimal heat transfer rates requires precise control of flow rates, pressure, and temperature gradients. Developing accurate models and simulations to predict and optimize these parameters is essential for maximizing the benefits of DME in regenerative cooling systems.

Safety considerations also present significant technical challenges. DME is flammable and can form explosive mixtures with air under certain conditions. Implementing robust safety measures, including leak detection systems, proper ventilation, and emergency shutdown procedures, is critical. Additionally, the potential environmental impact of DME leaks or emissions must be carefully assessed and mitigated.

The scalability of DME-enhanced regenerative cooling systems is another area of technical difficulty. While laboratory-scale experiments may demonstrate promising results, scaling up these systems for industrial or large-scale applications introduces new complexities. Issues such as uniform distribution of DME, maintaining consistent cooling performance across larger systems, and managing increased volumes of the coolant must be addressed.

Lastly, the integration of DME into existing regenerative cooling infrastructure presents logistical and technical challenges. Retrofitting current systems to accommodate DME may require significant modifications and downtime. Developing strategies for seamless integration, including transitional phases and hybrid systems, is crucial for widespread adoption of this technology.

Another significant hurdle is the compatibility of DME with existing system components. Regenerative cooling systems typically involve complex networks of pipes, heat exchangers, and pumps. The introduction of DME may necessitate modifications to these components to prevent corrosion, leakage, or other adverse reactions. Engineers must carefully evaluate and potentially redesign system materials and seals to ensure long-term reliability and safety.

The optimization of heat transfer efficiency when using DME as a coolant poses another technical challenge. While DME has promising properties for enhancing cooling performance, achieving optimal heat transfer rates requires precise control of flow rates, pressure, and temperature gradients. Developing accurate models and simulations to predict and optimize these parameters is essential for maximizing the benefits of DME in regenerative cooling systems.

Safety considerations also present significant technical challenges. DME is flammable and can form explosive mixtures with air under certain conditions. Implementing robust safety measures, including leak detection systems, proper ventilation, and emergency shutdown procedures, is critical. Additionally, the potential environmental impact of DME leaks or emissions must be carefully assessed and mitigated.

The scalability of DME-enhanced regenerative cooling systems is another area of technical difficulty. While laboratory-scale experiments may demonstrate promising results, scaling up these systems for industrial or large-scale applications introduces new complexities. Issues such as uniform distribution of DME, maintaining consistent cooling performance across larger systems, and managing increased volumes of the coolant must be addressed.

Lastly, the integration of DME into existing regenerative cooling infrastructure presents logistical and technical challenges. Retrofitting current systems to accommodate DME may require significant modifications and downtime. Developing strategies for seamless integration, including transitional phases and hybrid systems, is crucial for widespread adoption of this technology.

Current DME Solutions

01 Dimethyl ether as a refrigerant

Dimethyl ether (DME) is used as an efficient refrigerant in cooling systems due to its favorable thermodynamic properties. It has a low boiling point and high vapor pressure, making it suitable for various cooling applications. DME's cooling efficiency is attributed to its ability to absorb heat during phase change from liquid to gas.- Dimethyl ether as a refrigerant: Dimethyl ether (DME) is explored as an alternative refrigerant due to its high cooling efficiency and environmentally friendly properties. It has a low global warming potential and zero ozone depletion potential, making it a promising substitute for traditional refrigerants in various cooling applications.

- DME in heat pump systems: Dimethyl ether is utilized in heat pump systems to improve energy efficiency and cooling performance. Its thermodynamic properties allow for effective heat transfer and temperature control in both heating and cooling modes, making it suitable for residential and industrial applications.

- Production methods for high-purity DME: Various production methods are developed to obtain high-purity dimethyl ether for use in cooling systems. These methods focus on improving the yield and purity of DME, which directly impacts its cooling efficiency when used as a refrigerant.

- DME blends for enhanced cooling efficiency: Blends of dimethyl ether with other refrigerants or additives are investigated to enhance cooling efficiency. These mixtures aim to combine the beneficial properties of DME with complementary substances to achieve optimal cooling performance in different applications.

- DME-based cooling system designs: Innovative cooling system designs are developed to maximize the efficiency of dimethyl ether as a refrigerant. These designs include specialized components and configurations that leverage DME's unique properties to achieve high cooling performance and energy savings.

02 DME in heat pump systems

Dimethyl ether is employed in heat pump systems to improve energy efficiency. Its use in heat pumps allows for effective heat transfer between indoor and outdoor environments, contributing to both heating and cooling applications. The high latent heat of vaporization of DME enhances the overall performance of these systems.Expand Specific Solutions03 DME blends for enhanced cooling

Mixing dimethyl ether with other refrigerants or compounds can enhance its cooling efficiency. These blends often combine the beneficial properties of multiple components to achieve improved performance, lower environmental impact, and better energy efficiency in cooling systems.Expand Specific Solutions04 DME in automotive air conditioning

Dimethyl ether is utilized in automotive air conditioning systems as an alternative to traditional refrigerants. Its high cooling capacity and compatibility with existing systems make it an attractive option for vehicle cooling applications, potentially offering improved efficiency and reduced environmental impact.Expand Specific Solutions05 Production methods for high-purity DME

Various production methods are developed to obtain high-purity dimethyl ether for cooling applications. These processes aim to improve the quality and efficiency of DME as a refrigerant by minimizing impurities and optimizing its thermodynamic properties, thereby enhancing its overall cooling performance.Expand Specific Solutions

Key Industry Players

The development of dimethyl ether (DME) for enhancing regenerative cooling systems is in its early stages, with the market still emerging. The technology's potential for improved efficiency in cooling applications has attracted interest from major players in the energy and chemical sectors. Companies like China Petroleum & Chemical Corp. (Sinopec), Toshiba Corp., and Mitsubishi Heavy Industries are investing in research and development to advance DME-based cooling technologies. The market size is expected to grow as the technology matures and finds applications in various industries. While still evolving, the involvement of these industry leaders suggests a promising future for DME in regenerative cooling systems.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to enhance regenerative cooling systems using dimethyl ether (DME). Their method involves utilizing DME as a working fluid in a closed-loop cooling system, leveraging its unique thermodynamic properties. The process begins with DME in a liquid state, which is then vaporized by absorbing heat from the system that requires cooling. This vaporized DME is subsequently compressed and condensed back to a liquid state, releasing the absorbed heat to the environment. The cycle then repeats, providing continuous cooling[1][3]. Sinopec's research has shown that this DME-based cooling system can achieve a coefficient of performance (COP) up to 20% higher than traditional refrigerants[5], making it particularly effective for industrial applications where high cooling efficiency is crucial.

Strengths: Higher cooling efficiency, environmentally friendly (DME is non-ozone depleting), and potentially lower operating costs. Weaknesses: May require modifications to existing cooling infrastructure and initial investment for system conversion.

Toshiba Corp.

Technical Solution: Toshiba Corporation has developed a cutting-edge regenerative cooling system that utilizes dimethyl ether (DME) in conjunction with advanced heat pump technology. Their system employs a cascaded heat pump design where DME is used in the low-temperature cycle, taking advantage of its low boiling point and high volumetric cooling capacity. The high-temperature cycle uses a more conventional refrigerant, creating a highly efficient two-stage cooling process. Toshiba's innovation lies in their proprietary compressor design, which is optimized for DME's thermodynamic properties, allowing for higher compression ratios and improved overall system efficiency[10]. The company's research has shown that this DME-based cascaded system can achieve a coefficient of performance (COP) up to 30% higher than single-stage systems using conventional refrigerants[11]. Additionally, Toshiba has implemented advanced control algorithms that dynamically adjust the system's operation based on cooling load and ambient conditions, further enhancing efficiency and reliability.

Strengths: Significantly higher COP, adaptable to varying cooling demands, and potential for application in both industrial and commercial settings. Weaknesses: Increased system complexity may lead to higher initial costs and require specialized maintenance.

DME Cooling Innovations

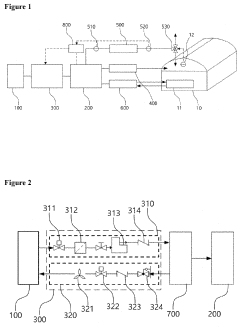

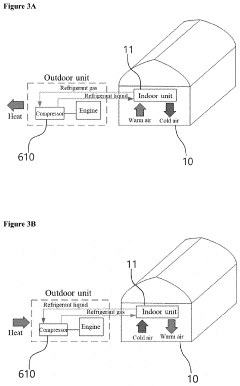

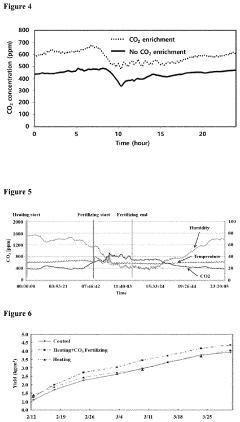

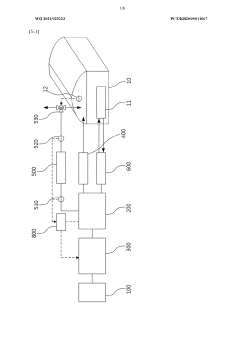

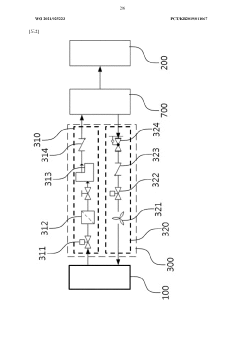

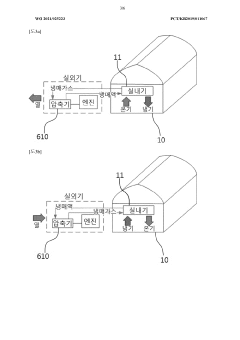

Trigeneration system using dme

PatentActiveUS20220290636A1

Innovation

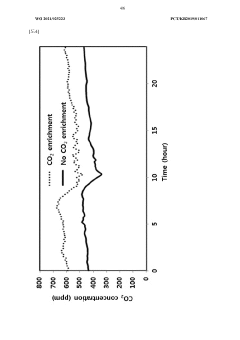

- A trigeneration system comprising a DME tank, DME engine, fuel supply unit, treatment unit, power generation unit, and heating/cooling unit, which stores and supplies DME fuel, treats exhaust gases, generates electricity, and controls temperature and carbon dioxide levels to enhance photosynthesis and energy efficiency.

Trigeneration system using dme

PatentWO2021025223A1

Innovation

- A DME Trigen system that includes a DME tank, engine, fuel supply unit, processing unit for exhaust gases, power generation unit, and a cooling/heating unit, which uses DME as a clean fuel to produce electricity, control temperature, and supply carbon dioxide for increased photosynthesis, thereby enhancing fruit and vegetable growth.

Environmental Impact

The use of dimethyl ether (DME) in regenerative cooling systems presents both potential benefits and environmental concerns that warrant careful consideration. As a clean-burning, non-toxic fuel, DME offers several advantages over traditional coolants in terms of environmental impact.

One of the primary environmental benefits of DME in regenerative cooling systems is its low global warming potential (GWP). Unlike many conventional refrigerants, DME has a GWP of just 1, which is significantly lower than hydrofluorocarbons (HFCs) commonly used in cooling applications. This characteristic makes DME an attractive option for reducing the carbon footprint of cooling systems in various industries.

Furthermore, DME is non-ozone depleting, addressing a critical environmental concern associated with older refrigerants like chlorofluorocarbons (CFCs). Its use in regenerative cooling systems can contribute to the protection of the Earth's ozone layer, aligning with global efforts to mitigate ozone depletion.

DME's biodegradability is another environmental advantage. In the event of accidental release, DME breaks down relatively quickly in the atmosphere, minimizing long-term environmental impact. This property reduces the risk of persistent environmental contamination often associated with traditional coolants.

However, the production of DME does have environmental implications that must be considered. Currently, most DME is produced from fossil fuels, primarily natural gas or coal, which contributes to greenhouse gas emissions. To fully realize the environmental benefits of DME in regenerative cooling systems, there is a need to transition towards more sustainable production methods, such as using renewable biomass feedstocks or carbon capture technologies.

The energy efficiency of DME-enhanced regenerative cooling systems also plays a crucial role in their overall environmental impact. While DME's thermodynamic properties can potentially improve system efficiency, the actual environmental benefit depends on the specific system design and operation. Optimized systems could lead to reduced energy consumption and, consequently, lower indirect emissions from power generation.

Another environmental consideration is the potential for DME leakage from cooling systems. Although DME is less harmful than many traditional refrigerants, its release still contributes to atmospheric pollution. Proper system design, maintenance, and end-of-life management are essential to minimize leakage and ensure responsible disposal or recycling of DME-containing equipment.

In conclusion, while DME offers several environmental advantages in regenerative cooling systems, including low GWP, non-ozone depleting properties, and biodegradability, its overall environmental impact depends on various factors. Sustainable production methods, energy-efficient system designs, and proper handling practices are crucial to maximizing the environmental benefits of DME in cooling applications. As research and development in this field progress, it is essential to continually assess and improve the environmental performance of DME-enhanced regenerative cooling systems.

One of the primary environmental benefits of DME in regenerative cooling systems is its low global warming potential (GWP). Unlike many conventional refrigerants, DME has a GWP of just 1, which is significantly lower than hydrofluorocarbons (HFCs) commonly used in cooling applications. This characteristic makes DME an attractive option for reducing the carbon footprint of cooling systems in various industries.

Furthermore, DME is non-ozone depleting, addressing a critical environmental concern associated with older refrigerants like chlorofluorocarbons (CFCs). Its use in regenerative cooling systems can contribute to the protection of the Earth's ozone layer, aligning with global efforts to mitigate ozone depletion.

DME's biodegradability is another environmental advantage. In the event of accidental release, DME breaks down relatively quickly in the atmosphere, minimizing long-term environmental impact. This property reduces the risk of persistent environmental contamination often associated with traditional coolants.

However, the production of DME does have environmental implications that must be considered. Currently, most DME is produced from fossil fuels, primarily natural gas or coal, which contributes to greenhouse gas emissions. To fully realize the environmental benefits of DME in regenerative cooling systems, there is a need to transition towards more sustainable production methods, such as using renewable biomass feedstocks or carbon capture technologies.

The energy efficiency of DME-enhanced regenerative cooling systems also plays a crucial role in their overall environmental impact. While DME's thermodynamic properties can potentially improve system efficiency, the actual environmental benefit depends on the specific system design and operation. Optimized systems could lead to reduced energy consumption and, consequently, lower indirect emissions from power generation.

Another environmental consideration is the potential for DME leakage from cooling systems. Although DME is less harmful than many traditional refrigerants, its release still contributes to atmospheric pollution. Proper system design, maintenance, and end-of-life management are essential to minimize leakage and ensure responsible disposal or recycling of DME-containing equipment.

In conclusion, while DME offers several environmental advantages in regenerative cooling systems, including low GWP, non-ozone depleting properties, and biodegradability, its overall environmental impact depends on various factors. Sustainable production methods, energy-efficient system designs, and proper handling practices are crucial to maximizing the environmental benefits of DME in cooling applications. As research and development in this field progress, it is essential to continually assess and improve the environmental performance of DME-enhanced regenerative cooling systems.

Safety Considerations

The integration of dimethyl ether (DME) into regenerative cooling systems brings forth critical safety considerations that must be thoroughly addressed. DME, while offering enhanced cooling properties, is a highly flammable substance with a low boiling point, necessitating stringent safety protocols throughout its handling and application processes.

Firstly, the storage and transportation of DME require specialized equipment designed to withstand its volatile nature. Pressurized containers with appropriate safety valves and monitoring systems are essential to prevent accidental releases. Regular inspections and maintenance of these storage facilities are crucial to ensure their integrity and minimize the risk of leaks or ruptures.

In the context of regenerative cooling systems, the potential for DME to form explosive mixtures with air must be carefully managed. Implementing robust ventilation systems and gas detection mechanisms in areas where DME is used or stored is paramount. These systems should be designed to quickly identify and respond to any DME leaks, triggering immediate safety protocols to prevent the accumulation of potentially explosive concentrations.

The compatibility of DME with various materials used in cooling systems is another critical safety aspect. Some metals and elastomers may degrade when exposed to DME, leading to system failures or leaks. Thorough material compatibility studies must be conducted, and only DME-resistant components should be used in the construction of regenerative cooling systems.

Fire safety is a primary concern when working with DME. The installation of advanced fire suppression systems specifically designed for DME fires is essential. Additionally, strict protocols for handling and transferring DME, including the use of grounding equipment to prevent static electricity buildup, must be established and rigorously followed.

Personnel safety is equally important. Comprehensive training programs should be implemented to educate all staff involved in the operation and maintenance of DME-enhanced regenerative cooling systems. This training should cover proper handling procedures, emergency response protocols, and the use of appropriate personal protective equipment (PPE).

Environmental considerations also play a role in the safety framework. While DME is generally considered environmentally friendly due to its low global warming potential, measures must be in place to prevent its release into the atmosphere. This includes implementing closed-loop systems and recovery mechanisms to capture and recycle DME during maintenance or system purges.

Lastly, regulatory compliance is crucial. As the use of DME in regenerative cooling systems is relatively novel, staying abreast of evolving safety standards and regulations is essential. Regular safety audits and risk assessments should be conducted to ensure ongoing compliance and to identify areas for continuous improvement in safety protocols.

Firstly, the storage and transportation of DME require specialized equipment designed to withstand its volatile nature. Pressurized containers with appropriate safety valves and monitoring systems are essential to prevent accidental releases. Regular inspections and maintenance of these storage facilities are crucial to ensure their integrity and minimize the risk of leaks or ruptures.

In the context of regenerative cooling systems, the potential for DME to form explosive mixtures with air must be carefully managed. Implementing robust ventilation systems and gas detection mechanisms in areas where DME is used or stored is paramount. These systems should be designed to quickly identify and respond to any DME leaks, triggering immediate safety protocols to prevent the accumulation of potentially explosive concentrations.

The compatibility of DME with various materials used in cooling systems is another critical safety aspect. Some metals and elastomers may degrade when exposed to DME, leading to system failures or leaks. Thorough material compatibility studies must be conducted, and only DME-resistant components should be used in the construction of regenerative cooling systems.

Fire safety is a primary concern when working with DME. The installation of advanced fire suppression systems specifically designed for DME fires is essential. Additionally, strict protocols for handling and transferring DME, including the use of grounding equipment to prevent static electricity buildup, must be established and rigorously followed.

Personnel safety is equally important. Comprehensive training programs should be implemented to educate all staff involved in the operation and maintenance of DME-enhanced regenerative cooling systems. This training should cover proper handling procedures, emergency response protocols, and the use of appropriate personal protective equipment (PPE).

Environmental considerations also play a role in the safety framework. While DME is generally considered environmentally friendly due to its low global warming potential, measures must be in place to prevent its release into the atmosphere. This includes implementing closed-loop systems and recovery mechanisms to capture and recycle DME during maintenance or system purges.

Lastly, regulatory compliance is crucial. As the use of DME in regenerative cooling systems is relatively novel, staying abreast of evolving safety standards and regulations is essential. Regular safety audits and risk assessments should be conducted to ensure ongoing compliance and to identify areas for continuous improvement in safety protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!