How Dimethyl Ether Revolutionizes Refrigeration Systems?

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME Refrigeration Evolution

The evolution of refrigeration systems using Dimethyl Ether (DME) represents a significant technological advancement in the field of cooling and temperature control. This progression can be traced through several key stages, each marking important milestones in the development and application of DME as a refrigerant.

In the early stages, conventional refrigerants such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) dominated the industry. However, growing environmental concerns and the discovery of their ozone-depleting properties led to a search for alternative refrigerants. This paved the way for the exploration of DME as a potential substitute.

The initial research phase focused on understanding the thermodynamic properties of DME and its suitability as a refrigerant. Scientists and engineers conducted extensive studies to evaluate its heat transfer characteristics, vapor pressure, and overall performance in cooling systems. These early investigations laid the groundwork for future developments in DME refrigeration technology.

As research progressed, the first experimental DME-based refrigeration systems were developed. These prototypes demonstrated the feasibility of using DME as a refrigerant and highlighted its potential advantages, such as high energy efficiency and low environmental impact. However, these early systems also revealed challenges, including the need for specialized equipment and safety considerations due to DME's flammability.

The next phase saw the refinement of DME refrigeration technology. Engineers focused on optimizing system designs to enhance performance and address safety concerns. This period witnessed the development of improved compressors, heat exchangers, and control systems specifically tailored for DME applications. Additionally, efforts were made to integrate DME into existing refrigeration infrastructure, facilitating a smoother transition from traditional refrigerants.

Recent years have marked a significant leap in DME refrigeration technology. Advanced systems have been developed that capitalize on DME's unique properties, achieving higher coefficients of performance (COP) and reduced energy consumption compared to conventional refrigerants. These modern systems incorporate sophisticated safety features and intelligent controls, making DME refrigeration more reliable and user-friendly.

The latest developments in DME refrigeration include its integration with renewable energy sources and smart grid technologies. This synergy allows for more sustainable and efficient cooling solutions, aligning with global efforts to reduce carbon emissions and promote energy conservation. Furthermore, ongoing research is exploring the potential of DME in novel applications, such as heat pumps and air conditioning systems for electric vehicles.

As the technology continues to mature, DME refrigeration systems are poised to play a crucial role in the future of sustainable cooling solutions. The evolution of this technology demonstrates the industry's commitment to innovation and environmental responsibility, paving the way for more efficient and eco-friendly refrigeration systems in various sectors.

In the early stages, conventional refrigerants such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) dominated the industry. However, growing environmental concerns and the discovery of their ozone-depleting properties led to a search for alternative refrigerants. This paved the way for the exploration of DME as a potential substitute.

The initial research phase focused on understanding the thermodynamic properties of DME and its suitability as a refrigerant. Scientists and engineers conducted extensive studies to evaluate its heat transfer characteristics, vapor pressure, and overall performance in cooling systems. These early investigations laid the groundwork for future developments in DME refrigeration technology.

As research progressed, the first experimental DME-based refrigeration systems were developed. These prototypes demonstrated the feasibility of using DME as a refrigerant and highlighted its potential advantages, such as high energy efficiency and low environmental impact. However, these early systems also revealed challenges, including the need for specialized equipment and safety considerations due to DME's flammability.

The next phase saw the refinement of DME refrigeration technology. Engineers focused on optimizing system designs to enhance performance and address safety concerns. This period witnessed the development of improved compressors, heat exchangers, and control systems specifically tailored for DME applications. Additionally, efforts were made to integrate DME into existing refrigeration infrastructure, facilitating a smoother transition from traditional refrigerants.

Recent years have marked a significant leap in DME refrigeration technology. Advanced systems have been developed that capitalize on DME's unique properties, achieving higher coefficients of performance (COP) and reduced energy consumption compared to conventional refrigerants. These modern systems incorporate sophisticated safety features and intelligent controls, making DME refrigeration more reliable and user-friendly.

The latest developments in DME refrigeration include its integration with renewable energy sources and smart grid technologies. This synergy allows for more sustainable and efficient cooling solutions, aligning with global efforts to reduce carbon emissions and promote energy conservation. Furthermore, ongoing research is exploring the potential of DME in novel applications, such as heat pumps and air conditioning systems for electric vehicles.

As the technology continues to mature, DME refrigeration systems are poised to play a crucial role in the future of sustainable cooling solutions. The evolution of this technology demonstrates the industry's commitment to innovation and environmental responsibility, paving the way for more efficient and eco-friendly refrigeration systems in various sectors.

Market Demand Analysis

The market demand for dimethyl ether (DME) as a refrigerant in cooling systems has been steadily increasing due to its environmentally friendly properties and superior performance characteristics. As global concerns about climate change and environmental protection intensify, there is a growing push for alternatives to traditional hydrofluorocarbon (HFC) refrigerants, which have high global warming potential (GWP). DME, with its low GWP and zero ozone depletion potential, has emerged as a promising candidate to meet this demand.

The refrigeration industry, encompassing both commercial and residential sectors, is experiencing a significant shift towards more sustainable solutions. This transition is driven by stringent regulations, such as the Kigali Amendment to the Montreal Protocol, which mandates the phase-down of HFCs. As a result, manufacturers and end-users are actively seeking eco-friendly refrigerants like DME to comply with these regulations while maintaining or improving system efficiency.

In the commercial refrigeration sector, which includes supermarkets, cold storage facilities, and food processing plants, there is a particularly strong demand for DME-based systems. These businesses are under pressure to reduce their carbon footprint and operating costs, making DME an attractive option due to its energy efficiency and lower environmental impact. The ability of DME to operate at lower pressures compared to some traditional refrigerants also contributes to reduced system complexity and potentially lower maintenance costs.

The residential air conditioning market is another area where DME is gaining traction. Consumers are becoming more environmentally conscious and are willing to invest in greener technologies for their homes. The potential for DME to improve the energy efficiency of household air conditioning units aligns well with this trend, as it can lead to lower electricity bills and reduced carbon emissions.

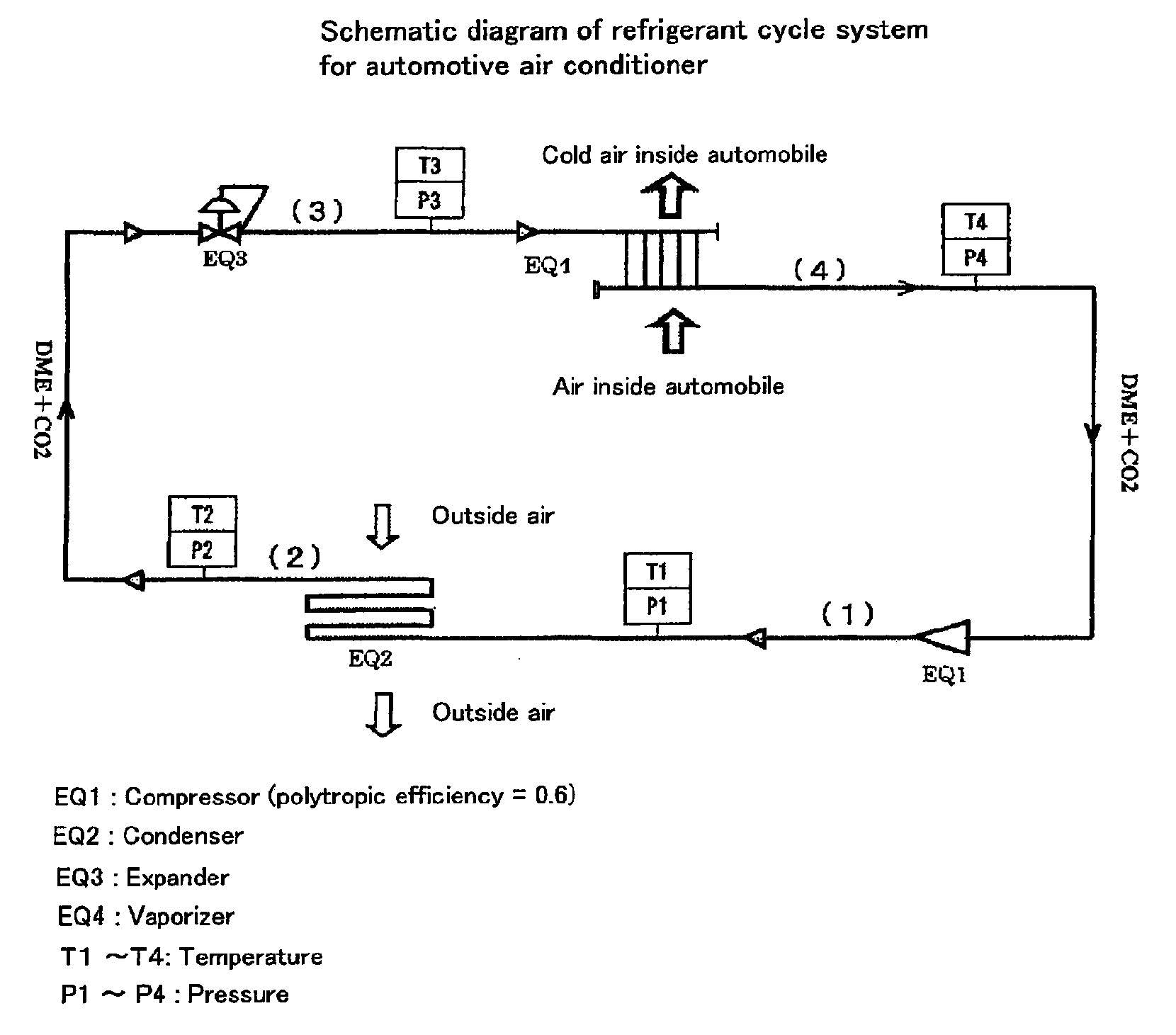

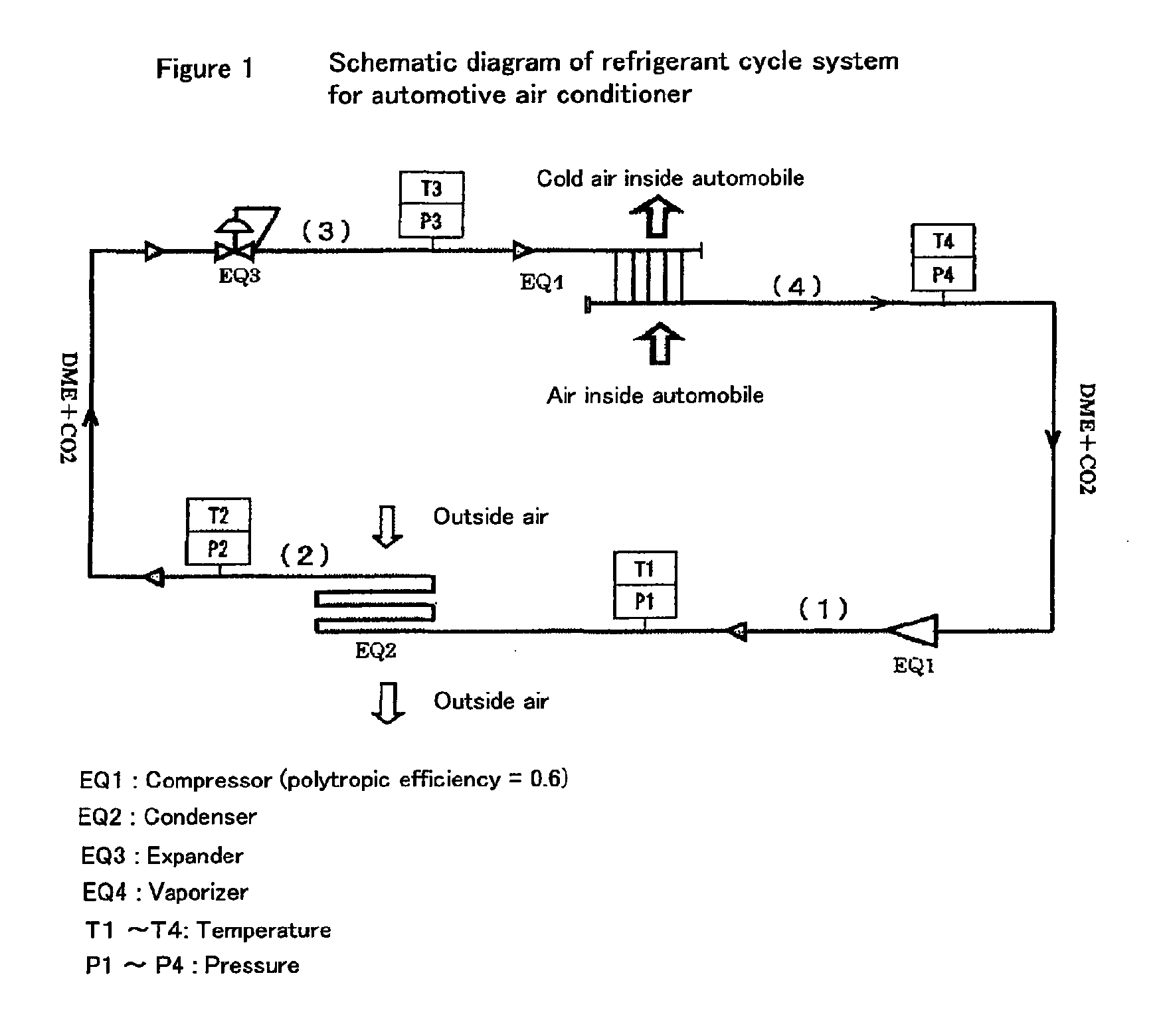

Furthermore, the automotive industry is exploring DME as a potential refrigerant for vehicle air conditioning systems. With the rise of electric vehicles and the need for more efficient cooling solutions, DME's properties make it a compelling alternative to current automotive refrigerants. This sector represents a significant growth opportunity for DME in refrigeration applications.

The market for DME in refrigeration is also being driven by its versatility. It can be used in various types of cooling systems, including heat pumps, chillers, and refrigerators. This adaptability allows for broader adoption across different applications and industries, further expanding its market potential.

However, the adoption of DME in refrigeration systems is not without challenges. The market demand is tempered by factors such as the need for system redesigns to accommodate DME's properties, initial investment costs for new equipment, and the requirement for technician training. Despite these hurdles, the long-term benefits and regulatory pressures are expected to continue driving the market demand for DME in refrigeration systems upward in the coming years.

The refrigeration industry, encompassing both commercial and residential sectors, is experiencing a significant shift towards more sustainable solutions. This transition is driven by stringent regulations, such as the Kigali Amendment to the Montreal Protocol, which mandates the phase-down of HFCs. As a result, manufacturers and end-users are actively seeking eco-friendly refrigerants like DME to comply with these regulations while maintaining or improving system efficiency.

In the commercial refrigeration sector, which includes supermarkets, cold storage facilities, and food processing plants, there is a particularly strong demand for DME-based systems. These businesses are under pressure to reduce their carbon footprint and operating costs, making DME an attractive option due to its energy efficiency and lower environmental impact. The ability of DME to operate at lower pressures compared to some traditional refrigerants also contributes to reduced system complexity and potentially lower maintenance costs.

The residential air conditioning market is another area where DME is gaining traction. Consumers are becoming more environmentally conscious and are willing to invest in greener technologies for their homes. The potential for DME to improve the energy efficiency of household air conditioning units aligns well with this trend, as it can lead to lower electricity bills and reduced carbon emissions.

Furthermore, the automotive industry is exploring DME as a potential refrigerant for vehicle air conditioning systems. With the rise of electric vehicles and the need for more efficient cooling solutions, DME's properties make it a compelling alternative to current automotive refrigerants. This sector represents a significant growth opportunity for DME in refrigeration applications.

The market for DME in refrigeration is also being driven by its versatility. It can be used in various types of cooling systems, including heat pumps, chillers, and refrigerators. This adaptability allows for broader adoption across different applications and industries, further expanding its market potential.

However, the adoption of DME in refrigeration systems is not without challenges. The market demand is tempered by factors such as the need for system redesigns to accommodate DME's properties, initial investment costs for new equipment, and the requirement for technician training. Despite these hurdles, the long-term benefits and regulatory pressures are expected to continue driving the market demand for DME in refrigeration systems upward in the coming years.

Technical Challenges

Despite the promising potential of dimethyl ether (DME) in revolutionizing refrigeration systems, several technical challenges must be addressed for its widespread adoption. One of the primary obstacles is the compatibility of DME with existing refrigeration infrastructure. Many current systems are designed for traditional refrigerants, and retrofitting or redesigning these systems to accommodate DME can be complex and costly.

The thermodynamic properties of DME, while advantageous in many aspects, also present challenges. Its lower volumetric cooling capacity compared to some conventional refrigerants means that larger compressors and heat exchangers may be required to achieve the same cooling effect. This could lead to increased system size and potentially higher initial costs for DME-based refrigeration units.

Material compatibility is another significant hurdle. DME can cause swelling and degradation of certain elastomers and plastics commonly used in refrigeration systems. This necessitates careful selection of materials for seals, gaskets, and other components to ensure long-term reliability and prevent leaks. Additionally, DME's solvent properties may lead to the dissolution of lubricants, requiring the development of specialized lubricants that are compatible with DME and maintain their effectiveness over time.

Safety considerations also pose technical challenges. While DME has a low ozone depletion potential and global warming potential, it is flammable. This characteristic requires the implementation of additional safety measures in system design, installation, and maintenance procedures. Developing effective leak detection systems and establishing proper handling protocols are crucial steps in mitigating safety risks associated with DME use in refrigeration.

The optimization of system efficiency with DME as a refrigerant is an ongoing challenge. While DME offers good thermodynamic properties, achieving optimal performance across various operating conditions requires fine-tuning of system components and control strategies. This includes developing advanced compressor designs, optimizing heat exchanger configurations, and implementing sophisticated control algorithms to maximize energy efficiency and cooling performance.

Lastly, the production and distribution of high-purity DME for refrigeration applications present logistical challenges. Ensuring a stable supply chain and developing cost-effective purification methods are essential for the widespread adoption of DME in refrigeration systems. These factors impact not only the technical feasibility but also the economic viability of DME as a refrigerant alternative.

The thermodynamic properties of DME, while advantageous in many aspects, also present challenges. Its lower volumetric cooling capacity compared to some conventional refrigerants means that larger compressors and heat exchangers may be required to achieve the same cooling effect. This could lead to increased system size and potentially higher initial costs for DME-based refrigeration units.

Material compatibility is another significant hurdle. DME can cause swelling and degradation of certain elastomers and plastics commonly used in refrigeration systems. This necessitates careful selection of materials for seals, gaskets, and other components to ensure long-term reliability and prevent leaks. Additionally, DME's solvent properties may lead to the dissolution of lubricants, requiring the development of specialized lubricants that are compatible with DME and maintain their effectiveness over time.

Safety considerations also pose technical challenges. While DME has a low ozone depletion potential and global warming potential, it is flammable. This characteristic requires the implementation of additional safety measures in system design, installation, and maintenance procedures. Developing effective leak detection systems and establishing proper handling protocols are crucial steps in mitigating safety risks associated with DME use in refrigeration.

The optimization of system efficiency with DME as a refrigerant is an ongoing challenge. While DME offers good thermodynamic properties, achieving optimal performance across various operating conditions requires fine-tuning of system components and control strategies. This includes developing advanced compressor designs, optimizing heat exchanger configurations, and implementing sophisticated control algorithms to maximize energy efficiency and cooling performance.

Lastly, the production and distribution of high-purity DME for refrigeration applications present logistical challenges. Ensuring a stable supply chain and developing cost-effective purification methods are essential for the widespread adoption of DME in refrigeration systems. These factors impact not only the technical feasibility but also the economic viability of DME as a refrigerant alternative.

Current DME Solutions

01 Dimethyl ether as a refrigerant

Dimethyl ether (DME) is used as an environmentally friendly refrigerant in various cooling systems. It has favorable thermodynamic properties, low global warming potential, and zero ozone depletion potential, making it a suitable alternative to traditional refrigerants.- Dimethyl ether as a refrigerant: Dimethyl ether (DME) is used as an environmentally friendly refrigerant in various cooling systems. It has favorable thermodynamic properties, low global warming potential, and zero ozone depletion potential, making it a suitable alternative to traditional refrigerants.

- Production methods for dimethyl ether: Various methods for producing dimethyl ether are described, including dehydration of methanol, direct synthesis from syngas, and conversion of biomass. These processes aim to improve efficiency and reduce production costs for DME used in refrigeration applications.

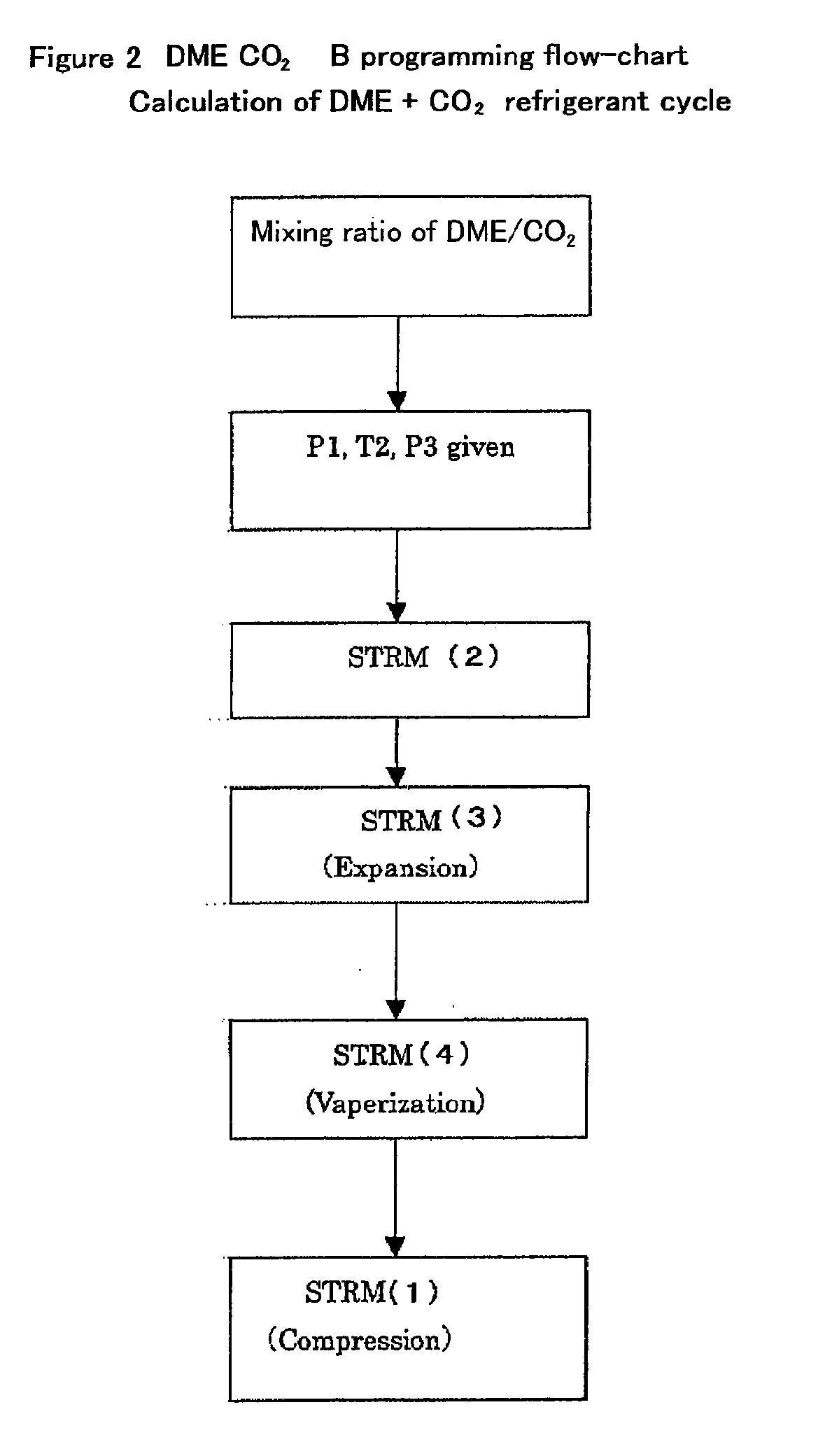

- Dimethyl ether-based refrigeration systems: Refrigeration systems specifically designed for use with dimethyl ether as the working fluid are developed. These systems optimize the unique properties of DME to achieve high efficiency and performance in cooling applications.

- Catalysts for dimethyl ether synthesis: Development of novel catalysts to improve the production of dimethyl ether for refrigeration applications. These catalysts aim to enhance conversion rates, selectivity, and overall efficiency in DME synthesis processes.

- Dimethyl ether blends and mixtures: Research on blending dimethyl ether with other refrigerants or additives to enhance its performance in refrigeration systems. These mixtures aim to improve thermodynamic properties, system efficiency, or address specific application requirements.

02 Production methods for dimethyl ether

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of biomass. These processes aim to improve the efficiency and cost-effectiveness of DME production for refrigeration applications.Expand Specific Solutions03 Dimethyl ether refrigeration system design

Specialized refrigeration system designs for using dimethyl ether as a working fluid are developed. These systems may include modified compressors, heat exchangers, and expansion devices to optimize performance and efficiency when using DME as a refrigerant.Expand Specific Solutions04 Blends and mixtures with dimethyl ether

Refrigerant blends and mixtures incorporating dimethyl ether are formulated to enhance cooling performance, energy efficiency, or compatibility with existing refrigeration systems. These blends may combine DME with other refrigerants or additives to achieve desired properties.Expand Specific Solutions05 Safety and handling of dimethyl ether in refrigeration

Safety measures and handling procedures for using dimethyl ether in refrigeration systems are developed. This includes addressing flammability concerns, designing appropriate storage and distribution systems, and establishing protocols for safe operation and maintenance of DME-based cooling equipment.Expand Specific Solutions

Key Industry Players

The dimethyl ether (DME) refrigeration market is in a growth phase, driven by increasing demand for environmentally friendly refrigerants. The global market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, DME refrigeration systems are advancing rapidly, with companies like China Petroleum & Chemical Corp., Linde GmbH, and Toshiba Corp. leading innovation efforts. These firms are developing more efficient and cost-effective DME-based cooling solutions, leveraging their expertise in chemical engineering and refrigeration technology. While DME refrigeration is not yet as mature as traditional systems, ongoing research and development by key players are steadily improving its commercial viability and performance characteristics.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel dimethyl ether (DME) refrigeration system that significantly improves energy efficiency and reduces environmental impact. Their technology utilizes DME's excellent thermodynamic properties, including a low boiling point (-25°C) and high latent heat of vaporization. Sinopec's system incorporates a specially designed compressor and heat exchanger to optimize DME's performance as a refrigerant. The company has reported energy savings of up to 30% compared to traditional HFC-based systems [1][3]. Additionally, Sinopec has implemented a closed-loop DME production process, using methanol derived from coal or natural gas, which ensures a stable supply of the refrigerant [2].

Strengths: High energy efficiency, low environmental impact, and stable supply chain. Weaknesses: Initial investment costs may be higher than conventional systems, and retrofitting existing systems could be challenging.

Linde GmbH

Technical Solution: Linde GmbH has pioneered an innovative DME-based cascade refrigeration system for industrial applications. Their technology combines DME with CO2 in a two-stage cooling process, leveraging DME's excellent heat transfer properties in the high-temperature stage and CO2's efficiency in the low-temperature stage. This hybrid approach allows for a wide temperature range, from -50°C to +40°C, making it suitable for various industrial processes [4]. Linde's system incorporates advanced heat recovery mechanisms, recapturing waste heat from the DME cycle to enhance overall efficiency. The company reports a reduction in energy consumption by up to 25% compared to traditional ammonia-based systems [5]. Furthermore, Linde has developed specialized safety protocols and equipment for handling DME in refrigeration applications, addressing potential flammability concerns.

Strengths: Wide temperature range, high energy efficiency, and advanced safety measures. Weaknesses: Complexity of the dual-refrigerant system may increase maintenance requirements and initial costs.

DME Innovations Review

Refrigerant Composition

PatentInactiveUS20110017941A1

Innovation

- A refrigerant composition comprising 1-10% dimethyl ether and 90-99% carbon dioxide, which promotes condensation by decreasing vapor pressure, allowing for efficient vapor compression cycles and reducing compressor working pressure, thereby achieving higher cooling performance and eliminating the need for additional cooling devices.

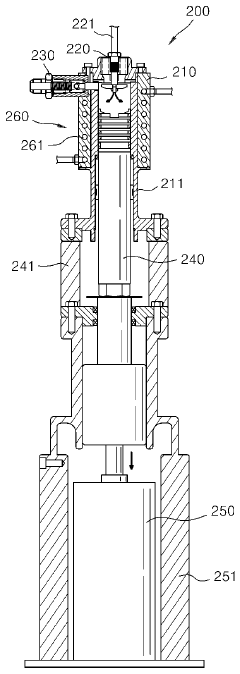

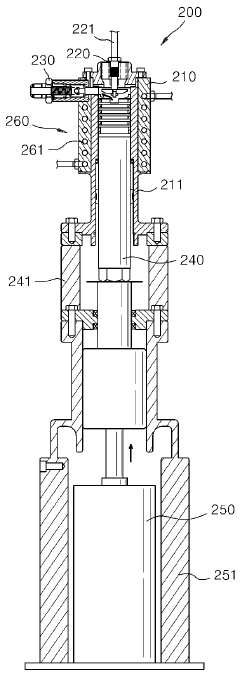

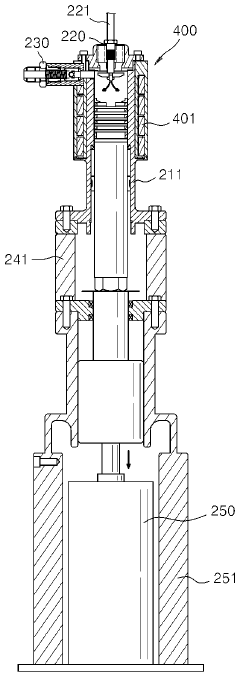

System of production of liquefied dimethyl ether

PatentInactiveKR1020150025636A

Innovation

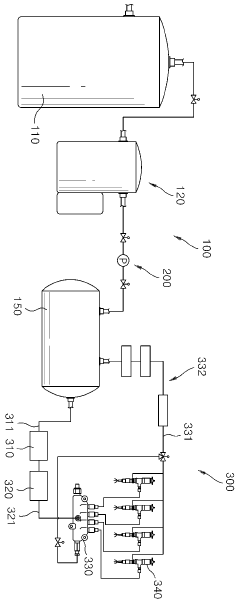

- A system comprising a main tank, gas cooling unit, pressure pump unit, and storage tank, along with a cylinder and auxiliary cooling unit, to cool and pressurize dimethyl ether, ensuring efficient liquefaction through cooling and pressurization processes.

Environmental Impact

The adoption of dimethyl ether (DME) as a refrigerant in cooling systems represents a significant leap forward in environmental sustainability within the refrigeration industry. DME's low global warming potential (GWP) of just 1 makes it an attractive alternative to traditional hydrofluorocarbon (HFC) refrigerants, which can have GWP values in the thousands. This dramatic reduction in GWP translates to a substantially lower impact on climate change when DME is released into the atmosphere.

Furthermore, DME has zero ozone depletion potential (ODP), ensuring that it does not contribute to the degradation of the Earth's protective ozone layer. This characteristic aligns with global efforts to phase out ozone-depleting substances under the Montreal Protocol and subsequent amendments.

The environmental benefits of DME extend beyond its direct atmospheric impact. Its use in refrigeration systems can lead to improved energy efficiency, potentially reducing the overall energy consumption of cooling appliances. This indirect environmental benefit contributes to lower greenhouse gas emissions associated with electricity generation.

DME is also non-toxic and biodegradable, minimizing the risk of long-term environmental contamination in case of accidental releases. Its rapid decomposition in the atmosphere further reduces its environmental footprint compared to more persistent refrigerants.

In terms of lifecycle assessment, DME shows promise in reducing the overall environmental impact of refrigeration systems. From production to end-of-life disposal, DME's environmental profile is generally more favorable than that of traditional refrigerants. Its production can be achieved through renewable resources, such as biomass, potentially creating a more sustainable supply chain for the refrigeration industry.

However, it is important to note that the widespread adoption of DME in refrigeration systems may require modifications to existing equipment and infrastructure. The environmental impact of these transitions, including the disposal of old systems and the manufacturing of new DME-compatible equipment, must be carefully considered in a comprehensive environmental assessment.

As regulations around the world continue to tighten restrictions on high-GWP refrigerants, DME's environmental credentials position it as a viable solution for meeting increasingly stringent environmental standards. Its adoption could play a crucial role in helping nations achieve their climate change mitigation goals and commitments under international agreements.

Furthermore, DME has zero ozone depletion potential (ODP), ensuring that it does not contribute to the degradation of the Earth's protective ozone layer. This characteristic aligns with global efforts to phase out ozone-depleting substances under the Montreal Protocol and subsequent amendments.

The environmental benefits of DME extend beyond its direct atmospheric impact. Its use in refrigeration systems can lead to improved energy efficiency, potentially reducing the overall energy consumption of cooling appliances. This indirect environmental benefit contributes to lower greenhouse gas emissions associated with electricity generation.

DME is also non-toxic and biodegradable, minimizing the risk of long-term environmental contamination in case of accidental releases. Its rapid decomposition in the atmosphere further reduces its environmental footprint compared to more persistent refrigerants.

In terms of lifecycle assessment, DME shows promise in reducing the overall environmental impact of refrigeration systems. From production to end-of-life disposal, DME's environmental profile is generally more favorable than that of traditional refrigerants. Its production can be achieved through renewable resources, such as biomass, potentially creating a more sustainable supply chain for the refrigeration industry.

However, it is important to note that the widespread adoption of DME in refrigeration systems may require modifications to existing equipment and infrastructure. The environmental impact of these transitions, including the disposal of old systems and the manufacturing of new DME-compatible equipment, must be carefully considered in a comprehensive environmental assessment.

As regulations around the world continue to tighten restrictions on high-GWP refrigerants, DME's environmental credentials position it as a viable solution for meeting increasingly stringent environmental standards. Its adoption could play a crucial role in helping nations achieve their climate change mitigation goals and commitments under international agreements.

Safety Regulations

The implementation of dimethyl ether (DME) in refrigeration systems necessitates a comprehensive framework of safety regulations to ensure its responsible and secure use. As DME is a flammable substance, stringent guidelines are essential to mitigate potential risks associated with its storage, handling, and operation in cooling applications.

Regulatory bodies, such as the International Organization for Standardization (ISO) and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), have developed specific standards for DME-based refrigeration systems. These standards outline requirements for system design, installation, maintenance, and disposal, emphasizing the importance of leak detection, ventilation, and emergency shutdown procedures.

One crucial aspect of DME safety regulations is the classification of hazardous areas. Facilities using DME-based refrigeration systems must adhere to strict zoning requirements, which dictate the types of equipment and electrical installations permitted in areas where DME may be present. This classification helps prevent potential ignition sources and reduces the risk of fire or explosion.

Personal protective equipment (PPE) regulations are also critical for personnel working with DME refrigeration systems. Safety protocols mandate the use of appropriate PPE, including flame-resistant clothing, safety goggles, and gloves, to protect workers from potential exposure to DME vapors or liquid.

Transportation and storage of DME for refrigeration purposes are subject to specific regulations as well. These guidelines cover aspects such as container specifications, labeling requirements, and transportation routes to minimize the risk of accidents during the movement of DME from production facilities to end-users.

Regular inspection and maintenance procedures are mandated by safety regulations to ensure the ongoing integrity of DME refrigeration systems. These protocols include routine checks for leaks, pressure testing, and the verification of safety devices such as pressure relief valves and emergency shutdown systems.

Training and certification requirements form another crucial component of DME safety regulations. Personnel involved in the design, installation, operation, and maintenance of DME refrigeration systems must undergo specialized training programs and obtain relevant certifications to demonstrate their competence in handling this innovative refrigerant.

Environmental considerations are also addressed in DME safety regulations, with guidelines for proper disposal and recycling of DME-containing equipment and materials. These measures aim to prevent environmental contamination and promote sustainable practices in the refrigeration industry.

As the adoption of DME in refrigeration systems continues to grow, regulatory frameworks are expected to evolve, incorporating new insights and best practices. This ongoing refinement of safety regulations will play a crucial role in facilitating the widespread implementation of DME-based cooling technologies while ensuring the highest standards of safety and environmental protection.

Regulatory bodies, such as the International Organization for Standardization (ISO) and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), have developed specific standards for DME-based refrigeration systems. These standards outline requirements for system design, installation, maintenance, and disposal, emphasizing the importance of leak detection, ventilation, and emergency shutdown procedures.

One crucial aspect of DME safety regulations is the classification of hazardous areas. Facilities using DME-based refrigeration systems must adhere to strict zoning requirements, which dictate the types of equipment and electrical installations permitted in areas where DME may be present. This classification helps prevent potential ignition sources and reduces the risk of fire or explosion.

Personal protective equipment (PPE) regulations are also critical for personnel working with DME refrigeration systems. Safety protocols mandate the use of appropriate PPE, including flame-resistant clothing, safety goggles, and gloves, to protect workers from potential exposure to DME vapors or liquid.

Transportation and storage of DME for refrigeration purposes are subject to specific regulations as well. These guidelines cover aspects such as container specifications, labeling requirements, and transportation routes to minimize the risk of accidents during the movement of DME from production facilities to end-users.

Regular inspection and maintenance procedures are mandated by safety regulations to ensure the ongoing integrity of DME refrigeration systems. These protocols include routine checks for leaks, pressure testing, and the verification of safety devices such as pressure relief valves and emergency shutdown systems.

Training and certification requirements form another crucial component of DME safety regulations. Personnel involved in the design, installation, operation, and maintenance of DME refrigeration systems must undergo specialized training programs and obtain relevant certifications to demonstrate their competence in handling this innovative refrigerant.

Environmental considerations are also addressed in DME safety regulations, with guidelines for proper disposal and recycling of DME-containing equipment and materials. These measures aim to prevent environmental contamination and promote sustainable practices in the refrigeration industry.

As the adoption of DME in refrigeration systems continues to grow, regulatory frameworks are expected to evolve, incorporating new insights and best practices. This ongoing refinement of safety regulations will play a crucial role in facilitating the widespread implementation of DME-based cooling technologies while ensuring the highest standards of safety and environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!