How Environment Responsive Additives Affect Polypropylene Polymers

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Additive-Polymer Interaction Background

The interaction between additives and polymers is a fundamental aspect of polymer science and engineering, particularly in the context of polypropylene (PP) and environment responsive additives. This interaction plays a crucial role in determining the final properties and performance of the polymer composite. Historically, the use of additives in polymers dates back to the early days of polymer production, with the primary goal of enhancing specific properties or introducing new functionalities.

Environment responsive additives represent a more recent development in this field, emerging as a response to growing environmental concerns and the need for smart materials. These additives are designed to react to specific environmental stimuli such as temperature, pH, light, or moisture, thereby altering the properties of the polymer matrix in a controlled manner. In the case of polypropylene, which is widely used in various applications due to its versatility and low cost, the incorporation of such additives can significantly expand its functionality and application range.

The interaction between environment responsive additives and polypropylene occurs at the molecular level, involving complex physicochemical processes. These interactions can be broadly categorized into physical and chemical interactions. Physical interactions typically involve van der Waals forces, hydrogen bonding, or electrostatic interactions, while chemical interactions may include covalent bonding or the formation of new chemical species at the interface between the additive and the polymer.

The nature and strength of these interactions are influenced by various factors, including the chemical structure of both the additive and the polymer, the processing conditions, and the environmental conditions to which the composite is exposed. For instance, the crystalline structure of polypropylene can affect the distribution and effectiveness of the additives, while the polarity of the additive can determine its compatibility with the non-polar PP matrix.

Understanding these interactions is crucial for predicting and controlling the behavior of the polymer composite under different environmental conditions. It allows for the design of materials with tailored properties that can respond to specific environmental triggers in a predetermined manner. This has led to the development of a wide range of applications, from smart packaging materials that can indicate food spoilage to self-healing polymers that can repair damage autonomously.

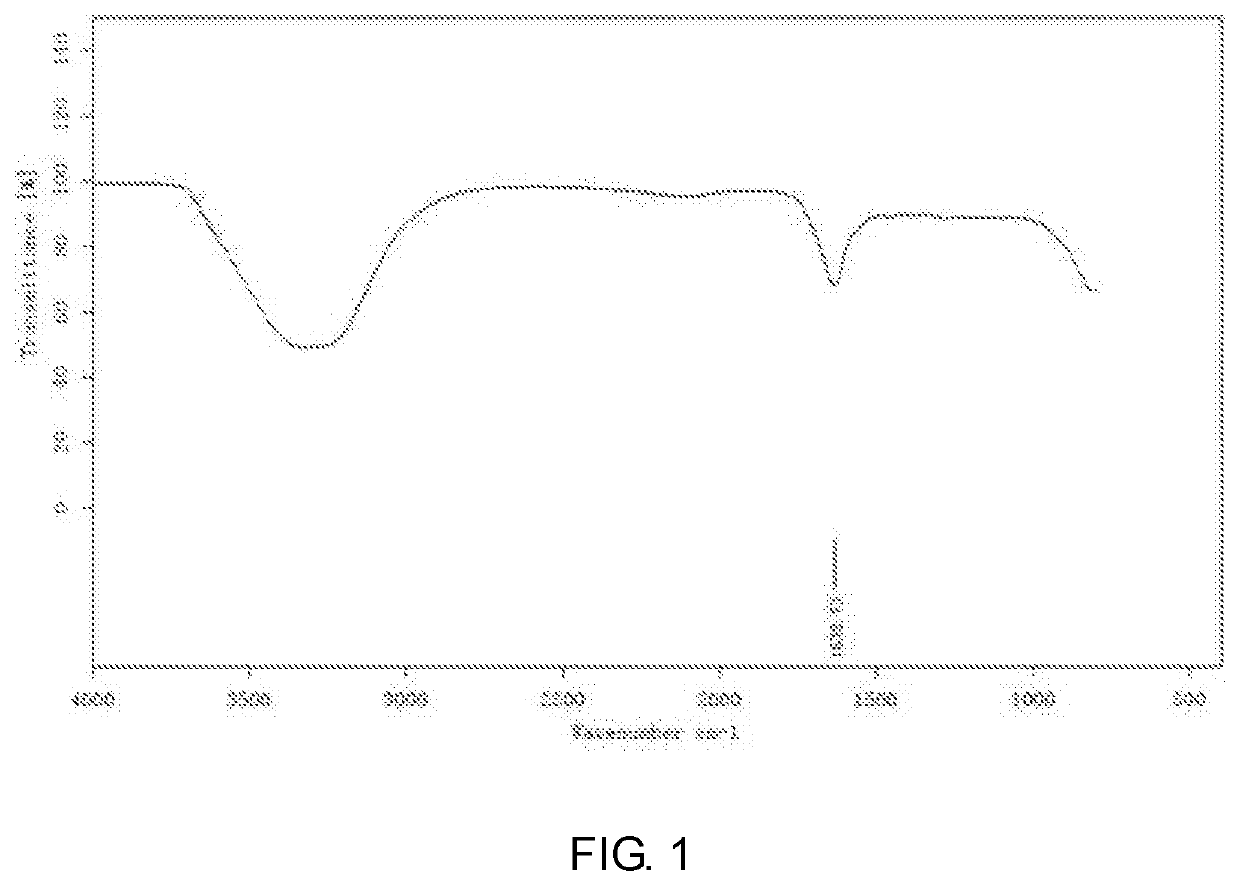

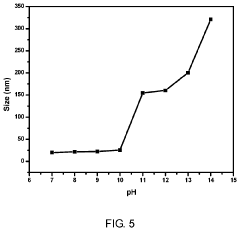

The study of additive-polymer interactions in the context of environment responsive additives and polypropylene continues to be an active area of research. Advances in analytical techniques, such as spectroscopy and microscopy, have enabled researchers to gain deeper insights into these interactions at the molecular and nanoscale levels. This knowledge is essential for the development of new additives and the optimization of existing formulations to meet the evolving demands of various industries.

Environment responsive additives represent a more recent development in this field, emerging as a response to growing environmental concerns and the need for smart materials. These additives are designed to react to specific environmental stimuli such as temperature, pH, light, or moisture, thereby altering the properties of the polymer matrix in a controlled manner. In the case of polypropylene, which is widely used in various applications due to its versatility and low cost, the incorporation of such additives can significantly expand its functionality and application range.

The interaction between environment responsive additives and polypropylene occurs at the molecular level, involving complex physicochemical processes. These interactions can be broadly categorized into physical and chemical interactions. Physical interactions typically involve van der Waals forces, hydrogen bonding, or electrostatic interactions, while chemical interactions may include covalent bonding or the formation of new chemical species at the interface between the additive and the polymer.

The nature and strength of these interactions are influenced by various factors, including the chemical structure of both the additive and the polymer, the processing conditions, and the environmental conditions to which the composite is exposed. For instance, the crystalline structure of polypropylene can affect the distribution and effectiveness of the additives, while the polarity of the additive can determine its compatibility with the non-polar PP matrix.

Understanding these interactions is crucial for predicting and controlling the behavior of the polymer composite under different environmental conditions. It allows for the design of materials with tailored properties that can respond to specific environmental triggers in a predetermined manner. This has led to the development of a wide range of applications, from smart packaging materials that can indicate food spoilage to self-healing polymers that can repair damage autonomously.

The study of additive-polymer interactions in the context of environment responsive additives and polypropylene continues to be an active area of research. Advances in analytical techniques, such as spectroscopy and microscopy, have enabled researchers to gain deeper insights into these interactions at the molecular and nanoscale levels. This knowledge is essential for the development of new additives and the optimization of existing formulations to meet the evolving demands of various industries.

Market Analysis for Smart Polypropylene

The market for smart polypropylene, enhanced with environment-responsive additives, is experiencing significant growth and transformation. This innovative material category combines the versatility and cost-effectiveness of traditional polypropylene with advanced functionalities, opening up new applications across various industries. The global smart polypropylene market is driven by increasing demand for high-performance materials in automotive, packaging, and consumer goods sectors.

In the automotive industry, smart polypropylene is gaining traction due to its ability to reduce vehicle weight, improve fuel efficiency, and enhance safety features. The material's responsiveness to environmental stimuli, such as temperature and humidity, allows for adaptive performance in different driving conditions. This has led to a surge in demand for smart polypropylene components in interior and exterior automotive applications.

The packaging sector represents another key market for smart polypropylene. With growing consumer awareness and stringent regulations regarding sustainable packaging, manufacturers are turning to environment-responsive polypropylene solutions. These materials offer improved barrier properties, extended shelf life for perishable goods, and potential biodegradability, addressing both functional and environmental concerns in the packaging industry.

Consumer goods manufacturers are also embracing smart polypropylene for its unique properties. Products ranging from household appliances to sports equipment benefit from the material's ability to adapt to environmental conditions, providing enhanced durability, comfort, and performance. This trend is particularly evident in the growing market for smart textiles and wearable technologies.

The healthcare and medical device industry is emerging as a promising market for smart polypropylene. The material's biocompatibility, coupled with its responsive nature, makes it suitable for applications such as drug delivery systems, implants, and diagnostic devices. The ability to create polypropylene formulations that respond to specific biological triggers opens up new possibilities in personalized medicine and targeted therapies.

Geographically, North America and Europe are leading the adoption of smart polypropylene, driven by stringent environmental regulations and a strong focus on innovation in materials science. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, increasing automotive production, and a burgeoning consumer goods market.

Despite the promising outlook, challenges remain in the widespread adoption of smart polypropylene. These include the need for standardization in production processes, potential higher costs compared to conventional polypropylene, and the requirement for specialized processing equipment. Overcoming these hurdles will be crucial for the continued expansion of the smart polypropylene market.

In the automotive industry, smart polypropylene is gaining traction due to its ability to reduce vehicle weight, improve fuel efficiency, and enhance safety features. The material's responsiveness to environmental stimuli, such as temperature and humidity, allows for adaptive performance in different driving conditions. This has led to a surge in demand for smart polypropylene components in interior and exterior automotive applications.

The packaging sector represents another key market for smart polypropylene. With growing consumer awareness and stringent regulations regarding sustainable packaging, manufacturers are turning to environment-responsive polypropylene solutions. These materials offer improved barrier properties, extended shelf life for perishable goods, and potential biodegradability, addressing both functional and environmental concerns in the packaging industry.

Consumer goods manufacturers are also embracing smart polypropylene for its unique properties. Products ranging from household appliances to sports equipment benefit from the material's ability to adapt to environmental conditions, providing enhanced durability, comfort, and performance. This trend is particularly evident in the growing market for smart textiles and wearable technologies.

The healthcare and medical device industry is emerging as a promising market for smart polypropylene. The material's biocompatibility, coupled with its responsive nature, makes it suitable for applications such as drug delivery systems, implants, and diagnostic devices. The ability to create polypropylene formulations that respond to specific biological triggers opens up new possibilities in personalized medicine and targeted therapies.

Geographically, North America and Europe are leading the adoption of smart polypropylene, driven by stringent environmental regulations and a strong focus on innovation in materials science. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, increasing automotive production, and a burgeoning consumer goods market.

Despite the promising outlook, challenges remain in the widespread adoption of smart polypropylene. These include the need for standardization in production processes, potential higher costs compared to conventional polypropylene, and the requirement for specialized processing equipment. Overcoming these hurdles will be crucial for the continued expansion of the smart polypropylene market.

Current Challenges in Responsive Polymers

The field of responsive polymers, particularly in relation to polypropylene, faces several significant challenges that hinder their widespread adoption and optimal performance. One of the primary obstacles is achieving precise control over the responsiveness of these materials to environmental stimuli. While environment responsive additives can impart sensitivity to factors such as temperature, pH, or light, fine-tuning the degree and speed of response remains difficult.

Another major challenge lies in maintaining the mechanical properties of polypropylene while incorporating responsive additives. The addition of these components often leads to a trade-off between responsiveness and the polymer's inherent strength, flexibility, or durability. Balancing these competing properties to create materials that are both highly responsive and mechanically robust is an ongoing struggle for researchers and engineers.

Stability and longevity of responsive polypropylene systems pose additional challenges. Many responsive additives are susceptible to degradation over time, especially when exposed to harsh environmental conditions or repeated stimulation cycles. This can lead to a gradual loss of responsiveness or changes in the material's overall properties, limiting the long-term reliability and applicability of these smart polymers.

Scalability and cost-effectiveness present further hurdles in the development of responsive polypropylene materials. While laboratory-scale production may yield promising results, translating these into large-scale manufacturing processes that are economically viable remains challenging. The cost of specialized responsive additives and the potential need for modified processing techniques can significantly impact the commercial feasibility of these materials.

Compatibility issues between polypropylene and responsive additives also present ongoing challenges. Ensuring uniform dispersion of additives within the polymer matrix and preventing phase separation or aggregation is crucial for consistent performance. Additionally, the hydrophobic nature of polypropylene can sometimes conflict with the hydrophilic characteristics of certain responsive additives, necessitating careful selection and modification of components.

Lastly, the complexity of multi-responsive systems poses a significant challenge. Developing polypropylene materials that can respond intelligently to multiple environmental stimuli simultaneously, or in a predetermined sequence, requires intricate molecular design and engineering. Achieving this level of sophistication while maintaining other desirable properties of the polymer remains a formidable task for researchers in the field.

Another major challenge lies in maintaining the mechanical properties of polypropylene while incorporating responsive additives. The addition of these components often leads to a trade-off between responsiveness and the polymer's inherent strength, flexibility, or durability. Balancing these competing properties to create materials that are both highly responsive and mechanically robust is an ongoing struggle for researchers and engineers.

Stability and longevity of responsive polypropylene systems pose additional challenges. Many responsive additives are susceptible to degradation over time, especially when exposed to harsh environmental conditions or repeated stimulation cycles. This can lead to a gradual loss of responsiveness or changes in the material's overall properties, limiting the long-term reliability and applicability of these smart polymers.

Scalability and cost-effectiveness present further hurdles in the development of responsive polypropylene materials. While laboratory-scale production may yield promising results, translating these into large-scale manufacturing processes that are economically viable remains challenging. The cost of specialized responsive additives and the potential need for modified processing techniques can significantly impact the commercial feasibility of these materials.

Compatibility issues between polypropylene and responsive additives also present ongoing challenges. Ensuring uniform dispersion of additives within the polymer matrix and preventing phase separation or aggregation is crucial for consistent performance. Additionally, the hydrophobic nature of polypropylene can sometimes conflict with the hydrophilic characteristics of certain responsive additives, necessitating careful selection and modification of components.

Lastly, the complexity of multi-responsive systems poses a significant challenge. Developing polypropylene materials that can respond intelligently to multiple environmental stimuli simultaneously, or in a predetermined sequence, requires intricate molecular design and engineering. Achieving this level of sophistication while maintaining other desirable properties of the polymer remains a formidable task for researchers in the field.

Existing Responsive Polypropylene Solutions

01 Environment-responsive polypropylene composites

Development of polypropylene-based composites that respond to environmental stimuli such as temperature, pH, or light. These materials can change their properties or behavior in response to external triggers, making them suitable for smart packaging, sensors, or adaptive structures.- Environment-responsive polypropylene composites: Development of polypropylene-based composites that respond to environmental stimuli such as temperature, pH, or light. These materials can change their properties or behavior in response to external triggers, making them suitable for smart packaging, sensors, or adaptive structures.

- Biodegradable polypropylene blends: Creation of biodegradable polypropylene blends by incorporating natural or synthetic biodegradable polymers. These blends aim to reduce environmental impact while maintaining the desirable properties of polypropylene, suitable for packaging and disposable products.

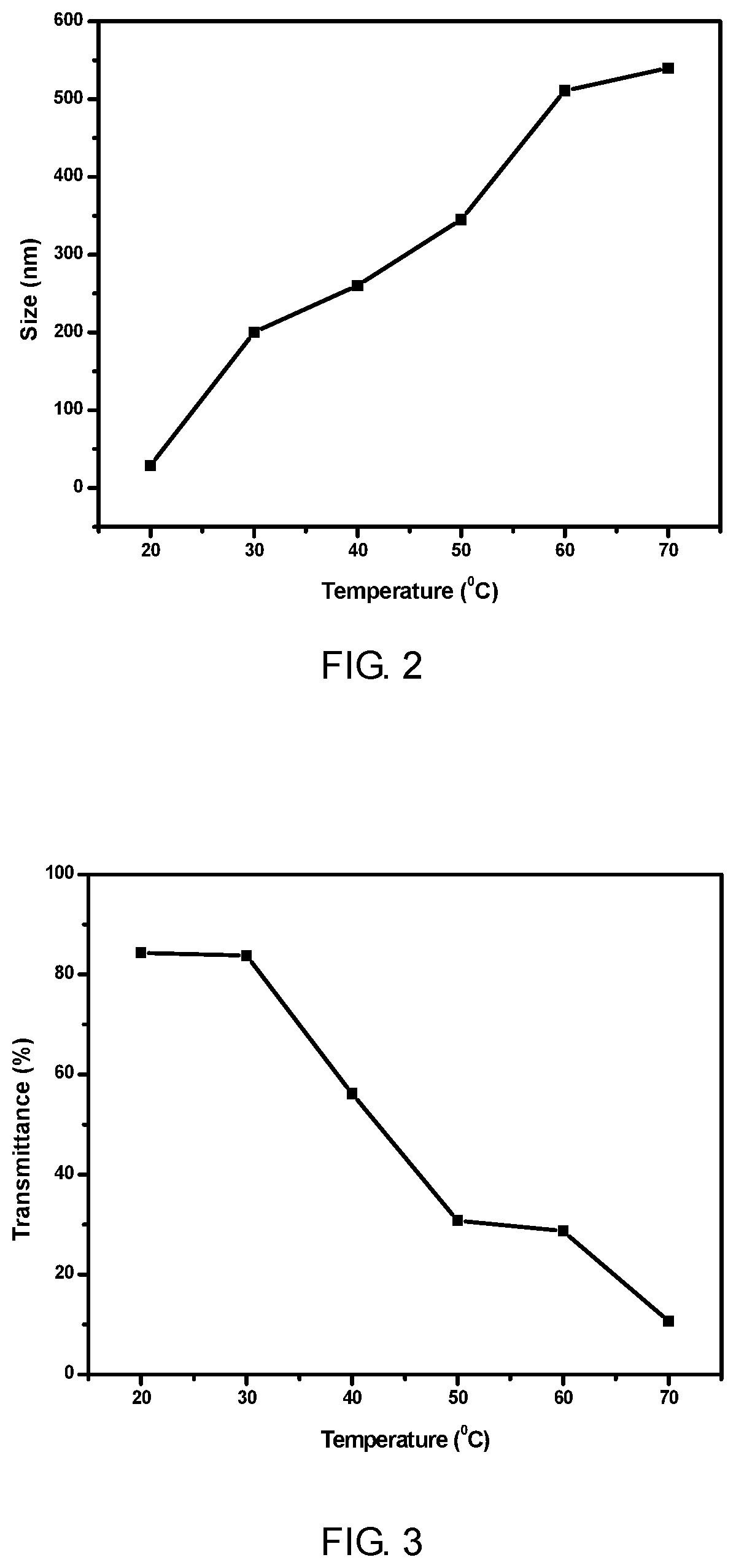

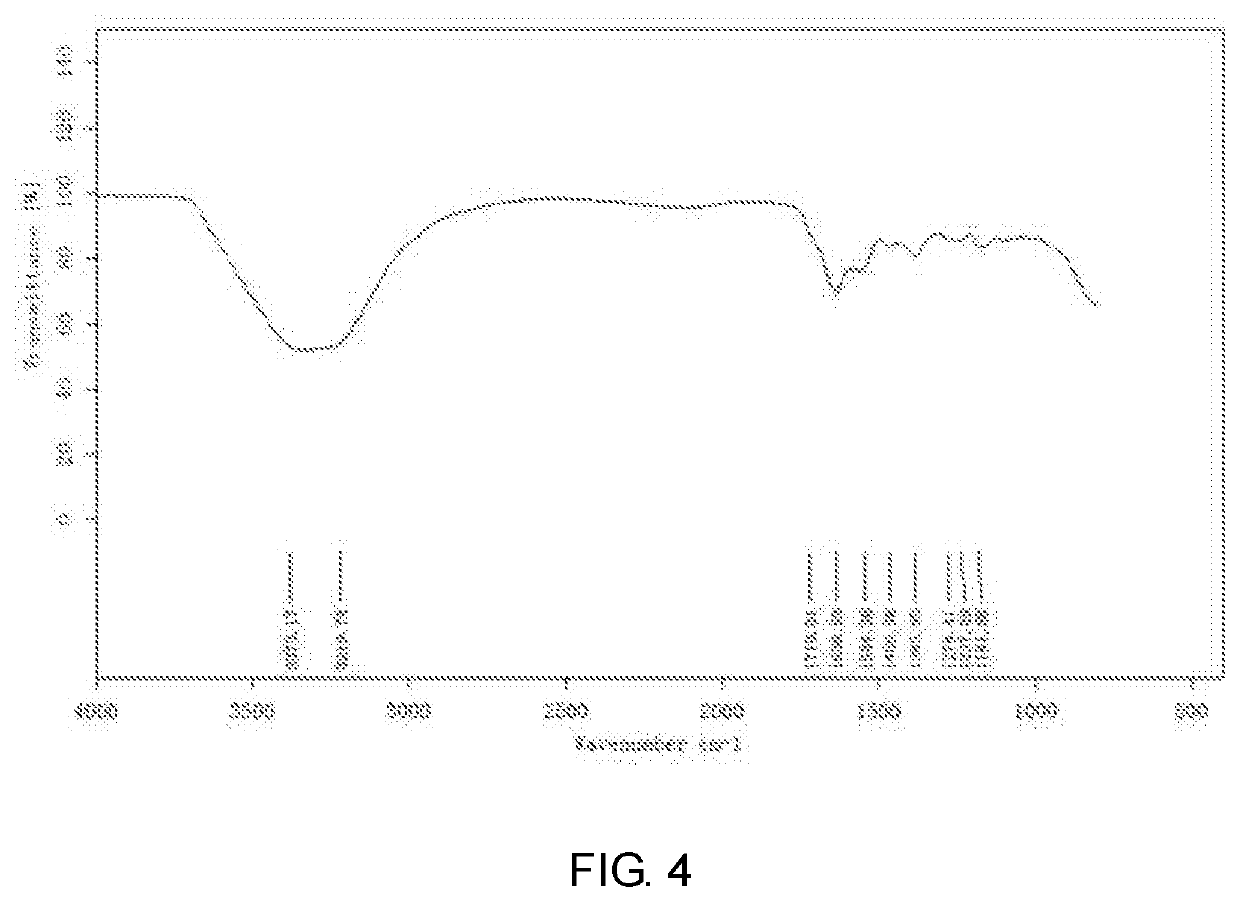

- Polypropylene with improved thermal responsiveness: Development of polypropylene formulations with enhanced thermal responsiveness, including shape memory properties or temperature-dependent mechanical behavior. These materials can be used in applications such as self-adjusting seals, temperature-controlled valves, or smart textiles.

- Polypropylene-based smart packaging: Creation of intelligent packaging systems using polypropylene as the base material, incorporating sensors or indicators that respond to environmental conditions such as temperature, humidity, or gas composition. These packaging solutions can monitor product freshness or integrity.

- Polypropylene with self-healing properties: Development of polypropylene materials with self-healing capabilities, able to repair minor damage or cracks autonomously in response to environmental triggers. These materials can extend the lifespan of products and improve their durability in various applications.

02 Biodegradable polypropylene blends

Creation of biodegradable polypropylene blends by incorporating natural fibers, biodegradable additives, or other environmentally friendly components. These blends aim to reduce the environmental impact of polypropylene while maintaining its desirable properties.Expand Specific Solutions03 Temperature-responsive polypropylene films

Development of polypropylene films that exhibit temperature-dependent properties, such as changes in permeability, opacity, or mechanical strength. These films can be used in smart packaging applications or temperature-sensitive devices.Expand Specific Solutions04 Polypropylene-based shape memory polymers

Creation of polypropylene-based shape memory polymers that can change their shape in response to environmental stimuli like temperature or light. These materials have potential applications in self-adjusting components, actuators, or smart textiles.Expand Specific Solutions05 Polypropylene nanocomposites with enhanced properties

Development of polypropylene nanocomposites incorporating nanomaterials to enhance specific properties such as mechanical strength, barrier properties, or electrical conductivity. These nanocomposites can exhibit improved performance in various environmental conditions.Expand Specific Solutions

Key Players in Smart Polymer Industry

The competitive landscape for environment responsive additives affecting polypropylene polymers is characterized by a mature market with significant growth potential. The global market size for these additives is expanding, driven by increasing demand for advanced polymer materials across various industries. Technologically, the field is evolving rapidly, with companies like Total Petrochemicals, Borealis AG, and SABIC Global Technologies leading innovation. These firms, along with others such as Kingfa Sci. & Tech. and DuPont de Nemours, are investing heavily in R&D to develop more efficient and sustainable additives. The market is seeing a shift towards eco-friendly solutions, with companies like Milliken & Co. focusing on environmentally responsive technologies. As the industry progresses, collaboration between academic institutions and corporations is becoming increasingly crucial for breakthrough developments.

SABIC Global Technologies BV

Technical Solution: SABIC has developed innovative environment responsive additives for polypropylene polymers, focusing on enhancing material performance in varying conditions. Their technology incorporates smart additives that respond to environmental stimuli such as temperature, humidity, or pH changes. These additives can alter the polymer's properties dynamically, improving its adaptability and functionality. For instance, SABIC's thermo-responsive additives can modify the polymer's stiffness or permeability based on temperature fluctuations[1]. They have also explored moisture-sensitive additives that can adjust the polymer's barrier properties in response to humidity levels[2]. Additionally, SABIC has investigated pH-responsive additives that can trigger controlled release mechanisms in specific environments, potentially useful for packaging or biomedical applications[3].

Strengths: Highly adaptable materials suitable for diverse applications; improved product performance in varying conditions; potential for smart packaging and biomedical uses. Weaknesses: Complexity in manufacturing process; potential higher costs; may require specialized processing equipment.

Borealis AG

Technical Solution: Borealis AG has made significant strides in developing environment responsive additives for polypropylene polymers. Their approach focuses on creating multi-functional additive systems that can respond to various environmental factors simultaneously. Borealis has developed a proprietary technology called "Smart Additive Technology" (SAT) that incorporates nano-scale sensors within the polymer matrix[4]. These sensors can detect changes in temperature, light exposure, and mechanical stress, triggering specific responses in the material. For example, their UV-responsive additives can increase the polymer's UV resistance when exposed to sunlight, extending the material's lifespan in outdoor applications[5]. Borealis has also explored thermo-chromic additives that change the polymer's color in response to temperature variations, useful for temperature-sensitive packaging or safety indicators[6].

Strengths: Advanced multi-functional responsive systems; improved material longevity and performance; potential for smart packaging and safety applications. Weaknesses: Higher production costs; potential regulatory challenges due to nano-scale additives; may require specialized processing and quality control measures.

Core Innovations in Additive Technology

End-group functionalized comb structure polycarboxylic acid and method for preparing the same

PatentActiveUS20200216619A1

Innovation

- A comb structure temperature/pH-responsive polycarboxylic acid material is synthesized through self-polymerization, substitution, and co-polymerization, featuring end-group functionalization and a unique molecular structure that allows for temperature and pH-responsive properties, enhancing anchorage adsorption and hydrophilic/hydrophobic conversion within cement concrete.

Environmental Impact Assessment

The incorporation of environment responsive additives into polypropylene polymers has significant implications for environmental impact assessment. These additives can alter the polymer's behavior in response to environmental stimuli, potentially affecting its lifecycle and ecological footprint.

One of the primary environmental considerations is the impact on biodegradability. Some environment responsive additives can enhance the biodegradation rate of polypropylene, which is traditionally resistant to natural decomposition. This can lead to reduced persistence of plastic waste in ecosystems, particularly in marine environments where plastic pollution is a critical issue. However, the accelerated breakdown may also result in the release of microplastics, necessitating careful evaluation of the long-term environmental consequences.

The production process of these modified polymers also warrants scrutiny. The synthesis of environment responsive additives may involve complex chemical processes, potentially increasing the overall energy consumption and carbon footprint of the manufacturing phase. It is crucial to conduct a comprehensive life cycle assessment to determine whether the environmental benefits of the final product outweigh the additional resources required for production.

Recycling capabilities are another key aspect of environmental impact. Some additives may improve the recyclability of polypropylene by enhancing its thermal stability or compatibility with other materials in the recycling stream. Conversely, certain additives could complicate existing recycling processes, potentially leading to contamination or reduced quality of recycled materials. This highlights the need for developing specialized recycling technologies tailored to these modified polymers.

The potential for leaching of additives from the polymer matrix into the environment must also be considered. While some additives are designed to respond to specific environmental triggers, unintended release could occur under various conditions. This may lead to soil or water contamination, affecting ecosystems and potentially entering the food chain. Rigorous testing protocols are essential to assess the stability of these additives within the polymer structure across a range of environmental conditions.

Furthermore, the end-of-life scenarios for products containing these modified polymers require careful consideration. If the additives promote faster degradation, it could lead to premature product failure, potentially increasing waste generation. Conversely, if the additives extend the product lifespan, it could reduce the frequency of replacement and associated waste.

In conclusion, the environmental impact assessment of environment responsive additives in polypropylene polymers is a complex, multifaceted process. It requires a holistic approach that considers the entire lifecycle of the material, from production to disposal, and its interactions with various ecosystems. While these additives offer potential benefits in terms of biodegradability and recycling, their overall environmental impact must be carefully evaluated to ensure that they contribute positively to sustainability goals.

One of the primary environmental considerations is the impact on biodegradability. Some environment responsive additives can enhance the biodegradation rate of polypropylene, which is traditionally resistant to natural decomposition. This can lead to reduced persistence of plastic waste in ecosystems, particularly in marine environments where plastic pollution is a critical issue. However, the accelerated breakdown may also result in the release of microplastics, necessitating careful evaluation of the long-term environmental consequences.

The production process of these modified polymers also warrants scrutiny. The synthesis of environment responsive additives may involve complex chemical processes, potentially increasing the overall energy consumption and carbon footprint of the manufacturing phase. It is crucial to conduct a comprehensive life cycle assessment to determine whether the environmental benefits of the final product outweigh the additional resources required for production.

Recycling capabilities are another key aspect of environmental impact. Some additives may improve the recyclability of polypropylene by enhancing its thermal stability or compatibility with other materials in the recycling stream. Conversely, certain additives could complicate existing recycling processes, potentially leading to contamination or reduced quality of recycled materials. This highlights the need for developing specialized recycling technologies tailored to these modified polymers.

The potential for leaching of additives from the polymer matrix into the environment must also be considered. While some additives are designed to respond to specific environmental triggers, unintended release could occur under various conditions. This may lead to soil or water contamination, affecting ecosystems and potentially entering the food chain. Rigorous testing protocols are essential to assess the stability of these additives within the polymer structure across a range of environmental conditions.

Furthermore, the end-of-life scenarios for products containing these modified polymers require careful consideration. If the additives promote faster degradation, it could lead to premature product failure, potentially increasing waste generation. Conversely, if the additives extend the product lifespan, it could reduce the frequency of replacement and associated waste.

In conclusion, the environmental impact assessment of environment responsive additives in polypropylene polymers is a complex, multifaceted process. It requires a holistic approach that considers the entire lifecycle of the material, from production to disposal, and its interactions with various ecosystems. While these additives offer potential benefits in terms of biodegradability and recycling, their overall environmental impact must be carefully evaluated to ensure that they contribute positively to sustainability goals.

Regulatory Framework for Smart Materials

The regulatory framework for smart materials, including environment responsive additives in polypropylene polymers, is a complex and evolving landscape. As these innovative materials gain traction in various industries, governments and regulatory bodies are working to establish guidelines that ensure their safe use and environmental compatibility.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating smart materials under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices for new chemical substances, including environment responsive additives. This process allows the EPA to assess potential risks and determine if further regulation is necessary.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to smart materials and their components. Under REACH, manufacturers must register substances produced or imported in quantities over one tonne per year and provide safety data. This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

In Japan, the Chemical Substances Control Law (CSCL) governs the regulation of new chemical substances, including those used in smart materials. Manufacturers must notify the government before producing or importing new chemicals, allowing for risk assessment and potential restrictions.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, are developing guidelines for the characterization and testing of smart materials. These standards help ensure consistency in product development and facilitate global trade.

As the field of environment responsive additives in polypropylene polymers advances, regulatory frameworks are adapting to address specific concerns. For instance, the potential for these materials to release substances into the environment under certain conditions is a key focus area. Regulators are working to establish protocols for assessing the long-term stability and environmental impact of these materials.

The food contact materials sector is particularly sensitive to the use of smart materials. In the EU, the European Food Safety Authority (EFSA) evaluates the safety of substances used in food contact materials, including environment responsive additives. Similar regulations exist in other regions, such as the FDA's oversight in the United States.

As the technology progresses, regulatory bodies are likely to implement more specific guidelines for environment responsive additives in polypropylene polymers. This may include requirements for lifecycle assessments, biodegradability studies, and specific labeling requirements to inform consumers about the presence and properties of these smart materials.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating smart materials under the Toxic Substances Control Act (TSCA). The TSCA requires manufacturers to submit premanufacture notices for new chemical substances, including environment responsive additives. This process allows the EPA to assess potential risks and determine if further regulation is necessary.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to smart materials and their components. Under REACH, manufacturers must register substances produced or imported in quantities over one tonne per year and provide safety data. This regulation aims to protect human health and the environment while promoting innovation in the chemical industry.

In Japan, the Chemical Substances Control Law (CSCL) governs the regulation of new chemical substances, including those used in smart materials. Manufacturers must notify the government before producing or importing new chemicals, allowing for risk assessment and potential restrictions.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, are developing guidelines for the characterization and testing of smart materials. These standards help ensure consistency in product development and facilitate global trade.

As the field of environment responsive additives in polypropylene polymers advances, regulatory frameworks are adapting to address specific concerns. For instance, the potential for these materials to release substances into the environment under certain conditions is a key focus area. Regulators are working to establish protocols for assessing the long-term stability and environmental impact of these materials.

The food contact materials sector is particularly sensitive to the use of smart materials. In the EU, the European Food Safety Authority (EFSA) evaluates the safety of substances used in food contact materials, including environment responsive additives. Similar regulations exist in other regions, such as the FDA's oversight in the United States.

As the technology progresses, regulatory bodies are likely to implement more specific guidelines for environment responsive additives in polypropylene polymers. This may include requirements for lifecycle assessments, biodegradability studies, and specific labeling requirements to inform consumers about the presence and properties of these smart materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!