How High-Precision 3D Printing Uses Polypropylene Filaments

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Printing Evolution and Precision Goals

3D printing technology has undergone a remarkable evolution since its inception in the 1980s. Initially limited to rapid prototyping, it has now expanded into various industries, including aerospace, automotive, healthcare, and consumer goods. The journey of 3D printing has been marked by continuous improvements in precision, speed, and material versatility.

The early stages of 3D printing focused on basic plastic extrusion techniques, offering limited resolution and material options. As the technology progressed, new methods such as stereolithography (SLA) and selective laser sintering (SLS) emerged, enabling higher precision and the use of a broader range of materials, including metals and ceramics.

In recent years, the focus has shifted towards achieving high-precision 3D printing, particularly in industries requiring intricate and accurate parts. This drive for precision has led to the development of advanced techniques like digital light processing (DLP) and continuous liquid interface production (CLIP), which can produce parts with micron-level accuracy.

The use of polypropylene filaments in high-precision 3D printing represents a significant milestone in this evolutionary journey. Polypropylene, known for its durability, chemical resistance, and flexibility, has long been a challenging material for 3D printing due to its tendency to warp and poor layer adhesion. Overcoming these challenges to achieve high-precision printing with polypropylene has been a key goal in recent years.

The precision goals for 3D printing with polypropylene filaments are multifaceted. They include achieving sub-micron resolution, ensuring dimensional accuracy across complex geometries, and maintaining consistent material properties throughout the printed part. Additionally, there is a focus on improving surface finish quality, reducing post-processing requirements, and enhancing the overall structural integrity of printed objects.

Another critical objective is to increase the speed of high-precision printing without compromising quality. This involves optimizing printer hardware, developing advanced slicing algorithms, and fine-tuning the properties of polypropylene filaments to behave predictably under various printing conditions.

As the technology continues to advance, the ultimate goal is to achieve a level of precision with polypropylene filaments that rivals or surpasses traditional manufacturing methods. This would enable the production of complex, functional parts with tight tolerances directly from digital designs, opening up new possibilities in rapid manufacturing and customization across various industries.

The early stages of 3D printing focused on basic plastic extrusion techniques, offering limited resolution and material options. As the technology progressed, new methods such as stereolithography (SLA) and selective laser sintering (SLS) emerged, enabling higher precision and the use of a broader range of materials, including metals and ceramics.

In recent years, the focus has shifted towards achieving high-precision 3D printing, particularly in industries requiring intricate and accurate parts. This drive for precision has led to the development of advanced techniques like digital light processing (DLP) and continuous liquid interface production (CLIP), which can produce parts with micron-level accuracy.

The use of polypropylene filaments in high-precision 3D printing represents a significant milestone in this evolutionary journey. Polypropylene, known for its durability, chemical resistance, and flexibility, has long been a challenging material for 3D printing due to its tendency to warp and poor layer adhesion. Overcoming these challenges to achieve high-precision printing with polypropylene has been a key goal in recent years.

The precision goals for 3D printing with polypropylene filaments are multifaceted. They include achieving sub-micron resolution, ensuring dimensional accuracy across complex geometries, and maintaining consistent material properties throughout the printed part. Additionally, there is a focus on improving surface finish quality, reducing post-processing requirements, and enhancing the overall structural integrity of printed objects.

Another critical objective is to increase the speed of high-precision printing without compromising quality. This involves optimizing printer hardware, developing advanced slicing algorithms, and fine-tuning the properties of polypropylene filaments to behave predictably under various printing conditions.

As the technology continues to advance, the ultimate goal is to achieve a level of precision with polypropylene filaments that rivals or surpasses traditional manufacturing methods. This would enable the production of complex, functional parts with tight tolerances directly from digital designs, opening up new possibilities in rapid manufacturing and customization across various industries.

Market Demand for High-Precision PP 3D Printing

The market demand for high-precision polypropylene (PP) 3D printing has been steadily growing, driven by the unique properties of PP and the increasing need for complex, customized parts across various industries. PP's excellent chemical resistance, fatigue resistance, and low density make it an attractive material for applications ranging from automotive components to consumer goods and medical devices.

In the automotive sector, there is a rising demand for lightweight, durable parts that can withstand harsh environments. High-precision PP 3D printing enables the production of complex geometries with tight tolerances, allowing for the creation of functional prototypes and end-use parts. This technology is particularly valuable for producing small batches of customized components, reducing tooling costs and lead times compared to traditional manufacturing methods.

The medical industry has also shown significant interest in high-precision PP 3D printing. The biocompatibility and sterilizability of PP make it suitable for producing medical devices, surgical guides, and anatomical models. The ability to create patient-specific implants and prosthetics with intricate internal structures has opened new possibilities for personalized healthcare solutions.

Consumer goods manufacturers are leveraging high-precision PP 3D printing to develop innovative products with improved functionality and aesthetics. The technology allows for rapid prototyping and iterative design, enabling companies to bring products to market faster and respond more quickly to changing consumer preferences. Additionally, the ability to produce small batches economically has facilitated the growth of customized and limited-edition product offerings.

The packaging industry is exploring high-precision PP 3D printing for creating molds and prototypes for packaging designs. This approach allows for quick validation of concepts and reduces the time and cost associated with traditional mold-making processes. The technology also enables the production of complex, lightweight packaging solutions that can enhance product protection while reducing material usage.

As sustainability concerns grow, the recyclability of PP has become an important factor driving market demand. High-precision 3D printing with PP allows for the creation of products with optimized designs that use less material while maintaining or improving performance. This aligns with the increasing focus on circular economy principles and the need for more environmentally friendly manufacturing processes.

The market for high-precision PP 3D printing is expected to continue expanding as the technology matures and becomes more accessible. Improvements in printing speed, resolution, and material properties are likely to further broaden the range of applications and industries that can benefit from this technology. As a result, the demand for specialized PP filaments, advanced 3D printers, and related services is projected to grow significantly in the coming years.

In the automotive sector, there is a rising demand for lightweight, durable parts that can withstand harsh environments. High-precision PP 3D printing enables the production of complex geometries with tight tolerances, allowing for the creation of functional prototypes and end-use parts. This technology is particularly valuable for producing small batches of customized components, reducing tooling costs and lead times compared to traditional manufacturing methods.

The medical industry has also shown significant interest in high-precision PP 3D printing. The biocompatibility and sterilizability of PP make it suitable for producing medical devices, surgical guides, and anatomical models. The ability to create patient-specific implants and prosthetics with intricate internal structures has opened new possibilities for personalized healthcare solutions.

Consumer goods manufacturers are leveraging high-precision PP 3D printing to develop innovative products with improved functionality and aesthetics. The technology allows for rapid prototyping and iterative design, enabling companies to bring products to market faster and respond more quickly to changing consumer preferences. Additionally, the ability to produce small batches economically has facilitated the growth of customized and limited-edition product offerings.

The packaging industry is exploring high-precision PP 3D printing for creating molds and prototypes for packaging designs. This approach allows for quick validation of concepts and reduces the time and cost associated with traditional mold-making processes. The technology also enables the production of complex, lightweight packaging solutions that can enhance product protection while reducing material usage.

As sustainability concerns grow, the recyclability of PP has become an important factor driving market demand. High-precision 3D printing with PP allows for the creation of products with optimized designs that use less material while maintaining or improving performance. This aligns with the increasing focus on circular economy principles and the need for more environmentally friendly manufacturing processes.

The market for high-precision PP 3D printing is expected to continue expanding as the technology matures and becomes more accessible. Improvements in printing speed, resolution, and material properties are likely to further broaden the range of applications and industries that can benefit from this technology. As a result, the demand for specialized PP filaments, advanced 3D printers, and related services is projected to grow significantly in the coming years.

Challenges in High-Precision PP 3D Printing

High-precision 3D printing with polypropylene (PP) filaments presents several significant challenges that researchers and manufacturers must overcome to achieve optimal results. One of the primary obstacles is the inherent properties of polypropylene itself. PP has a high shrinkage rate and tends to warp during cooling, which can lead to dimensional inaccuracies and poor layer adhesion in printed parts.

The low surface energy of polypropylene also makes it difficult to achieve proper bed adhesion, a crucial factor in high-precision printing. Without strong adhesion to the print bed, parts are prone to detachment or warping during the printing process, compromising the overall precision and quality of the final product.

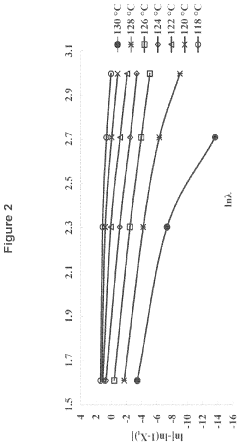

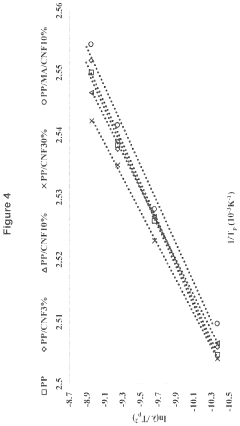

Temperature control is another critical challenge in high-precision PP 3D printing. Polypropylene has a narrow processing window, requiring precise temperature management throughout the printing process. Maintaining consistent temperatures across the entire print bed and throughout the duration of the print can be particularly challenging, especially for large or complex parts.

The flow behavior of molten polypropylene presents additional difficulties. PP has a high melt flow index, which can lead to inconsistent extrusion and potential stringing or oozing during printing. This behavior can result in reduced surface quality and dimensional accuracy, particularly in areas with fine details or intricate geometries.

Achieving high-precision prints with PP also requires careful consideration of print speed and cooling rates. Printing too quickly can lead to poor layer adhesion and reduced structural integrity, while printing too slowly may exacerbate warping issues. Balancing these factors to optimize both print quality and production efficiency is a significant challenge.

The hygroscopic nature of polypropylene filaments adds another layer of complexity to high-precision printing. Moisture absorption can lead to inconsistent extrusion, bubbling, and reduced mechanical properties in the printed parts. Proper storage and handling of PP filaments are essential to maintain their quality and ensure consistent print results.

Lastly, the limited availability of specialized PP filaments and compatible printing equipment poses a challenge for widespread adoption of high-precision PP 3D printing. Many standard 3D printers and materials are not optimized for use with polypropylene, requiring significant modifications or investments in specialized hardware to achieve the desired level of precision.

Overcoming these challenges requires a multifaceted approach, combining advancements in material science, printer hardware, and printing techniques. Researchers and manufacturers are actively working on developing improved PP filament formulations, specialized print surfaces, and optimized printing parameters to address these issues and unlock the full potential of high-precision polypropylene 3D printing.

The low surface energy of polypropylene also makes it difficult to achieve proper bed adhesion, a crucial factor in high-precision printing. Without strong adhesion to the print bed, parts are prone to detachment or warping during the printing process, compromising the overall precision and quality of the final product.

Temperature control is another critical challenge in high-precision PP 3D printing. Polypropylene has a narrow processing window, requiring precise temperature management throughout the printing process. Maintaining consistent temperatures across the entire print bed and throughout the duration of the print can be particularly challenging, especially for large or complex parts.

The flow behavior of molten polypropylene presents additional difficulties. PP has a high melt flow index, which can lead to inconsistent extrusion and potential stringing or oozing during printing. This behavior can result in reduced surface quality and dimensional accuracy, particularly in areas with fine details or intricate geometries.

Achieving high-precision prints with PP also requires careful consideration of print speed and cooling rates. Printing too quickly can lead to poor layer adhesion and reduced structural integrity, while printing too slowly may exacerbate warping issues. Balancing these factors to optimize both print quality and production efficiency is a significant challenge.

The hygroscopic nature of polypropylene filaments adds another layer of complexity to high-precision printing. Moisture absorption can lead to inconsistent extrusion, bubbling, and reduced mechanical properties in the printed parts. Proper storage and handling of PP filaments are essential to maintain their quality and ensure consistent print results.

Lastly, the limited availability of specialized PP filaments and compatible printing equipment poses a challenge for widespread adoption of high-precision PP 3D printing. Many standard 3D printers and materials are not optimized for use with polypropylene, requiring significant modifications or investments in specialized hardware to achieve the desired level of precision.

Overcoming these challenges requires a multifaceted approach, combining advancements in material science, printer hardware, and printing techniques. Researchers and manufacturers are actively working on developing improved PP filament formulations, specialized print surfaces, and optimized printing parameters to address these issues and unlock the full potential of high-precision polypropylene 3D printing.

Current PP Filament Printing Techniques

01 Precision manufacturing of polypropylene filaments

Advanced manufacturing techniques are employed to produce polypropylene filaments with high precision. These methods involve careful control of extrusion parameters, drawing processes, and cooling conditions to achieve consistent filament diameter, cross-sectional shape, and surface quality. Precision manufacturing enables the production of filaments with specific properties suitable for various applications.- Precision manufacturing of polypropylene filaments: Advanced manufacturing techniques are employed to produce polypropylene filaments with high precision. These methods involve careful control of extrusion parameters, drawing processes, and cooling conditions to achieve consistent filament diameter, cross-sectional shape, and surface characteristics. Precision manufacturing enables the production of filaments with specific properties suitable for various applications.

- Polypropylene filament composition and additives: The composition of polypropylene filaments can be modified with various additives to enhance their properties. These additives may include stabilizers, colorants, flame retardants, or performance-enhancing agents. The precise formulation of the polymer blend and the incorporation of specific additives can significantly impact the filament's mechanical, thermal, and chemical properties, allowing for customization to meet specific application requirements.

- Polypropylene filament surface treatment and modification: Surface treatment and modification techniques are applied to polypropylene filaments to improve their performance characteristics. These processes may include plasma treatment, chemical etching, or the application of functional coatings. Such modifications can enhance properties like adhesion, wettability, or biocompatibility, expanding the range of potential applications for polypropylene filaments.

- Precision control in polypropylene filament production equipment: Specialized equipment and machinery are developed to ensure precise control during the production of polypropylene filaments. These systems may incorporate advanced sensors, real-time monitoring, and feedback mechanisms to maintain consistent filament properties throughout the manufacturing process. Precision control equipment enables the production of high-quality filaments with minimal variations in physical and mechanical characteristics.

- Applications of precision polypropylene filaments: Precision-manufactured polypropylene filaments find applications in various industries due to their controlled properties. These applications may include textiles, medical devices, filtration systems, and 3D printing. The ability to produce filaments with precise dimensions and characteristics allows for their use in demanding applications where consistency and reliability are crucial.

02 Polypropylene filament composition and additives

The composition of polypropylene filaments can be modified with various additives to enhance their properties. These additives may include stabilizers, colorants, flame retardants, or performance-enhancing agents. The precise formulation of the polymer blend and the incorporation of specific additives can significantly influence the filament's mechanical, thermal, and chemical properties, allowing for customization to meet specific application requirements.Expand Specific Solutions03 Specialized equipment for polypropylene filament production

Customized machinery and equipment are developed for the production of high-precision polypropylene filaments. These may include advanced spinnerets, precision control systems, and specialized drawing units. The equipment is designed to maintain tight tolerances and ensure consistency in filament properties throughout the production process.Expand Specific Solutions04 Quality control and testing of polypropylene filaments

Rigorous quality control measures and testing procedures are implemented to ensure the precision of polypropylene filaments. This includes in-line monitoring systems, advanced measurement techniques, and comprehensive testing of mechanical and physical properties. Quality control processes help maintain consistency and meet stringent specifications for various applications.Expand Specific Solutions05 Applications of precision polypropylene filaments

High-precision polypropylene filaments find applications in various industries. These may include textiles, filtration, medical devices, and technical fabrics. The precise control of filament properties allows for the development of specialized products with enhanced performance characteristics, such as improved strength, uniformity, or specific functional properties.Expand Specific Solutions

Key Players in High-Precision 3D Printing

The high-precision 3D printing market using polypropylene filaments is in a growth phase, with increasing demand across various industries. The market size is expanding as more companies recognize the potential of this technology for producing complex, durable parts. Technologically, the field is advancing rapidly, with key players like Wanhua Chemical Group, Basell Polyolefine, and Braskem America driving innovation in filament development. These companies are focusing on improving the material properties and printability of polypropylene, addressing challenges such as warping and adhesion. Universities like ITB and the University of Maine are contributing to research and development, further accelerating the technology's maturity and application scope.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies has developed a comprehensive approach to high-precision 3D printing with polypropylene filaments. Their technology combines material science innovations with advanced printing techniques. Dow has formulated a range of polypropylene grades specifically engineered for 3D printing, featuring enhanced melt flow properties and reduced shrinkage [2]. These materials are complemented by a proprietary surface treatment process that improves bed adhesion, a common challenge with polypropylene [4]. Dow's printing system incorporates a heated build chamber and a specialized extruder design that maintains precise temperature control throughout the printing process, ensuring consistent material flow and layer bonding [6]. The company has also developed software algorithms that optimize print parameters in real-time based on part geometry and ambient conditions, resulting in improved dimensional accuracy and surface finish.

Strengths: Comprehensive material and process expertise, wide range of tailored polypropylene grades. Weaknesses: May require significant investment in specialized equipment and materials.

Braskem America, Inc.

Technical Solution: Braskem America has developed an innovative approach to high-precision 3D printing with polypropylene filaments, leveraging their expertise as a major polypropylene producer. Their technology focuses on tailoring the molecular structure of polypropylene for optimal 3D printing performance. Braskem has engineered a range of polypropylene grades with controlled molecular weight distribution and tacticity, resulting in improved melt flow characteristics and reduced warping tendency [1]. Their printing process incorporates a specialized extrusion system with precise temperature zoning, ensuring consistent material properties from filament to printed part [3]. Braskem has also developed a proprietary bed adhesion solution that addresses one of the key challenges in polypropylene printing without compromising the material's inherent properties [5]. The company's software platform includes advanced toolpath generation algorithms that optimize for polypropylene's unique flow behavior, resulting in improved surface finish and mechanical properties.

Strengths: Deep material expertise, tailored polypropylene grades, comprehensive printing solution. Weaknesses: May be focused primarily on material development, potential limitations in hardware innovations.

Innovations in PP Filament Composition

Propylene terpolymer for filament for 3D printer

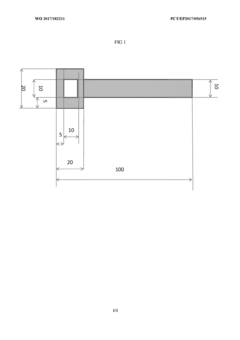

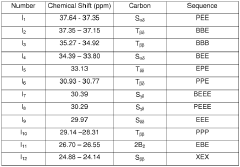

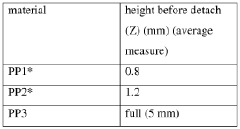

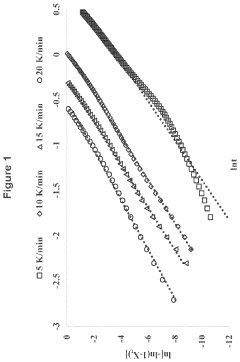

PatentWO2017182211A1

Innovation

- A consumable filament comprising a propylene terpolymer with ethylene and 1-butene or 1-hexene as comonomers, with specific Melt Flow Rate and xylene solubles ranges, is developed to ensure consistent extrusion and improved mechanical properties, allowing for the creation of filaments with constant diameters like 1.75 mm or 3 mm, and potentially incorporating additives for enhanced performance.

Filaments for 3D printing

PatentActiveUS11873582B2

Innovation

- A composite material comprising a polymer matrix blend of polypropylene (PP) and polyethylene (PE) with natural cellulosic nanofibers is developed, which slows crystallization rates and enhances mechanical properties, allowing for improved dimensional stability and reduced shrinkage during the 3D printing process.

Environmental Impact of PP 3D Printing

The environmental impact of 3D printing with polypropylene (PP) filaments is a complex issue that requires careful consideration. While 3D printing technology offers potential benefits in terms of reduced waste and localized production, the use of PP filaments presents both advantages and challenges from an environmental perspective.

PP is a thermoplastic polymer known for its durability, chemical resistance, and recyclability. When used in high-precision 3D printing, PP filaments can contribute to the production of long-lasting, lightweight parts that may replace more resource-intensive materials. This potential for material efficiency and product longevity can lead to reduced overall environmental impact throughout the lifecycle of printed objects.

However, the production of PP filaments itself involves energy-intensive processes and the use of fossil fuel-based raw materials. The environmental footprint of PP production includes greenhouse gas emissions, water consumption, and potential chemical pollutants. As 3D printing with PP becomes more widespread, the cumulative impact of increased filament production must be carefully monitored and mitigated.

One significant environmental concern is the disposal of PP 3D printed objects at the end of their life cycle. While PP is theoretically recyclable, the reality of recycling 3D printed PP parts is complicated by factors such as material purity, additives used in filaments, and the lack of widespread recycling infrastructure for 3D printed materials. Improper disposal can lead to plastic pollution, particularly in marine environments where PP's buoyancy allows it to persist and potentially harm wildlife.

On the positive side, high-precision 3D printing with PP can contribute to more efficient manufacturing processes. The ability to produce complex geometries with minimal material waste can lead to optimized designs that use less material overall. Additionally, the on-demand nature of 3D printing can reduce overproduction and associated waste, potentially decreasing the environmental impact of traditional manufacturing and supply chain processes.

The energy consumption of 3D printers during the printing process is another factor to consider. While individual desktop 3D printers may not consume significant amounts of energy, the cumulative effect of widespread adoption could lead to increased energy demand. However, this may be offset by reductions in energy use from traditional manufacturing and transportation if 3D printing enables more localized production.

To mitigate the environmental impact of PP 3D printing, several strategies can be employed. These include developing more sustainable PP filament production methods, improving the recyclability of printed parts, and optimizing printer energy efficiency. Additionally, the development of bio-based or biodegradable alternatives to traditional PP filaments could further reduce the environmental footprint of 3D printing technology.

PP is a thermoplastic polymer known for its durability, chemical resistance, and recyclability. When used in high-precision 3D printing, PP filaments can contribute to the production of long-lasting, lightweight parts that may replace more resource-intensive materials. This potential for material efficiency and product longevity can lead to reduced overall environmental impact throughout the lifecycle of printed objects.

However, the production of PP filaments itself involves energy-intensive processes and the use of fossil fuel-based raw materials. The environmental footprint of PP production includes greenhouse gas emissions, water consumption, and potential chemical pollutants. As 3D printing with PP becomes more widespread, the cumulative impact of increased filament production must be carefully monitored and mitigated.

One significant environmental concern is the disposal of PP 3D printed objects at the end of their life cycle. While PP is theoretically recyclable, the reality of recycling 3D printed PP parts is complicated by factors such as material purity, additives used in filaments, and the lack of widespread recycling infrastructure for 3D printed materials. Improper disposal can lead to plastic pollution, particularly in marine environments where PP's buoyancy allows it to persist and potentially harm wildlife.

On the positive side, high-precision 3D printing with PP can contribute to more efficient manufacturing processes. The ability to produce complex geometries with minimal material waste can lead to optimized designs that use less material overall. Additionally, the on-demand nature of 3D printing can reduce overproduction and associated waste, potentially decreasing the environmental impact of traditional manufacturing and supply chain processes.

The energy consumption of 3D printers during the printing process is another factor to consider. While individual desktop 3D printers may not consume significant amounts of energy, the cumulative effect of widespread adoption could lead to increased energy demand. However, this may be offset by reductions in energy use from traditional manufacturing and transportation if 3D printing enables more localized production.

To mitigate the environmental impact of PP 3D printing, several strategies can be employed. These include developing more sustainable PP filament production methods, improving the recyclability of printed parts, and optimizing printer energy efficiency. Additionally, the development of bio-based or biodegradable alternatives to traditional PP filaments could further reduce the environmental footprint of 3D printing technology.

Quality Control in PP 3D Printing

Quality control is a critical aspect of high-precision 3D printing using polypropylene (PP) filaments. The process involves several key steps and considerations to ensure consistent and high-quality output.

One of the primary factors in quality control is the proper selection and preparation of PP filaments. The filament must meet specific requirements in terms of diameter consistency, purity, and moisture content. Prior to printing, filaments should be stored in a dry environment and may require pre-drying to remove any absorbed moisture, which can significantly affect print quality.

Temperature control is another crucial element in PP 3D printing. The printing temperature must be precisely maintained within a narrow range to achieve optimal flow and adhesion properties. This typically requires a heated build platform and carefully calibrated extruder temperatures. Monitoring and adjusting these temperatures throughout the printing process is essential for maintaining quality.

Print speed and layer height are also important parameters that need to be carefully controlled. Slower print speeds and thinner layer heights generally result in higher quality prints but at the cost of increased production time. Finding the right balance between speed and quality is a key aspect of the quality control process.

Proper bed adhesion is critical for PP printing due to its low coefficient of friction. Various bed preparation techniques, such as using specialized adhesives or textured build surfaces, are employed to ensure the first layer adheres properly. This initial layer is crucial for the overall print quality and dimensional accuracy.

Post-processing steps are often necessary to achieve the desired final product quality. These may include support removal, surface smoothing, and heat treatment to relieve internal stresses and improve mechanical properties. Each of these steps requires careful control to maintain the dimensional accuracy and structural integrity of the printed part.

Implementing a comprehensive quality management system is essential for consistent results. This includes regular calibration of equipment, standardized procedures for machine setup and operation, and thorough documentation of printing parameters for each job. Regular inspection and testing of printed parts, using methods such as dimensional measurement and mechanical testing, help ensure that quality standards are consistently met.

Advanced monitoring systems, including real-time process monitoring and machine vision systems, are increasingly being used to detect and correct issues during the printing process. These systems can identify problems such as filament jams, layer shifts, or temperature fluctuations, allowing for immediate corrective action or automatic adjustments to maintain print quality.

One of the primary factors in quality control is the proper selection and preparation of PP filaments. The filament must meet specific requirements in terms of diameter consistency, purity, and moisture content. Prior to printing, filaments should be stored in a dry environment and may require pre-drying to remove any absorbed moisture, which can significantly affect print quality.

Temperature control is another crucial element in PP 3D printing. The printing temperature must be precisely maintained within a narrow range to achieve optimal flow and adhesion properties. This typically requires a heated build platform and carefully calibrated extruder temperatures. Monitoring and adjusting these temperatures throughout the printing process is essential for maintaining quality.

Print speed and layer height are also important parameters that need to be carefully controlled. Slower print speeds and thinner layer heights generally result in higher quality prints but at the cost of increased production time. Finding the right balance between speed and quality is a key aspect of the quality control process.

Proper bed adhesion is critical for PP printing due to its low coefficient of friction. Various bed preparation techniques, such as using specialized adhesives or textured build surfaces, are employed to ensure the first layer adheres properly. This initial layer is crucial for the overall print quality and dimensional accuracy.

Post-processing steps are often necessary to achieve the desired final product quality. These may include support removal, surface smoothing, and heat treatment to relieve internal stresses and improve mechanical properties. Each of these steps requires careful control to maintain the dimensional accuracy and structural integrity of the printed part.

Implementing a comprehensive quality management system is essential for consistent results. This includes regular calibration of equipment, standardized procedures for machine setup and operation, and thorough documentation of printing parameters for each job. Regular inspection and testing of printed parts, using methods such as dimensional measurement and mechanical testing, help ensure that quality standards are consistently met.

Advanced monitoring systems, including real-time process monitoring and machine vision systems, are increasingly being used to detect and correct issues during the printing process. These systems can identify problems such as filament jams, layer shifts, or temperature fluctuations, allowing for immediate corrective action or automatic adjustments to maintain print quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!