How Graphene Additives Improve Polypropylene Graphene Containers

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene-PP Composite Evolution and Objectives

Graphene, a two-dimensional carbon allotrope, has emerged as a revolutionary material in the field of composite engineering. The integration of graphene additives into polypropylene (PP) containers represents a significant advancement in materials science, aiming to enhance the properties and performance of conventional plastic packaging. This technological evolution has been driven by the increasing demand for stronger, lighter, and more sustainable packaging solutions across various industries.

The journey of graphene-PP composites began with the discovery of graphene in 2004, which opened up new possibilities for material enhancement. Initially, the focus was on understanding the fundamental properties of graphene and its potential applications. As research progressed, scientists and engineers recognized the potential of incorporating graphene into polymer matrices, particularly polypropylene, due to its widespread use in packaging applications.

The evolution of graphene-PP composites has been marked by several key milestones. Early experiments focused on developing effective methods for dispersing graphene within the PP matrix, a critical challenge due to the tendency of graphene sheets to agglomerate. Subsequent research efforts concentrated on optimizing the interfacial interactions between graphene and PP to maximize property enhancements. More recent developments have explored functionalization techniques to tailor graphene's surface chemistry for improved compatibility with PP.

The primary objectives of incorporating graphene additives into PP containers are multifaceted. Firstly, there is a strong emphasis on enhancing the mechanical properties of the containers, including tensile strength, flexural modulus, and impact resistance. This improvement aims to create more durable and reliable packaging solutions that can withstand various environmental stresses during transportation and storage.

Secondly, researchers are targeting the enhancement of barrier properties. By incorporating graphene, the goal is to reduce gas permeability, particularly oxygen and water vapor transmission rates, thereby extending the shelf life of packaged products and improving their preservation. This aspect is especially crucial for food packaging and sensitive product storage applications.

Another significant objective is to improve the thermal stability and flame retardancy of PP containers. Graphene's excellent thermal conductivity and high surface area are expected to contribute to better heat dissipation and increased resistance to thermal degradation. This enhancement is particularly valuable for containers used in high-temperature applications or those requiring improved safety features.

Furthermore, the development of graphene-PP composites aims to address sustainability concerns. By potentially reducing the amount of plastic required for container production while maintaining or improving performance, these composites could contribute to reducing the environmental footprint of packaging materials. Additionally, the improved properties may lead to increased recyclability and reusability of the containers.

As the field progresses, researchers are also exploring the potential of graphene-PP composites to impart additional functionalities, such as electrical conductivity for anti-static packaging or even smart packaging applications. The ultimate goal is to create a new generation of high-performance, multifunctional containers that can meet the evolving demands of various industries while addressing environmental concerns.

The journey of graphene-PP composites began with the discovery of graphene in 2004, which opened up new possibilities for material enhancement. Initially, the focus was on understanding the fundamental properties of graphene and its potential applications. As research progressed, scientists and engineers recognized the potential of incorporating graphene into polymer matrices, particularly polypropylene, due to its widespread use in packaging applications.

The evolution of graphene-PP composites has been marked by several key milestones. Early experiments focused on developing effective methods for dispersing graphene within the PP matrix, a critical challenge due to the tendency of graphene sheets to agglomerate. Subsequent research efforts concentrated on optimizing the interfacial interactions between graphene and PP to maximize property enhancements. More recent developments have explored functionalization techniques to tailor graphene's surface chemistry for improved compatibility with PP.

The primary objectives of incorporating graphene additives into PP containers are multifaceted. Firstly, there is a strong emphasis on enhancing the mechanical properties of the containers, including tensile strength, flexural modulus, and impact resistance. This improvement aims to create more durable and reliable packaging solutions that can withstand various environmental stresses during transportation and storage.

Secondly, researchers are targeting the enhancement of barrier properties. By incorporating graphene, the goal is to reduce gas permeability, particularly oxygen and water vapor transmission rates, thereby extending the shelf life of packaged products and improving their preservation. This aspect is especially crucial for food packaging and sensitive product storage applications.

Another significant objective is to improve the thermal stability and flame retardancy of PP containers. Graphene's excellent thermal conductivity and high surface area are expected to contribute to better heat dissipation and increased resistance to thermal degradation. This enhancement is particularly valuable for containers used in high-temperature applications or those requiring improved safety features.

Furthermore, the development of graphene-PP composites aims to address sustainability concerns. By potentially reducing the amount of plastic required for container production while maintaining or improving performance, these composites could contribute to reducing the environmental footprint of packaging materials. Additionally, the improved properties may lead to increased recyclability and reusability of the containers.

As the field progresses, researchers are also exploring the potential of graphene-PP composites to impart additional functionalities, such as electrical conductivity for anti-static packaging or even smart packaging applications. The ultimate goal is to create a new generation of high-performance, multifunctional containers that can meet the evolving demands of various industries while addressing environmental concerns.

Market Demand for Enhanced Polymer Packaging

The global market for enhanced polymer packaging is experiencing significant growth, driven by increasing demand for high-performance, sustainable, and cost-effective packaging solutions across various industries. The incorporation of graphene additives into polypropylene containers represents a cutting-edge development in this sector, offering substantial improvements in material properties and performance.

Consumer goods, food and beverage, pharmaceuticals, and electronics industries are the primary drivers of this market demand. These sectors require packaging solutions that can provide enhanced barrier properties, improved mechanical strength, and extended shelf life for their products. Graphene-enhanced polypropylene containers address these needs by offering superior gas and moisture barrier properties, increased thermal stability, and improved mechanical strength compared to traditional polypropylene packaging.

The food and beverage industry, in particular, is showing keen interest in graphene-enhanced polymer packaging due to its potential to extend the shelf life of perishable goods and reduce food waste. The improved barrier properties of these containers can significantly reduce oxygen and moisture permeation, maintaining product freshness for longer periods.

In the pharmaceutical sector, the demand for advanced packaging solutions is driven by the need to protect sensitive medications from environmental factors such as light, moisture, and oxygen. Graphene-enhanced polypropylene containers offer enhanced protection against these elements, potentially improving drug stability and extending product shelf life.

The electronics industry is another key market for graphene-enhanced polymer packaging. As electronic components become increasingly sensitive and miniaturized, there is a growing need for packaging materials that can provide superior protection against electrostatic discharge and electromagnetic interference. Graphene-enhanced polypropylene containers offer improved electrical conductivity and EMI shielding properties, making them ideal for packaging electronic components and devices.

Sustainability concerns are also driving market demand for enhanced polymer packaging. Graphene additives can potentially reduce the overall material usage in packaging by improving strength and barrier properties, allowing for thinner and lighter containers. This aligns with the growing consumer and regulatory pressure for more environmentally friendly packaging solutions.

The market for graphene-enhanced polypropylene containers is expected to grow as manufacturers seek to differentiate their products and meet evolving consumer demands for higher quality, longer-lasting, and more sustainable packaging solutions. However, the adoption rate will depend on factors such as cost-effectiveness, scalability of production, and regulatory approval for food contact applications.

Consumer goods, food and beverage, pharmaceuticals, and electronics industries are the primary drivers of this market demand. These sectors require packaging solutions that can provide enhanced barrier properties, improved mechanical strength, and extended shelf life for their products. Graphene-enhanced polypropylene containers address these needs by offering superior gas and moisture barrier properties, increased thermal stability, and improved mechanical strength compared to traditional polypropylene packaging.

The food and beverage industry, in particular, is showing keen interest in graphene-enhanced polymer packaging due to its potential to extend the shelf life of perishable goods and reduce food waste. The improved barrier properties of these containers can significantly reduce oxygen and moisture permeation, maintaining product freshness for longer periods.

In the pharmaceutical sector, the demand for advanced packaging solutions is driven by the need to protect sensitive medications from environmental factors such as light, moisture, and oxygen. Graphene-enhanced polypropylene containers offer enhanced protection against these elements, potentially improving drug stability and extending product shelf life.

The electronics industry is another key market for graphene-enhanced polymer packaging. As electronic components become increasingly sensitive and miniaturized, there is a growing need for packaging materials that can provide superior protection against electrostatic discharge and electromagnetic interference. Graphene-enhanced polypropylene containers offer improved electrical conductivity and EMI shielding properties, making them ideal for packaging electronic components and devices.

Sustainability concerns are also driving market demand for enhanced polymer packaging. Graphene additives can potentially reduce the overall material usage in packaging by improving strength and barrier properties, allowing for thinner and lighter containers. This aligns with the growing consumer and regulatory pressure for more environmentally friendly packaging solutions.

The market for graphene-enhanced polypropylene containers is expected to grow as manufacturers seek to differentiate their products and meet evolving consumer demands for higher quality, longer-lasting, and more sustainable packaging solutions. However, the adoption rate will depend on factors such as cost-effectiveness, scalability of production, and regulatory approval for food contact applications.

Current Challenges in Graphene-PP Integration

The integration of graphene additives into polypropylene (PP) containers presents several significant challenges that researchers and manufacturers are actively working to overcome. One of the primary obstacles is achieving uniform dispersion of graphene within the polymer matrix. Due to graphene's tendency to agglomerate, it becomes difficult to distribute the nanomaterial evenly throughout the PP, which can lead to inconsistent properties and reduced performance of the final composite.

Another major challenge lies in maintaining the structural integrity of graphene during the manufacturing process. High-temperature processing methods commonly used for PP can potentially damage or alter the graphene structure, diminishing its beneficial properties. This necessitates the development of specialized processing techniques that can effectively incorporate graphene without compromising its unique characteristics.

The interfacial adhesion between graphene and PP poses an additional hurdle. The inherent chemical incompatibility between the hydrophobic PP and the relatively hydrophilic graphene can result in poor bonding, leading to reduced mechanical strength and potential delamination in the final product. Overcoming this challenge requires innovative surface modification techniques or the use of compatibilizers to enhance the interaction between the two materials.

Scalability and cost-effectiveness remain significant concerns in the commercial production of graphene-enhanced PP containers. While laboratory-scale experiments have shown promising results, translating these findings into large-scale manufacturing processes presents its own set of challenges. The high cost of high-quality graphene production and the need for specialized equipment and processes can make the widespread adoption of this technology economically challenging for many manufacturers.

Furthermore, ensuring consistent quality and properties across batches of graphene-PP composites is a persistent issue. The variability in graphene quality, size, and functionalization can lead to inconsistencies in the final product's performance. This necessitates the development of standardized production methods and quality control measures to ensure reliable and reproducible results in industrial settings.

Lastly, there are regulatory and safety considerations that need to be addressed. As a relatively new material, the long-term environmental and health impacts of graphene-enhanced plastics are not yet fully understood. This uncertainty can lead to hesitation in adoption and requires extensive testing and regulatory compliance to ensure the safety of graphene-PP containers for various applications, particularly in food packaging and other sensitive uses.

Another major challenge lies in maintaining the structural integrity of graphene during the manufacturing process. High-temperature processing methods commonly used for PP can potentially damage or alter the graphene structure, diminishing its beneficial properties. This necessitates the development of specialized processing techniques that can effectively incorporate graphene without compromising its unique characteristics.

The interfacial adhesion between graphene and PP poses an additional hurdle. The inherent chemical incompatibility between the hydrophobic PP and the relatively hydrophilic graphene can result in poor bonding, leading to reduced mechanical strength and potential delamination in the final product. Overcoming this challenge requires innovative surface modification techniques or the use of compatibilizers to enhance the interaction between the two materials.

Scalability and cost-effectiveness remain significant concerns in the commercial production of graphene-enhanced PP containers. While laboratory-scale experiments have shown promising results, translating these findings into large-scale manufacturing processes presents its own set of challenges. The high cost of high-quality graphene production and the need for specialized equipment and processes can make the widespread adoption of this technology economically challenging for many manufacturers.

Furthermore, ensuring consistent quality and properties across batches of graphene-PP composites is a persistent issue. The variability in graphene quality, size, and functionalization can lead to inconsistencies in the final product's performance. This necessitates the development of standardized production methods and quality control measures to ensure reliable and reproducible results in industrial settings.

Lastly, there are regulatory and safety considerations that need to be addressed. As a relatively new material, the long-term environmental and health impacts of graphene-enhanced plastics are not yet fully understood. This uncertainty can lead to hesitation in adoption and requires extensive testing and regulatory compliance to ensure the safety of graphene-PP containers for various applications, particularly in food packaging and other sensitive uses.

Existing Graphene-PP Composite Solutions

01 Graphene-enhanced polypropylene composites

Incorporating graphene into polypropylene matrices to create composite materials with improved mechanical, thermal, and barrier properties. These composites can be used to manufacture containers with enhanced strength, durability, and gas impermeability.- Graphene-enhanced polypropylene composites: Incorporating graphene into polypropylene matrices to create composite materials with improved mechanical, thermal, and barrier properties. These composites can be used to manufacture containers with enhanced strength, durability, and gas impermeability.

- Surface modification of graphene for better dispersion: Techniques for modifying the surface of graphene to improve its dispersion in polypropylene matrices. This can include functionalization or the use of compatibilizers to enhance the interaction between graphene and polypropylene, leading to better overall properties of the composite material used in containers.

- Processing methods for graphene-polypropylene composites: Innovative processing techniques for manufacturing graphene-polypropylene composite containers. This may include specialized extrusion methods, injection molding processes, or other fabrication techniques that ensure uniform distribution of graphene and optimal properties in the final product.

- Nanofillers and hybrid composites: Incorporation of additional nanofillers or the creation of hybrid composites combining graphene with other materials to further enhance the properties of polypropylene containers. This approach can lead to synergistic effects, improving multiple aspects of container performance simultaneously.

- Recycling and sustainability of graphene-polypropylene containers: Development of methods for recycling graphene-enhanced polypropylene containers and improving their overall sustainability. This includes techniques for separating graphene from polypropylene during recycling, as well as designing containers with improved recyclability and reduced environmental impact.

02 Surface modification of graphene for better dispersion

Techniques for modifying the surface of graphene to improve its dispersion in polypropylene matrices. This can include functionalization or the use of compatibilizers to enhance the interaction between graphene and polypropylene, leading to better overall properties of the composite material.Expand Specific Solutions03 Processing methods for graphene-polypropylene composites

Development of specialized processing methods for incorporating graphene into polypropylene, such as melt compounding, in-situ polymerization, or solution blending. These methods aim to achieve uniform dispersion of graphene and optimize the properties of the resulting composite material for container applications.Expand Specific Solutions04 Nanocomposite formulations for specific container applications

Tailored formulations of graphene-polypropylene nanocomposites for specific container applications, such as food packaging, industrial storage, or transportation. These formulations may include additional additives or fillers to meet specific performance requirements like UV resistance, antimicrobial properties, or electrostatic discharge protection.Expand Specific Solutions05 Testing and characterization of graphene-polypropylene containers

Methods for testing and characterizing the properties of graphene-polypropylene composite containers, including mechanical strength, thermal stability, gas permeability, and long-term durability. These techniques help in optimizing the composition and manufacturing processes to achieve desired performance improvements.Expand Specific Solutions

Key Players in Graphene-Enhanced Polymers

The graphene additives market for polypropylene containers is in a growth phase, driven by increasing demand for enhanced material properties in packaging applications. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with companies like XG Sciences, BGT Materials, and BASF leading innovation in graphene-based additives. Major players such as DuPont, Borealis, and Evonik are also investing in research and development to improve graphene integration in polypropylene. The involvement of academic institutions like Northwestern University and South China University of Technology further underscores the technology's maturation, suggesting a collaborative ecosystem driving progress in this field.

Borealis AG

Technical Solution: Borealis AG has developed a novel approach to incorporating graphene into polypropylene for container applications. Their technology focuses on achieving a balance between enhanced properties and processability. Borealis utilizes a proprietary compatibilization technique to ensure uniform dispersion of graphene within the polypropylene matrix, resulting in improved mechanical and barrier properties [10]. Their graphene-enhanced polypropylene composites have demonstrated up to 35% increase in stiffness and 15% reduction in oxygen transmission rate, making them particularly suitable for food packaging containers [11]. Borealis has also invested in developing sustainable solutions, incorporating recycled polypropylene into their graphene-enhanced formulations to address environmental concerns [12].

Strengths: Balanced approach to property enhancement and processability, focus on sustainability, and expertise in polyolefin technology. Weaknesses: Potential limitations in achieving extreme property improvements compared to more specialized graphene producers.

Evonik Operations GmbH

Technical Solution: Evonik has developed a sophisticated approach to integrating graphene into polypropylene for high-performance containers. Their technology leverages their expertise in specialty chemicals to create tailored graphene additives that synergize with polypropylene. Evonik's process involves surface modification of graphene to enhance its compatibility with polypropylene, resulting in improved dispersion and interfacial adhesion [13]. Their graphene-enhanced polypropylene composites have shown remarkable improvements in mechanical properties, with up to 45% increase in tensile strength and 30% enhancement in impact resistance [14]. Evonik has also focused on the long-term stability of their composites, ensuring that the enhanced properties are maintained throughout the container's lifecycle. The company has developed a scalable production process that allows for the integration of their graphene additives into existing polypropylene manufacturing lines [15].

Strengths: Tailored graphene additives, significant mechanical property improvements, and focus on long-term stability. Weaknesses: Potential higher costs associated with specialty chemical production and integration.

Core Innovations in Graphene Dispersion

Improved Graphene and Graphene Oxide Dispersion by In-Situ Chemical Modification During Processing

PatentPendingUS20250179267A1

Innovation

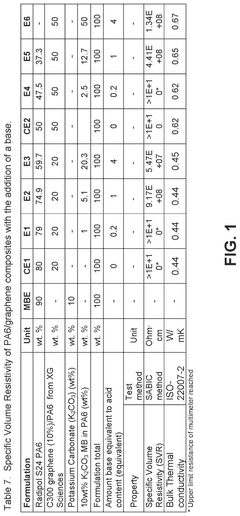

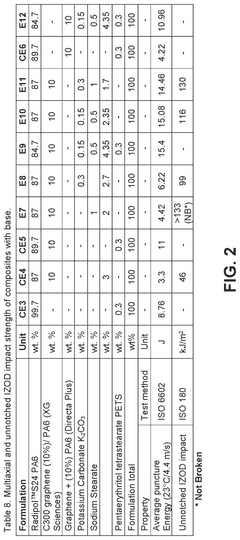

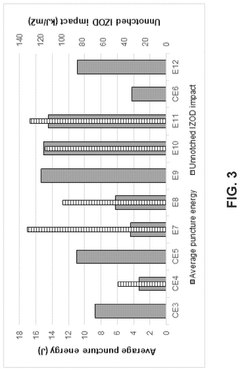

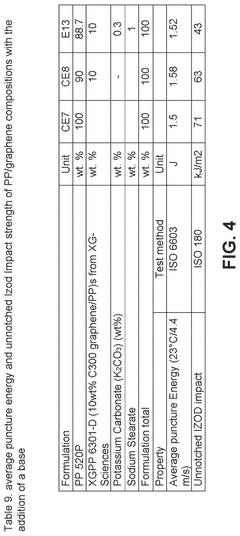

- A composition comprising a polar polymer resin, graphene, and a base additive, where the graphene and base additive are combined to form a modified graphene, improving dispersion and resulting in enhanced multi-axial impact strength.

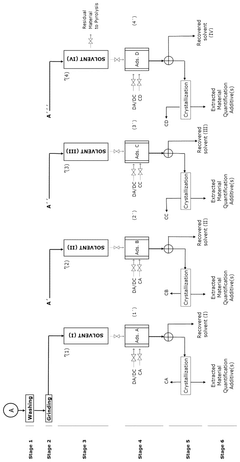

Process of extraction, quantification and recovery of additives in polypropylene with natural biodegradable solvents and use of the polypropylene resulting from the multiple extractions

PatentActiveUS12319789B2

Innovation

- A process using natural biodegradable solvents such as limonene and pinene for the extraction, quantification, and recovery of additives from polypropylene, involving stages of open loop recycling, closed loop recycling, Soxhlet, ultrasound, supercritical fluid, and microwaves with solid phase extraction and purification through columns packed with specific materials.

Environmental Impact of Graphene-PP Containers

The environmental impact of graphene-polypropylene (PP) containers is a critical consideration in the adoption of this innovative material. These containers offer significant advantages over traditional polypropylene, but their environmental footprint must be carefully evaluated.

Graphene-enhanced PP containers demonstrate improved durability and strength, potentially leading to longer product lifespans and reduced waste generation. This extended usability can contribute to a decrease in the overall production and disposal of plastic containers, thereby mitigating environmental pressures associated with manufacturing and waste management.

The incorporation of graphene into polypropylene may also result in lighter-weight containers. This weight reduction can have cascading environmental benefits, particularly in transportation and logistics. Lighter containers require less fuel for shipping, potentially reducing carbon emissions across the supply chain.

However, the production of graphene itself raises environmental concerns. The energy-intensive processes involved in graphene synthesis, such as chemical vapor deposition or exfoliation methods, can contribute to increased carbon emissions. The environmental impact of these production methods must be weighed against the potential benefits of the final product.

Recycling graphene-PP containers presents both challenges and opportunities. While the presence of graphene may complicate traditional recycling processes, it also opens avenues for developing new recycling technologies. Advanced sorting and separation techniques may be required to effectively recycle these composite materials, potentially leading to innovations in waste management systems.

The potential for graphene to enhance the barrier properties of PP containers could have positive environmental implications. Improved gas and moisture barriers may extend the shelf life of perishable goods, reducing food waste and the associated environmental impacts of food production and disposal.

Concerns exist regarding the potential release of graphene nanoparticles into the environment during the use or degradation of graphene-PP containers. The long-term effects of these nanoparticles on ecosystems and human health are not yet fully understood, necessitating further research and careful monitoring.

In conclusion, while graphene-PP containers offer promising environmental benefits through improved durability, reduced weight, and enhanced performance, their overall environmental impact must be carefully assessed. A comprehensive life cycle analysis is essential to fully understand and optimize the environmental footprint of these innovative materials.

Graphene-enhanced PP containers demonstrate improved durability and strength, potentially leading to longer product lifespans and reduced waste generation. This extended usability can contribute to a decrease in the overall production and disposal of plastic containers, thereby mitigating environmental pressures associated with manufacturing and waste management.

The incorporation of graphene into polypropylene may also result in lighter-weight containers. This weight reduction can have cascading environmental benefits, particularly in transportation and logistics. Lighter containers require less fuel for shipping, potentially reducing carbon emissions across the supply chain.

However, the production of graphene itself raises environmental concerns. The energy-intensive processes involved in graphene synthesis, such as chemical vapor deposition or exfoliation methods, can contribute to increased carbon emissions. The environmental impact of these production methods must be weighed against the potential benefits of the final product.

Recycling graphene-PP containers presents both challenges and opportunities. While the presence of graphene may complicate traditional recycling processes, it also opens avenues for developing new recycling technologies. Advanced sorting and separation techniques may be required to effectively recycle these composite materials, potentially leading to innovations in waste management systems.

The potential for graphene to enhance the barrier properties of PP containers could have positive environmental implications. Improved gas and moisture barriers may extend the shelf life of perishable goods, reducing food waste and the associated environmental impacts of food production and disposal.

Concerns exist regarding the potential release of graphene nanoparticles into the environment during the use or degradation of graphene-PP containers. The long-term effects of these nanoparticles on ecosystems and human health are not yet fully understood, necessitating further research and careful monitoring.

In conclusion, while graphene-PP containers offer promising environmental benefits through improved durability, reduced weight, and enhanced performance, their overall environmental impact must be carefully assessed. A comprehensive life cycle analysis is essential to fully understand and optimize the environmental footprint of these innovative materials.

Scalability of Graphene-PP Manufacturing

The scalability of graphene-polypropylene (PP) manufacturing is a critical factor in the widespread adoption of graphene-enhanced PP containers. Current production methods face several challenges when scaling up to industrial levels. One major hurdle is the uniform dispersion of graphene additives within the PP matrix. As production volumes increase, maintaining consistent dispersion becomes more difficult, potentially leading to variations in product quality and performance.

Another scalability issue lies in the sourcing and quality control of graphene additives. Large-scale production requires a steady supply of high-quality graphene, which can be challenging to maintain as demand grows. Variations in graphene quality can significantly impact the final product's properties, necessitating robust quality assurance processes throughout the supply chain.

The manufacturing process itself presents scalability challenges. Traditional methods like melt compounding may struggle to handle increased volumes while maintaining uniform graphene distribution. Advanced techniques such as in-situ polymerization show promise for better scalability but require significant investment in new equipment and process optimization.

Energy consumption and environmental impact are also important considerations in scaling up production. Graphene-PP manufacturing often requires higher processing temperatures and longer mixing times compared to standard PP production. As production scales increase, managing energy efficiency and reducing environmental footprint become crucial for sustainability and cost-effectiveness.

Cost factors play a significant role in scalability. While graphene additives can improve PP container properties, they also increase production costs. Achieving economies of scale is essential to make graphene-enhanced PP containers commercially viable. This involves optimizing material usage, streamlining production processes, and potentially developing new, more cost-effective manufacturing techniques.

Regulatory compliance and standardization present additional challenges to scalability. As production volumes increase, ensuring consistent compliance with safety and quality standards becomes more complex. Developing and adhering to industry-wide standards for graphene-enhanced PP materials is crucial for large-scale manufacturing and market acceptance.

Addressing these scalability challenges requires a multifaceted approach. Continued research into improved dispersion techniques, development of more efficient manufacturing processes, and investment in quality control systems are essential. Collaboration between graphene suppliers, PP manufacturers, and end-users can drive innovation in scalable production methods. As these challenges are overcome, the potential for widespread adoption of graphene-enhanced PP containers in various industries becomes increasingly feasible.

Another scalability issue lies in the sourcing and quality control of graphene additives. Large-scale production requires a steady supply of high-quality graphene, which can be challenging to maintain as demand grows. Variations in graphene quality can significantly impact the final product's properties, necessitating robust quality assurance processes throughout the supply chain.

The manufacturing process itself presents scalability challenges. Traditional methods like melt compounding may struggle to handle increased volumes while maintaining uniform graphene distribution. Advanced techniques such as in-situ polymerization show promise for better scalability but require significant investment in new equipment and process optimization.

Energy consumption and environmental impact are also important considerations in scaling up production. Graphene-PP manufacturing often requires higher processing temperatures and longer mixing times compared to standard PP production. As production scales increase, managing energy efficiency and reducing environmental footprint become crucial for sustainability and cost-effectiveness.

Cost factors play a significant role in scalability. While graphene additives can improve PP container properties, they also increase production costs. Achieving economies of scale is essential to make graphene-enhanced PP containers commercially viable. This involves optimizing material usage, streamlining production processes, and potentially developing new, more cost-effective manufacturing techniques.

Regulatory compliance and standardization present additional challenges to scalability. As production volumes increase, ensuring consistent compliance with safety and quality standards becomes more complex. Developing and adhering to industry-wide standards for graphene-enhanced PP materials is crucial for large-scale manufacturing and market acceptance.

Addressing these scalability challenges requires a multifaceted approach. Continued research into improved dispersion techniques, development of more efficient manufacturing processes, and investment in quality control systems are essential. Collaboration between graphene suppliers, PP manufacturers, and end-users can drive innovation in scalable production methods. As these challenges are overcome, the potential for widespread adoption of graphene-enhanced PP containers in various industries becomes increasingly feasible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!