How Fiber-Reinforced Polypropylene Drives Future Construction Materials

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FRP Evolution & Goals

Fiber-reinforced polypropylene (FRP) has emerged as a revolutionary material in the construction industry, marking a significant milestone in the evolution of building materials. The development of FRP can be traced back to the mid-20th century when researchers began exploring ways to enhance the properties of conventional materials. Over the decades, FRP has undergone substantial improvements, driven by advancements in polymer science and fiber technology.

The evolution of FRP has been characterized by continuous refinement of its composition and manufacturing processes. Initially, glass fibers were the primary reinforcement material, but the introduction of carbon and aramid fibers expanded the possibilities for strength-to-weight ratios and durability. Concurrently, improvements in matrix materials, particularly polypropylene, have led to enhanced chemical resistance and thermal stability.

A key milestone in FRP development was the transition from manual layup techniques to automated manufacturing processes, such as pultrusion and resin transfer molding. These advancements significantly improved production efficiency and consistency, making FRP more viable for large-scale construction applications.

The goals for FRP in construction materials are multifaceted and ambitious. Foremost is the aim to further enhance the strength-to-weight ratio, enabling the creation of lighter yet more robust structures. This objective aligns with the broader industry trend towards sustainable and energy-efficient buildings. Additionally, there is a push to improve the fire resistance of FRP composites, addressing one of the primary concerns in their widespread adoption.

Another critical goal is to increase the durability and longevity of FRP materials, particularly in harsh environmental conditions. This includes developing formulations that resist UV degradation, chemical corrosion, and fatigue. Researchers are also focusing on improving the recyclability and environmental footprint of FRP, aiming to create more sustainable lifecycle management solutions.

In the realm of smart materials, there are efforts to integrate sensing and self-healing capabilities into FRP composites. This could lead to structures that can monitor their own structural health and potentially repair minor damages autonomously. The integration of nanotechnology in FRP production is another frontier, with the potential to dramatically enhance material properties at the molecular level.

As we look to the future, the evolution of FRP in construction materials is expected to continue at a rapid pace. The goals are set on creating materials that not only meet but exceed the performance of traditional construction materials in terms of strength, durability, and sustainability. This ongoing development promises to reshape the landscape of modern construction, offering innovative solutions to longstanding challenges in the industry.

The evolution of FRP has been characterized by continuous refinement of its composition and manufacturing processes. Initially, glass fibers were the primary reinforcement material, but the introduction of carbon and aramid fibers expanded the possibilities for strength-to-weight ratios and durability. Concurrently, improvements in matrix materials, particularly polypropylene, have led to enhanced chemical resistance and thermal stability.

A key milestone in FRP development was the transition from manual layup techniques to automated manufacturing processes, such as pultrusion and resin transfer molding. These advancements significantly improved production efficiency and consistency, making FRP more viable for large-scale construction applications.

The goals for FRP in construction materials are multifaceted and ambitious. Foremost is the aim to further enhance the strength-to-weight ratio, enabling the creation of lighter yet more robust structures. This objective aligns with the broader industry trend towards sustainable and energy-efficient buildings. Additionally, there is a push to improve the fire resistance of FRP composites, addressing one of the primary concerns in their widespread adoption.

Another critical goal is to increase the durability and longevity of FRP materials, particularly in harsh environmental conditions. This includes developing formulations that resist UV degradation, chemical corrosion, and fatigue. Researchers are also focusing on improving the recyclability and environmental footprint of FRP, aiming to create more sustainable lifecycle management solutions.

In the realm of smart materials, there are efforts to integrate sensing and self-healing capabilities into FRP composites. This could lead to structures that can monitor their own structural health and potentially repair minor damages autonomously. The integration of nanotechnology in FRP production is another frontier, with the potential to dramatically enhance material properties at the molecular level.

As we look to the future, the evolution of FRP in construction materials is expected to continue at a rapid pace. The goals are set on creating materials that not only meet but exceed the performance of traditional construction materials in terms of strength, durability, and sustainability. This ongoing development promises to reshape the landscape of modern construction, offering innovative solutions to longstanding challenges in the industry.

Market Demand Analysis

The market demand for fiber-reinforced polypropylene (FRPP) in the construction industry is experiencing significant growth, driven by the material's unique properties and the evolving needs of modern construction practices. FRPP combines the lightweight and cost-effective nature of polypropylene with the strength and durability of reinforcing fibers, making it an attractive option for various construction applications.

In recent years, there has been a notable shift towards sustainable and eco-friendly construction materials. FRPP aligns well with this trend, as it offers improved recyclability compared to traditional materials like steel-reinforced concrete. This sustainability factor has led to increased interest from environmentally conscious developers and architects, contributing to the growing market demand.

The construction industry's focus on reducing project timelines and labor costs has also fueled the demand for FRPP. The material's lightweight nature allows for easier handling and installation, potentially reducing construction time and associated labor expenses. This efficiency gain is particularly appealing in large-scale construction projects where time and cost savings can be substantial.

Another key driver of market demand is the superior performance characteristics of FRPP. Its high strength-to-weight ratio, excellent chemical resistance, and thermal insulation properties make it suitable for a wide range of applications, from structural components to facade elements. The material's ability to withstand harsh environmental conditions and resist corrosion has made it particularly attractive for infrastructure projects in coastal areas or regions with extreme weather conditions.

The global construction industry's continuous growth, especially in emerging economies, has created a fertile ground for FRPP adoption. As urbanization accelerates and the need for rapid, cost-effective construction increases, FRPP is well-positioned to meet these demands. The material's versatility allows it to be used in various construction sectors, including residential, commercial, and industrial buildings, as well as infrastructure projects.

Furthermore, the ongoing research and development in FRPP technology are expanding its potential applications and improving its performance. This continuous innovation is expected to open up new market opportunities and drive further demand growth. As manufacturers develop new fiber reinforcement techniques and optimize the material's properties, FRPP is likely to find applications in even more specialized construction niches.

However, it's important to note that the market demand for FRPP in construction is not without challenges. The relatively higher initial cost compared to some traditional materials and the need for specialized knowledge in its application can be barriers to widespread adoption. Additionally, building codes and regulations in some regions may need to be updated to fully accommodate the use of FRPP in structural applications, which could temporarily limit market growth in certain areas.

In recent years, there has been a notable shift towards sustainable and eco-friendly construction materials. FRPP aligns well with this trend, as it offers improved recyclability compared to traditional materials like steel-reinforced concrete. This sustainability factor has led to increased interest from environmentally conscious developers and architects, contributing to the growing market demand.

The construction industry's focus on reducing project timelines and labor costs has also fueled the demand for FRPP. The material's lightweight nature allows for easier handling and installation, potentially reducing construction time and associated labor expenses. This efficiency gain is particularly appealing in large-scale construction projects where time and cost savings can be substantial.

Another key driver of market demand is the superior performance characteristics of FRPP. Its high strength-to-weight ratio, excellent chemical resistance, and thermal insulation properties make it suitable for a wide range of applications, from structural components to facade elements. The material's ability to withstand harsh environmental conditions and resist corrosion has made it particularly attractive for infrastructure projects in coastal areas or regions with extreme weather conditions.

The global construction industry's continuous growth, especially in emerging economies, has created a fertile ground for FRPP adoption. As urbanization accelerates and the need for rapid, cost-effective construction increases, FRPP is well-positioned to meet these demands. The material's versatility allows it to be used in various construction sectors, including residential, commercial, and industrial buildings, as well as infrastructure projects.

Furthermore, the ongoing research and development in FRPP technology are expanding its potential applications and improving its performance. This continuous innovation is expected to open up new market opportunities and drive further demand growth. As manufacturers develop new fiber reinforcement techniques and optimize the material's properties, FRPP is likely to find applications in even more specialized construction niches.

However, it's important to note that the market demand for FRPP in construction is not without challenges. The relatively higher initial cost compared to some traditional materials and the need for specialized knowledge in its application can be barriers to widespread adoption. Additionally, building codes and regulations in some regions may need to be updated to fully accommodate the use of FRPP in structural applications, which could temporarily limit market growth in certain areas.

FRP Tech Challenges

Fiber-reinforced polypropylene (FRP) faces several significant technical challenges in its journey to becoming a mainstream construction material. One of the primary obstacles is achieving optimal fiber-matrix adhesion. The hydrophobic nature of polypropylene often results in poor interfacial bonding with reinforcing fibers, leading to reduced mechanical properties and durability of the composite. Researchers are exploring various surface treatments and compatibilizers to enhance this adhesion, but finding a cost-effective and scalable solution remains elusive.

Another critical challenge lies in the long-term performance and durability of FRP in construction applications. While polypropylene offers excellent chemical resistance, its susceptibility to UV degradation and thermal aging can compromise the structural integrity of FRP composites over time. Developing effective UV stabilizers and heat-resistant additives that do not negatively impact other material properties is an ongoing area of research.

The processing and manufacturing of FRP composites for construction also present technical hurdles. Achieving uniform fiber distribution and orientation within the polypropylene matrix is crucial for consistent mechanical properties. Current manufacturing methods often struggle to maintain this uniformity, especially in large-scale production. Additionally, the high processing temperatures required for polypropylene can lead to fiber degradation, particularly with natural fibers, limiting the range of reinforcement options.

Fire resistance is another significant concern for FRP in construction applications. Polypropylene is inherently flammable, and while flame retardants can be added, they often compromise the material's mechanical properties and recyclability. Developing fire-resistant FRP composites that meet stringent building codes without sacrificing performance or sustainability is a complex challenge facing researchers and manufacturers.

The recyclability and end-of-life management of FRP composites also pose technical difficulties. The heterogeneous nature of these materials makes them challenging to recycle effectively. Separating fibers from the polypropylene matrix without degrading either component is a complex process, and current recycling methods often result in downcycled products with inferior properties. Developing efficient recycling technologies that maintain material quality is crucial for the long-term sustainability of FRP in construction.

Lastly, the integration of FRP composites with traditional construction materials and methods presents its own set of challenges. Developing effective joining techniques, such as adhesive bonding or mechanical fastening, that maintain the integrity of the FRP while ensuring structural reliability is an ongoing area of research. Furthermore, the lack of standardized design guidelines and long-term performance data for FRP in construction applications hinders its widespread adoption, necessitating extensive testing and validation processes.

Another critical challenge lies in the long-term performance and durability of FRP in construction applications. While polypropylene offers excellent chemical resistance, its susceptibility to UV degradation and thermal aging can compromise the structural integrity of FRP composites over time. Developing effective UV stabilizers and heat-resistant additives that do not negatively impact other material properties is an ongoing area of research.

The processing and manufacturing of FRP composites for construction also present technical hurdles. Achieving uniform fiber distribution and orientation within the polypropylene matrix is crucial for consistent mechanical properties. Current manufacturing methods often struggle to maintain this uniformity, especially in large-scale production. Additionally, the high processing temperatures required for polypropylene can lead to fiber degradation, particularly with natural fibers, limiting the range of reinforcement options.

Fire resistance is another significant concern for FRP in construction applications. Polypropylene is inherently flammable, and while flame retardants can be added, they often compromise the material's mechanical properties and recyclability. Developing fire-resistant FRP composites that meet stringent building codes without sacrificing performance or sustainability is a complex challenge facing researchers and manufacturers.

The recyclability and end-of-life management of FRP composites also pose technical difficulties. The heterogeneous nature of these materials makes them challenging to recycle effectively. Separating fibers from the polypropylene matrix without degrading either component is a complex process, and current recycling methods often result in downcycled products with inferior properties. Developing efficient recycling technologies that maintain material quality is crucial for the long-term sustainability of FRP in construction.

Lastly, the integration of FRP composites with traditional construction materials and methods presents its own set of challenges. Developing effective joining techniques, such as adhesive bonding or mechanical fastening, that maintain the integrity of the FRP while ensuring structural reliability is an ongoing area of research. Furthermore, the lack of standardized design guidelines and long-term performance data for FRP in construction applications hinders its widespread adoption, necessitating extensive testing and validation processes.

Current FRP Solutions

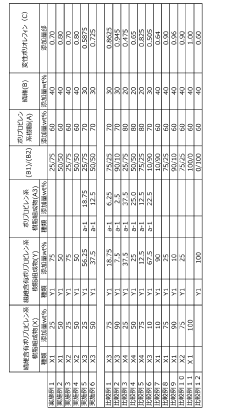

01 Composition and manufacturing of fiber-reinforced polypropylene

Fiber-reinforced polypropylene composites are manufactured by combining polypropylene with various types of fibers, such as glass, carbon, or natural fibers. The manufacturing process often involves melt compounding, extrusion, or injection molding techniques to ensure proper dispersion of fibers within the polymer matrix. The resulting material exhibits enhanced mechanical properties, including improved strength and stiffness.- Composition and manufacturing of fiber-reinforced polypropylene: Fiber-reinforced polypropylene composites are manufactured by combining polypropylene with various types of fibers, such as glass, carbon, or natural fibers. The manufacturing process often involves melt compounding, extrusion, or injection molding techniques to ensure proper dispersion of fibers within the polymer matrix. The resulting material exhibits enhanced mechanical properties, including improved strength and stiffness.

- Modification of fiber-matrix interface: To improve the adhesion between fibers and the polypropylene matrix, various surface treatments and coupling agents are employed. These modifications enhance the interfacial bonding, leading to better stress transfer and overall mechanical performance of the composite. Common techniques include chemical treatments, plasma treatments, and the use of compatibilizers or sizing agents.

- Incorporation of nanofillers in fiber-reinforced polypropylene: Nanofillers, such as nanoclay, carbon nanotubes, or graphene, are incorporated into fiber-reinforced polypropylene composites to further enhance their properties. These nanofillers can improve mechanical strength, thermal stability, and barrier properties of the composite. The challenge lies in achieving proper dispersion of nanofillers within the polymer matrix.

- Development of long fiber-reinforced polypropylene: Long fiber-reinforced polypropylene composites are developed to achieve superior mechanical properties compared to short fiber composites. These materials often use continuous or long discontinuous fibers, which are aligned in specific directions to optimize strength and stiffness. The manufacturing process typically involves pultrusion or in-line compounding techniques to maintain fiber length and orientation.

- Recycling and sustainability of fiber-reinforced polypropylene: Research focuses on improving the recyclability and sustainability of fiber-reinforced polypropylene composites. This includes developing methods for separating fibers from the polymer matrix, using biodegradable fibers or matrices, and incorporating recycled materials into new composites. The goal is to reduce environmental impact while maintaining or improving material performance.

02 Surface treatment and compatibilization of fibers

To improve the interfacial adhesion between fibers and the polypropylene matrix, various surface treatments and compatibilization techniques are employed. These methods may include chemical modifications, use of coupling agents, or application of sizing agents to the fiber surface. Enhanced fiber-matrix adhesion leads to better mechanical properties and overall performance of the composite material.Expand Specific Solutions03 Additives and modifiers for enhanced properties

Various additives and modifiers are incorporated into fiber-reinforced polypropylene composites to enhance specific properties. These may include impact modifiers, flame retardants, UV stabilizers, or processing aids. The selection and optimization of these additives contribute to improved performance characteristics such as impact resistance, flame retardancy, or weatherability of the final product.Expand Specific Solutions04 Applications in automotive and industrial sectors

Fiber-reinforced polypropylene finds extensive applications in automotive and industrial sectors due to its lightweight nature, high strength-to-weight ratio, and cost-effectiveness. It is used in manufacturing automotive parts, such as interior components, under-the-hood applications, and structural elements. In industrial applications, it is utilized for producing pipes, tanks, and other durable goods.Expand Specific Solutions05 Recycling and sustainability considerations

As environmental concerns grow, research focuses on developing recyclable and sustainable fiber-reinforced polypropylene composites. This includes the use of natural fibers, development of easily separable composite systems, and exploration of chemical recycling methods. These efforts aim to reduce the environmental impact of fiber-reinforced polypropylene products and promote circular economy principles in their lifecycle.Expand Specific Solutions

Key Industry Players

The fiber-reinforced polypropylene market for construction materials is in a growth phase, driven by increasing demand for lightweight, durable, and sustainable building solutions. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, with companies like Borealis AG, LX Hausys Ltd., and Kingfa Sci. & Tech. Co., Ltd. leading innovation in material development. Major players such as SABIC Global Technologies BV and Sumitomo Chemical Co., Ltd. are investing heavily in R&D to improve performance characteristics and production efficiency. The involvement of academic institutions like The Hong Kong University of Science & Technology suggests ongoing research to further enhance the technology's potential in construction applications.

Borealis AG

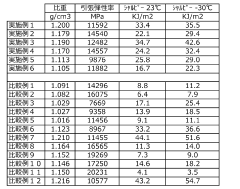

Technical Solution: Borealis AG has developed a proprietary technology called Borstar® for producing fiber-reinforced polypropylene (FRPP) with enhanced mechanical properties. Their FRPP compounds utilize a bimodal polymerization process, resulting in a unique molecular structure that combines high stiffness with excellent impact resistance[1]. The company has also introduced Fibremod™, a range of FRPP grades specifically designed for construction applications. These materials offer up to 60% weight reduction compared to traditional materials while maintaining structural integrity[2]. Borealis' FRPP solutions incorporate long glass fibers, which provide superior strength and dimensional stability, making them ideal for load-bearing construction elements[3].

Strengths: Superior mechanical properties, significant weight reduction, and versatility in construction applications. Weaknesses: Potentially higher production costs and limited recyclability compared to non-reinforced polypropylene.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a range of FRPP materials under its brand Sinopec HMS PP. These materials utilize a proprietary high melt strength polypropylene as the matrix, combined with carefully selected glass fibers. The company's FRPP compounds are engineered to exhibit excellent flow properties during processing, allowing for the production of complex shapes and thin-walled structures[4]. Sinopec's FRPP grades also feature enhanced thermal stability and chemical resistance, making them suitable for both interior and exterior construction applications. The company has reported a 30% increase in tensile strength and a 40% improvement in flexural modulus compared to standard polypropylene[5].

Strengths: Excellent processability, high thermal stability, and improved mechanical properties. Weaknesses: Potential limitations in extreme temperature applications and higher raw material costs.

Core FRP Innovations

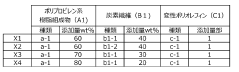

Fiber-reinforced polypropylene resin composition

PatentActiveJP2022174644A

Innovation

- A specific blend of carbon and glass fibers in a polypropylene resin composition, with a ratio of 20/80 to 80/20, along with a modified polyolefin resin, to enhance interfacial strength and maintain mechanical properties.

Fiber-Reinforced Polypropylene/Elastomer Composite

PatentActiveUS20120157631A1

Innovation

- A fiber-reinforced composite with a propylene polymer containing 90% or more propylene monomeric units, grafted with 10-80% fibers and 5-50% elastomers, where greater than 50% of the fibers are dispersed in the propylene polymer phase, achieved through a process involving peroxide-initiated grafting and dispersion in a propylene master batch.

Sustainability Impact

Fiber-reinforced polypropylene (FRPP) is making significant strides in enhancing the sustainability of construction materials. This innovative composite material combines the lightweight and cost-effective properties of polypropylene with the strength and durability of reinforcing fibers, resulting in a material that offers substantial environmental benefits.

One of the primary sustainability advantages of FRPP is its potential to reduce the overall carbon footprint of construction projects. The production of FRPP requires less energy compared to traditional materials like steel or concrete, leading to lower greenhouse gas emissions during the manufacturing process. Additionally, the lightweight nature of FRPP reduces transportation costs and associated emissions, further minimizing its environmental impact.

FRPP's durability and resistance to corrosion contribute to extended service life for structures, reducing the need for frequent replacements or repairs. This longevity translates to fewer resources consumed over time and less waste generated, aligning with circular economy principles. Moreover, FRPP's resistance to chemical degradation makes it an ideal choice for applications in harsh environments, where traditional materials might require more frequent maintenance or replacement.

The recyclability of FRPP is another crucial aspect of its sustainability profile. At the end of its life cycle, FRPP can be recycled and repurposed, reducing the amount of construction waste sent to landfills. This recyclability not only conserves raw materials but also helps close the loop in material usage, promoting a more sustainable approach to construction.

FRPP's thermal insulation properties contribute to improved energy efficiency in buildings. Structures incorporating FRPP components can achieve better temperature regulation, reducing the energy demands for heating and cooling. This energy-saving characteristic translates to lower operational costs and reduced carbon emissions over the lifetime of the building.

The use of FRPP in construction also supports sustainable design practices. Its versatility allows for innovative architectural solutions that can incorporate passive solar design, natural ventilation, and other eco-friendly features. The material's adaptability enables the creation of lightweight, yet strong structures that can be easily modified or expanded, promoting flexible and sustainable building designs.

As the construction industry faces increasing pressure to adopt more sustainable practices, FRPP emerges as a promising solution. Its ability to combine strength, durability, and environmental benefits positions it as a key driver in the transition towards more sustainable construction materials. The ongoing research and development in FRPP technology continue to enhance its sustainability credentials, paving the way for a greener future in the construction sector.

One of the primary sustainability advantages of FRPP is its potential to reduce the overall carbon footprint of construction projects. The production of FRPP requires less energy compared to traditional materials like steel or concrete, leading to lower greenhouse gas emissions during the manufacturing process. Additionally, the lightweight nature of FRPP reduces transportation costs and associated emissions, further minimizing its environmental impact.

FRPP's durability and resistance to corrosion contribute to extended service life for structures, reducing the need for frequent replacements or repairs. This longevity translates to fewer resources consumed over time and less waste generated, aligning with circular economy principles. Moreover, FRPP's resistance to chemical degradation makes it an ideal choice for applications in harsh environments, where traditional materials might require more frequent maintenance or replacement.

The recyclability of FRPP is another crucial aspect of its sustainability profile. At the end of its life cycle, FRPP can be recycled and repurposed, reducing the amount of construction waste sent to landfills. This recyclability not only conserves raw materials but also helps close the loop in material usage, promoting a more sustainable approach to construction.

FRPP's thermal insulation properties contribute to improved energy efficiency in buildings. Structures incorporating FRPP components can achieve better temperature regulation, reducing the energy demands for heating and cooling. This energy-saving characteristic translates to lower operational costs and reduced carbon emissions over the lifetime of the building.

The use of FRPP in construction also supports sustainable design practices. Its versatility allows for innovative architectural solutions that can incorporate passive solar design, natural ventilation, and other eco-friendly features. The material's adaptability enables the creation of lightweight, yet strong structures that can be easily modified or expanded, promoting flexible and sustainable building designs.

As the construction industry faces increasing pressure to adopt more sustainable practices, FRPP emerges as a promising solution. Its ability to combine strength, durability, and environmental benefits positions it as a key driver in the transition towards more sustainable construction materials. The ongoing research and development in FRPP technology continue to enhance its sustainability credentials, paving the way for a greener future in the construction sector.

Regulatory Landscape

The regulatory landscape surrounding fiber-reinforced polypropylene (FRPP) in construction materials is complex and evolving. As this innovative material gains traction in the building industry, governments and regulatory bodies are adapting their frameworks to ensure safety, sustainability, and performance standards are met.

In many jurisdictions, building codes and standards are being updated to incorporate FRPP as a recognized construction material. These updates often include specific requirements for material composition, strength, durability, and fire resistance. For instance, the International Building Code (IBC) has introduced provisions for the use of fiber-reinforced polymers in structural applications, which encompass FRPP.

Environmental regulations also play a significant role in shaping the adoption of FRPP. Many countries have implemented policies to promote sustainable construction practices, which can favor the use of FRPP due to its potential for recycling and reduced carbon footprint compared to traditional materials. The European Union's Construction Products Regulation (CPR) mandates that construction products meet specific environmental and safety requirements, influencing the development and use of FRPP in the region.

Safety standards for FRPP are particularly stringent, given its application in critical infrastructure. Regulatory bodies such as ASTM International and the European Committee for Standardization (CEN) have developed specific testing protocols and performance criteria for fiber-reinforced composites used in construction. These standards address issues such as load-bearing capacity, resistance to environmental factors, and long-term durability.

The regulatory landscape also extends to the manufacturing processes of FRPP. Occupational health and safety regulations govern the production environment, ensuring worker protection from potential hazards associated with polymer processing and fiber handling. Additionally, quality control standards are in place to maintain consistency and reliability in FRPP production.

As FRPP technology continues to advance, regulatory bodies are working to keep pace with innovation. This includes the development of new testing methodologies and performance metrics specifically tailored to the unique properties of FRPP. Collaborative efforts between industry stakeholders, research institutions, and regulatory agencies are crucial in establishing appropriate guidelines that balance innovation with public safety.

The global nature of the construction industry necessitates international harmonization of FRPP regulations. Efforts are underway to align standards across different regions, facilitating trade and ensuring consistent quality worldwide. Organizations such as the International Organization for Standardization (ISO) are instrumental in developing globally recognized standards for FRPP and other advanced construction materials.

In many jurisdictions, building codes and standards are being updated to incorporate FRPP as a recognized construction material. These updates often include specific requirements for material composition, strength, durability, and fire resistance. For instance, the International Building Code (IBC) has introduced provisions for the use of fiber-reinforced polymers in structural applications, which encompass FRPP.

Environmental regulations also play a significant role in shaping the adoption of FRPP. Many countries have implemented policies to promote sustainable construction practices, which can favor the use of FRPP due to its potential for recycling and reduced carbon footprint compared to traditional materials. The European Union's Construction Products Regulation (CPR) mandates that construction products meet specific environmental and safety requirements, influencing the development and use of FRPP in the region.

Safety standards for FRPP are particularly stringent, given its application in critical infrastructure. Regulatory bodies such as ASTM International and the European Committee for Standardization (CEN) have developed specific testing protocols and performance criteria for fiber-reinforced composites used in construction. These standards address issues such as load-bearing capacity, resistance to environmental factors, and long-term durability.

The regulatory landscape also extends to the manufacturing processes of FRPP. Occupational health and safety regulations govern the production environment, ensuring worker protection from potential hazards associated with polymer processing and fiber handling. Additionally, quality control standards are in place to maintain consistency and reliability in FRPP production.

As FRPP technology continues to advance, regulatory bodies are working to keep pace with innovation. This includes the development of new testing methodologies and performance metrics specifically tailored to the unique properties of FRPP. Collaborative efforts between industry stakeholders, research institutions, and regulatory agencies are crucial in establishing appropriate guidelines that balance innovation with public safety.

The global nature of the construction industry necessitates international harmonization of FRPP regulations. Efforts are underway to align standards across different regions, facilitating trade and ensuring consistent quality worldwide. Organizations such as the International Organization for Standardization (ISO) are instrumental in developing globally recognized standards for FRPP and other advanced construction materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!