Exploring Polypropylene in Advanced Micro-Electromechanical Systems

MEMS PP Integration

The integration of polypropylene (PP) into Micro-Electromechanical Systems (MEMS) represents a significant advancement in the field of advanced materials for microdevices. PP, a thermoplastic polymer, offers unique properties that make it an attractive candidate for MEMS applications. Its low density, high chemical resistance, and excellent mechanical properties provide new possibilities for device fabrication and performance enhancement.

One of the primary advantages of incorporating PP into MEMS is its potential to reduce overall device weight while maintaining structural integrity. This characteristic is particularly valuable in applications where minimizing mass is crucial, such as in aerospace or portable electronic devices. Additionally, PP's resistance to a wide range of chemicals and solvents makes it suitable for MEMS devices operating in harsh environments or those exposed to various chemical agents.

The integration process of PP into MEMS structures involves several innovative techniques. One approach is the use of micro-injection molding, which allows for the precise shaping of PP components at the microscale. This method enables the creation of complex geometries and fine features that are essential for many MEMS devices. Another technique involves the surface modification of PP to enhance its adhesion properties, facilitating better integration with other materials commonly used in MEMS fabrication, such as silicon or metals.

Researchers have also explored the use of PP as a sacrificial layer in MEMS fabrication processes. In this application, PP serves as a temporary support structure that can be easily removed after the formation of the desired device components. This approach offers new possibilities for creating suspended structures and complex 3D geometries in MEMS devices.

The electrical properties of PP present both challenges and opportunities in MEMS integration. While PP is inherently an electrical insulator, researchers have investigated methods to modify its conductivity. These include the incorporation of conductive fillers or the creation of composite materials that combine PP with conductive elements. Such modifications open up new avenues for developing MEMS devices with tailored electrical characteristics.

Despite the promising aspects of PP integration in MEMS, several challenges remain. Ensuring consistent material properties at the microscale, developing reliable bonding techniques with other MEMS materials, and optimizing processing parameters for PP-based MEMS fabrication are areas that require further research and development. Additionally, the long-term stability and performance of PP in MEMS devices under various operating conditions need to be thoroughly evaluated to ensure reliability in practical applications.

As the field progresses, the integration of PP in MEMS is expected to enable new device designs and functionalities. The combination of PP's unique properties with established MEMS fabrication techniques has the potential to revolutionize areas such as biomedical sensors, microfluidic devices, and flexible electronics. Ongoing research in this area continues to push the boundaries of what is possible in MEMS technology, paving the way for more advanced and versatile microdevices in the future.

MEMS Market Analysis

The MEMS (Micro-Electromechanical Systems) market has experienced significant growth in recent years, driven by increasing demand for miniaturized and high-performance electronic devices across various industries. The global MEMS market size was valued at approximately $11.5 billion in 2019 and is projected to reach $18.2 billion by 2025, growing at a CAGR of 8.3% during the forecast period.

The automotive sector represents one of the largest application areas for MEMS devices, accounting for about 30% of the market share. MEMS sensors and actuators are extensively used in advanced driver assistance systems (ADAS), airbag deployment systems, and tire pressure monitoring systems. The consumer electronics segment follows closely, with MEMS components being integral to smartphones, wearables, and gaming devices.

In the healthcare industry, MEMS technology is gaining traction in medical devices and diagnostic equipment. The market for MEMS in healthcare is expected to grow at a CAGR of 12.5% from 2020 to 2025, driven by the increasing adoption of minimally invasive surgical procedures and the development of smart medical implants.

The industrial sector is another key market for MEMS, with applications in process control, automation, and condition monitoring. The industrial MEMS market is projected to grow at a CAGR of 7.8% from 2020 to 2025, fueled by the ongoing Industry 4.0 revolution and the increasing focus on predictive maintenance.

Geographically, Asia Pacific dominates the MEMS market, accounting for over 40% of the global market share. This is primarily due to the presence of major semiconductor manufacturers and the rapid growth of consumer electronics industries in countries like China, Japan, and South Korea. North America and Europe follow, with significant contributions from the automotive and aerospace sectors.

The integration of polypropylene in advanced MEMS devices presents new opportunities for market growth. Polypropylene's unique properties, such as low density, high chemical resistance, and excellent mechanical strength, make it an attractive material for MEMS applications. The use of polypropylene in MEMS is expected to drive innovation in areas such as microfluidics, biomedical devices, and environmental sensors.

As the demand for smaller, more efficient, and cost-effective MEMS devices continues to grow, the market is likely to witness further expansion and diversification. The ongoing research and development efforts in materials science, including the exploration of polypropylene in MEMS, are expected to open up new application areas and contribute to the overall market growth in the coming years.

PP MEMS Challenges

The integration of polypropylene (PP) into advanced Micro-Electromechanical Systems (MEMS) presents several significant challenges that researchers and engineers must address. These challenges stem from the inherent properties of PP and the demanding requirements of MEMS applications.

One of the primary challenges is the thermal stability of polypropylene in MEMS devices. MEMS often operate in environments with fluctuating temperatures, and PP's relatively low melting point (around 160°C) can limit its use in high-temperature applications. This thermal sensitivity can lead to dimensional instability and potential failure of MEMS components under extreme conditions.

Another critical issue is the mechanical properties of PP in micro-scale structures. While PP offers good flexibility and impact resistance in macro-scale applications, its behavior at the micro-level can be less predictable. The polymer chains' orientation and crystallinity can significantly affect the material's strength and elasticity in MEMS devices, potentially leading to inconsistent performance across different batches or even within the same device.

The surface properties of PP also pose challenges in MEMS fabrication. PP's hydrophobic nature can make it difficult to achieve proper adhesion with other materials commonly used in MEMS, such as silicon or metals. This can result in delamination or poor interfacial bonding, compromising the integrity and functionality of the MEMS device.

Precision manufacturing of PP components for MEMS is another hurdle. Traditional microfabrication techniques, often optimized for silicon and other inorganic materials, may not be directly applicable to PP. Developing new or adapting existing microfabrication processes to work effectively with PP while maintaining the high precision required for MEMS is a significant challenge.

The long-term stability and aging of PP in MEMS environments is also a concern. Exposure to various environmental factors, such as UV radiation, moisture, and chemical agents, can degrade PP over time. This degradation can alter the material's properties and potentially lead to device failure, especially in applications requiring long-term reliability.

Lastly, the integration of PP with other MEMS materials and components presents compatibility issues. Ensuring that PP can coexist and function effectively alongside other materials without causing contamination, unwanted chemical reactions, or performance degradation is crucial for successful MEMS design and operation.

Addressing these challenges requires interdisciplinary research efforts, combining expertise from polymer science, microfabrication technology, and MEMS design. Innovations in material science, such as developing PP composites or surface treatments, may offer solutions to some of these issues. Additionally, advancements in manufacturing techniques and design strategies tailored specifically for PP in MEMS applications will be essential for overcoming these obstacles and fully leveraging the potential benefits of PP in advanced MEMS technologies.

PP MEMS Solutions

01 Polypropylene synthesis and production methods

Various methods for synthesizing and producing polypropylene, including catalytic processes, polymerization techniques, and reactor designs. These methods aim to improve the efficiency and quality of polypropylene production, resulting in materials with enhanced properties for diverse applications.- Polypropylene synthesis and production methods: Various methods for synthesizing and producing polypropylene, including polymerization techniques, catalyst systems, and process improvements to enhance yield and quality of the resulting polymer.

- Polypropylene compositions and blends: Development of polypropylene compositions and blends with other materials to enhance specific properties such as strength, flexibility, or heat resistance for various applications in industries like packaging, automotive, and construction.

- Polypropylene modification techniques: Methods for modifying polypropylene through chemical or physical processes to improve its properties, such as impact resistance, weatherability, or compatibility with other materials for specific end-use applications.

- Polypropylene film and fiber applications: Innovations in polypropylene film and fiber production, including orientation techniques, surface treatments, and specialized formulations for applications in packaging, textiles, and non-woven materials.

- Recycling and sustainability of polypropylene: Advancements in polypropylene recycling technologies, development of bio-based polypropylene alternatives, and methods to improve the overall sustainability and environmental impact of polypropylene production and use.

02 Polypropylene composites and blends

Development of polypropylene-based composites and blends with other materials to enhance specific properties such as strength, durability, or thermal resistance. These formulations can be tailored for various industrial applications, including automotive parts, packaging, and construction materials.Expand Specific Solutions03 Polypropylene modification techniques

Methods for modifying polypropylene to improve its performance characteristics, such as impact resistance, weatherability, or compatibility with other materials. These techniques may include chemical treatments, additives, or physical modifications to enhance the polymer's properties for specific applications.Expand Specific Solutions04 Polypropylene processing and manufacturing

Innovative processing and manufacturing techniques for polypropylene products, including extrusion, injection molding, and film production. These methods focus on improving production efficiency, reducing costs, and enhancing the quality of final polypropylene products.Expand Specific Solutions05 Polypropylene applications and end-use products

Development of specific polypropylene formulations and products for various industries, such as packaging, textiles, automotive, and medical devices. These applications leverage the unique properties of polypropylene to create innovative solutions and improve existing products.Expand Specific Solutions

MEMS Industry Leaders

The exploration of polypropylene in advanced micro-electromechanical systems (MEMS) is in a growth phase, with increasing market size and technological advancements. The competitive landscape is characterized by a mix of established petrochemical giants and specialized materials companies. Key players like ExxonMobil Chemical, LG Chem, and Borealis AG are leveraging their expertise in polymer science to develop high-performance polypropylene for MEMS applications. Emerging companies such as Kingfa Sci. & Tech. and Shanghai PRET Composites are focusing on innovative composites and modified plastics. The technology is maturing, with companies like Mitsui Chemicals and SABIC Global Technologies investing in R&D to enhance polypropylene's properties for miniaturized electronic systems.

ExxonMobil Chemical Patents, Inc.

Mitsui Chemicals, Inc.

PP MEMS Innovations

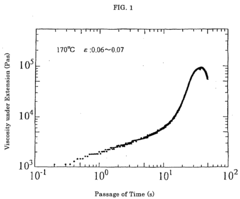

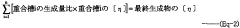

- A two-stage polymerization process using specific catalysts and polyenes to control the molecular weight and branching of polypropylene, ensuring improved melting elasticity, secondary workability, and the absence of gel content, while maintaining environmental sustainability.

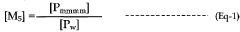

- Precise control of polypropylene properties, including melting flow rate, mesopentad fraction, and impurity content, to achieve consistent high-level electrical insulation.

- Development of polypropylene with excellent electrical insulation and rough surface properties without the need for additives like β-crystal nucleation agents.

- Versatile application of the developed polypropylene in various electrical materials, including capacitor films, electric wire covering, and electronic material transport apparatus.

PP MEMS Standards

The development of standards for polypropylene (PP) in Micro-Electromechanical Systems (MEMS) is crucial for ensuring consistency, reliability, and interoperability in this rapidly evolving field. These standards encompass various aspects of PP MEMS, including material properties, fabrication processes, testing methodologies, and performance metrics.

One of the primary focuses of PP MEMS standards is the characterization of polypropylene's mechanical and electrical properties when used in microscale devices. This includes standardized testing procedures for measuring tensile strength, flexural modulus, dielectric constant, and thermal stability at the micro and nanoscale levels. These standards help engineers and researchers accurately predict and optimize the performance of PP-based MEMS devices.

Fabrication process standards for PP MEMS are also being developed to ensure reproducibility and quality control. These standards cover aspects such as injection molding parameters, surface treatment techniques, and bonding protocols specific to polypropylene in MEMS applications. By adhering to these standards, manufacturers can achieve consistent results and improve the overall reliability of PP MEMS devices.

Testing and characterization standards for PP MEMS devices are essential for evaluating their performance and durability. These standards define protocols for assessing factors such as fatigue resistance, environmental stability, and long-term reliability. Standardized testing methods enable meaningful comparisons between different PP MEMS designs and facilitate the selection of appropriate materials for specific applications.

Dimensional and tolerance standards for PP MEMS components are being established to ensure compatibility and interchangeability across different manufacturers and applications. These standards define acceptable ranges for critical dimensions, surface roughness, and feature sizes, taking into account the unique properties of polypropylene and the challenges of working with it at the microscale.

Environmental and safety standards for PP MEMS are also being developed, addressing concerns such as biocompatibility, chemical resistance, and potential environmental impacts. These standards are particularly important for applications in medical devices, environmental sensors, and consumer electronics, where the safety and sustainability of materials are paramount.

As the field of PP MEMS continues to advance, standards organizations are working to keep pace with new developments and emerging applications. This includes the creation of guidelines for novel fabrication techniques, such as 3D printing of PP MEMS structures, and the integration of PP MEMS with other materials and technologies.

PP MEMS Sustainability

The integration of polypropylene (PP) in advanced Micro-Electromechanical Systems (MEMS) presents a significant opportunity for enhancing sustainability in the field of microelectronics. PP, a versatile thermoplastic polymer, offers several advantages that align with sustainable practices in MEMS manufacturing and application.

One of the primary sustainability benefits of using PP in MEMS is its recyclability. Unlike many traditional materials used in microelectronics, PP can be easily recycled and repurposed, reducing waste and promoting a circular economy. This characteristic is particularly valuable in an industry that often struggles with electronic waste management.

PP's low density and high strength-to-weight ratio contribute to resource efficiency in MEMS production. By utilizing less material to achieve the same or better performance, PP-based MEMS components can reduce the overall environmental footprint of devices. This efficiency extends to energy consumption during manufacturing processes, as PP typically requires lower processing temperatures compared to some alternative materials.

The durability and chemical resistance of PP also play crucial roles in sustainability. MEMS devices incorporating PP components often exhibit extended lifespans, reducing the need for frequent replacements and thereby minimizing waste generation. Additionally, PP's resistance to a wide range of chemicals enhances the longevity of MEMS devices in various applications, including those in harsh environments.

In terms of eco-friendly production, PP offers advantages in MEMS fabrication. Many PP-based MEMS can be manufactured using additive manufacturing techniques, such as 3D printing, which typically produce less waste compared to traditional subtractive manufacturing methods. This approach not only conserves resources but also allows for more precise and customized production, potentially reducing overproduction and associated waste.

The biocompatibility of certain grades of PP opens up sustainable applications in biomedical MEMS. These devices can be used for non-invasive or minimally invasive medical procedures, potentially reducing the need for more resource-intensive treatments. Furthermore, the use of PP in disposable medical MEMS can offer a more environmentally friendly alternative to traditional single-use devices.

As the MEMS industry continues to evolve, the exploration of PP in advanced applications aligns with broader sustainability goals. Research into bio-based polypropylene derivatives could further enhance the environmental credentials of PP-based MEMS. Additionally, ongoing efforts to improve PP's properties, such as enhanced thermal stability and electrical characteristics, may expand its use in sustainable MEMS applications, potentially replacing less environmentally friendly materials in certain devices.