How Polypropylene Reinforcement Strengthens Seismic Safety Products

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Seismic Safety Evolution

The evolution of seismic safety products has been closely tied to advancements in materials science and engineering. Over the past century, significant progress has been made in developing technologies to mitigate the devastating effects of earthquakes on structures and human lives. The journey began with simple reinforcement techniques using steel and concrete, gradually evolving into more sophisticated systems incorporating innovative materials and designs.

In the early 20th century, seismic safety primarily relied on rigid structural designs and basic reinforcement methods. As understanding of seismic behavior improved, engineers began implementing more flexible designs that could absorb and dissipate seismic energy. The introduction of base isolation systems in the 1960s marked a major breakthrough, allowing buildings to move independently from the ground during earthquakes.

The 1970s and 1980s saw the development of energy dissipation devices, such as viscous dampers and friction dampers, which further enhanced the ability of structures to withstand seismic forces. These innovations were complemented by advances in computer modeling and simulation, enabling more accurate predictions of building behavior during earthquakes.

The late 20th century witnessed a shift towards performance-based seismic design, focusing on achieving specific levels of structural performance under various earthquake scenarios. This approach led to the development of more tailored and efficient seismic safety solutions.

In recent years, the integration of smart materials and technologies has revolutionized seismic safety products. Shape memory alloys, magnetorheological fluids, and other adaptive materials have been incorporated into innovative damping systems, offering enhanced responsiveness to seismic events.

The introduction of polypropylene reinforcement represents a significant milestone in this evolutionary timeline. Polypropylene fibers, known for their high tensile strength and durability, have emerged as a promising material for enhancing the seismic performance of concrete structures. When dispersed throughout concrete mixtures, these fibers create a three-dimensional reinforcement network that significantly improves the material's ductility and crack resistance.

The adoption of polypropylene reinforcement in seismic safety products has gained momentum due to its ability to address key challenges in earthquake-resistant design. Unlike traditional steel reinforcement, polypropylene fibers do not corrode, ensuring long-term durability in aggressive environments. Moreover, their lightweight nature allows for easier handling and installation, potentially reducing construction costs and time.

As research continues, the potential of polypropylene reinforcement in seismic safety applications is being further explored. Scientists and engineers are investigating optimal fiber geometries, dosages, and combinations with other materials to maximize the seismic performance of structures. This ongoing evolution promises to yield even more effective and efficient seismic safety solutions in the future, contributing to the resilience of built environments in earthquake-prone regions worldwide.

In the early 20th century, seismic safety primarily relied on rigid structural designs and basic reinforcement methods. As understanding of seismic behavior improved, engineers began implementing more flexible designs that could absorb and dissipate seismic energy. The introduction of base isolation systems in the 1960s marked a major breakthrough, allowing buildings to move independently from the ground during earthquakes.

The 1970s and 1980s saw the development of energy dissipation devices, such as viscous dampers and friction dampers, which further enhanced the ability of structures to withstand seismic forces. These innovations were complemented by advances in computer modeling and simulation, enabling more accurate predictions of building behavior during earthquakes.

The late 20th century witnessed a shift towards performance-based seismic design, focusing on achieving specific levels of structural performance under various earthquake scenarios. This approach led to the development of more tailored and efficient seismic safety solutions.

In recent years, the integration of smart materials and technologies has revolutionized seismic safety products. Shape memory alloys, magnetorheological fluids, and other adaptive materials have been incorporated into innovative damping systems, offering enhanced responsiveness to seismic events.

The introduction of polypropylene reinforcement represents a significant milestone in this evolutionary timeline. Polypropylene fibers, known for their high tensile strength and durability, have emerged as a promising material for enhancing the seismic performance of concrete structures. When dispersed throughout concrete mixtures, these fibers create a three-dimensional reinforcement network that significantly improves the material's ductility and crack resistance.

The adoption of polypropylene reinforcement in seismic safety products has gained momentum due to its ability to address key challenges in earthquake-resistant design. Unlike traditional steel reinforcement, polypropylene fibers do not corrode, ensuring long-term durability in aggressive environments. Moreover, their lightweight nature allows for easier handling and installation, potentially reducing construction costs and time.

As research continues, the potential of polypropylene reinforcement in seismic safety applications is being further explored. Scientists and engineers are investigating optimal fiber geometries, dosages, and combinations with other materials to maximize the seismic performance of structures. This ongoing evolution promises to yield even more effective and efficient seismic safety solutions in the future, contributing to the resilience of built environments in earthquake-prone regions worldwide.

Market Demand Analysis

The market demand for seismic safety products reinforced with polypropylene has been steadily increasing in recent years, driven by growing awareness of earthquake risks and stricter building codes in seismically active regions. This trend is particularly evident in countries along the Pacific Ring of Fire, including Japan, the United States, Chile, and New Zealand, as well as other earthquake-prone areas such as Turkey and Italy.

The construction industry, especially in high-risk seismic zones, has shown a significant interest in polypropylene-reinforced seismic safety products due to their superior performance in enhancing structural integrity during earthquakes. These products offer improved ductility, energy absorption, and crack resistance compared to traditional reinforcement materials, making them highly desirable for both new construction and retrofitting projects.

In the residential sector, homeowners and developers are increasingly seeking cost-effective solutions to improve the seismic resilience of buildings. This has led to a growing demand for polypropylene-reinforced concrete and other structural elements that can be easily incorporated into existing structures or new builds. The retrofit market, in particular, presents a substantial opportunity as older buildings in seismic zones require upgrades to meet current safety standards.

The commercial and industrial sectors also contribute significantly to the market demand. Large-scale infrastructure projects, including bridges, highways, and public buildings, are adopting polypropylene-reinforced materials to enhance their seismic performance. This trend is expected to continue as governments and private entities invest in resilient infrastructure to mitigate the economic and social impacts of earthquakes.

The global market for seismic safety products is projected to grow substantially in the coming years. Factors contributing to this growth include urbanization in earthquake-prone regions, increasing investments in infrastructure development, and the implementation of more stringent building codes. The Asia-Pacific region is expected to be a key driver of market growth, with China and Japan leading in terms of adoption and innovation in seismic safety technologies.

Moreover, the insurance industry's emphasis on risk mitigation has created additional incentives for property owners to invest in seismic safety products. Insurance companies are increasingly offering premium discounts for buildings equipped with advanced seismic protection systems, further stimulating market demand.

As sustainability becomes a more prominent concern in the construction industry, the eco-friendly nature of polypropylene-reinforced products adds to their appeal. These materials often require less energy to produce and can contribute to reducing the overall carbon footprint of buildings, aligning with green building initiatives and regulations.

The construction industry, especially in high-risk seismic zones, has shown a significant interest in polypropylene-reinforced seismic safety products due to their superior performance in enhancing structural integrity during earthquakes. These products offer improved ductility, energy absorption, and crack resistance compared to traditional reinforcement materials, making them highly desirable for both new construction and retrofitting projects.

In the residential sector, homeowners and developers are increasingly seeking cost-effective solutions to improve the seismic resilience of buildings. This has led to a growing demand for polypropylene-reinforced concrete and other structural elements that can be easily incorporated into existing structures or new builds. The retrofit market, in particular, presents a substantial opportunity as older buildings in seismic zones require upgrades to meet current safety standards.

The commercial and industrial sectors also contribute significantly to the market demand. Large-scale infrastructure projects, including bridges, highways, and public buildings, are adopting polypropylene-reinforced materials to enhance their seismic performance. This trend is expected to continue as governments and private entities invest in resilient infrastructure to mitigate the economic and social impacts of earthquakes.

The global market for seismic safety products is projected to grow substantially in the coming years. Factors contributing to this growth include urbanization in earthquake-prone regions, increasing investments in infrastructure development, and the implementation of more stringent building codes. The Asia-Pacific region is expected to be a key driver of market growth, with China and Japan leading in terms of adoption and innovation in seismic safety technologies.

Moreover, the insurance industry's emphasis on risk mitigation has created additional incentives for property owners to invest in seismic safety products. Insurance companies are increasingly offering premium discounts for buildings equipped with advanced seismic protection systems, further stimulating market demand.

As sustainability becomes a more prominent concern in the construction industry, the eco-friendly nature of polypropylene-reinforced products adds to their appeal. These materials often require less energy to produce and can contribute to reducing the overall carbon footprint of buildings, aligning with green building initiatives and regulations.

PP Reinforcement Status

Polypropylene (PP) reinforcement has emerged as a crucial component in enhancing the seismic safety of various products and structures. The current status of PP reinforcement in seismic safety applications reflects significant advancements in material science and engineering, with widespread adoption across multiple industries.

In recent years, the integration of PP reinforcement into seismic safety products has gained substantial traction due to its exceptional mechanical properties and cost-effectiveness. The material's high strength-to-weight ratio, coupled with its resistance to fatigue and chemical corrosion, makes it an ideal choice for reinforcing structures subjected to seismic loads.

The construction industry has been at the forefront of adopting PP reinforcement for seismic safety. Fiber-reinforced concrete (FRC) incorporating PP fibers has shown remarkable improvements in ductility, crack resistance, and energy absorption capacity. This has led to its increased use in critical infrastructure such as bridges, tunnels, and high-rise buildings located in seismically active regions.

In the realm of geotechnical engineering, PP geotextiles and geogrids have proven effective in soil stabilization and reinforcement. These materials enhance the load-bearing capacity of foundations and retaining walls, crucial for maintaining structural integrity during seismic events. The lightweight nature of PP reinforcement also reduces the overall mass of structures, thereby decreasing seismic forces.

The automotive industry has also embraced PP reinforcement in the design of seismic safety components. PP-reinforced composites are increasingly used in the manufacture of energy-absorbing structures, such as crash boxes and bumper systems, enhancing vehicle occupant safety during seismic-induced accidents.

Recent technological advancements have further improved the performance of PP reinforcement. Nano-reinforced PP composites, incorporating carbon nanotubes or graphene, have shown promise in enhancing the material's mechanical properties and seismic resistance. Additionally, the development of long-chain branched PP has led to improved melt strength and processability, expanding its applications in complex seismic safety products.

Despite these advancements, challenges remain in the widespread adoption of PP reinforcement for seismic safety. Concerns regarding long-term durability under extreme environmental conditions and the need for standardized testing protocols specific to seismic applications persist. Ongoing research focuses on addressing these issues and optimizing PP reinforcement for diverse seismic safety applications.

In conclusion, the current status of PP reinforcement in seismic safety products reflects a rapidly evolving field with significant potential for further innovation and improvement. As research continues and new applications emerge, PP reinforcement is poised to play an increasingly vital role in enhancing the resilience of structures and products against seismic events.

In recent years, the integration of PP reinforcement into seismic safety products has gained substantial traction due to its exceptional mechanical properties and cost-effectiveness. The material's high strength-to-weight ratio, coupled with its resistance to fatigue and chemical corrosion, makes it an ideal choice for reinforcing structures subjected to seismic loads.

The construction industry has been at the forefront of adopting PP reinforcement for seismic safety. Fiber-reinforced concrete (FRC) incorporating PP fibers has shown remarkable improvements in ductility, crack resistance, and energy absorption capacity. This has led to its increased use in critical infrastructure such as bridges, tunnels, and high-rise buildings located in seismically active regions.

In the realm of geotechnical engineering, PP geotextiles and geogrids have proven effective in soil stabilization and reinforcement. These materials enhance the load-bearing capacity of foundations and retaining walls, crucial for maintaining structural integrity during seismic events. The lightweight nature of PP reinforcement also reduces the overall mass of structures, thereby decreasing seismic forces.

The automotive industry has also embraced PP reinforcement in the design of seismic safety components. PP-reinforced composites are increasingly used in the manufacture of energy-absorbing structures, such as crash boxes and bumper systems, enhancing vehicle occupant safety during seismic-induced accidents.

Recent technological advancements have further improved the performance of PP reinforcement. Nano-reinforced PP composites, incorporating carbon nanotubes or graphene, have shown promise in enhancing the material's mechanical properties and seismic resistance. Additionally, the development of long-chain branched PP has led to improved melt strength and processability, expanding its applications in complex seismic safety products.

Despite these advancements, challenges remain in the widespread adoption of PP reinforcement for seismic safety. Concerns regarding long-term durability under extreme environmental conditions and the need for standardized testing protocols specific to seismic applications persist. Ongoing research focuses on addressing these issues and optimizing PP reinforcement for diverse seismic safety applications.

In conclusion, the current status of PP reinforcement in seismic safety products reflects a rapidly evolving field with significant potential for further innovation and improvement. As research continues and new applications emerge, PP reinforcement is poised to play an increasingly vital role in enhancing the resilience of structures and products against seismic events.

Current PP Solutions

01 Fiber reinforcement for polypropylene

Incorporating fibers into polypropylene matrices can significantly enhance the material's strength. Various types of fibers, such as glass, carbon, or natural fibers, can be used to create composite materials with improved mechanical properties. The fiber reinforcement increases tensile strength, impact resistance, and overall durability of polypropylene-based products.- Fiber reinforcement for polypropylene: Incorporating various types of fibers into polypropylene matrices can significantly enhance the material's strength. These fibers, which may include glass, carbon, or natural fibers, create a composite structure that improves tensile strength, impact resistance, and overall mechanical properties of the polypropylene.

- Nanoparticle additives for strength enhancement: The addition of nanoparticles, such as carbon nanotubes, graphene, or nano-clays, to polypropylene can dramatically increase its strength. These nanoparticles create a more uniform distribution within the polymer matrix, leading to improved mechanical properties, including tensile strength and modulus.

- Copolymerization and blending techniques: Copolymerization of polypropylene with other monomers or blending with different polymers can enhance its strength properties. This approach allows for the creation of materials with tailored mechanical characteristics, combining the benefits of multiple polymer types to achieve superior strength and performance.

- Cross-linking and molecular weight optimization: Techniques involving cross-linking of polypropylene chains or optimizing the molecular weight distribution can significantly improve the material's strength. These methods alter the polymer's molecular structure, leading to enhanced mechanical properties, including improved tensile strength and impact resistance.

- Surface treatment and compatibilization: Surface treatment of reinforcing agents or the use of compatibilizers can improve the interfacial adhesion between polypropylene and reinforcing materials. This enhanced interaction leads to better stress transfer and overall improvement in the composite's strength and mechanical properties.

02 Nanoparticle additives for strength enhancement

Adding nanoparticles to polypropylene can greatly improve its strength characteristics. Materials such as nanoclay, carbon nanotubes, or metal oxide nanoparticles can be dispersed within the polymer matrix to enhance mechanical properties. These nanocomposites often exhibit increased tensile strength, stiffness, and barrier properties compared to unmodified polypropylene.Expand Specific Solutions03 Copolymerization and blending techniques

Copolymerization of polypropylene with other monomers or blending with different polymers can lead to improved strength properties. This approach allows for the creation of materials with tailored characteristics, combining the benefits of multiple polymer types. The resulting copolymers or blends often show enhanced mechanical strength, impact resistance, and processability.Expand Specific Solutions04 Cross-linking and molecular weight control

Controlling the molecular weight distribution and introducing cross-linking in polypropylene can significantly affect its strength. Higher molecular weight and controlled cross-linking can lead to improved mechanical properties, including increased tensile strength and impact resistance. Various techniques, such as electron beam irradiation or chemical cross-linking agents, can be employed to achieve these modifications.Expand Specific Solutions05 Surface treatment and compatibilization

Surface treatment of reinforcing agents or the use of compatibilizers can enhance the interfacial adhesion between polypropylene and reinforcing materials. This improved interaction leads to better stress transfer and overall strength enhancement. Techniques such as silane coupling, plasma treatment, or the addition of maleic anhydride grafted polypropylene as a compatibilizer can be employed to achieve stronger composite materials.Expand Specific Solutions

Industry Leaders

The polypropylene reinforcement market for seismic safety products is in a growth phase, driven by increasing awareness of earthquake risks and stricter building codes. The global market size is expanding, with significant potential in earthquake-prone regions. Technologically, the field is advancing rapidly, with companies like Kingfa Sci. & Tech., ExxonMobil, and Borealis AG leading innovation. These firms are developing high-performance polypropylene composites that offer improved strength-to-weight ratios and durability. Hyundai Motor Co. and Shanghai PRET Composites are integrating these materials into automotive applications, while universities like Rice and IIT Roorkee contribute to research advancements. The industry is characterized by a mix of established petrochemical giants and specialized materials companies, indicating a competitive and dynamic landscape.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced polypropylene (PP) grades specifically designed for seismic safety products. Their Achieve™ Advanced PP technology incorporates proprietary catalyst and process innovations to create high-performance resins with enhanced stiffness, impact resistance, and long-term durability[1]. These PP grades are engineered to maintain structural integrity under extreme seismic loads, with some formulations exhibiting up to 30% higher flexural modulus compared to conventional PP[2]. ExxonMobil's reinforced PP compounds also feature improved creep resistance and fatigue performance, critical for maintaining the long-term effectiveness of seismic safety devices[3].

Strengths: Superior mechanical properties, long-term durability, and tailored formulations for seismic applications. Weaknesses: Potentially higher cost compared to standard PP grades, may require specialized processing equipment.

Borealis AG

Technical Solution: Borealis has pioneered the development of Fibremod™, a family of fiber-reinforced PP compounds specifically engineered for demanding structural applications, including seismic safety products. Their technology combines long glass fiber reinforcement with specially modified PP matrices, resulting in materials with exceptional strength-to-weight ratios and impact resistance[4]. Borealis' reinforced PP grades have demonstrated up to 50% weight reduction compared to traditional metal solutions while maintaining comparable mechanical performance[5]. The company has also developed proprietary coupling agents that enhance the fiber-matrix interface, leading to improved stress transfer and overall structural integrity in seismic applications[6].

Strengths: Significant weight reduction, excellent impact resistance, and tailored fiber-matrix interface. Weaknesses: Higher material costs, potential challenges in recycling composite materials.

Key PP Innovations

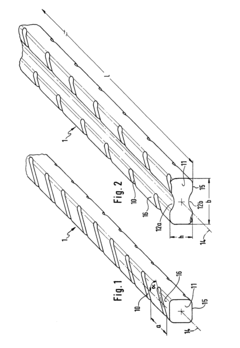

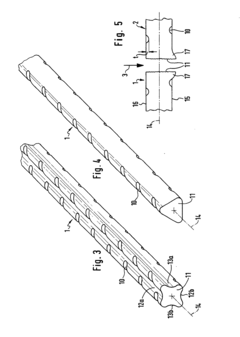

Synthetic reinforcing element for reinforcing of building materials or the like

PatentInactiveEP0438809A1

Innovation

- Highly stretched polypropylene monofilaments with roughened ends and obliquely profiled surfaces are used to create reinforcement elements with enhanced mechanical anchoring and chemical resistance, allowing for improved adhesion and distribution within the composite material.

Filled composite material

PatentInactiveEP0945253B1

Innovation

- Incorporating a polyolefin matrix with chopped glass fibers and mineral fillers such as talc, mica, or calcium carbonate, which enhance the mechanical properties and reduce costs, while maintaining or exceeding the strength of non-filled GMT materials, and minimizing shrinkage and warpage.

Regulatory Framework

The regulatory framework surrounding seismic safety products reinforced with polypropylene is a critical aspect of their development, implementation, and widespread adoption. Building codes and standards play a pivotal role in ensuring the safety and reliability of structures in earthquake-prone regions. These regulations are continuously evolving to incorporate the latest advancements in materials and construction techniques, including the use of polypropylene reinforcement in seismic safety products.

At the international level, organizations such as the International Code Council (ICC) and the International Organization for Standardization (ISO) provide guidelines and standards that influence national and local building codes. The ICC's International Building Code (IBC) and the ISO 3010:2017 standard for seismic actions on structures serve as foundational documents for many countries' regulatory frameworks.

In the United States, the Federal Emergency Management Agency (FEMA) and the National Institute of Standards and Technology (NIST) collaborate to develop seismic design provisions. These provisions are then incorporated into model building codes, such as those published by the American Society of Civil Engineers (ASCE). The ASCE 7 standard, "Minimum Design Loads and Associated Criteria for Buildings and Other Structures," is particularly influential in setting requirements for seismic design and the use of innovative materials like polypropylene reinforcement.

The European Union has established the Eurocode 8 (EN 1998) for the design of structures for earthquake resistance. This code provides a framework for member states to develop their national annexes, allowing for regional variations in seismic risk and construction practices. The incorporation of polypropylene reinforcement in seismic safety products must align with these established standards to gain acceptance and approval for use in construction projects.

Regulatory bodies often require extensive testing and validation of new materials and technologies before they can be integrated into building codes. For polypropylene reinforcement in seismic safety products, this typically involves rigorous laboratory testing, full-scale structural experiments, and computer simulations to demonstrate performance under various seismic scenarios. Certification processes, such as those conducted by the ICC Evaluation Service (ICC-ES) in the United States, provide a pathway for innovative products to gain recognition and acceptance within the regulatory framework.

As the benefits of polypropylene reinforcement in seismic safety products become more apparent, regulatory bodies are likely to update their codes and standards to accommodate and potentially encourage its use. This process involves ongoing collaboration between researchers, industry professionals, and regulatory authorities to ensure that the regulatory framework remains current with technological advancements while maintaining the highest standards of public safety.

At the international level, organizations such as the International Code Council (ICC) and the International Organization for Standardization (ISO) provide guidelines and standards that influence national and local building codes. The ICC's International Building Code (IBC) and the ISO 3010:2017 standard for seismic actions on structures serve as foundational documents for many countries' regulatory frameworks.

In the United States, the Federal Emergency Management Agency (FEMA) and the National Institute of Standards and Technology (NIST) collaborate to develop seismic design provisions. These provisions are then incorporated into model building codes, such as those published by the American Society of Civil Engineers (ASCE). The ASCE 7 standard, "Minimum Design Loads and Associated Criteria for Buildings and Other Structures," is particularly influential in setting requirements for seismic design and the use of innovative materials like polypropylene reinforcement.

The European Union has established the Eurocode 8 (EN 1998) for the design of structures for earthquake resistance. This code provides a framework for member states to develop their national annexes, allowing for regional variations in seismic risk and construction practices. The incorporation of polypropylene reinforcement in seismic safety products must align with these established standards to gain acceptance and approval for use in construction projects.

Regulatory bodies often require extensive testing and validation of new materials and technologies before they can be integrated into building codes. For polypropylene reinforcement in seismic safety products, this typically involves rigorous laboratory testing, full-scale structural experiments, and computer simulations to demonstrate performance under various seismic scenarios. Certification processes, such as those conducted by the ICC Evaluation Service (ICC-ES) in the United States, provide a pathway for innovative products to gain recognition and acceptance within the regulatory framework.

As the benefits of polypropylene reinforcement in seismic safety products become more apparent, regulatory bodies are likely to update their codes and standards to accommodate and potentially encourage its use. This process involves ongoing collaboration between researchers, industry professionals, and regulatory authorities to ensure that the regulatory framework remains current with technological advancements while maintaining the highest standards of public safety.

Environmental Impact

The use of polypropylene reinforcement in seismic safety products has significant environmental implications that warrant careful consideration. This innovative approach to enhancing structural resilience offers several environmental benefits compared to traditional reinforcement methods.

Polypropylene, being a thermoplastic polymer, is highly recyclable. This characteristic aligns well with circular economy principles, allowing for the potential reuse and repurposing of materials at the end of a structure's life cycle. The recyclability of polypropylene reinforcement contributes to reducing waste in the construction industry, which is known for its substantial environmental footprint.

Furthermore, the production of polypropylene reinforcement typically requires less energy compared to the manufacturing of steel reinforcements. This lower energy demand translates to reduced carbon emissions during the production phase, contributing to a smaller overall carbon footprint for seismic safety products incorporating this material.

The lightweight nature of polypropylene reinforcement also offers environmental advantages in terms of transportation and installation. The reduced weight compared to traditional steel reinforcements means less fuel consumption during transportation and potentially simpler installation processes, further minimizing the environmental impact associated with construction activities.

However, it is important to note that polypropylene is derived from petroleum, a non-renewable resource. This aspect raises concerns about the long-term sustainability of its widespread use. The environmental impact of polypropylene production, including potential pollution and resource depletion, must be carefully weighed against its benefits in seismic safety applications.

In terms of durability and longevity, polypropylene reinforcement has shown promising results in resisting corrosion and degradation. This increased durability can lead to extended lifespans for structures, potentially reducing the need for frequent repairs or replacements. Consequently, this may result in lower resource consumption and waste generation over time.

The environmental impact of polypropylene reinforcement in seismic safety products also extends to the end-of-life phase. While the material is recyclable, effective collection and recycling systems need to be in place to fully realize this benefit. Without proper management, there is a risk of polypropylene reinforcement contributing to plastic pollution if not disposed of or recycled correctly.

In conclusion, while polypropylene reinforcement in seismic safety products offers several environmental advantages, including recyclability, energy efficiency in production, and potential for extended product lifespans, it also presents challenges related to its petroleum-based origin and end-of-life management. Balancing these factors is crucial for assessing the overall environmental sustainability of this technology in seismic safety applications.

Polypropylene, being a thermoplastic polymer, is highly recyclable. This characteristic aligns well with circular economy principles, allowing for the potential reuse and repurposing of materials at the end of a structure's life cycle. The recyclability of polypropylene reinforcement contributes to reducing waste in the construction industry, which is known for its substantial environmental footprint.

Furthermore, the production of polypropylene reinforcement typically requires less energy compared to the manufacturing of steel reinforcements. This lower energy demand translates to reduced carbon emissions during the production phase, contributing to a smaller overall carbon footprint for seismic safety products incorporating this material.

The lightweight nature of polypropylene reinforcement also offers environmental advantages in terms of transportation and installation. The reduced weight compared to traditional steel reinforcements means less fuel consumption during transportation and potentially simpler installation processes, further minimizing the environmental impact associated with construction activities.

However, it is important to note that polypropylene is derived from petroleum, a non-renewable resource. This aspect raises concerns about the long-term sustainability of its widespread use. The environmental impact of polypropylene production, including potential pollution and resource depletion, must be carefully weighed against its benefits in seismic safety applications.

In terms of durability and longevity, polypropylene reinforcement has shown promising results in resisting corrosion and degradation. This increased durability can lead to extended lifespans for structures, potentially reducing the need for frequent repairs or replacements. Consequently, this may result in lower resource consumption and waste generation over time.

The environmental impact of polypropylene reinforcement in seismic safety products also extends to the end-of-life phase. While the material is recyclable, effective collection and recycling systems need to be in place to fully realize this benefit. Without proper management, there is a risk of polypropylene reinforcement contributing to plastic pollution if not disposed of or recycled correctly.

In conclusion, while polypropylene reinforcement in seismic safety products offers several environmental advantages, including recyclability, energy efficiency in production, and potential for extended product lifespans, it also presents challenges related to its petroleum-based origin and end-of-life management. Balancing these factors is crucial for assessing the overall environmental sustainability of this technology in seismic safety applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!