How Biobased Polypropylene Embedded Rivets innovate aerodynamics

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biobased PP Rivet Aerodynamics: Background and Objectives

Biobased polypropylene (PP) embedded rivets represent a significant advancement in the field of aerodynamics, combining sustainable materials with innovative design to enhance aircraft performance. This technology has emerged as a response to the growing demand for eco-friendly solutions in the aviation industry, while simultaneously addressing the need for improved aerodynamic efficiency.

The development of biobased PP rivets can be traced back to the early 2000s when researchers began exploring alternatives to traditional petroleum-based plastics. The aviation sector, known for its stringent safety and performance requirements, has been cautious in adopting new materials. However, the pressing need for reducing carbon footprints and improving fuel efficiency has accelerated the integration of sustainable technologies.

Polypropylene, a versatile thermoplastic polymer, has long been used in various industries due to its excellent mechanical properties and chemical resistance. The transition to biobased PP marks a significant step towards sustainability, as it is derived from renewable resources such as corn, sugarcane, or other plant-based feedstocks. This shift aligns with global initiatives to reduce dependency on fossil fuels and minimize environmental impact.

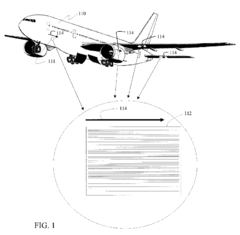

The concept of embedded rivets in aerodynamics is not new, but the application of biobased PP in this context represents a novel approach. Traditional rivets, often made of metal, can create surface irregularities that disrupt airflow and increase drag. By embedding rivets made from biobased PP, engineers aim to create smoother surfaces that enhance laminar flow and reduce turbulence.

The primary objective of this research is to investigate how biobased PP embedded rivets can innovate aerodynamics. This involves a comprehensive analysis of the material properties, manufacturing processes, and aerodynamic performance of these rivets compared to conventional solutions. The study aims to quantify the potential improvements in drag reduction, fuel efficiency, and overall aircraft performance.

Furthermore, this research seeks to address the challenges associated with implementing biobased materials in critical aerospace applications. These challenges include ensuring structural integrity, durability under extreme conditions, and compliance with aviation safety standards. By overcoming these hurdles, the industry can pave the way for wider adoption of sustainable materials in aircraft construction.

Another key objective is to explore the scalability and cost-effectiveness of biobased PP embedded rivets. For this technology to be viable, it must not only offer aerodynamic benefits but also be economically feasible for large-scale production and implementation across various aircraft models. This research aims to provide insights into the potential for mass production and the long-term economic implications of adopting this technology.

The development of biobased PP rivets can be traced back to the early 2000s when researchers began exploring alternatives to traditional petroleum-based plastics. The aviation sector, known for its stringent safety and performance requirements, has been cautious in adopting new materials. However, the pressing need for reducing carbon footprints and improving fuel efficiency has accelerated the integration of sustainable technologies.

Polypropylene, a versatile thermoplastic polymer, has long been used in various industries due to its excellent mechanical properties and chemical resistance. The transition to biobased PP marks a significant step towards sustainability, as it is derived from renewable resources such as corn, sugarcane, or other plant-based feedstocks. This shift aligns with global initiatives to reduce dependency on fossil fuels and minimize environmental impact.

The concept of embedded rivets in aerodynamics is not new, but the application of biobased PP in this context represents a novel approach. Traditional rivets, often made of metal, can create surface irregularities that disrupt airflow and increase drag. By embedding rivets made from biobased PP, engineers aim to create smoother surfaces that enhance laminar flow and reduce turbulence.

The primary objective of this research is to investigate how biobased PP embedded rivets can innovate aerodynamics. This involves a comprehensive analysis of the material properties, manufacturing processes, and aerodynamic performance of these rivets compared to conventional solutions. The study aims to quantify the potential improvements in drag reduction, fuel efficiency, and overall aircraft performance.

Furthermore, this research seeks to address the challenges associated with implementing biobased materials in critical aerospace applications. These challenges include ensuring structural integrity, durability under extreme conditions, and compliance with aviation safety standards. By overcoming these hurdles, the industry can pave the way for wider adoption of sustainable materials in aircraft construction.

Another key objective is to explore the scalability and cost-effectiveness of biobased PP embedded rivets. For this technology to be viable, it must not only offer aerodynamic benefits but also be economically feasible for large-scale production and implementation across various aircraft models. This research aims to provide insights into the potential for mass production and the long-term economic implications of adopting this technology.

Market Analysis for Sustainable Aerodynamic Solutions

The market for sustainable aerodynamic solutions is experiencing significant growth, driven by increasing environmental concerns and stringent regulations in the aviation and automotive industries. Biobased polypropylene embedded rivets represent a novel approach to enhancing aerodynamics while addressing sustainability challenges. This innovative technology combines the lightweight properties of polypropylene with the strength and durability of traditional rivets, offering a unique solution for reducing drag and improving fuel efficiency.

The global market for aerodynamic components is projected to expand rapidly in the coming years, with a particular focus on sustainable materials. The automotive sector, in particular, is showing strong interest in biobased solutions to meet increasingly strict emissions standards. Major automakers are investing heavily in research and development of eco-friendly materials that can improve vehicle performance without compromising sustainability goals.

In the aviation industry, there is a growing demand for lightweight, durable materials that can withstand extreme conditions while reducing overall aircraft weight. Biobased polypropylene embedded rivets offer a promising solution to this challenge, potentially revolutionizing aircraft design and construction. Airlines and aircraft manufacturers are actively seeking ways to reduce fuel consumption and carbon emissions, making this technology particularly attractive.

The market potential for biobased polypropylene embedded rivets extends beyond traditional transportation sectors. Wind energy is another area where improved aerodynamics can lead to significant efficiency gains. As the renewable energy sector continues to grow, there is increasing interest in materials that can enhance the performance of wind turbines while minimizing environmental impact.

Consumer awareness of environmental issues is also driving demand for sustainable products across various industries. This trend is likely to boost the adoption of biobased materials in consumer goods, sporting equipment, and other applications where aerodynamics play a role in product performance.

However, the market for sustainable aerodynamic solutions faces some challenges. The higher initial cost of biobased materials compared to traditional alternatives may slow adoption in price-sensitive markets. Additionally, there is a need for further research and development to optimize the performance and durability of biobased polypropylene embedded rivets in diverse applications.

Despite these challenges, the long-term outlook for sustainable aerodynamic solutions remains positive. As technology advances and production scales up, costs are expected to decrease, making biobased alternatives more competitive. Government incentives and regulations promoting sustainable materials are likely to further accelerate market growth in the coming years.

The global market for aerodynamic components is projected to expand rapidly in the coming years, with a particular focus on sustainable materials. The automotive sector, in particular, is showing strong interest in biobased solutions to meet increasingly strict emissions standards. Major automakers are investing heavily in research and development of eco-friendly materials that can improve vehicle performance without compromising sustainability goals.

In the aviation industry, there is a growing demand for lightweight, durable materials that can withstand extreme conditions while reducing overall aircraft weight. Biobased polypropylene embedded rivets offer a promising solution to this challenge, potentially revolutionizing aircraft design and construction. Airlines and aircraft manufacturers are actively seeking ways to reduce fuel consumption and carbon emissions, making this technology particularly attractive.

The market potential for biobased polypropylene embedded rivets extends beyond traditional transportation sectors. Wind energy is another area where improved aerodynamics can lead to significant efficiency gains. As the renewable energy sector continues to grow, there is increasing interest in materials that can enhance the performance of wind turbines while minimizing environmental impact.

Consumer awareness of environmental issues is also driving demand for sustainable products across various industries. This trend is likely to boost the adoption of biobased materials in consumer goods, sporting equipment, and other applications where aerodynamics play a role in product performance.

However, the market for sustainable aerodynamic solutions faces some challenges. The higher initial cost of biobased materials compared to traditional alternatives may slow adoption in price-sensitive markets. Additionally, there is a need for further research and development to optimize the performance and durability of biobased polypropylene embedded rivets in diverse applications.

Despite these challenges, the long-term outlook for sustainable aerodynamic solutions remains positive. As technology advances and production scales up, costs are expected to decrease, making biobased alternatives more competitive. Government incentives and regulations promoting sustainable materials are likely to further accelerate market growth in the coming years.

Current Challenges in Biobased PP Rivet Technology

The development of biobased polypropylene (PP) embedded rivets for aerodynamic applications faces several significant challenges. One of the primary obstacles is achieving the necessary mechanical properties to withstand the high-stress environments typical in aerospace and automotive industries. Biobased PP, derived from renewable resources, often exhibits lower tensile strength and impact resistance compared to traditional petroleum-based PP. This discrepancy in performance can lead to concerns about the long-term durability and reliability of rivets made from these materials, especially under extreme temperature and pressure conditions.

Another critical challenge lies in the manufacturing process of biobased PP rivets. The production of these rivets requires precise control over the material's crystallization and molecular orientation to ensure consistent performance. However, the variability in feedstock composition inherent to biobased materials can make this process more complex and less predictable than with conventional PP. This variability can result in inconsistencies in the final product, potentially compromising the aerodynamic efficiency and structural integrity of the components they are meant to secure.

The integration of biobased PP rivets into existing manufacturing and assembly processes presents additional hurdles. Many current production lines are optimized for traditional materials, and the introduction of biobased alternatives may require significant modifications to equipment and procedures. This adaptation can be costly and time-consuming, potentially slowing the adoption of these innovative rivets in large-scale industrial applications.

Furthermore, there are challenges related to the environmental performance and lifecycle assessment of biobased PP rivets. While these materials offer potential benefits in terms of reduced carbon footprint and renewable sourcing, questions remain about their overall environmental impact, including land use for feedstock production, water consumption, and end-of-life disposal or recycling options. Addressing these concerns is crucial for the widespread acceptance and adoption of biobased PP rivets in aerodynamic applications.

Lastly, the cost-effectiveness of biobased PP rivets remains a significant challenge. Currently, the production of these materials is often more expensive than their petroleum-based counterparts due to smaller scale production and the need for specialized processing techniques. This cost differential can be a major barrier to adoption, particularly in industries where profit margins are tight and material costs are a significant factor in overall product pricing.

Another critical challenge lies in the manufacturing process of biobased PP rivets. The production of these rivets requires precise control over the material's crystallization and molecular orientation to ensure consistent performance. However, the variability in feedstock composition inherent to biobased materials can make this process more complex and less predictable than with conventional PP. This variability can result in inconsistencies in the final product, potentially compromising the aerodynamic efficiency and structural integrity of the components they are meant to secure.

The integration of biobased PP rivets into existing manufacturing and assembly processes presents additional hurdles. Many current production lines are optimized for traditional materials, and the introduction of biobased alternatives may require significant modifications to equipment and procedures. This adaptation can be costly and time-consuming, potentially slowing the adoption of these innovative rivets in large-scale industrial applications.

Furthermore, there are challenges related to the environmental performance and lifecycle assessment of biobased PP rivets. While these materials offer potential benefits in terms of reduced carbon footprint and renewable sourcing, questions remain about their overall environmental impact, including land use for feedstock production, water consumption, and end-of-life disposal or recycling options. Addressing these concerns is crucial for the widespread acceptance and adoption of biobased PP rivets in aerodynamic applications.

Lastly, the cost-effectiveness of biobased PP rivets remains a significant challenge. Currently, the production of these materials is often more expensive than their petroleum-based counterparts due to smaller scale production and the need for specialized processing techniques. This cost differential can be a major barrier to adoption, particularly in industries where profit margins are tight and material costs are a significant factor in overall product pricing.

Existing Biobased PP Rivet Aerodynamic Solutions

01 Biobased polypropylene production methods

Various methods for producing biobased polypropylene from renewable resources are described. These processes involve the conversion of biomass-derived feedstocks into propylene monomers, which are then polymerized to create environmentally friendly polypropylene. The techniques aim to reduce dependency on fossil fuels and decrease the carbon footprint of plastic production.- Biobased polypropylene production methods: Various methods for producing biobased polypropylene from renewable resources are described. These processes involve the conversion of biomass-derived feedstocks into propylene monomers, which are then polymerized to form biobased polypropylene. The techniques aim to reduce reliance on fossil fuels and decrease the carbon footprint of polypropylene production.

- Embedded rivet design for aerodynamic applications: Innovative designs for embedded rivets that enhance aerodynamic performance are presented. These rivets are specifically engineered to minimize drag and improve overall aerodynamic efficiency when used in various applications, such as aircraft or automotive structures. The designs focus on reducing protrusion and creating smooth surface transitions.

- Composite materials incorporating biobased polypropylene: Development of composite materials that incorporate biobased polypropylene as a matrix or reinforcement component. These composites aim to combine the environmental benefits of biobased materials with enhanced mechanical and physical properties, making them suitable for a wide range of applications, including those requiring aerodynamic performance.

- Surface treatments for improved aerodynamics: Various surface treatment methods are described to enhance the aerodynamic properties of materials, including those containing biobased polypropylene and embedded rivets. These treatments may involve coatings, texturing, or other modifications to reduce drag and improve overall aerodynamic performance in applications such as transportation or renewable energy systems.

- Testing and simulation of aerodynamic properties: Advanced testing and simulation techniques for evaluating the aerodynamic properties of materials and structures, including those incorporating biobased polypropylene and embedded rivets. These methods enable accurate prediction and optimization of aerodynamic performance, facilitating the development of more efficient designs for various applications.

02 Embedded rivet design for aerodynamic applications

Innovative designs for embedded rivets that enhance aerodynamic performance are presented. These rivets are specifically engineered to minimize drag and improve overall aerodynamic efficiency when used in various applications, such as automotive or aerospace industries. The designs focus on reducing protrusion and creating smooth surfaces to optimize airflow.Expand Specific Solutions03 Composite materials incorporating biobased polypropylene

Development of composite materials that incorporate biobased polypropylene as a key component is discussed. These composites aim to combine the environmental benefits of biobased materials with enhanced mechanical and physical properties. Applications include lightweight structures for transportation and consumer goods.Expand Specific Solutions04 Surface treatments for improved aerodynamics

Various surface treatment techniques are explored to enhance the aerodynamic properties of materials, including those containing biobased polypropylene and embedded rivets. These treatments may involve coatings, texturing, or other modifications to reduce friction and improve airflow over the surface, potentially benefiting industries such as automotive and aerospace.Expand Specific Solutions05 Aerodynamic testing and simulation methods

Advanced methods for testing and simulating the aerodynamic performance of materials and structures, including those with biobased polypropylene and embedded rivets, are presented. These techniques involve computational fluid dynamics (CFD) simulations, wind tunnel testing, and other analytical approaches to optimize designs for improved aerodynamic efficiency.Expand Specific Solutions

Key Players in Biobased PP and Aerodynamic Innovation

The research on Biobased Polypropylene Embedded Rivets for aerodynamic innovation is in its early stages, with the market still developing. The technology's potential to enhance aircraft performance and sustainability is driving interest from major aerospace companies like Boeing and Airbus. While the market size is currently limited, it's expected to grow as environmental regulations tighten. Companies such as ExxonMobil Chemical, Sumitomo Chemical, and Prime Polymer are at the forefront of developing biobased polypropylene materials, while aerospace suppliers like Aerospace Precision Products are likely to play a key role in rivet manufacturing. The technology's maturity is still evolving, with ongoing research at institutions like the University of Guelph and Daegu Gyeongbuk Institute of Science & Technology contributing to its advancement.

The Boeing Co.

Technical Solution: Boeing has been pioneering the use of biobased polypropylene embedded rivets to enhance aerodynamics in aircraft design. Their approach involves integrating these eco-friendly rivets into the aircraft's skin, creating a smoother surface that reduces drag. The company has developed a proprietary process to manufacture these rivets using renewable resources, potentially reducing the carbon footprint of aircraft production[1]. Boeing's research indicates that these biobased rivets can withstand the extreme temperatures and pressures experienced during flight while maintaining their aerodynamic properties[2]. The company is also exploring the use of these rivets in conjunction with advanced composite materials to further optimize aircraft performance and fuel efficiency[3].

Strengths: Improved aerodynamics, reduced environmental impact, potential for weight reduction. Weaknesses: Higher initial costs, limited long-term performance data, potential regulatory hurdles for new materials in aerospace.

Prime Polymer Co. Ltd.

Technical Solution: Prime Polymer Co. Ltd. has been at the forefront of developing advanced biobased polypropylene materials suitable for aerospace applications, including embedded rivets. Their research focuses on enhancing the thermal stability and mechanical properties of biobased polypropylene to meet the stringent requirements of aircraft components[7]. The company has developed a proprietary blend of biobased polypropylene with nanofillers that significantly improves its strength-to-weight ratio and resistance to environmental factors[8]. Prime Polymer's materials have shown promise in maintaining their aerodynamic properties under various atmospheric conditions, making them suitable for use in embedded rivets across different aircraft types and flight profiles[9].

Strengths: Specialized expertise in biobased polymers, advanced material formulations tailored for aerospace. Weaknesses: Limited experience in direct aerospace applications, potential scalability challenges for mass production.

Core Innovations in Biobased PP Rivet Technology

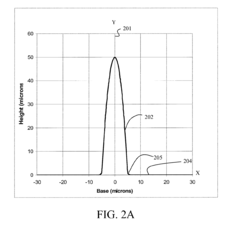

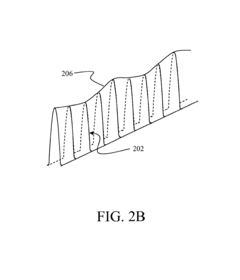

Structurally designed aerodynamic riblets

PatentActiveEP2650214A1

Innovation

- The development of riblets with a parabolic cross-section equation y=px^2 + h, fabricated using high elongation elastomers and high modulus materials like nickel, which are designed to distribute stress evenly and resist impact, combined with a multi-layer structure including a polymer support layer and UV reflective coating for enhanced durability.

Composite materials

PatentInactiveEP2254748A1

Innovation

- A method involving a film that becomes attached to the prepreg during consolidation, using a film with specific properties such as high peel strength, suitable for temperatures up to 400°C, and capable of forming a continuous layer on the composite material, which can be used as a bagging material or to create a hollow structure without access points.

Environmental Impact Assessment

The environmental impact assessment of biobased polypropylene embedded rivets in aerodynamic applications reveals both positive and negative aspects. On the positive side, these rivets contribute to reducing the carbon footprint of aircraft manufacturing. Biobased polypropylene, derived from renewable resources such as corn or sugarcane, offers a more sustainable alternative to traditional petroleum-based plastics. The production process of biobased polypropylene generally requires less energy and emits fewer greenhouse gases compared to conventional polypropylene manufacturing.

Furthermore, the use of these rivets in aerodynamic applications can lead to improved fuel efficiency in aircraft. By enhancing the aerodynamic properties of the aircraft's surface, these rivets contribute to reduced drag, which in turn lowers fuel consumption and associated emissions during flight operations. This long-term benefit can significantly offset the environmental impact of their production and installation.

However, there are potential environmental concerns to consider. The cultivation of crops for biobased polypropylene production may lead to land-use changes, potentially affecting biodiversity and local ecosystems. There is also the risk of competition with food crops, which could impact food security in certain regions. Additionally, the agricultural practices involved in growing these crops may require the use of fertilizers and pesticides, which can have negative effects on soil and water quality.

The end-of-life management of biobased polypropylene embedded rivets presents another environmental challenge. While theoretically biodegradable, the actual decomposition process in real-world conditions may be slow and incomplete. Proper recycling infrastructure for these materials may not be widely available, potentially leading to improper disposal and environmental contamination.

It is also important to consider the durability and longevity of these rivets in aerodynamic applications. If they require more frequent replacement compared to traditional rivets, the increased production and installation cycles could negate some of the environmental benefits. Therefore, extensive testing and lifecycle assessments are crucial to ensure that the overall environmental impact is indeed positive.

In conclusion, while biobased polypropylene embedded rivets offer promising environmental benefits in aerodynamic applications, particularly in terms of reduced carbon emissions and improved fuel efficiency, their full environmental impact must be carefully evaluated. This assessment should encompass the entire lifecycle of the product, from raw material sourcing to end-of-life management, to ensure a comprehensive understanding of its environmental implications.

Furthermore, the use of these rivets in aerodynamic applications can lead to improved fuel efficiency in aircraft. By enhancing the aerodynamic properties of the aircraft's surface, these rivets contribute to reduced drag, which in turn lowers fuel consumption and associated emissions during flight operations. This long-term benefit can significantly offset the environmental impact of their production and installation.

However, there are potential environmental concerns to consider. The cultivation of crops for biobased polypropylene production may lead to land-use changes, potentially affecting biodiversity and local ecosystems. There is also the risk of competition with food crops, which could impact food security in certain regions. Additionally, the agricultural practices involved in growing these crops may require the use of fertilizers and pesticides, which can have negative effects on soil and water quality.

The end-of-life management of biobased polypropylene embedded rivets presents another environmental challenge. While theoretically biodegradable, the actual decomposition process in real-world conditions may be slow and incomplete. Proper recycling infrastructure for these materials may not be widely available, potentially leading to improper disposal and environmental contamination.

It is also important to consider the durability and longevity of these rivets in aerodynamic applications. If they require more frequent replacement compared to traditional rivets, the increased production and installation cycles could negate some of the environmental benefits. Therefore, extensive testing and lifecycle assessments are crucial to ensure that the overall environmental impact is indeed positive.

In conclusion, while biobased polypropylene embedded rivets offer promising environmental benefits in aerodynamic applications, particularly in terms of reduced carbon emissions and improved fuel efficiency, their full environmental impact must be carefully evaluated. This assessment should encompass the entire lifecycle of the product, from raw material sourcing to end-of-life management, to ensure a comprehensive understanding of its environmental implications.

Regulatory Framework for Biobased Materials in Aviation

The regulatory framework for biobased materials in aviation is a complex and evolving landscape that plays a crucial role in the adoption of innovative technologies such as Biobased Polypropylene Embedded Rivets. This framework is primarily governed by international aviation authorities and national regulatory bodies, with a focus on safety, performance, and environmental sustainability.

At the international level, the International Civil Aviation Organization (ICAO) sets standards and recommended practices for the use of materials in aircraft construction. While ICAO has not yet established specific regulations for biobased materials, it has recognized the potential of sustainable aviation fuels and materials in its environmental protection initiatives.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are at the forefront of developing regulations for biobased materials in aviation. These agencies have established certification processes for new materials, including those derived from renewable sources. The FAA's Advisory Circular AC 20-107B provides guidance on composite material airframe structures, which can be applied to biobased materials like polypropylene.

Environmental regulations also play a significant role in shaping the use of biobased materials in aviation. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the development and use of new materials, including biobased alternatives. Similarly, the U.S. Environmental Protection Agency (EPA) has regulations that affect the production and use of biobased materials.

Certification standards for biobased materials in aviation are still evolving. Organizations such as ASTM International and SAE International are working on developing standards for the testing and qualification of biobased materials for aerospace applications. These standards will be crucial in ensuring the safety and reliability of components like Biobased Polypropylene Embedded Rivets.

The regulatory framework also addresses end-of-life considerations for biobased materials. Regulations such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive influence how aircraft components, including those made from biobased materials, are disposed of or recycled at the end of their lifecycle.

As the aviation industry moves towards more sustainable practices, regulatory bodies are likely to introduce more specific guidelines for biobased materials. This may include lifecycle assessment requirements, biodegradability standards, and specific performance criteria for biobased components used in critical applications like aerodynamics.

At the international level, the International Civil Aviation Organization (ICAO) sets standards and recommended practices for the use of materials in aircraft construction. While ICAO has not yet established specific regulations for biobased materials, it has recognized the potential of sustainable aviation fuels and materials in its environmental protection initiatives.

The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) are at the forefront of developing regulations for biobased materials in aviation. These agencies have established certification processes for new materials, including those derived from renewable sources. The FAA's Advisory Circular AC 20-107B provides guidance on composite material airframe structures, which can be applied to biobased materials like polypropylene.

Environmental regulations also play a significant role in shaping the use of biobased materials in aviation. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the development and use of new materials, including biobased alternatives. Similarly, the U.S. Environmental Protection Agency (EPA) has regulations that affect the production and use of biobased materials.

Certification standards for biobased materials in aviation are still evolving. Organizations such as ASTM International and SAE International are working on developing standards for the testing and qualification of biobased materials for aerospace applications. These standards will be crucial in ensuring the safety and reliability of components like Biobased Polypropylene Embedded Rivets.

The regulatory framework also addresses end-of-life considerations for biobased materials. Regulations such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive influence how aircraft components, including those made from biobased materials, are disposed of or recycled at the end of their lifecycle.

As the aviation industry moves towards more sustainable practices, regulatory bodies are likely to introduce more specific guidelines for biobased materials. This may include lifecycle assessment requirements, biodegradability standards, and specific performance criteria for biobased components used in critical applications like aerodynamics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!