How Polypropylene in Fiber Boards Enhances Sound Absorption

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Fiber Boards: Background and Objectives

Polypropylene fiber boards have emerged as a significant innovation in the field of acoustic materials, offering enhanced sound absorption properties compared to traditional alternatives. The development of these boards represents a convergence of polymer science and acoustic engineering, addressing the growing demand for effective noise control solutions in various sectors.

The evolution of polypropylene fiber boards can be traced back to the mid-20th century when polypropylene was first synthesized. However, it wasn't until recent decades that its potential in sound absorption applications was fully recognized and exploited. The journey from basic polymer to sophisticated acoustic material has been marked by continuous research and technological advancements.

In the context of sound absorption, polypropylene fiber boards leverage the unique properties of polypropylene, including its low density, high porosity, and excellent thermal stability. These characteristics, when properly engineered into fiber board structures, create an ideal medium for sound wave attenuation. The fibrous nature of the boards allows for the creation of complex networks of air pockets, which play a crucial role in absorbing and dissipating acoustic energy.

The primary objective in developing polypropylene fiber boards for sound absorption is to achieve superior acoustic performance while maintaining practical advantages such as durability, cost-effectiveness, and environmental sustainability. Researchers and manufacturers aim to optimize the fiber structure, density, and overall composition of these boards to maximize their sound absorption coefficients across a wide range of frequencies.

Another key goal is to enhance the versatility of polypropylene fiber boards, making them suitable for diverse applications. This includes their use in architectural acoustics, automotive interiors, industrial noise control, and even in consumer electronics. The adaptability of polypropylene as a material allows for the creation of boards with varying thicknesses, densities, and surface treatments, catering to specific acoustic requirements in different environments.

As the field progresses, there is an increasing focus on developing polypropylene fiber boards that not only excel in sound absorption but also address other performance criteria. This includes fire resistance, moisture resistance, and the ability to withstand harsh environmental conditions. The integration of these properties is essential for expanding the application scope of these materials and meeting stringent building and safety regulations.

The evolution of polypropylene fiber boards can be traced back to the mid-20th century when polypropylene was first synthesized. However, it wasn't until recent decades that its potential in sound absorption applications was fully recognized and exploited. The journey from basic polymer to sophisticated acoustic material has been marked by continuous research and technological advancements.

In the context of sound absorption, polypropylene fiber boards leverage the unique properties of polypropylene, including its low density, high porosity, and excellent thermal stability. These characteristics, when properly engineered into fiber board structures, create an ideal medium for sound wave attenuation. The fibrous nature of the boards allows for the creation of complex networks of air pockets, which play a crucial role in absorbing and dissipating acoustic energy.

The primary objective in developing polypropylene fiber boards for sound absorption is to achieve superior acoustic performance while maintaining practical advantages such as durability, cost-effectiveness, and environmental sustainability. Researchers and manufacturers aim to optimize the fiber structure, density, and overall composition of these boards to maximize their sound absorption coefficients across a wide range of frequencies.

Another key goal is to enhance the versatility of polypropylene fiber boards, making them suitable for diverse applications. This includes their use in architectural acoustics, automotive interiors, industrial noise control, and even in consumer electronics. The adaptability of polypropylene as a material allows for the creation of boards with varying thicknesses, densities, and surface treatments, catering to specific acoustic requirements in different environments.

As the field progresses, there is an increasing focus on developing polypropylene fiber boards that not only excel in sound absorption but also address other performance criteria. This includes fire resistance, moisture resistance, and the ability to withstand harsh environmental conditions. The integration of these properties is essential for expanding the application scope of these materials and meeting stringent building and safety regulations.

Acoustic Market Demand Analysis

The acoustic market has witnessed significant growth in recent years, driven by increasing awareness of noise pollution and its adverse effects on human health and productivity. The demand for sound absorption solutions spans various sectors, including construction, automotive, industrial, and consumer electronics. In the construction industry, there is a growing emphasis on creating acoustically optimized spaces in both residential and commercial buildings. This trend is fueled by the rise of open-plan offices, multi-purpose living spaces, and the need for improved sound quality in educational and healthcare facilities.

The automotive sector represents another substantial market for acoustic solutions, with manufacturers focusing on enhancing in-vehicle comfort and reducing external noise intrusion. As electric vehicles gain popularity, the need for innovative sound absorption materials becomes more critical to address the unique acoustic challenges posed by these quieter powertrains. The industrial sector also contributes significantly to the acoustic market demand, with factories and manufacturing plants seeking ways to reduce noise levels for worker safety and compliance with regulatory standards.

Consumer electronics is an emerging area of growth for acoustic materials, as manufacturers strive to improve the sound quality of devices such as smartphones, laptops, and smart speakers. The increasing popularity of home entertainment systems and the rise of remote work have further amplified the need for effective sound absorption solutions in residential settings.

The global acoustic insulation market size was valued at USD 13.5 billion in 2020 and is projected to reach USD 17.1 billion by 2025, growing at a CAGR of 4.7% during the forecast period. This growth is attributed to stringent noise pollution regulations, increasing construction activities, and the growing automotive and industrial sectors. The Asia-Pacific region is expected to witness the highest growth rate due to rapid urbanization, infrastructure development, and increasing awareness of acoustic comfort.

The demand for innovative and sustainable acoustic materials is on the rise, with a particular focus on eco-friendly solutions. This trend aligns well with the potential of polypropylene in fiber boards for sound absorption, as it offers recyclability and durability advantages over traditional materials. The market is also seeing a shift towards multi-functional acoustic materials that not only absorb sound but also provide thermal insulation, fire resistance, and aesthetic appeal.

As the importance of acoustic comfort continues to gain recognition across various industries, the market for advanced sound absorption solutions is expected to expand further. This presents significant opportunities for materials like polypropylene-enhanced fiber boards to address the growing demand for effective, sustainable, and versatile acoustic solutions in diverse applications.

The automotive sector represents another substantial market for acoustic solutions, with manufacturers focusing on enhancing in-vehicle comfort and reducing external noise intrusion. As electric vehicles gain popularity, the need for innovative sound absorption materials becomes more critical to address the unique acoustic challenges posed by these quieter powertrains. The industrial sector also contributes significantly to the acoustic market demand, with factories and manufacturing plants seeking ways to reduce noise levels for worker safety and compliance with regulatory standards.

Consumer electronics is an emerging area of growth for acoustic materials, as manufacturers strive to improve the sound quality of devices such as smartphones, laptops, and smart speakers. The increasing popularity of home entertainment systems and the rise of remote work have further amplified the need for effective sound absorption solutions in residential settings.

The global acoustic insulation market size was valued at USD 13.5 billion in 2020 and is projected to reach USD 17.1 billion by 2025, growing at a CAGR of 4.7% during the forecast period. This growth is attributed to stringent noise pollution regulations, increasing construction activities, and the growing automotive and industrial sectors. The Asia-Pacific region is expected to witness the highest growth rate due to rapid urbanization, infrastructure development, and increasing awareness of acoustic comfort.

The demand for innovative and sustainable acoustic materials is on the rise, with a particular focus on eco-friendly solutions. This trend aligns well with the potential of polypropylene in fiber boards for sound absorption, as it offers recyclability and durability advantages over traditional materials. The market is also seeing a shift towards multi-functional acoustic materials that not only absorb sound but also provide thermal insulation, fire resistance, and aesthetic appeal.

As the importance of acoustic comfort continues to gain recognition across various industries, the market for advanced sound absorption solutions is expected to expand further. This presents significant opportunities for materials like polypropylene-enhanced fiber boards to address the growing demand for effective, sustainable, and versatile acoustic solutions in diverse applications.

Current State of Sound Absorption Technology

Sound absorption technology has made significant strides in recent years, with a focus on developing materials and structures that effectively reduce noise pollution in various environments. The current state of sound absorption technology is characterized by a diverse range of solutions, each tailored to specific applications and frequency ranges.

One of the most prevalent approaches in sound absorption is the use of porous materials. These materials, such as foam, fiberglass, and mineral wool, work by converting sound energy into heat through friction as sound waves pass through their complex network of interconnected pores. The efficiency of these materials depends on factors like porosity, tortuosity, and flow resistivity.

Another important development in sound absorption technology is the use of resonant absorbers. These systems, which include Helmholtz resonators and membrane absorbers, are designed to target specific frequency ranges. They work by creating a resonant cavity that vibrates in response to incident sound waves, effectively dissipating acoustic energy.

Microperforated panels have also gained prominence in modern sound absorption solutions. These thin panels, typically made of metal or plastic, feature numerous sub-millimeter perforations that create viscous losses and thermal exchanges, resulting in broadband sound absorption. Their sleek appearance makes them particularly attractive for architectural applications.

In recent years, there has been growing interest in metamaterials for sound absorption. These engineered structures manipulate acoustic waves in ways not possible with conventional materials, offering the potential for highly efficient, compact absorbers. While still largely in the research phase, metamaterial-based absorbers show promise for low-frequency noise control, a traditionally challenging area.

The integration of active noise control systems with passive absorbers represents another frontier in sound absorption technology. These hybrid systems use electronic sensors and actuators to generate anti-noise, effectively canceling out unwanted sound waves. While complex and potentially costly, they offer superior performance in scenarios where traditional passive methods fall short.

Sustainable and eco-friendly sound absorption solutions have also gained traction. Materials derived from recycled plastics, natural fibers, and agricultural waste are being developed and implemented, addressing both acoustic and environmental concerns. These green alternatives often exhibit comparable or even superior performance to traditional synthetic materials.

The current state of sound absorption technology is marked by a trend towards multi-functional materials. Researchers and manufacturers are developing absorbers that not only attenuate sound but also provide thermal insulation, fire resistance, or aesthetic value. This holistic approach to material design is driving innovation in fields ranging from building construction to automotive engineering.

One of the most prevalent approaches in sound absorption is the use of porous materials. These materials, such as foam, fiberglass, and mineral wool, work by converting sound energy into heat through friction as sound waves pass through their complex network of interconnected pores. The efficiency of these materials depends on factors like porosity, tortuosity, and flow resistivity.

Another important development in sound absorption technology is the use of resonant absorbers. These systems, which include Helmholtz resonators and membrane absorbers, are designed to target specific frequency ranges. They work by creating a resonant cavity that vibrates in response to incident sound waves, effectively dissipating acoustic energy.

Microperforated panels have also gained prominence in modern sound absorption solutions. These thin panels, typically made of metal or plastic, feature numerous sub-millimeter perforations that create viscous losses and thermal exchanges, resulting in broadband sound absorption. Their sleek appearance makes them particularly attractive for architectural applications.

In recent years, there has been growing interest in metamaterials for sound absorption. These engineered structures manipulate acoustic waves in ways not possible with conventional materials, offering the potential for highly efficient, compact absorbers. While still largely in the research phase, metamaterial-based absorbers show promise for low-frequency noise control, a traditionally challenging area.

The integration of active noise control systems with passive absorbers represents another frontier in sound absorption technology. These hybrid systems use electronic sensors and actuators to generate anti-noise, effectively canceling out unwanted sound waves. While complex and potentially costly, they offer superior performance in scenarios where traditional passive methods fall short.

Sustainable and eco-friendly sound absorption solutions have also gained traction. Materials derived from recycled plastics, natural fibers, and agricultural waste are being developed and implemented, addressing both acoustic and environmental concerns. These green alternatives often exhibit comparable or even superior performance to traditional synthetic materials.

The current state of sound absorption technology is marked by a trend towards multi-functional materials. Researchers and manufacturers are developing absorbers that not only attenuate sound but also provide thermal insulation, fire resistance, or aesthetic value. This holistic approach to material design is driving innovation in fields ranging from building construction to automotive engineering.

Polypropylene Integration Methods

01 Polypropylene fiber composition for sound absorption

Polypropylene fibers are used in sound-absorbing boards due to their excellent acoustic properties. The composition of these fibers can be optimized to enhance sound absorption across different frequency ranges. Factors such as fiber diameter, length, and density play crucial roles in determining the sound absorption efficiency of the boards.- Polypropylene fiber composition for sound absorption: Polypropylene fibers are used in sound-absorbing boards due to their excellent acoustic properties. The composition of these fibers can be optimized to enhance sound absorption across different frequency ranges. Factors such as fiber diameter, length, and density play crucial roles in determining the sound absorption efficiency of the boards.

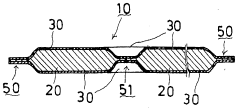

- Multilayer structure for improved sound absorption: Sound-absorbing boards can be designed with multiple layers of polypropylene fibers, each layer having different densities or compositions. This multilayer structure allows for better sound absorption across a wider range of frequencies, as each layer can be optimized for specific sound wavelengths.

- Incorporation of additives for enhanced performance: Various additives can be incorporated into polypropylene fiber boards to improve their sound absorption properties. These additives may include flame retardants, UV stabilizers, or other materials that can enhance the overall performance and durability of the sound-absorbing boards while maintaining their acoustic properties.

- Surface treatment and perforation techniques: The surface of polypropylene fiber boards can be treated or perforated to improve sound absorption. Techniques such as needle-punching, thermal bonding, or creating micro-perforations on the surface can increase the sound absorption coefficient by allowing sound waves to penetrate deeper into the material.

- Combination with other materials for synergistic effects: Polypropylene fibers can be combined with other materials such as recycled fibers, natural fibers, or synthetic materials to create composite sound-absorbing boards. These combinations can lead to improved acoustic performance, sustainability, and cost-effectiveness compared to boards made solely from polypropylene fibers.

02 Multilayer structure for improved sound absorption

Sound-absorbing boards can be designed with multiple layers of polypropylene fibers, each layer having different densities or compositions. This multilayer structure allows for better sound absorption across a wider range of frequencies. The combination of different fiber types or the inclusion of other materials in certain layers can further enhance the acoustic performance.Expand Specific Solutions03 Surface treatment of polypropylene fibers

Surface treatments can be applied to polypropylene fibers to improve their sound absorption capabilities. These treatments may include chemical modifications or physical alterations to the fiber surface, which can enhance the interaction between sound waves and the fibers, leading to increased sound absorption efficiency.Expand Specific Solutions04 Incorporation of additives for enhanced performance

Various additives can be incorporated into polypropylene fiber boards to enhance their sound absorption properties. These additives may include other types of fibers, particles, or materials that complement the acoustic properties of polypropylene. The combination of different materials can create a synergistic effect, resulting in improved sound absorption across a broader frequency spectrum.Expand Specific Solutions05 Manufacturing techniques for optimized sound absorption

Specific manufacturing techniques can be employed to optimize the sound absorption properties of polypropylene fiber boards. These may include specialized fiber formation processes, controlled bonding methods, or unique board shaping techniques. The manufacturing process can significantly influence the final acoustic performance of the boards by affecting factors such as porosity, fiber orientation, and overall structure.Expand Specific Solutions

Key Players in Acoustic Materials Industry

The market for polypropylene in fiber boards for sound absorption is in a growth phase, driven by increasing demand for acoustic solutions in various industries. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Certainteed Gypsum, Kingfa Sci. & Tech., and INOAC Corp. leading innovation. These firms are developing enhanced polypropylene-based materials that offer superior sound absorption properties. While the technology is relatively mature, ongoing research by companies such as Murata Manufacturing and GoerTek is pushing the boundaries of performance and application versatility.

Certainteed Gypsum, Inc.

Technical Solution: Certainteed Gypsum has developed innovative fiber boards incorporating polypropylene fibers to enhance sound absorption. Their technology involves a multi-layered structure where polypropylene fibers are strategically dispersed within gypsum-based boards. This combination creates a network of micro-cavities that effectively trap and dissipate sound waves[1]. The polypropylene fibers, with their low density and high porosity, contribute to increased sound absorption across a wide frequency range. Certainteed's boards achieve a Noise Reduction Coefficient (NRC) of up to 0.95, indicating excellent sound absorption properties[3]. The manufacturing process ensures uniform distribution of polypropylene fibers, resulting in consistent performance across the entire board surface.

Strengths: High sound absorption efficiency, lightweight construction, and versatility in application. Weaknesses: Potential higher cost compared to traditional gypsum boards and limited fire resistance without additional treatments.

Kingfa Sci. & Tech. Co., Ltd.

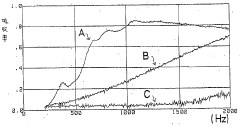

Technical Solution: Kingfa has pioneered a unique approach to incorporating polypropylene in fiber boards for enhanced sound absorption. Their method involves creating a composite material that combines polypropylene fibers with natural fibers in a carefully controlled ratio. This hybrid composition allows for optimized porosity and tortuosity within the board structure, leading to improved sound absorption characteristics[2]. Kingfa's boards utilize a proprietary heat treatment process that partially melts the polypropylene fibers, creating additional micro-pores and increasing the overall surface area for sound absorption. Their technology has demonstrated a significant improvement in sound absorption coefficients, particularly in the mid to high-frequency ranges, with absorption values reaching up to 0.85 at 1000 Hz[4].

Strengths: Excellent mid to high-frequency absorption, environmentally friendly due to the use of natural fibers, and good durability. Weaknesses: Potentially less effective at low frequencies and may require specialized manufacturing equipment.

Core Innovations in Fiber Board Acoustics

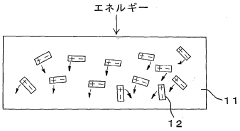

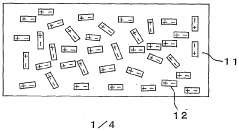

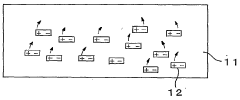

Highly sound-absorbing fibrous sheet

PatentWO2001070874A1

Innovation

- A highly sound-absorbing fiber sheet is developed by attaching a polymer with an active ingredient that increases the dipole moment to the surface or between fibers, enhancing sound absorption through frictional heat generation and internal frictional resistance, allowing for compact and efficient sound absorption.

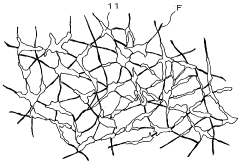

Sound absorbing material

PatentWO2005052529A1

Innovation

- A sheet-like sound absorbing material is created by laminating force bar sheets made of nonwoven fabrics with polypropylene ultrafine fibers on both sides of a base sheet, which is also made using the meltblown method, combining with a cover sheet of polyester long fibers to enhance sound absorption synergistically.

Environmental Impact Assessment

The incorporation of polypropylene in fiber boards for sound absorption raises important environmental considerations. The production of polypropylene, a synthetic polymer derived from petroleum, involves energy-intensive processes and contributes to greenhouse gas emissions. However, the use of polypropylene in fiber boards can potentially extend the lifespan of these materials, reducing the need for frequent replacements and thereby minimizing overall resource consumption.

Polypropylene's durability and resistance to moisture make it an attractive option for sound absorption applications, particularly in humid environments. This characteristic can lead to reduced maintenance requirements and less frequent disposal of damaged materials, potentially lowering the environmental impact over the product's lifecycle. Additionally, polypropylene's lightweight nature may contribute to reduced transportation-related emissions during distribution.

The recyclability of polypropylene is a significant factor in its environmental profile. While pure polypropylene is highly recyclable, the integration with other materials in fiber boards may complicate the recycling process. Efforts to develop effective separation techniques and recycling methods for composite materials containing polypropylene are ongoing and could significantly improve the environmental footprint of these products.

It is essential to consider the end-of-life management of polypropylene-enhanced fiber boards. If not properly disposed of or recycled, these materials may contribute to plastic pollution, particularly if they degrade into microplastics. Implementing robust waste management strategies and promoting circular economy principles are crucial to mitigating these potential negative impacts.

The production of polypropylene-enhanced fiber boards may also have implications for indoor air quality. While polypropylene itself is generally considered inert, the manufacturing process and any additives used may result in the emission of volatile organic compounds (VOCs). Rigorous testing and adherence to indoor air quality standards are necessary to ensure that these materials do not negatively impact human health in enclosed spaces.

From a broader perspective, the use of polypropylene in sound absorption applications could potentially reduce the demand for traditional materials with higher environmental impacts, such as certain types of foams or fiberglass. This substitution effect should be carefully evaluated to determine the net environmental benefit across the entire lifecycle of the product.

Polypropylene's durability and resistance to moisture make it an attractive option for sound absorption applications, particularly in humid environments. This characteristic can lead to reduced maintenance requirements and less frequent disposal of damaged materials, potentially lowering the environmental impact over the product's lifecycle. Additionally, polypropylene's lightweight nature may contribute to reduced transportation-related emissions during distribution.

The recyclability of polypropylene is a significant factor in its environmental profile. While pure polypropylene is highly recyclable, the integration with other materials in fiber boards may complicate the recycling process. Efforts to develop effective separation techniques and recycling methods for composite materials containing polypropylene are ongoing and could significantly improve the environmental footprint of these products.

It is essential to consider the end-of-life management of polypropylene-enhanced fiber boards. If not properly disposed of or recycled, these materials may contribute to plastic pollution, particularly if they degrade into microplastics. Implementing robust waste management strategies and promoting circular economy principles are crucial to mitigating these potential negative impacts.

The production of polypropylene-enhanced fiber boards may also have implications for indoor air quality. While polypropylene itself is generally considered inert, the manufacturing process and any additives used may result in the emission of volatile organic compounds (VOCs). Rigorous testing and adherence to indoor air quality standards are necessary to ensure that these materials do not negatively impact human health in enclosed spaces.

From a broader perspective, the use of polypropylene in sound absorption applications could potentially reduce the demand for traditional materials with higher environmental impacts, such as certain types of foams or fiberglass. This substitution effect should be carefully evaluated to determine the net environmental benefit across the entire lifecycle of the product.

Cost-Benefit Analysis of Polypropylene Fiber Boards

The cost-benefit analysis of polypropylene fiber boards reveals a compelling case for their adoption in sound absorption applications. Initial investment in polypropylene fiber boards may be higher compared to traditional materials, but the long-term benefits often outweigh the upfront costs.

From a manufacturing perspective, polypropylene fibers are relatively inexpensive to produce and can be easily integrated into existing fiber board production processes. The lightweight nature of polypropylene reduces transportation and installation costs, providing additional savings throughout the supply chain.

In terms of performance, polypropylene fiber boards demonstrate superior sound absorption properties, particularly in mid to high-frequency ranges. This enhanced acoustic performance can lead to significant cost savings in various applications. For instance, in commercial buildings, improved sound insulation can reduce the need for additional soundproofing measures, potentially lowering overall construction costs.

The durability of polypropylene fiber boards also contributes to their cost-effectiveness. These boards are resistant to moisture, mold, and mildew, which can extend their lifespan and reduce maintenance and replacement costs over time. This is particularly beneficial in high-humidity environments or areas prone to water exposure.

Energy efficiency is another factor to consider. The thermal insulation properties of polypropylene fiber boards can contribute to reduced heating and cooling costs in buildings. While this may not be the primary purpose of their installation, it represents an additional benefit that can positively impact the overall cost-benefit analysis.

From an environmental perspective, polypropylene is recyclable, which can lead to cost savings in waste management and align with sustainability goals. However, it's important to note that the recycling process for composite materials like fiber boards can be complex and may require specialized facilities.

When comparing polypropylene fiber boards to alternative sound absorption solutions, such as foam-based products or mineral wool, the cost-benefit analysis often favors polypropylene. While some alternatives may have lower initial costs, the durability, performance, and multi-functional benefits of polypropylene fiber boards typically result in a better long-term value proposition.

It's worth noting that the exact cost-benefit ratio can vary depending on specific applications, local material costs, and regulatory requirements. Therefore, a detailed analysis considering these factors is recommended for each individual project or implementation scenario.

From a manufacturing perspective, polypropylene fibers are relatively inexpensive to produce and can be easily integrated into existing fiber board production processes. The lightweight nature of polypropylene reduces transportation and installation costs, providing additional savings throughout the supply chain.

In terms of performance, polypropylene fiber boards demonstrate superior sound absorption properties, particularly in mid to high-frequency ranges. This enhanced acoustic performance can lead to significant cost savings in various applications. For instance, in commercial buildings, improved sound insulation can reduce the need for additional soundproofing measures, potentially lowering overall construction costs.

The durability of polypropylene fiber boards also contributes to their cost-effectiveness. These boards are resistant to moisture, mold, and mildew, which can extend their lifespan and reduce maintenance and replacement costs over time. This is particularly beneficial in high-humidity environments or areas prone to water exposure.

Energy efficiency is another factor to consider. The thermal insulation properties of polypropylene fiber boards can contribute to reduced heating and cooling costs in buildings. While this may not be the primary purpose of their installation, it represents an additional benefit that can positively impact the overall cost-benefit analysis.

From an environmental perspective, polypropylene is recyclable, which can lead to cost savings in waste management and align with sustainability goals. However, it's important to note that the recycling process for composite materials like fiber boards can be complex and may require specialized facilities.

When comparing polypropylene fiber boards to alternative sound absorption solutions, such as foam-based products or mineral wool, the cost-benefit analysis often favors polypropylene. While some alternatives may have lower initial costs, the durability, performance, and multi-functional benefits of polypropylene fiber boards typically result in a better long-term value proposition.

It's worth noting that the exact cost-benefit ratio can vary depending on specific applications, local material costs, and regulatory requirements. Therefore, a detailed analysis considering these factors is recommended for each individual project or implementation scenario.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!