How Twin-Screw Extrusion Enhances Polypropylene Barrier Films

Twin-Screw Extrusion and PP Barrier Film Evolution

Twin-screw extrusion has played a pivotal role in the evolution of polypropylene (PP) barrier films, marking significant milestones in the packaging industry. The journey began in the 1950s when polypropylene was first synthesized, but it wasn't until the 1970s that twin-screw extrusion technology started to be applied to PP film production. This technological advancement addressed the limitations of single-screw extrusion, particularly in terms of mixing efficiency and material homogeneity.

The 1980s saw a surge in research and development focused on enhancing PP film properties through twin-screw extrusion. This period was characterized by the introduction of various additives and modifiers to improve barrier properties, leading to the development of the first generation of high-performance PP barrier films. These films found immediate applications in food packaging, where they offered improved shelf life for perishable goods.

By the 1990s, twin-screw extrusion had become the preferred method for producing PP barrier films. This decade witnessed the refinement of screw designs and the optimization of processing parameters, resulting in films with superior gas and moisture barrier properties. The introduction of multilayer extrusion techniques further expanded the capabilities of PP films, allowing for the incorporation of specialized barrier layers.

The turn of the millennium brought about a focus on sustainability, driving innovations in twin-screw extrusion technology for PP barrier films. Manufacturers began exploring bio-based additives and developing more efficient extrusion processes to reduce energy consumption and material waste. This period also saw the integration of nanotechnology, with nanocomposites being incorporated into PP films to enhance barrier properties at lower thicknesses.

In recent years, the evolution of twin-screw extrusion in PP barrier film production has been marked by advancements in automation and process control. Industry 4.0 technologies have enabled real-time monitoring and adjustment of extrusion parameters, leading to more consistent film quality and reduced production costs. Additionally, the development of high-performance twin-screw extruders has allowed for the processing of increasingly complex PP formulations, resulting in films with unprecedented barrier properties and functionality.

Looking ahead, the trajectory of twin-screw extrusion in PP barrier film evolution points towards even greater material efficiency and performance. Emerging trends include the development of smart packaging solutions, where barrier films can incorporate sensors or indicators, and the continued pursuit of fully recyclable barrier films that maintain high-performance characteristics. The ongoing refinement of twin-screw extrusion technology promises to unlock new possibilities in PP barrier film applications, driving innovation in packaging and beyond.

Market Demand for Enhanced Barrier Films

The market demand for enhanced barrier films, particularly those utilizing polypropylene (PP) and twin-screw extrusion technology, has been steadily increasing across various industries. This growth is primarily driven by the need for improved packaging solutions that offer superior protection against moisture, oxygen, and other external factors that can compromise product quality and shelf life.

In the food and beverage sector, there is a significant demand for high-performance barrier films to extend the shelf life of perishable goods and maintain product freshness. The ability of twin-screw extruded PP barrier films to provide excellent moisture and oxygen barriers makes them particularly attractive for packaging applications in this industry. As consumers increasingly seek convenience and longer-lasting food products, manufacturers are turning to these advanced barrier films to meet market expectations.

The pharmaceutical and healthcare industries also contribute substantially to the growing demand for enhanced barrier films. These sectors require packaging materials that can protect sensitive medications and medical devices from environmental factors that could affect their efficacy and safety. Twin-screw extruded PP barrier films offer the necessary protection while also providing transparency and durability, making them ideal for blister packs, sachets, and other pharmaceutical packaging formats.

In the personal care and cosmetics market, there is a rising demand for barrier films that can preserve the quality and efficacy of products while also offering aesthetic appeal. The ability of twin-screw extruded PP films to combine barrier properties with clarity and printability makes them highly desirable for packaging premium personal care items and cosmetics.

The electronics industry is another significant driver of demand for enhanced barrier films. As electronic devices become more sophisticated and sensitive, there is an increasing need for packaging materials that can protect components from moisture, static electricity, and other potentially damaging factors. Twin-screw extruded PP barrier films offer the necessary protection while also being lightweight and cost-effective.

Market analysts project that the global barrier film market will continue to expand at a compound annual growth rate (CAGR) of over 4% in the coming years. This growth is attributed to the increasing adoption of flexible packaging solutions across various end-use industries and the ongoing development of more advanced barrier film technologies.

The demand for sustainable packaging solutions is also influencing the market for enhanced barrier films. As environmental concerns become more prominent, there is a growing interest in barrier films that offer high performance while also being recyclable or biodegradable. This trend is driving research and development efforts to create more eco-friendly barrier film solutions using twin-screw extrusion technology and PP materials.

Current Challenges in PP Barrier Film Production

The production of polypropylene (PP) barrier films faces several significant challenges that hinder the widespread adoption and optimization of this technology. One of the primary issues is achieving consistent and uniform film thickness across the entire width of the extruded film. Variations in thickness can lead to weak points in the barrier properties, compromising the overall performance of the film.

Another major challenge is the control of crystallinity in PP films. The degree of crystallinity directly affects the barrier properties, with higher crystallinity generally resulting in better barrier performance. However, achieving the optimal level of crystallinity while maintaining other desirable film properties, such as flexibility and optical clarity, remains a complex balancing act.

The incorporation of barrier-enhancing additives into PP films presents its own set of difficulties. These additives, while crucial for improving gas and moisture barrier properties, can often lead to processing complications. Issues such as poor dispersion, agglomeration, and potential degradation of the additives during the high-temperature extrusion process can significantly impact the final film quality and performance.

Thermal stability during processing is another critical challenge. PP is sensitive to thermal degradation, which can occur during the extrusion process, especially at higher temperatures required for certain additives or when aiming for increased throughput. This degradation can lead to a reduction in molecular weight, affecting the mechanical properties and long-term stability of the film.

The adhesion between different layers in multi-layer barrier films is a persistent issue. Ensuring strong interlayer adhesion while maintaining the distinct functionalities of each layer is crucial for the overall performance of the barrier film. Poor adhesion can lead to delamination, compromising the barrier properties and structural integrity of the film.

Furthermore, achieving high barrier properties while maintaining film transparency is a significant challenge. Many barrier-enhancing additives or processing techniques that improve gas and moisture resistance can negatively impact the optical properties of the film, which is undesirable for many packaging applications where product visibility is important.

Lastly, the scalability of laboratory-developed solutions to industrial-scale production remains a significant hurdle. Processes and formulations that show promise in small-scale experiments often face unforeseen challenges when scaled up to commercial production levels, necessitating further optimization and adjustment.

Twin-Screw Extrusion Techniques for PP Barrier Films

01 Multilayer polypropylene barrier films

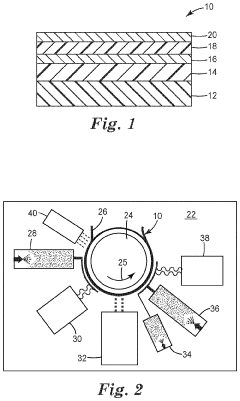

Multilayer polypropylene films are developed to enhance barrier properties. These films typically consist of a core layer of polypropylene and one or more barrier layers made of materials such as ethylene vinyl alcohol (EVOH) or polyamide. The combination of different materials in layers allows for improved gas and moisture barrier properties while maintaining the benefits of polypropylene.- Multilayer polypropylene barrier films: Multilayer polypropylene films are developed to enhance barrier properties. These films typically consist of different layers, each contributing to specific barrier functions such as moisture resistance, oxygen impermeability, or UV protection. The combination of layers allows for customization of barrier properties to meet various packaging requirements.

- Incorporation of nanoparticles: Nanoparticles are added to polypropylene films to improve barrier properties. Common nanoparticles include clay, silica, and metal oxides. These nanoparticles create a tortuous path for gas molecules, effectively reducing permeability and enhancing the overall barrier performance of the film.

- Surface treatment and coatings: Various surface treatments and coatings are applied to polypropylene films to enhance barrier properties. These may include plasma treatment, chemical modifications, or the application of specialized barrier coatings. Such treatments can significantly improve the film's resistance to gas and moisture permeation.

- Orientation and crystallinity control: The barrier properties of polypropylene films are improved through controlled orientation and crystallinity. Techniques such as biaxial orientation and annealing are used to optimize the film structure, resulting in enhanced barrier performance against gases and moisture.

- Blending with other polymers: Polypropylene is blended with other polymers to create films with superior barrier properties. Common blend partners include polyethylene, ethylene vinyl alcohol (EVOH), and polyamides. These blends combine the desirable properties of different polymers to achieve enhanced barrier performance.

02 Nanocomposite polypropylene barrier films

Incorporating nanoparticles into polypropylene films can significantly improve their barrier properties. Nanocomposites, such as those using clay or silica nanoparticles, create a tortuous path for gas and moisture molecules, thereby enhancing the film's barrier performance. This approach allows for thinner films with improved barrier characteristics.Expand Specific Solutions03 Surface treatment and coatings for barrier enhancement

Various surface treatments and coatings can be applied to polypropylene films to improve their barrier properties. These may include plasma treatment, application of metal oxide coatings, or the use of specialized barrier coatings. Such treatments can significantly reduce the permeability of the films to gases and moisture.Expand Specific Solutions04 Orientation and crystallinity control

The barrier properties of polypropylene films can be enhanced by controlling the orientation and crystallinity of the polymer chains. Techniques such as biaxial orientation and controlled cooling during film production can lead to a more ordered structure, reducing the free volume within the polymer and improving barrier performance.Expand Specific Solutions05 Blending and compatibilization for improved barriers

Blending polypropylene with other polymers or additives can enhance barrier properties. Compatibilizers are often used to improve the miscibility of different polymers, resulting in a more homogeneous blend with superior barrier characteristics. This approach allows for customization of barrier properties for specific applications.Expand Specific Solutions

Key Players in Extrusion and Barrier Film Industry

The twin-screw extrusion technology for enhancing polypropylene barrier films is in a growth phase, with increasing market demand driven by packaging and automotive industries. The global market size for this technology is expanding, projected to reach several billion dollars by 2025. Technologically, it's advancing rapidly, with companies like Reifenhäuser GmbH, KraussMaffei Extrusion GmbH, and Coperion Werner & Pfleiderer leading innovations. These firms are developing more efficient and precise extrusion systems, focusing on improved barrier properties and sustainability. Other players like ExxonMobil Chemical Patents and BASF Corp. are contributing to material advancements, while research institutions such as CNRS and Université Claude Bernard Lyon 1 are pushing theoretical boundaries in polymer science.

Reifenhäuser GmbH & Co. KG Maschinenfabrik

KraussMaffei Technologies GmbH

Innovations in Twin-Screw Extrusion for Barrier Properties

- A process using a twin-screw extruder with co-rotating screws, where a mixture of styrene polymer, nucleating agent, surfactant, and immiscible foreign polymer is melted and injected with a physical blowing agent under controlled pressure, then cooled and extruded to form a foam film with adjustable open-cell structure and fluid absorption properties.

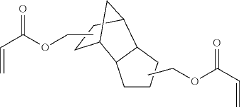

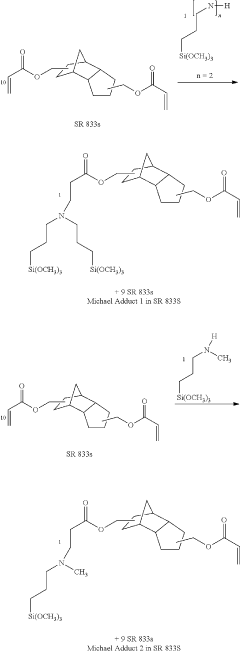

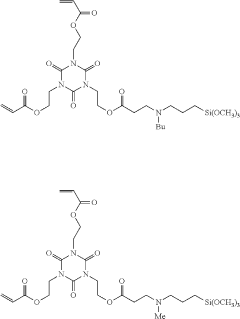

- A barrier film composition comprising a substrate with a base polymer layer, an oxide layer, and a protective polymer layer formed from a reaction product of a (meth)acryloyl compound and a (meth)acryl-silane compound derived from a Michael reaction, which improves moisture resistance and adhesion without requiring a silicon sub-oxide tie layer.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of twin-screw extrusion in enhancing polypropylene barrier films are crucial aspects that demand attention in today's eco-conscious manufacturing landscape. This process offers several advantages in terms of sustainability, but also presents challenges that need to be addressed.

Twin-screw extrusion, when compared to traditional film production methods, generally exhibits improved energy efficiency. The process allows for better heat transfer and mixing, resulting in reduced energy consumption per unit of film produced. This energy efficiency translates to a lower carbon footprint, aligning with global efforts to mitigate climate change.

Furthermore, the enhanced barrier properties achieved through twin-screw extrusion can contribute to sustainability by extending the shelf life of packaged products. This reduction in food waste indirectly lessens the environmental impact associated with food production, transportation, and disposal.

However, the production of polypropylene barrier films still relies on petroleum-based raw materials, which raises concerns about resource depletion and long-term sustainability. To address this, research is ongoing into the incorporation of bio-based additives and fillers that can partially replace fossil-fuel-derived components without compromising film performance.

The recyclability of polypropylene barrier films produced via twin-screw extrusion is another critical consideration. While polypropylene is generally recyclable, the additives and multi-layer structures used to enhance barrier properties can complicate the recycling process. Efforts are being made to develop more easily recyclable barrier films, including the use of compatible additives and design for disassembly approaches.

Water usage in the twin-screw extrusion process is relatively low compared to some other manufacturing methods, which is a positive aspect from a sustainability standpoint. However, the cleaning of equipment and potential for microplastic generation during production and use of the films remain areas of concern that require ongoing attention and mitigation strategies.

The durability of barrier films produced through twin-screw extrusion can be seen as a double-edged sword from an environmental perspective. While their longevity reduces the need for frequent replacement, it also means that these materials persist in the environment for extended periods if not properly disposed of or recycled.

As the industry moves forward, there is a growing focus on developing circular economy models for polypropylene barrier films. This includes exploring options for chemical recycling, which could break down the films into their chemical constituents for reuse in new products, potentially closing the loop on material use.

Cost-Benefit Analysis of Twin-Screw Extrusion for PP Films

The cost-benefit analysis of twin-screw extrusion for polypropylene (PP) barrier films reveals significant advantages that justify the initial investment in this advanced technology. The primary benefit lies in the enhanced barrier properties achieved through this process, which directly translates to improved product quality and performance.

Twin-screw extrusion allows for better dispersion and distribution of additives within the PP matrix, resulting in more uniform and consistent film properties. This improved homogeneity leads to superior gas and moisture barrier characteristics, extending the shelf life of packaged products and reducing material waste. The process also enables the incorporation of higher concentrations of barrier-enhancing additives without compromising the film's mechanical properties.

From a production standpoint, twin-screw extrusion offers increased throughput rates compared to conventional single-screw systems. This higher productivity translates to reduced manufacturing costs per unit of output, offsetting the higher initial equipment investment. Additionally, the improved melt homogeneity achieved through twin-screw extrusion often results in fewer quality issues and reduced scrap rates, further contributing to cost savings.

Energy efficiency is another key benefit of twin-screw extrusion. The process allows for better heat transfer and more efficient melting of the polymer, resulting in lower energy consumption per unit of production. This not only reduces operational costs but also aligns with sustainability goals by minimizing the carbon footprint of the manufacturing process.

The versatility of twin-screw extrusion systems provides manufacturers with the flexibility to produce a wider range of PP film formulations. This adaptability allows companies to quickly respond to market demands and develop innovative products, potentially opening new revenue streams and market opportunities.

While the initial capital investment for twin-screw extrusion equipment is higher than that of single-screw systems, the long-term benefits often outweigh this cost. The improved product quality, increased production efficiency, and enhanced material properties contribute to a stronger market position and potential price premiums for the resulting barrier films.

In conclusion, the cost-benefit analysis strongly favors the adoption of twin-screw extrusion for PP barrier films. The technology's ability to enhance product performance, increase production efficiency, and provide greater manufacturing flexibility offers a compelling value proposition for companies looking to gain a competitive edge in the packaging industry.