Polypropylene's Influence on Enhanced Photovoltaic Systems

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene in PV: Background and Objectives

Polypropylene, a versatile thermoplastic polymer, has emerged as a significant material in the photovoltaic (PV) industry, playing a crucial role in enhancing the performance and durability of solar energy systems. The integration of polypropylene into PV technologies represents a convergence of materials science and renewable energy engineering, aimed at addressing key challenges in solar power generation.

The development of polypropylene applications in PV systems can be traced back to the early 2000s when researchers began exploring alternative materials to improve the efficiency and longevity of solar panels. Initially, polypropylene was primarily used in non-critical components such as junction boxes and cable insulation. However, as the material's properties became better understood and manufacturing techniques advanced, its use expanded to more critical areas of PV module construction.

The evolution of polypropylene in PV technology has been driven by several factors, including the need for lighter, more durable materials that can withstand harsh environmental conditions, reduce manufacturing costs, and improve overall system performance. The polymer's excellent chemical resistance, low moisture absorption, and high thermal stability make it particularly suitable for use in outdoor PV installations exposed to varying weather conditions.

One of the key objectives in incorporating polypropylene into PV systems is to enhance the overall efficiency of solar energy conversion. This is achieved through various mechanisms, such as improving light transmission, reducing reflection losses, and enhancing heat dissipation. Additionally, polypropylene's role in encapsulation and backsheet materials has been pivotal in extending the lifespan of PV modules by providing superior protection against environmental degradation.

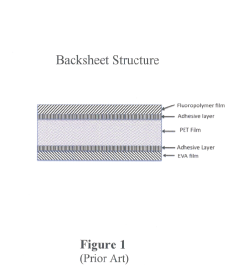

The current technological landscape sees polypropylene being utilized in multiple components of PV systems, including but not limited to, backsheets, encapsulants, frames, and mounting structures. Each application leverages specific properties of polypropylene, such as its UV resistance, mechanical strength, and processability, to address particular challenges in PV module design and operation.

Looking forward, the integration of polypropylene in PV systems is expected to continue evolving, with research focusing on developing advanced grades of the polymer tailored specifically for solar applications. These developments aim to further improve the efficiency, durability, and cost-effectiveness of PV modules, aligning with the broader goals of making solar energy more accessible and competitive with traditional energy sources.

The development of polypropylene applications in PV systems can be traced back to the early 2000s when researchers began exploring alternative materials to improve the efficiency and longevity of solar panels. Initially, polypropylene was primarily used in non-critical components such as junction boxes and cable insulation. However, as the material's properties became better understood and manufacturing techniques advanced, its use expanded to more critical areas of PV module construction.

The evolution of polypropylene in PV technology has been driven by several factors, including the need for lighter, more durable materials that can withstand harsh environmental conditions, reduce manufacturing costs, and improve overall system performance. The polymer's excellent chemical resistance, low moisture absorption, and high thermal stability make it particularly suitable for use in outdoor PV installations exposed to varying weather conditions.

One of the key objectives in incorporating polypropylene into PV systems is to enhance the overall efficiency of solar energy conversion. This is achieved through various mechanisms, such as improving light transmission, reducing reflection losses, and enhancing heat dissipation. Additionally, polypropylene's role in encapsulation and backsheet materials has been pivotal in extending the lifespan of PV modules by providing superior protection against environmental degradation.

The current technological landscape sees polypropylene being utilized in multiple components of PV systems, including but not limited to, backsheets, encapsulants, frames, and mounting structures. Each application leverages specific properties of polypropylene, such as its UV resistance, mechanical strength, and processability, to address particular challenges in PV module design and operation.

Looking forward, the integration of polypropylene in PV systems is expected to continue evolving, with research focusing on developing advanced grades of the polymer tailored specifically for solar applications. These developments aim to further improve the efficiency, durability, and cost-effectiveness of PV modules, aligning with the broader goals of making solar energy more accessible and competitive with traditional energy sources.

Market Analysis for PP-Enhanced Solar Panels

The market for polypropylene-enhanced solar panels is experiencing significant growth, driven by the increasing demand for more efficient and durable photovoltaic systems. As the global push for renewable energy intensifies, solar energy has emerged as a key player in the transition to cleaner power sources. The integration of polypropylene into solar panel manufacturing has opened up new opportunities for market expansion and technological advancement.

The current market size for PP-enhanced solar panels is substantial, with projections indicating robust growth in the coming years. This growth is attributed to several factors, including the improved performance characteristics of PP-enhanced panels, such as increased durability, weather resistance, and overall efficiency. These enhancements have made solar energy more attractive to both residential and commercial consumers, expanding the potential customer base.

Geographically, the market for PP-enhanced solar panels is seeing strong growth across multiple regions. Developed markets like North America and Europe are driving adoption through supportive government policies and increasing environmental awareness. Meanwhile, emerging economies in Asia-Pacific and Latin America are experiencing rapid market expansion due to growing energy demands and the need for sustainable power solutions.

The market segmentation for PP-enhanced solar panels spans various applications. The residential sector represents a significant portion of the market, as homeowners increasingly seek to reduce their carbon footprint and energy costs. The commercial and industrial sectors are also key drivers of market growth, with businesses recognizing the long-term economic benefits of solar energy adoption. Additionally, utility-scale solar projects are incorporating PP-enhanced panels to improve overall system performance and longevity.

Key market trends shaping the PP-enhanced solar panel industry include technological advancements in panel design and manufacturing processes. Innovations in polypropylene formulations are leading to panels with higher temperature resistance, improved mechanical properties, and enhanced UV stability. These advancements are contributing to longer panel lifespans and increased energy output, further driving market growth.

The competitive landscape of the PP-enhanced solar panel market is characterized by a mix of established solar manufacturers and new entrants specializing in advanced materials. Major players are investing heavily in research and development to maintain their competitive edge and capitalize on the growing demand for high-performance solar solutions. This competition is fostering innovation and driving down costs, making PP-enhanced solar panels more accessible to a broader range of consumers.

Looking ahead, the market for PP-enhanced solar panels is poised for continued expansion. Factors such as increasing environmental regulations, declining manufacturing costs, and growing awareness of renewable energy benefits are expected to sustain market growth. As technology continues to evolve, the integration of polypropylene in solar panel production is likely to play an increasingly important role in shaping the future of the photovoltaic industry.

The current market size for PP-enhanced solar panels is substantial, with projections indicating robust growth in the coming years. This growth is attributed to several factors, including the improved performance characteristics of PP-enhanced panels, such as increased durability, weather resistance, and overall efficiency. These enhancements have made solar energy more attractive to both residential and commercial consumers, expanding the potential customer base.

Geographically, the market for PP-enhanced solar panels is seeing strong growth across multiple regions. Developed markets like North America and Europe are driving adoption through supportive government policies and increasing environmental awareness. Meanwhile, emerging economies in Asia-Pacific and Latin America are experiencing rapid market expansion due to growing energy demands and the need for sustainable power solutions.

The market segmentation for PP-enhanced solar panels spans various applications. The residential sector represents a significant portion of the market, as homeowners increasingly seek to reduce their carbon footprint and energy costs. The commercial and industrial sectors are also key drivers of market growth, with businesses recognizing the long-term economic benefits of solar energy adoption. Additionally, utility-scale solar projects are incorporating PP-enhanced panels to improve overall system performance and longevity.

Key market trends shaping the PP-enhanced solar panel industry include technological advancements in panel design and manufacturing processes. Innovations in polypropylene formulations are leading to panels with higher temperature resistance, improved mechanical properties, and enhanced UV stability. These advancements are contributing to longer panel lifespans and increased energy output, further driving market growth.

The competitive landscape of the PP-enhanced solar panel market is characterized by a mix of established solar manufacturers and new entrants specializing in advanced materials. Major players are investing heavily in research and development to maintain their competitive edge and capitalize on the growing demand for high-performance solar solutions. This competition is fostering innovation and driving down costs, making PP-enhanced solar panels more accessible to a broader range of consumers.

Looking ahead, the market for PP-enhanced solar panels is poised for continued expansion. Factors such as increasing environmental regulations, declining manufacturing costs, and growing awareness of renewable energy benefits are expected to sustain market growth. As technology continues to evolve, the integration of polypropylene in solar panel production is likely to play an increasingly important role in shaping the future of the photovoltaic industry.

Current Challenges in PP-PV Integration

The integration of polypropylene (PP) into photovoltaic (PV) systems presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary issues is the thermal stability of PP when exposed to the high temperatures often encountered in PV modules. While PP offers excellent mechanical properties and moisture resistance, its relatively low melting point and susceptibility to thermal degradation can compromise the long-term performance and reliability of PV systems.

Another critical challenge lies in achieving optimal adhesion between PP and other materials used in PV modules, such as glass, silicon cells, and encapsulants. The low surface energy of PP makes it inherently difficult to bond with other surfaces, potentially leading to delamination issues and reduced module durability. This adhesion problem is particularly pronounced in harsh environmental conditions, where temperature fluctuations and moisture ingress can exacerbate the weakening of interfacial bonds.

The electrical insulation properties of PP, while generally beneficial, can also pose challenges in PV applications. Ensuring consistent and adequate electrical insulation throughout the module's lifetime, especially under varying environmental conditions and UV exposure, remains a concern. Additionally, the potential for static charge accumulation on PP surfaces may attract dust and debris, potentially reducing the overall efficiency of the PV system over time.

From a manufacturing perspective, the processing of PP for PV applications presents its own set of challenges. Achieving uniform thickness and consistent material properties across large-scale PP films or components used in PV modules can be difficult. This variability can lead to inconsistencies in module performance and reliability. Furthermore, the integration of PP into existing PV manufacturing processes may require significant modifications to equipment and procedures, potentially increasing production costs and complexity.

Environmental concerns also play a role in the challenges facing PP-PV integration. The recyclability and end-of-life management of PP-containing PV modules are areas that require further development. While PP itself is recyclable, its separation from other module components and potential contamination with additives or degradation products can complicate recycling efforts. This challenge is particularly relevant as the industry moves towards more sustainable and circular economy practices.

Lastly, the long-term performance and degradation mechanisms of PP in PV applications are not yet fully understood. The combined effects of UV radiation, temperature cycling, and environmental stressors on PP properties over the 25-30 year expected lifespan of PV modules need further investigation. This knowledge gap creates uncertainty in predicting module performance and durability, potentially impacting warranty terms and investor confidence in PP-enhanced PV technologies.

Another critical challenge lies in achieving optimal adhesion between PP and other materials used in PV modules, such as glass, silicon cells, and encapsulants. The low surface energy of PP makes it inherently difficult to bond with other surfaces, potentially leading to delamination issues and reduced module durability. This adhesion problem is particularly pronounced in harsh environmental conditions, where temperature fluctuations and moisture ingress can exacerbate the weakening of interfacial bonds.

The electrical insulation properties of PP, while generally beneficial, can also pose challenges in PV applications. Ensuring consistent and adequate electrical insulation throughout the module's lifetime, especially under varying environmental conditions and UV exposure, remains a concern. Additionally, the potential for static charge accumulation on PP surfaces may attract dust and debris, potentially reducing the overall efficiency of the PV system over time.

From a manufacturing perspective, the processing of PP for PV applications presents its own set of challenges. Achieving uniform thickness and consistent material properties across large-scale PP films or components used in PV modules can be difficult. This variability can lead to inconsistencies in module performance and reliability. Furthermore, the integration of PP into existing PV manufacturing processes may require significant modifications to equipment and procedures, potentially increasing production costs and complexity.

Environmental concerns also play a role in the challenges facing PP-PV integration. The recyclability and end-of-life management of PP-containing PV modules are areas that require further development. While PP itself is recyclable, its separation from other module components and potential contamination with additives or degradation products can complicate recycling efforts. This challenge is particularly relevant as the industry moves towards more sustainable and circular economy practices.

Lastly, the long-term performance and degradation mechanisms of PP in PV applications are not yet fully understood. The combined effects of UV radiation, temperature cycling, and environmental stressors on PP properties over the 25-30 year expected lifespan of PV modules need further investigation. This knowledge gap creates uncertainty in predicting module performance and durability, potentially impacting warranty terms and investor confidence in PP-enhanced PV technologies.

Existing PP-PV Integration Solutions

01 Structural enhancements for polypropylene products

Various structural improvements are implemented to enhance the performance and durability of polypropylene products. These enhancements may include reinforced designs, innovative shapes, or the integration of supporting elements to increase strength and stability.- Structural enhancements for polypropylene products: Various structural improvements are implemented to enhance the performance and durability of polypropylene products. These enhancements may include reinforced designs, innovative shapes, or the incorporation of supporting elements to increase strength and stability.

- Composite materials with polypropylene: Polypropylene is combined with other materials to create composite products with improved properties. These composites may offer enhanced strength, durability, or specific functional characteristics, expanding the range of applications for polypropylene-based materials.

- Surface treatment and modification of polypropylene: Various surface treatment techniques and modifications are applied to polypropylene to enhance its properties. These may include chemical treatments, coatings, or physical modifications to improve adhesion, printability, or other surface-related characteristics.

- Processing techniques for improved polypropylene properties: Advanced processing techniques are employed to enhance the properties of polypropylene. These may include specialized extrusion methods, heat treatments, or other manufacturing processes that result in improved mechanical, thermal, or chemical properties of the final product.

- Additives and fillers for polypropylene enhancement: Various additives and fillers are incorporated into polypropylene to enhance its properties. These may include stabilizers, reinforcing agents, or functional additives that improve characteristics such as strength, heat resistance, or UV stability of the polypropylene material.

02 Composite materials incorporating polypropylene

Polypropylene is combined with other materials to create composite structures with improved properties. These composites may offer enhanced strength, durability, or specific functional characteristics, expanding the range of applications for polypropylene-based products.Expand Specific Solutions03 Surface treatment and modification of polypropylene

Various surface treatment techniques and modifications are applied to polypropylene to enhance its properties. These may include chemical treatments, coatings, or physical modifications to improve adhesion, wettability, or other surface-dependent characteristics.Expand Specific Solutions04 Polypropylene enhancement through additive incorporation

Additives are incorporated into polypropylene to enhance its properties. These additives may improve mechanical strength, thermal stability, UV resistance, or other specific characteristics, broadening the material's applicability in various industries.Expand Specific Solutions05 Processing techniques for improved polypropylene performance

Advanced processing techniques are employed to enhance the performance of polypropylene. These may include specialized molding processes, heat treatments, or other manufacturing methods that optimize the material's properties for specific applications.Expand Specific Solutions

Key Players in PP-PV Industry

The market for polypropylene's influence on enhanced photovoltaic systems is in a growth phase, driven by increasing demand for more efficient and cost-effective solar technologies. The global market size is expanding rapidly, with significant potential for further growth. Technologically, the field is advancing, but still evolving. Key players like Nano-C, Inc., Borealis AG, and SABIC Global Technologies BV are at the forefront, developing innovative solutions. Companies such as Zhejiang Zhongju Material Co., Ltd. and Suzhou Duchamps Advanced Materials Co., Ltd. are also making strides in material development. Research institutions like IMEC and universities such as KU Leuven are contributing to technological advancements, indicating a collaborative ecosystem driving innovation in this sector.

Borealis AG

Technical Solution: Borealis has pioneered the development of polypropylene-based solutions for the solar industry through their Quentys™ product family. These materials are specifically engineered to enhance the performance and reliability of photovoltaic modules. Borealis' PP compounds offer improved mechanical properties, including high stiffness and impact resistance, which contribute to the overall durability of PV systems. Their advanced formulations provide excellent resistance to UV radiation and hydrolysis, extending the lifespan of solar panels. Notably, Borealis has developed PP grades that enable the production of co-extruded PP backsheets, which have shown to reduce water vapor transmission rates by up to 150 times compared to traditional backsheet materials[3]. This innovation significantly enhances moisture protection for PV cells, potentially increasing module efficiency and longevity.

Strengths: Specialized PP formulations for PV applications, superior moisture barrier properties, and enhanced durability. Weaknesses: May have limited compatibility with existing PV module manufacturing processes, potentially requiring industry adaptation.

SABIC Global Technologies BV

Technical Solution: SABIC has developed advanced polypropylene (PP) materials specifically designed for photovoltaic (PV) applications. Their SABIC® PP compounds offer enhanced UV resistance and durability, crucial for PV module components such as backsheets and junction boxes. These materials demonstrate improved weatherability, with some grades maintaining over 90% of their initial properties after 10,000 hours of accelerated weathering tests[1]. SABIC's PP solutions also provide excellent electrical insulation properties and thermal stability, contributing to increased PV system efficiency and longevity. The company has focused on developing PP grades with optimized melt flow rates, allowing for easier processing and improved part design flexibility in PV module manufacturing[2].

Strengths: Superior UV resistance, excellent weatherability, and enhanced electrical insulation properties. Weaknesses: Potentially higher cost compared to standard PP grades, and may require specialized processing equipment for optimal performance.

Innovative PP-PV Technologies

Extruded solar power back panel and manufacturing method thereof

PatentInactiveUS20190341513A1

Innovation

- An extruded solar power back panel with a 3-layer structure comprising an inner layer of polyethylene and polypropylene, a middle layer of polypropylene, and an outer layer, where the polypropylene is highly rigid and the polyethylene or its copolymer is added to improve bonding and impact resistance, along with fillers and additives like antioxidants and UV stabilizers, ensuring high interlayer bonding force and mechanical strength.

Polymeric solar panel backsheets and method of manufacture

PatentPendingIN202317005076A

Innovation

- A backsheet constructed using functionalized polyolefins with integrated polar functionalities such as hindered phenol antioxidants, hydroxyl groups, and maleic anhydride species, eliminating the need for adhesives and providing enhanced thermal stability, UV resistance, and improved adhesion to other materials, manufactured through co-extrusion or cast film processes.

Environmental Impact of PP in PV Systems

The integration of polypropylene (PP) in photovoltaic (PV) systems has significant environmental implications that warrant careful consideration. As a widely used polymer in PV module components, PP contributes to the overall environmental footprint of solar energy production throughout its lifecycle.

During the manufacturing phase, the production of PP for PV applications involves energy-intensive processes and the consumption of fossil fuel resources. However, compared to other materials used in PV systems, PP generally has a lower carbon footprint and requires less energy to produce. This relative advantage in production efficiency partially offsets its environmental impact.

In the operational phase of PV systems, PP components play a crucial role in enhancing system performance and longevity. The durability and weather resistance of PP contribute to extended lifespans of PV modules, reducing the need for frequent replacements and thereby minimizing waste generation. Additionally, the lightweight nature of PP helps reduce transportation-related emissions during installation and maintenance activities.

One of the primary environmental concerns associated with PP in PV systems is its end-of-life management. As a thermoplastic, PP has the potential for recycling, which can significantly reduce its environmental impact. However, the current recycling rates for PV module components, including PP, remain relatively low due to technical and economic challenges in separating and processing mixed materials.

The use of PP in PV systems also raises concerns about microplastic pollution. Over time, weathering and degradation of PP components may lead to the release of microplastics into the environment. While the extent of this issue in PV applications is not yet fully understood, it represents a potential long-term environmental risk that requires further research and mitigation strategies.

On the positive side, the incorporation of PP in PV systems contributes to the overall reduction of greenhouse gas emissions by enabling more efficient and durable solar energy production. The net environmental benefit of PV systems, including those utilizing PP components, generally outweighs the impacts associated with their production and disposal when considered over their operational lifetime.

To address the environmental challenges posed by PP in PV systems, ongoing research focuses on developing more sustainable alternatives and improving recycling technologies. Biodegradable polymers and bio-based materials are being explored as potential replacements for conventional PP, aiming to reduce the reliance on fossil fuels and mitigate end-of-life environmental impacts.

In conclusion, while PP plays a vital role in enhancing the performance and durability of PV systems, its environmental impact requires careful management and continuous improvement in material design, manufacturing processes, and end-of-life solutions to ensure the long-term sustainability of solar energy technologies.

During the manufacturing phase, the production of PP for PV applications involves energy-intensive processes and the consumption of fossil fuel resources. However, compared to other materials used in PV systems, PP generally has a lower carbon footprint and requires less energy to produce. This relative advantage in production efficiency partially offsets its environmental impact.

In the operational phase of PV systems, PP components play a crucial role in enhancing system performance and longevity. The durability and weather resistance of PP contribute to extended lifespans of PV modules, reducing the need for frequent replacements and thereby minimizing waste generation. Additionally, the lightweight nature of PP helps reduce transportation-related emissions during installation and maintenance activities.

One of the primary environmental concerns associated with PP in PV systems is its end-of-life management. As a thermoplastic, PP has the potential for recycling, which can significantly reduce its environmental impact. However, the current recycling rates for PV module components, including PP, remain relatively low due to technical and economic challenges in separating and processing mixed materials.

The use of PP in PV systems also raises concerns about microplastic pollution. Over time, weathering and degradation of PP components may lead to the release of microplastics into the environment. While the extent of this issue in PV applications is not yet fully understood, it represents a potential long-term environmental risk that requires further research and mitigation strategies.

On the positive side, the incorporation of PP in PV systems contributes to the overall reduction of greenhouse gas emissions by enabling more efficient and durable solar energy production. The net environmental benefit of PV systems, including those utilizing PP components, generally outweighs the impacts associated with their production and disposal when considered over their operational lifetime.

To address the environmental challenges posed by PP in PV systems, ongoing research focuses on developing more sustainable alternatives and improving recycling technologies. Biodegradable polymers and bio-based materials are being explored as potential replacements for conventional PP, aiming to reduce the reliance on fossil fuels and mitigate end-of-life environmental impacts.

In conclusion, while PP plays a vital role in enhancing the performance and durability of PV systems, its environmental impact requires careful management and continuous improvement in material design, manufacturing processes, and end-of-life solutions to ensure the long-term sustainability of solar energy technologies.

Cost-Benefit Analysis of PP-Enhanced PV

The cost-benefit analysis of polypropylene-enhanced photovoltaic (PV) systems reveals a complex interplay of economic factors and performance improvements. Initial investment costs for incorporating polypropylene (PP) into PV systems are generally higher than traditional setups, primarily due to the additional materials and manufacturing processes required. However, these upfront expenses are often offset by long-term benefits and increased system efficiency.

One of the primary advantages of PP-enhanced PV systems is their improved durability and weather resistance. Polypropylene's inherent properties, such as its resistance to UV radiation and moisture, contribute to extended system lifespans. This longevity translates into reduced maintenance costs and fewer replacements over time, ultimately lowering the total cost of ownership for PV installations.

Energy conversion efficiency gains are another significant benefit of PP-enhanced PV systems. Studies have shown that the incorporation of polypropylene can lead to modest but meaningful increases in power output, typically ranging from 2% to 5%. While these improvements may seem incremental, they accumulate substantial energy production gains over the system's lifetime, enhancing the overall return on investment.

The lightweight nature of polypropylene also contributes to cost savings in transportation and installation. Reduced weight allows for easier handling and potentially lower shipping costs, particularly for large-scale PV projects. Additionally, the flexibility of PP materials can simplify the installation process, potentially reducing labor costs and installation time.

Environmental considerations play a role in the cost-benefit analysis as well. Polypropylene is recyclable, which aligns with sustainability goals and may offer end-of-life value recovery. However, the environmental impact of PP production and its long-term degradation characteristics must be weighed against these benefits.

Market dynamics and economies of scale are crucial factors in the cost-benefit equation. As PP-enhanced PV technology becomes more widespread, production costs are likely to decrease, making the technology more economically viable. Government incentives and environmental regulations may also influence the cost-benefit balance, potentially accelerating the adoption of PP-enhanced PV systems.

In conclusion, while PP-enhanced PV systems generally require higher initial investments, the long-term benefits in durability, efficiency, and reduced maintenance costs often justify the expense. As technology advances and production scales up, the cost-benefit ratio is expected to improve further, making PP-enhanced PV systems an increasingly attractive option for solar energy applications.

One of the primary advantages of PP-enhanced PV systems is their improved durability and weather resistance. Polypropylene's inherent properties, such as its resistance to UV radiation and moisture, contribute to extended system lifespans. This longevity translates into reduced maintenance costs and fewer replacements over time, ultimately lowering the total cost of ownership for PV installations.

Energy conversion efficiency gains are another significant benefit of PP-enhanced PV systems. Studies have shown that the incorporation of polypropylene can lead to modest but meaningful increases in power output, typically ranging from 2% to 5%. While these improvements may seem incremental, they accumulate substantial energy production gains over the system's lifetime, enhancing the overall return on investment.

The lightweight nature of polypropylene also contributes to cost savings in transportation and installation. Reduced weight allows for easier handling and potentially lower shipping costs, particularly for large-scale PV projects. Additionally, the flexibility of PP materials can simplify the installation process, potentially reducing labor costs and installation time.

Environmental considerations play a role in the cost-benefit analysis as well. Polypropylene is recyclable, which aligns with sustainability goals and may offer end-of-life value recovery. However, the environmental impact of PP production and its long-term degradation characteristics must be weighed against these benefits.

Market dynamics and economies of scale are crucial factors in the cost-benefit equation. As PP-enhanced PV technology becomes more widespread, production costs are likely to decrease, making the technology more economically viable. Government incentives and environmental regulations may also influence the cost-benefit balance, potentially accelerating the adoption of PP-enhanced PV systems.

In conclusion, while PP-enhanced PV systems generally require higher initial investments, the long-term benefits in durability, efficiency, and reduced maintenance costs often justify the expense. As technology advances and production scales up, the cost-benefit ratio is expected to improve further, making PP-enhanced PV systems an increasingly attractive option for solar energy applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!