Investigating Lightweight Mesh Formation Using Polypropylene Fibers

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Mesh Evolution and Objectives

Polypropylene mesh has undergone significant evolution since its introduction in the medical field, particularly in hernia repair and pelvic floor reconstruction. The journey began in the 1950s with the development of synthetic polymers, leading to the creation of polypropylene in 1954 by Giulio Natta. Initially used in various industrial applications, polypropylene's potential in medical devices was soon recognized due to its durability, flexibility, and biocompatibility.

The first surgical use of polypropylene mesh was reported in the 1960s for hernia repair. This marked a revolutionary change in surgical techniques, moving away from tension-based repairs to tension-free methods. The lightweight mesh concept emerged in the late 1990s as a response to complications associated with heavy-weight meshes, such as chronic pain and foreign body sensation.

Over the years, researchers and manufacturers have focused on optimizing mesh properties to enhance biocompatibility and reduce adverse effects. Key developments include the introduction of large-pore meshes, which allow for better tissue integration and reduced foreign body reaction. The evolution also saw the incorporation of absorbable components, creating partially absorbable meshes that provide initial strength while reducing long-term foreign material presence.

Recent advancements have centered on creating ultra-lightweight meshes using polypropylene fibers. These meshes aim to minimize the amount of foreign material while maintaining adequate strength for tissue support. The objectives of this ongoing evolution are multifaceted, addressing both clinical and patient-centric concerns.

Primary objectives include reducing post-operative complications such as chronic pain, mesh shrinkage, and infection rates. There is a strong focus on improving the mesh's integration with surrounding tissues, promoting faster healing, and minimizing the foreign body response. Another crucial goal is to enhance the mesh's mechanical properties, ensuring it provides adequate support while closely mimicking the natural tissue's biomechanics.

From a patient perspective, objectives include improving comfort, reducing the risk of mesh erosion or exposure, and minimizing long-term complications. There's also a growing emphasis on developing meshes that are compatible with minimally invasive surgical techniques, facilitating faster recovery and reduced scarring.

Looking forward, the field aims to leverage advanced manufacturing techniques like 3D printing and nanotechnology to create customized, patient-specific meshes. The ultimate goal is to develop a "ideal mesh" that combines optimal mechanical properties with excellent biocompatibility, minimal foreign body reaction, and the ability to adapt to the patient's anatomy and physiological changes over time.

The first surgical use of polypropylene mesh was reported in the 1960s for hernia repair. This marked a revolutionary change in surgical techniques, moving away from tension-based repairs to tension-free methods. The lightweight mesh concept emerged in the late 1990s as a response to complications associated with heavy-weight meshes, such as chronic pain and foreign body sensation.

Over the years, researchers and manufacturers have focused on optimizing mesh properties to enhance biocompatibility and reduce adverse effects. Key developments include the introduction of large-pore meshes, which allow for better tissue integration and reduced foreign body reaction. The evolution also saw the incorporation of absorbable components, creating partially absorbable meshes that provide initial strength while reducing long-term foreign material presence.

Recent advancements have centered on creating ultra-lightweight meshes using polypropylene fibers. These meshes aim to minimize the amount of foreign material while maintaining adequate strength for tissue support. The objectives of this ongoing evolution are multifaceted, addressing both clinical and patient-centric concerns.

Primary objectives include reducing post-operative complications such as chronic pain, mesh shrinkage, and infection rates. There is a strong focus on improving the mesh's integration with surrounding tissues, promoting faster healing, and minimizing the foreign body response. Another crucial goal is to enhance the mesh's mechanical properties, ensuring it provides adequate support while closely mimicking the natural tissue's biomechanics.

From a patient perspective, objectives include improving comfort, reducing the risk of mesh erosion or exposure, and minimizing long-term complications. There's also a growing emphasis on developing meshes that are compatible with minimally invasive surgical techniques, facilitating faster recovery and reduced scarring.

Looking forward, the field aims to leverage advanced manufacturing techniques like 3D printing and nanotechnology to create customized, patient-specific meshes. The ultimate goal is to develop a "ideal mesh" that combines optimal mechanical properties with excellent biocompatibility, minimal foreign body reaction, and the ability to adapt to the patient's anatomy and physiological changes over time.

Market Analysis for Lightweight Mesh Applications

The market for lightweight mesh applications using polypropylene fibers has experienced significant growth in recent years, driven by increasing demand across various industries. This market segment is characterized by its versatility, cost-effectiveness, and performance advantages over traditional materials.

In the construction sector, lightweight polypropylene mesh has gained traction for applications such as concrete reinforcement, soil stabilization, and erosion control. The global construction industry, valued at approximately $11 trillion in 2020, is expected to grow at a CAGR of 7.5% through 2030, presenting substantial opportunities for lightweight mesh products.

The automotive industry represents another key market for lightweight polypropylene mesh. As automakers strive to reduce vehicle weight and improve fuel efficiency, these materials are increasingly used in interior components, acoustic insulation, and filtration systems. The global automotive lightweight materials market is projected to reach $99 billion by 2025, with a CAGR of 7.2% from 2020 to 2025.

In the medical field, lightweight polypropylene mesh has found applications in surgical procedures, particularly for hernia repair and pelvic organ prolapse treatment. The global surgical mesh market was valued at $1.7 billion in 2020 and is expected to grow at a CAGR of 3.5% through 2027, driven by an aging population and increasing prevalence of hernia cases.

The packaging industry has also embraced lightweight polypropylene mesh for applications such as produce bags, protective packaging, and industrial sacks. The global flexible packaging market, which includes these mesh products, was valued at $248 billion in 2020 and is projected to grow at a CAGR of 4.5% through 2026.

Geographically, Asia-Pacific is expected to be the fastest-growing market for lightweight mesh applications, driven by rapid industrialization, infrastructure development, and increasing automotive production in countries like China and India. North America and Europe remain significant markets, with a focus on high-performance and sustainable solutions.

Key market drivers include the growing emphasis on lightweight materials across industries, increasing environmental regulations promoting sustainable solutions, and advancements in polypropylene fiber technology. However, challenges such as competition from alternative materials and fluctuating raw material prices may impact market growth.

In conclusion, the market for lightweight mesh applications using polypropylene fibers presents significant opportunities across multiple industries. As technology advances and new applications emerge, this market segment is poised for continued growth and innovation in the coming years.

In the construction sector, lightweight polypropylene mesh has gained traction for applications such as concrete reinforcement, soil stabilization, and erosion control. The global construction industry, valued at approximately $11 trillion in 2020, is expected to grow at a CAGR of 7.5% through 2030, presenting substantial opportunities for lightweight mesh products.

The automotive industry represents another key market for lightweight polypropylene mesh. As automakers strive to reduce vehicle weight and improve fuel efficiency, these materials are increasingly used in interior components, acoustic insulation, and filtration systems. The global automotive lightweight materials market is projected to reach $99 billion by 2025, with a CAGR of 7.2% from 2020 to 2025.

In the medical field, lightweight polypropylene mesh has found applications in surgical procedures, particularly for hernia repair and pelvic organ prolapse treatment. The global surgical mesh market was valued at $1.7 billion in 2020 and is expected to grow at a CAGR of 3.5% through 2027, driven by an aging population and increasing prevalence of hernia cases.

The packaging industry has also embraced lightweight polypropylene mesh for applications such as produce bags, protective packaging, and industrial sacks. The global flexible packaging market, which includes these mesh products, was valued at $248 billion in 2020 and is projected to grow at a CAGR of 4.5% through 2026.

Geographically, Asia-Pacific is expected to be the fastest-growing market for lightweight mesh applications, driven by rapid industrialization, infrastructure development, and increasing automotive production in countries like China and India. North America and Europe remain significant markets, with a focus on high-performance and sustainable solutions.

Key market drivers include the growing emphasis on lightweight materials across industries, increasing environmental regulations promoting sustainable solutions, and advancements in polypropylene fiber technology. However, challenges such as competition from alternative materials and fluctuating raw material prices may impact market growth.

In conclusion, the market for lightweight mesh applications using polypropylene fibers presents significant opportunities across multiple industries. As technology advances and new applications emerge, this market segment is poised for continued growth and innovation in the coming years.

Current Challenges in Polypropylene Fiber Mesh Formation

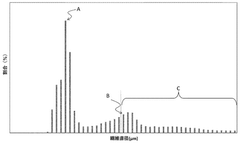

The formation of lightweight mesh using polypropylene fibers presents several significant challenges that researchers and manufacturers are currently grappling with. One of the primary obstacles is achieving consistent fiber distribution and orientation within the mesh structure. Polypropylene fibers tend to exhibit variability in their alignment during the manufacturing process, which can lead to inconsistencies in the mesh's mechanical properties and overall performance.

Another critical challenge lies in balancing the mesh's weight reduction with its structural integrity. As the demand for lighter materials increases, there is a constant push to minimize the amount of polypropylene used while maintaining the mesh's strength and durability. This delicate balance often requires innovative manufacturing techniques and precise control over fiber properties.

The bonding between individual polypropylene fibers within the mesh structure poses yet another hurdle. Traditional thermal bonding methods may compromise the fibers' inherent properties, potentially weakening the overall mesh. Developing alternative bonding techniques that preserve the fibers' characteristics while ensuring a stable mesh formation is an ongoing area of research.

Scalability of production processes for lightweight polypropylene fiber meshes remains a significant challenge. Many current manufacturing methods that yield high-quality, lightweight meshes are limited in their production capacity or are not economically viable for large-scale manufacturing. Bridging this gap between laboratory-scale production and industrial-scale manufacturing is crucial for widespread adoption of these materials.

Environmental concerns also present challenges in polypropylene fiber mesh formation. As sustainability becomes increasingly important, there is a growing need to develop eco-friendly production methods and explore recyclability options for these meshes. This includes finding ways to reduce energy consumption during manufacturing and developing end-of-life solutions that minimize environmental impact.

The customization of mesh properties for specific applications is another area of difficulty. Different use cases may require varying degrees of flexibility, porosity, or strength. Tailoring the mesh formation process to achieve these specific characteristics while maintaining the lightweight nature of the material demands sophisticated control over multiple manufacturing parameters.

Lastly, quality control and consistency in large-scale production of lightweight polypropylene fiber meshes remain ongoing challenges. Ensuring uniformity in fiber diameter, mesh pore size, and overall structural integrity across large production batches requires advanced monitoring systems and precise process control mechanisms. Overcoming these challenges is essential for meeting industry standards and regulatory requirements in various applications of lightweight polypropylene fiber meshes.

Another critical challenge lies in balancing the mesh's weight reduction with its structural integrity. As the demand for lighter materials increases, there is a constant push to minimize the amount of polypropylene used while maintaining the mesh's strength and durability. This delicate balance often requires innovative manufacturing techniques and precise control over fiber properties.

The bonding between individual polypropylene fibers within the mesh structure poses yet another hurdle. Traditional thermal bonding methods may compromise the fibers' inherent properties, potentially weakening the overall mesh. Developing alternative bonding techniques that preserve the fibers' characteristics while ensuring a stable mesh formation is an ongoing area of research.

Scalability of production processes for lightweight polypropylene fiber meshes remains a significant challenge. Many current manufacturing methods that yield high-quality, lightweight meshes are limited in their production capacity or are not economically viable for large-scale manufacturing. Bridging this gap between laboratory-scale production and industrial-scale manufacturing is crucial for widespread adoption of these materials.

Environmental concerns also present challenges in polypropylene fiber mesh formation. As sustainability becomes increasingly important, there is a growing need to develop eco-friendly production methods and explore recyclability options for these meshes. This includes finding ways to reduce energy consumption during manufacturing and developing end-of-life solutions that minimize environmental impact.

The customization of mesh properties for specific applications is another area of difficulty. Different use cases may require varying degrees of flexibility, porosity, or strength. Tailoring the mesh formation process to achieve these specific characteristics while maintaining the lightweight nature of the material demands sophisticated control over multiple manufacturing parameters.

Lastly, quality control and consistency in large-scale production of lightweight polypropylene fiber meshes remain ongoing challenges. Ensuring uniformity in fiber diameter, mesh pore size, and overall structural integrity across large production batches requires advanced monitoring systems and precise process control mechanisms. Overcoming these challenges is essential for meeting industry standards and regulatory requirements in various applications of lightweight polypropylene fiber meshes.

Existing Lightweight Mesh Formation Techniques

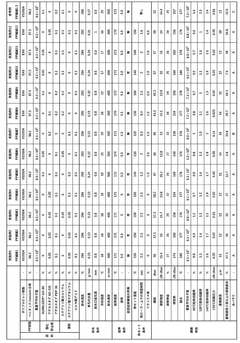

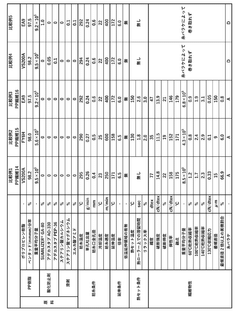

01 Lightweight polypropylene fiber production methods

Various techniques are employed to produce lightweight polypropylene fibers, including melt-spinning processes, drawing techniques, and the use of specific additives. These methods aim to reduce the density of the fibers while maintaining their strength and other desirable properties.- Lightweight polypropylene fiber production methods: Various methods are employed to produce lightweight polypropylene fibers, including melt-spinning techniques, drawing processes, and the use of specific additives. These methods aim to reduce the density of the fibers while maintaining their strength and other desirable properties.

- Blending polypropylene with other materials: Lightweight polypropylene fibers can be created by blending polypropylene with other materials such as polyethylene or natural fibers. This blending process can result in fibers with reduced weight and enhanced properties like improved strength or moisture-wicking capabilities.

- Foaming techniques for lightweight polypropylene fibers: Foaming techniques are used to create lightweight polypropylene fibers by introducing gas bubbles into the polymer matrix during processing. This results in a reduced density fiber with improved insulation properties and potential cost savings in material usage.

- Surface treatments for enhanced properties: Various surface treatments can be applied to lightweight polypropylene fibers to enhance their properties. These treatments may improve characteristics such as hydrophobicity, dyeability, or adhesion to other materials, while maintaining the low weight of the fibers.

- Applications of lightweight polypropylene fibers: Lightweight polypropylene fibers find applications in various industries, including textiles, automotive, and construction. They are used in products such as nonwoven fabrics, geotextiles, and composite materials, where their low weight and specific properties offer advantages.

02 Blending polypropylene with other materials

Polypropylene is often blended with other materials to create lightweight composite fibers. These blends can include other polymers, natural fibers, or inorganic materials, resulting in fibers with improved properties such as reduced weight, increased strength, or enhanced thermal insulation.Expand Specific Solutions03 Surface treatments for lightweight polypropylene fibers

Various surface treatments are applied to lightweight polypropylene fibers to enhance their properties. These treatments can improve adhesion, hydrophobicity, or other surface characteristics, making the fibers more suitable for specific applications while maintaining their lightweight nature.Expand Specific Solutions04 Applications of lightweight polypropylene fibers

Lightweight polypropylene fibers find applications in various industries, including textiles, automotive, construction, and packaging. Their low density, combined with other desirable properties, makes them suitable for products requiring reduced weight without compromising performance.Expand Specific Solutions05 Nanofiber and microfiber polypropylene structures

Advanced manufacturing techniques are used to create nanofiber and microfiber structures from polypropylene. These ultra-fine fibers offer exceptional lightweight properties while maintaining or improving other characteristics such as strength, filtration efficiency, or thermal insulation.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The lightweight mesh formation using polypropylene fibers is in a growth phase, with increasing market demand driven by applications in various industries. The global market for polypropylene fibers is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Borealis AG, Toray Industries, and LG Chem leading innovation. These firms are developing new manufacturing processes and enhancing fiber properties to meet evolving industry needs. The technology's maturity varies across applications, with some areas well-established and others still emerging. Collaboration between academic institutions like Donghua University and industry leaders is accelerating progress, particularly in areas such as improved strength-to-weight ratios and environmental sustainability.

Borealis AG

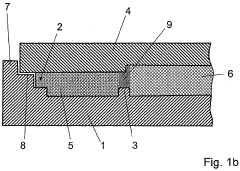

Technical Solution: Borealis AG has developed a proprietary technology for lightweight mesh formation using polypropylene fibers. Their approach involves a controlled melt-spinning process that produces ultra-fine polypropylene fibers with diameters as small as 0.5 microns[1]. These fibers are then thermally bonded to create a lightweight, high-strength mesh structure. The company has implemented a unique fiber orientation control system that allows for tailored mechanical properties in different directions[3]. Additionally, Borealis has incorporated nano-additives into the polypropylene matrix to enhance the mesh's overall performance, including improved tensile strength and thermal stability[5].

Strengths: High strength-to-weight ratio, customizable mechanical properties, and enhanced thermal stability. Weaknesses: Potentially higher production costs due to specialized processes and additives.

Toray Industries, Inc.

Technical Solution: Toray Industries has pioneered a novel approach to lightweight mesh formation using polypropylene fibers through their advanced fiber spinning technology. Their method employs a multi-stage drawing process that allows for precise control over fiber diameter and crystallinity[2]. The company has developed a proprietary surface treatment technique that enhances fiber-to-fiber bonding, resulting in a mesh with superior structural integrity[4]. Toray's process also incorporates a unique heat-setting step that optimizes the mesh's dimensional stability and resistance to deformation under load[6]. Furthermore, they have implemented a computerized fiber layering system that enables the creation of complex 3D mesh structures with varying densities and orientations[8].

Strengths: Excellent dimensional stability, ability to create complex 3D structures, and enhanced fiber bonding. Weaknesses: May require specialized equipment, potentially limiting scalability.

Innovative Approaches in Polypropylene Fiber Processing

Polypropylene fibers and method for producing polypropylene fibers

PatentWO2025135019A1

Innovation

- The production of polypropylene fibers involves melt-spinning high molecular weight polypropylene, followed by specific cooling, stretching, and heat-setting processes to suppress yarn breakage and fiber fusion, while achieving high strength, high elongation, and excellent thermal stability.

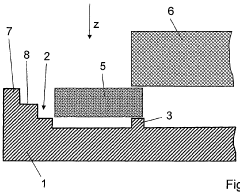

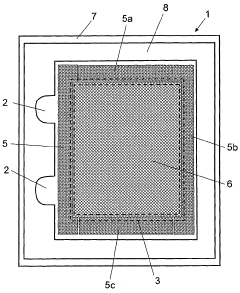

Method for the production of molded parts made of fiber-reinforced polypropylene containing pores

PatentWO2008101360A1

Innovation

- A process involving a flat blank of fiber-reinforced polypropylene with air voids and overlapping polypropylene strips, heated above the softening point, is used in a two-part mold to achieve deformation and filling of mold contours, allowing for the production of complex shapes without additional operations.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of lightweight mesh formation using polypropylene fibers are crucial aspects that require thorough examination. Polypropylene, a thermoplastic polymer, offers several advantages in terms of sustainability, but also presents challenges that need to be addressed.

One of the primary environmental benefits of using polypropylene fibers for lightweight mesh formation is their recyclability. Polypropylene can be recycled multiple times without significant degradation of its properties, which contributes to a circular economy model. This recyclability reduces the overall environmental footprint of products made from these meshes, as they can be repurposed at the end of their lifecycle rather than ending up in landfills.

However, the production of polypropylene fibers does have environmental implications. The manufacturing process relies on fossil fuel-based raw materials, which contributes to greenhouse gas emissions and resource depletion. To mitigate this impact, research into bio-based alternatives and more energy-efficient production methods is ongoing. Some companies are exploring the use of renewable energy sources in the manufacturing process to reduce the carbon footprint associated with polypropylene fiber production.

The lightweight nature of polypropylene mesh structures offers sustainability advantages in transportation and application. The reduced weight translates to lower fuel consumption during shipping, thereby decreasing transportation-related emissions. Additionally, in applications such as construction or automotive industries, lightweight materials contribute to improved energy efficiency of the final products.

Durability is another key factor in the sustainability profile of polypropylene fiber meshes. These materials exhibit excellent resistance to chemicals, moisture, and UV radiation, which leads to longer product lifespans. This longevity reduces the need for frequent replacements, ultimately conserving resources and minimizing waste generation over time.

Water conservation is an often-overlooked aspect of sustainability in material production. Polypropylene fiber manufacturing generally requires less water compared to natural fiber processing, which can be a significant environmental advantage in water-stressed regions. However, proper wastewater management remains crucial to prevent pollution from chemical additives used in the production process.

End-of-life considerations are paramount when assessing the environmental impact of polypropylene fiber meshes. While recyclable, these materials can pose challenges if not properly managed. Efforts are being made to improve collection and sorting systems to ensure that a higher percentage of polypropylene products are recycled. Additionally, research into biodegradable additives that can enhance the decomposition of polypropylene in natural environments is underway, although balancing degradability with the material's desirable properties remains a challenge.

As sustainability becomes increasingly important in material selection, the industry is focusing on developing more eco-friendly production methods and exploring bio-based alternatives to traditional polypropylene. These efforts aim to further reduce the environmental impact while maintaining the beneficial properties of lightweight mesh structures.

One of the primary environmental benefits of using polypropylene fibers for lightweight mesh formation is their recyclability. Polypropylene can be recycled multiple times without significant degradation of its properties, which contributes to a circular economy model. This recyclability reduces the overall environmental footprint of products made from these meshes, as they can be repurposed at the end of their lifecycle rather than ending up in landfills.

However, the production of polypropylene fibers does have environmental implications. The manufacturing process relies on fossil fuel-based raw materials, which contributes to greenhouse gas emissions and resource depletion. To mitigate this impact, research into bio-based alternatives and more energy-efficient production methods is ongoing. Some companies are exploring the use of renewable energy sources in the manufacturing process to reduce the carbon footprint associated with polypropylene fiber production.

The lightweight nature of polypropylene mesh structures offers sustainability advantages in transportation and application. The reduced weight translates to lower fuel consumption during shipping, thereby decreasing transportation-related emissions. Additionally, in applications such as construction or automotive industries, lightweight materials contribute to improved energy efficiency of the final products.

Durability is another key factor in the sustainability profile of polypropylene fiber meshes. These materials exhibit excellent resistance to chemicals, moisture, and UV radiation, which leads to longer product lifespans. This longevity reduces the need for frequent replacements, ultimately conserving resources and minimizing waste generation over time.

Water conservation is an often-overlooked aspect of sustainability in material production. Polypropylene fiber manufacturing generally requires less water compared to natural fiber processing, which can be a significant environmental advantage in water-stressed regions. However, proper wastewater management remains crucial to prevent pollution from chemical additives used in the production process.

End-of-life considerations are paramount when assessing the environmental impact of polypropylene fiber meshes. While recyclable, these materials can pose challenges if not properly managed. Efforts are being made to improve collection and sorting systems to ensure that a higher percentage of polypropylene products are recycled. Additionally, research into biodegradable additives that can enhance the decomposition of polypropylene in natural environments is underway, although balancing degradability with the material's desirable properties remains a challenge.

As sustainability becomes increasingly important in material selection, the industry is focusing on developing more eco-friendly production methods and exploring bio-based alternatives to traditional polypropylene. These efforts aim to further reduce the environmental impact while maintaining the beneficial properties of lightweight mesh structures.

Regulatory Framework for Polypropylene Mesh Products

The regulatory framework for polypropylene mesh products is a complex and evolving landscape that significantly impacts the development, manufacturing, and marketing of these medical devices. In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing the safety and efficacy of polypropylene mesh products. These devices are typically classified as Class II medical devices, requiring premarket notification (510(k)) clearance before they can be legally marketed.

The FDA has implemented specific guidelines for mesh products used in various applications, such as hernia repair and pelvic organ prolapse treatment. These guidelines outline the necessary clinical data, biocompatibility testing, and risk assessments required for regulatory approval. Manufacturers must demonstrate substantial equivalence to predicate devices and provide comprehensive documentation on the product's design, materials, and intended use.

In the European Union, polypropylene mesh products fall under the Medical Device Regulation (MDR), which came into full effect in May 2021. The MDR has introduced more stringent requirements for clinical evidence, post-market surveillance, and traceability of medical devices. Manufacturers seeking CE marking for their mesh products must now comply with these enhanced regulations, including the need for more robust clinical data and risk management processes.

Globally, regulatory bodies have increased scrutiny on polypropylene mesh products due to reported adverse events and complications associated with certain applications. This has led to the implementation of more rigorous post-market surveillance requirements and the establishment of registries to monitor long-term outcomes. Manufacturers are now expected to conduct thorough post-market studies and maintain vigilant reporting systems to detect and address any safety concerns promptly.

The regulatory framework also addresses the materials used in mesh production, with a focus on the quality and purity of polypropylene fibers. Standards such as ISO 13485 for quality management systems and ISO 10993 for biocompatibility testing are integral to the regulatory compliance process. Manufacturers must demonstrate that their lightweight mesh formations using polypropylene fibers meet these standards and do not pose unacceptable risks to patients.

As research continues to advance in the field of lightweight mesh formation, regulatory bodies are adapting their frameworks to accommodate new technologies and manufacturing processes. This includes considerations for novel fiber treatments, mesh designs, and integration of bioactive components. The evolving regulatory landscape aims to balance innovation with patient safety, ensuring that new developments in polypropylene mesh technology undergo rigorous evaluation before reaching the market.

The FDA has implemented specific guidelines for mesh products used in various applications, such as hernia repair and pelvic organ prolapse treatment. These guidelines outline the necessary clinical data, biocompatibility testing, and risk assessments required for regulatory approval. Manufacturers must demonstrate substantial equivalence to predicate devices and provide comprehensive documentation on the product's design, materials, and intended use.

In the European Union, polypropylene mesh products fall under the Medical Device Regulation (MDR), which came into full effect in May 2021. The MDR has introduced more stringent requirements for clinical evidence, post-market surveillance, and traceability of medical devices. Manufacturers seeking CE marking for their mesh products must now comply with these enhanced regulations, including the need for more robust clinical data and risk management processes.

Globally, regulatory bodies have increased scrutiny on polypropylene mesh products due to reported adverse events and complications associated with certain applications. This has led to the implementation of more rigorous post-market surveillance requirements and the establishment of registries to monitor long-term outcomes. Manufacturers are now expected to conduct thorough post-market studies and maintain vigilant reporting systems to detect and address any safety concerns promptly.

The regulatory framework also addresses the materials used in mesh production, with a focus on the quality and purity of polypropylene fibers. Standards such as ISO 13485 for quality management systems and ISO 10993 for biocompatibility testing are integral to the regulatory compliance process. Manufacturers must demonstrate that their lightweight mesh formations using polypropylene fibers meet these standards and do not pose unacceptable risks to patients.

As research continues to advance in the field of lightweight mesh formation, regulatory bodies are adapting their frameworks to accommodate new technologies and manufacturing processes. This includes considerations for novel fiber treatments, mesh designs, and integration of bioactive components. The evolving regulatory landscape aims to balance innovation with patient safety, ensuring that new developments in polypropylene mesh technology undergo rigorous evaluation before reaching the market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!