How Polypropylene Enhances Fast Turnaround in Manufacturing

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Evolution

Polypropylene, a versatile thermoplastic polymer, has undergone significant evolution since its discovery in the 1950s. Initially developed by Giulio Natta and Karl Ziegler, this material has transformed manufacturing processes across various industries. The journey of polypropylene's evolution is marked by continuous improvements in its properties, production techniques, and applications.

In the early stages, polypropylene was primarily used for simple molded products due to its limited mechanical properties. However, advancements in catalyst technology in the 1960s and 1970s led to the development of high-performance grades with enhanced strength, stiffness, and heat resistance. This breakthrough expanded polypropylene's use in more demanding applications, such as automotive parts and household appliances.

The 1980s and 1990s saw further refinements in polypropylene's molecular structure, resulting in the introduction of copolymers and impact-modified grades. These innovations significantly broadened the material's application range, enabling its use in flexible packaging, fibers, and durable consumer goods. Concurrently, improvements in processing technologies allowed for more efficient and precise manufacturing methods, including injection molding, extrusion, and blow molding.

The turn of the millennium brought about a focus on sustainability and environmental concerns. This shift led to the development of bio-based polypropylene and recycling technologies, addressing the growing demand for eco-friendly materials. Manufacturers began incorporating recycled polypropylene into their products, reducing waste and environmental impact while maintaining performance standards.

In recent years, nanotechnology has played a crucial role in polypropylene's evolution. The incorporation of nanoparticles and nanocomposites has resulted in polypropylene grades with exceptional mechanical, thermal, and barrier properties. These advanced materials have found applications in high-performance packaging, automotive components, and even medical devices.

The ongoing evolution of polypropylene continues to focus on enhancing its properties for specific applications. Research efforts are directed towards improving its heat resistance, chemical resistance, and long-term durability. Additionally, there is a growing emphasis on developing polypropylene grades that offer faster processing times and reduced energy consumption during manufacturing, directly contributing to faster turnaround in production cycles.

As industries increasingly prioritize efficiency and sustainability, polypropylene's evolution is likely to continue in directions that support these goals. Future developments may include smart polypropylene materials with self-healing properties, advanced recycling technologies for closed-loop manufacturing, and further improvements in bio-based alternatives. These advancements will undoubtedly shape the future of manufacturing, offering solutions that balance performance, cost-effectiveness, and environmental responsibility.

In the early stages, polypropylene was primarily used for simple molded products due to its limited mechanical properties. However, advancements in catalyst technology in the 1960s and 1970s led to the development of high-performance grades with enhanced strength, stiffness, and heat resistance. This breakthrough expanded polypropylene's use in more demanding applications, such as automotive parts and household appliances.

The 1980s and 1990s saw further refinements in polypropylene's molecular structure, resulting in the introduction of copolymers and impact-modified grades. These innovations significantly broadened the material's application range, enabling its use in flexible packaging, fibers, and durable consumer goods. Concurrently, improvements in processing technologies allowed for more efficient and precise manufacturing methods, including injection molding, extrusion, and blow molding.

The turn of the millennium brought about a focus on sustainability and environmental concerns. This shift led to the development of bio-based polypropylene and recycling technologies, addressing the growing demand for eco-friendly materials. Manufacturers began incorporating recycled polypropylene into their products, reducing waste and environmental impact while maintaining performance standards.

In recent years, nanotechnology has played a crucial role in polypropylene's evolution. The incorporation of nanoparticles and nanocomposites has resulted in polypropylene grades with exceptional mechanical, thermal, and barrier properties. These advanced materials have found applications in high-performance packaging, automotive components, and even medical devices.

The ongoing evolution of polypropylene continues to focus on enhancing its properties for specific applications. Research efforts are directed towards improving its heat resistance, chemical resistance, and long-term durability. Additionally, there is a growing emphasis on developing polypropylene grades that offer faster processing times and reduced energy consumption during manufacturing, directly contributing to faster turnaround in production cycles.

As industries increasingly prioritize efficiency and sustainability, polypropylene's evolution is likely to continue in directions that support these goals. Future developments may include smart polypropylene materials with self-healing properties, advanced recycling technologies for closed-loop manufacturing, and further improvements in bio-based alternatives. These advancements will undoubtedly shape the future of manufacturing, offering solutions that balance performance, cost-effectiveness, and environmental responsibility.

Market Demand Analysis

The market demand for polypropylene in manufacturing processes that require fast turnaround has been steadily increasing in recent years. This trend is driven by several factors, including the growing need for efficient production cycles, cost-effective materials, and sustainable manufacturing practices.

Polypropylene's unique properties make it an ideal material for fast-paced manufacturing environments. Its low density, high strength-to-weight ratio, and excellent chemical resistance contribute to its versatility across various industries. The automotive sector, in particular, has shown a significant uptick in demand for polypropylene components due to the material's ability to reduce vehicle weight and improve fuel efficiency.

In the packaging industry, the demand for polypropylene has surged as companies seek to streamline their production processes and reduce time-to-market for consumer goods. The material's compatibility with high-speed molding and forming techniques allows for rapid production of containers, bottles, and other packaging solutions.

The medical device and healthcare sectors have also contributed to the growing market demand for polypropylene in fast turnaround manufacturing. The material's biocompatibility and ease of sterilization make it suitable for producing disposable medical supplies and equipment, which often require quick production cycles to meet urgent healthcare needs.

The electronics industry has embraced polypropylene for its electrical insulation properties and ability to be molded into complex shapes quickly. This has led to increased demand in the production of consumer electronics and electrical components where fast turnaround times are critical to staying competitive in the market.

Market analysis indicates that the global polypropylene market is expected to continue its growth trajectory, with a particular emphasis on applications that benefit from rapid manufacturing processes. The material's recyclability aligns well with the increasing focus on circular economy principles, further driving its adoption in industries striving for sustainability.

As manufacturing technologies continue to evolve, the demand for materials that can keep pace with advanced production methods is likely to intensify. Polypropylene's adaptability to emerging manufacturing techniques, such as additive manufacturing and high-speed injection molding, positions it favorably in this evolving landscape.

The market trend suggests that manufacturers are increasingly seeking materials that not only enable fast production cycles but also offer long-term cost benefits. Polypropylene's durability and resistance to fatigue contribute to extended product lifecycles, reducing the need for frequent replacements and aligning with the market's demand for economical solutions.

Polypropylene's unique properties make it an ideal material for fast-paced manufacturing environments. Its low density, high strength-to-weight ratio, and excellent chemical resistance contribute to its versatility across various industries. The automotive sector, in particular, has shown a significant uptick in demand for polypropylene components due to the material's ability to reduce vehicle weight and improve fuel efficiency.

In the packaging industry, the demand for polypropylene has surged as companies seek to streamline their production processes and reduce time-to-market for consumer goods. The material's compatibility with high-speed molding and forming techniques allows for rapid production of containers, bottles, and other packaging solutions.

The medical device and healthcare sectors have also contributed to the growing market demand for polypropylene in fast turnaround manufacturing. The material's biocompatibility and ease of sterilization make it suitable for producing disposable medical supplies and equipment, which often require quick production cycles to meet urgent healthcare needs.

The electronics industry has embraced polypropylene for its electrical insulation properties and ability to be molded into complex shapes quickly. This has led to increased demand in the production of consumer electronics and electrical components where fast turnaround times are critical to staying competitive in the market.

Market analysis indicates that the global polypropylene market is expected to continue its growth trajectory, with a particular emphasis on applications that benefit from rapid manufacturing processes. The material's recyclability aligns well with the increasing focus on circular economy principles, further driving its adoption in industries striving for sustainability.

As manufacturing technologies continue to evolve, the demand for materials that can keep pace with advanced production methods is likely to intensify. Polypropylene's adaptability to emerging manufacturing techniques, such as additive manufacturing and high-speed injection molding, positions it favorably in this evolving landscape.

The market trend suggests that manufacturers are increasingly seeking materials that not only enable fast production cycles but also offer long-term cost benefits. Polypropylene's durability and resistance to fatigue contribute to extended product lifecycles, reducing the need for frequent replacements and aligning with the market's demand for economical solutions.

Current Challenges

Despite the numerous advantages of polypropylene in manufacturing, several challenges persist in fully leveraging its potential for fast turnaround. One of the primary obstacles is the material's inherent crystallinity, which can lead to warping and shrinkage during cooling. This issue is particularly pronounced in large or complex parts, where uneven cooling rates can result in dimensional inaccuracies and compromised structural integrity.

Another significant challenge lies in the optimization of processing parameters. While polypropylene offers a wide processing window, finding the ideal balance between temperature, pressure, and cooling rate to maximize production speed without sacrificing quality remains a complex task. This challenge is exacerbated by the variety of grades and additives available, each requiring specific processing conditions for optimal performance.

The surface properties of polypropylene present additional hurdles. Its low surface energy makes it difficult to bond, print, or coat without specialized surface treatments. This limitation can slow down post-processing steps, potentially negating some of the speed advantages gained in the initial manufacturing process.

Recycling and sustainability concerns also pose challenges to the widespread adoption of polypropylene in fast-turnaround manufacturing. While the material is recyclable, the presence of additives and the need for proper sorting can complicate recycling processes, potentially impacting the material's overall environmental footprint and circular economy potential.

Furthermore, the volatility of raw material prices and supply chain disruptions can affect the consistent availability of polypropylene, potentially leading to production delays or increased costs. This challenge is particularly relevant in industries that rely on just-in-time manufacturing principles.

Lastly, the development of new polypropylene grades with enhanced properties suitable for specific fast-turnaround applications requires significant research and development investment. Balancing improved performance characteristics with processability and cost-effectiveness remains an ongoing challenge for material scientists and manufacturers alike.

Addressing these challenges requires a multifaceted approach, involving advancements in material science, process engineering, and supply chain management. Overcoming these hurdles will be crucial in fully realizing the potential of polypropylene to enhance fast turnaround in manufacturing across various industries.

Another significant challenge lies in the optimization of processing parameters. While polypropylene offers a wide processing window, finding the ideal balance between temperature, pressure, and cooling rate to maximize production speed without sacrificing quality remains a complex task. This challenge is exacerbated by the variety of grades and additives available, each requiring specific processing conditions for optimal performance.

The surface properties of polypropylene present additional hurdles. Its low surface energy makes it difficult to bond, print, or coat without specialized surface treatments. This limitation can slow down post-processing steps, potentially negating some of the speed advantages gained in the initial manufacturing process.

Recycling and sustainability concerns also pose challenges to the widespread adoption of polypropylene in fast-turnaround manufacturing. While the material is recyclable, the presence of additives and the need for proper sorting can complicate recycling processes, potentially impacting the material's overall environmental footprint and circular economy potential.

Furthermore, the volatility of raw material prices and supply chain disruptions can affect the consistent availability of polypropylene, potentially leading to production delays or increased costs. This challenge is particularly relevant in industries that rely on just-in-time manufacturing principles.

Lastly, the development of new polypropylene grades with enhanced properties suitable for specific fast-turnaround applications requires significant research and development investment. Balancing improved performance characteristics with processability and cost-effectiveness remains an ongoing challenge for material scientists and manufacturers alike.

Addressing these challenges requires a multifaceted approach, involving advancements in material science, process engineering, and supply chain management. Overcoming these hurdles will be crucial in fully realizing the potential of polypropylene to enhance fast turnaround in manufacturing across various industries.

Rapid Turnaround Tech

01 Scheduling and optimization of turnaround processes

Efficient scheduling and optimization of turnaround processes for polypropylene production facilities. This involves using advanced algorithms and software systems to minimize downtime, improve resource allocation, and enhance overall productivity during maintenance and upgrade periods.- Scheduling and optimization of turnaround processes: Implementing advanced scheduling and optimization techniques to improve the efficiency of polypropylene plant turnarounds. This includes using algorithms and software tools to optimize resource allocation, minimize downtime, and streamline maintenance activities.

- Real-time monitoring and data analysis: Utilizing real-time monitoring systems and data analysis techniques to track the progress of turnaround activities, identify potential bottlenecks, and make informed decisions to reduce turnaround time. This may involve the use of sensors, IoT devices, and advanced analytics platforms.

- Automated material handling and logistics: Implementing automated material handling systems and logistics solutions to streamline the movement of equipment, parts, and materials during polypropylene plant turnarounds. This can include the use of robotics, automated guided vehicles, and intelligent inventory management systems.

- Predictive maintenance and condition monitoring: Employing predictive maintenance techniques and condition monitoring systems to identify potential equipment failures before they occur, allowing for more efficient planning and execution of turnaround activities. This may involve the use of machine learning algorithms and advanced sensor technologies.

- Digital twin technology for turnaround planning: Utilizing digital twin technology to create virtual representations of polypropylene plants and simulate turnaround scenarios. This allows for better planning, risk assessment, and optimization of turnaround processes before actual implementation.

02 Automated material handling systems

Implementation of automated material handling systems in polypropylene production to reduce turnaround time. This includes the use of robotic systems, conveyor belts, and smart storage solutions to streamline the movement of raw materials, intermediate products, and finished goods throughout the production process.Expand Specific Solutions03 Real-time monitoring and predictive maintenance

Utilization of sensors, IoT devices, and data analytics for real-time monitoring of polypropylene production equipment. This enables predictive maintenance, early detection of potential issues, and proactive scheduling of maintenance activities to minimize unexpected downtime and reduce overall turnaround time.Expand Specific Solutions04 Modular equipment design for quick replacement

Development of modular equipment designs for polypropylene production facilities. This approach allows for faster replacement of components during maintenance or upgrades, reducing the time required for disassembly, repair, and reassembly, thereby shortening overall turnaround time.Expand Specific Solutions05 Advanced process control and optimization

Implementation of advanced process control systems and optimization techniques in polypropylene production. These systems use machine learning algorithms and real-time data analysis to continuously adjust process parameters, improving efficiency and reducing the frequency and duration of turnarounds required for quality control or process adjustments.Expand Specific Solutions

Key Industry Players

The polypropylene manufacturing industry is in a mature stage, characterized by established players and steady market growth. The global market size for polypropylene is substantial, driven by its versatile applications across various sectors. Technologically, the industry is advancing, with companies like LG Chem, Total Petrochemicals, and ExxonMobil Chemical Patents leading innovations in fast turnaround manufacturing processes. These advancements are focused on improving production efficiency and reducing cycle times. Companies such as Borealis AG and Japan Polypropylene Corp. are also contributing to technological maturity through research and development efforts, enhancing the overall competitiveness of the industry.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced polypropylene (PP) grades that significantly enhance fast turnaround in manufacturing. Their high-flow PP resins, such as the H1500 series, offer improved processability and faster cycle times[1]. These materials feature a melt flow rate (MFR) of over 100 g/10 min, allowing for quicker mold filling and shorter cooling times. LG Chem's PP compounds also incorporate nucleating agents and clarifiers, which accelerate crystallization and reduce overall production time[2]. The company has implemented in-situ polymerization techniques to create PP with tailored molecular structures, optimizing both processing speed and end-product properties[3].

Strengths: High-flow resins for faster processing, advanced nucleation technology for quicker crystallization, and customized molecular structures. Weaknesses: Potential trade-offs between speed and mechanical properties, higher cost compared to standard PP grades.

Borealis AG

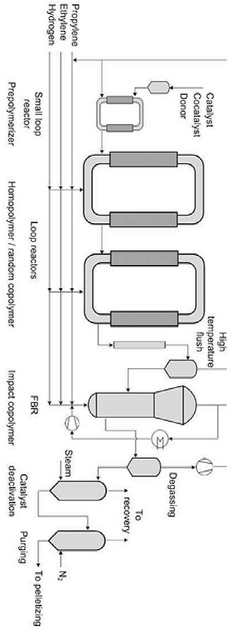

Technical Solution: Borealis AG has pioneered the development of Borstar® technology, a proprietary platform for producing advanced polypropylene that enhances fast turnaround in manufacturing. This technology enables the production of bimodal PP with a precisely controlled molecular weight distribution, resulting in materials with excellent processability and reduced cycle times[1]. Borealis' PP grades, such as the BorPure™ series, offer high melt flow rates (up to 100 g/10 min) while maintaining good mechanical properties[2]. The company has also introduced nucleated PP grades that crystallize more rapidly, further reducing cooling times in injection molding processes. Additionally, Borealis has developed PP random copolymers with enhanced clarity and low-temperature impact resistance, allowing for faster production of transparent and durable products[3].

Strengths: Proprietary Borstar® technology for optimized PP properties, high melt flow rates for faster processing, and advanced nucleation for quicker crystallization. Weaknesses: Higher material costs, potential limitations in extreme high-temperature applications.

Innovative PP Solutions

Method for preparing polypropylene improved productivity

PatentActiveKR1020230069386A

Innovation

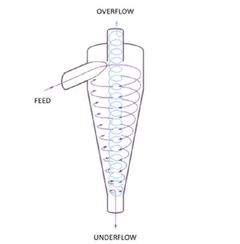

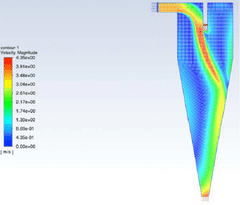

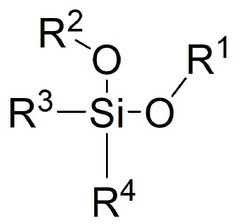

- Control the average particle size and particle size distribution of polypropylene resin particles during polymerization by adjusting the type and ratio of solid complex titanium catalyst, organoaluminum cocatalyst, external electron donor, and reaction conditions to minimize the flow of particles to the cyclone overhead, using a silane-based electron donor like cyclohexylmethyldimethoxysilane and optimizing reaction parameters such as time, temperature, and pressure.

Polypropylene suitable for producing BOPP films and method for the production thereof

PatentWO2024172702A1

Innovation

- Polypropylene is synthesized using a multi-stage process in a hydrocarbon solvent with specific molecular weight distribution, melt flow index, and crystalline fraction characteristics, resulting in a bimodal polymer with reduced xylene-soluble fractions, enabling high-speed processing and improved film quality.

Supply Chain Dynamics

The integration of polypropylene in manufacturing processes has significantly impacted supply chain dynamics, particularly in industries requiring fast turnaround times. This versatile material has revolutionized production methods, leading to more efficient and responsive supply chains across various sectors.

Polypropylene's lightweight nature and durability have streamlined transportation and logistics within supply chains. Its reduced weight compared to traditional materials allows for increased payload capacity during shipping, resulting in fewer trips and lower transportation costs. This efficiency extends to inventory management, as polypropylene products require less storage space and are less prone to damage during handling and storage.

The material's adaptability to various manufacturing techniques, such as injection molding and thermoforming, has enabled rapid production cycles. This flexibility allows manufacturers to quickly adjust production volumes and product specifications in response to changing market demands. As a result, companies can maintain leaner inventories and reduce lead times, enhancing overall supply chain agility.

Polypropylene's resistance to chemicals and moisture has improved product shelf life and reduced the need for protective packaging. This characteristic has simplified storage and distribution processes, minimizing the risk of product degradation throughout the supply chain. Consequently, businesses can extend their distribution networks and explore new markets without compromising product quality.

The recyclability of polypropylene has also contributed to more sustainable supply chains. Its ability to be reprocessed multiple times without significant loss of properties has encouraged the development of closed-loop supply chains. This circular approach reduces waste, lowers raw material costs, and aligns with growing consumer demand for environmentally friendly products.

In the automotive industry, polypropylene's use in lightweight components has led to fuel efficiency improvements and reduced emissions during transportation. This not only benefits the environment but also contributes to cost savings across the supply chain. Similarly, in the packaging industry, polypropylene's versatility has enabled the creation of innovative, space-efficient designs that optimize logistics and reduce transportation costs.

The material's compatibility with advanced manufacturing technologies, such as 3D printing, has further enhanced supply chain flexibility. On-demand production of polypropylene parts has reduced the need for extensive spare parts inventories and enabled localized manufacturing, shortening supply chains and improving response times to market demands.

Polypropylene's lightweight nature and durability have streamlined transportation and logistics within supply chains. Its reduced weight compared to traditional materials allows for increased payload capacity during shipping, resulting in fewer trips and lower transportation costs. This efficiency extends to inventory management, as polypropylene products require less storage space and are less prone to damage during handling and storage.

The material's adaptability to various manufacturing techniques, such as injection molding and thermoforming, has enabled rapid production cycles. This flexibility allows manufacturers to quickly adjust production volumes and product specifications in response to changing market demands. As a result, companies can maintain leaner inventories and reduce lead times, enhancing overall supply chain agility.

Polypropylene's resistance to chemicals and moisture has improved product shelf life and reduced the need for protective packaging. This characteristic has simplified storage and distribution processes, minimizing the risk of product degradation throughout the supply chain. Consequently, businesses can extend their distribution networks and explore new markets without compromising product quality.

The recyclability of polypropylene has also contributed to more sustainable supply chains. Its ability to be reprocessed multiple times without significant loss of properties has encouraged the development of closed-loop supply chains. This circular approach reduces waste, lowers raw material costs, and aligns with growing consumer demand for environmentally friendly products.

In the automotive industry, polypropylene's use in lightweight components has led to fuel efficiency improvements and reduced emissions during transportation. This not only benefits the environment but also contributes to cost savings across the supply chain. Similarly, in the packaging industry, polypropylene's versatility has enabled the creation of innovative, space-efficient designs that optimize logistics and reduce transportation costs.

The material's compatibility with advanced manufacturing technologies, such as 3D printing, has further enhanced supply chain flexibility. On-demand production of polypropylene parts has reduced the need for extensive spare parts inventories and enabled localized manufacturing, shortening supply chains and improving response times to market demands.

Sustainability Impact

The adoption of polypropylene in manufacturing processes has significant implications for sustainability. As a lightweight and durable material, polypropylene contributes to reduced energy consumption during production and transportation, leading to a lower carbon footprint. Its recyclability further enhances its environmental credentials, allowing for multiple use cycles and reducing waste.

Polypropylene's resistance to chemicals and moisture makes it an ideal choice for reusable packaging solutions, potentially replacing single-use plastics in various industries. This shift towards more sustainable packaging options aligns with global efforts to reduce plastic pollution and promote circular economy principles.

In the context of fast turnaround manufacturing, polypropylene's sustainability impact is particularly noteworthy. The material's ability to be rapidly molded and processed reduces energy consumption during production, contributing to more efficient resource utilization. Additionally, its low melting point compared to other plastics means less energy is required for processing, further reducing the environmental impact of manufacturing operations.

The durability of polypropylene products extends their lifespan, reducing the need for frequent replacements and consequently lowering resource consumption and waste generation. This longevity is especially valuable in industries where product reliability and extended use are critical, such as automotive and consumer goods manufacturing.

Furthermore, polypropylene's compatibility with advanced recycling technologies, such as chemical recycling, opens up new possibilities for end-of-life management. These innovative recycling methods can break down polypropylene into its base components, allowing for the creation of new, high-quality products without compromising material integrity.

The use of polypropylene in fast turnaround manufacturing also supports the development of more sustainable supply chains. Its lightweight nature reduces transportation-related emissions, while its versatility allows for the consolidation of materials in product design, potentially simplifying recycling processes and reducing overall material consumption.

As industries increasingly prioritize sustainability, the role of polypropylene in enhancing fast turnaround manufacturing aligns well with broader environmental goals. Its contribution to energy efficiency, waste reduction, and circular economy practices positions it as a material of choice for companies seeking to improve their sustainability performance while maintaining operational efficiency.

Polypropylene's resistance to chemicals and moisture makes it an ideal choice for reusable packaging solutions, potentially replacing single-use plastics in various industries. This shift towards more sustainable packaging options aligns with global efforts to reduce plastic pollution and promote circular economy principles.

In the context of fast turnaround manufacturing, polypropylene's sustainability impact is particularly noteworthy. The material's ability to be rapidly molded and processed reduces energy consumption during production, contributing to more efficient resource utilization. Additionally, its low melting point compared to other plastics means less energy is required for processing, further reducing the environmental impact of manufacturing operations.

The durability of polypropylene products extends their lifespan, reducing the need for frequent replacements and consequently lowering resource consumption and waste generation. This longevity is especially valuable in industries where product reliability and extended use are critical, such as automotive and consumer goods manufacturing.

Furthermore, polypropylene's compatibility with advanced recycling technologies, such as chemical recycling, opens up new possibilities for end-of-life management. These innovative recycling methods can break down polypropylene into its base components, allowing for the creation of new, high-quality products without compromising material integrity.

The use of polypropylene in fast turnaround manufacturing also supports the development of more sustainable supply chains. Its lightweight nature reduces transportation-related emissions, while its versatility allows for the consolidation of materials in product design, potentially simplifying recycling processes and reducing overall material consumption.

As industries increasingly prioritize sustainability, the role of polypropylene in enhancing fast turnaround manufacturing aligns well with broader environmental goals. Its contribution to energy efficiency, waste reduction, and circular economy practices positions it as a material of choice for companies seeking to improve their sustainability performance while maintaining operational efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!