Investigating Conductive Polypropylene for Electronic Packaging

JUL 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive PP Evolution

The evolution of conductive polypropylene (PP) for electronic packaging has been marked by significant advancements in material science and manufacturing techniques. Initially, polypropylene was primarily used in its non-conductive form for various packaging applications due to its excellent mechanical properties and chemical resistance. However, the growing demand for lightweight, cost-effective, and electrically conductive materials in the electronics industry has driven the development of conductive PP composites.

In the early stages of conductive PP evolution, researchers focused on incorporating conductive fillers such as carbon black, carbon fibers, and metallic particles into the PP matrix. These early attempts yielded materials with limited conductivity and often compromised the mechanical properties of the base polymer. The challenge was to achieve a balance between electrical conductivity and the inherent characteristics of PP that made it desirable for packaging applications.

A significant breakthrough came with the introduction of nanotechnology in the late 1990s and early 2000s. The use of carbon nanotubes (CNTs) and graphene as conductive fillers revolutionized the field of conductive polymers. These nanomaterials offered exceptional electrical properties while requiring lower filler loadings, thus preserving the mechanical integrity of the PP matrix. This period saw a surge in research activities focused on optimizing the dispersion of nanofillers and enhancing the interfacial interactions between the fillers and the polymer matrix.

The mid-2000s witnessed the emergence of hybrid filler systems, combining different types of conductive additives to achieve synergistic effects. For instance, the combination of carbon nanotubes with traditional conductive fillers like carbon black resulted in improved conductivity at lower overall filler loadings. This approach addressed some of the processing challenges associated with high filler concentrations and opened up new possibilities for tailoring the electrical and mechanical properties of conductive PP composites.

Recent years have seen a shift towards more sustainable and environmentally friendly approaches in conductive PP development. Researchers have explored bio-based conductive fillers and environmentally benign processing techniques to reduce the carbon footprint of these materials. Additionally, there has been a growing interest in developing conductive PP composites with multifunctional properties, such as electromagnetic interference (EMI) shielding and electrostatic discharge (ESD) protection, to meet the evolving needs of the electronics industry.

The latest frontier in conductive PP evolution involves the integration of smart functionalities. This includes the development of self-healing conductive PP composites and materials with tunable electrical properties in response to external stimuli. These advancements are paving the way for next-generation electronic packaging solutions that can adapt to changing environmental conditions and self-repair minor damages, thereby enhancing the reliability and longevity of electronic devices.

In the early stages of conductive PP evolution, researchers focused on incorporating conductive fillers such as carbon black, carbon fibers, and metallic particles into the PP matrix. These early attempts yielded materials with limited conductivity and often compromised the mechanical properties of the base polymer. The challenge was to achieve a balance between electrical conductivity and the inherent characteristics of PP that made it desirable for packaging applications.

A significant breakthrough came with the introduction of nanotechnology in the late 1990s and early 2000s. The use of carbon nanotubes (CNTs) and graphene as conductive fillers revolutionized the field of conductive polymers. These nanomaterials offered exceptional electrical properties while requiring lower filler loadings, thus preserving the mechanical integrity of the PP matrix. This period saw a surge in research activities focused on optimizing the dispersion of nanofillers and enhancing the interfacial interactions between the fillers and the polymer matrix.

The mid-2000s witnessed the emergence of hybrid filler systems, combining different types of conductive additives to achieve synergistic effects. For instance, the combination of carbon nanotubes with traditional conductive fillers like carbon black resulted in improved conductivity at lower overall filler loadings. This approach addressed some of the processing challenges associated with high filler concentrations and opened up new possibilities for tailoring the electrical and mechanical properties of conductive PP composites.

Recent years have seen a shift towards more sustainable and environmentally friendly approaches in conductive PP development. Researchers have explored bio-based conductive fillers and environmentally benign processing techniques to reduce the carbon footprint of these materials. Additionally, there has been a growing interest in developing conductive PP composites with multifunctional properties, such as electromagnetic interference (EMI) shielding and electrostatic discharge (ESD) protection, to meet the evolving needs of the electronics industry.

The latest frontier in conductive PP evolution involves the integration of smart functionalities. This includes the development of self-healing conductive PP composites and materials with tunable electrical properties in response to external stimuli. These advancements are paving the way for next-generation electronic packaging solutions that can adapt to changing environmental conditions and self-repair minor damages, thereby enhancing the reliability and longevity of electronic devices.

E-Packaging Market Trends

The electronic packaging market has been experiencing significant growth and transformation in recent years, driven by the increasing demand for smaller, lighter, and more efficient electronic devices. This trend is particularly evident in industries such as consumer electronics, automotive, aerospace, and healthcare. The global e-packaging market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years.

One of the key factors fueling this growth is the rapid advancement of technologies such as 5G, Internet of Things (IoT), artificial intelligence (AI), and edge computing. These technologies require more sophisticated and high-performance electronic packaging solutions to support their complex functionalities and increased data processing capabilities. As a result, there is a growing demand for advanced packaging materials and techniques that can provide better thermal management, electrical performance, and reliability.

The miniaturization trend in electronics has also been a significant driver for the e-packaging market. As devices become smaller and more compact, there is a need for packaging solutions that can accommodate higher component densities while maintaining or improving performance. This has led to the development of innovative packaging technologies such as 3D packaging, system-in-package (SiP), and wafer-level packaging (WLP).

Sustainability has emerged as a crucial consideration in the e-packaging market. With increasing environmental concerns and stricter regulations, there is a growing emphasis on developing eco-friendly packaging materials and processes. This includes the use of recyclable and biodegradable materials, as well as the implementation of more energy-efficient manufacturing techniques.

The automotive industry has become a significant driver of growth in the e-packaging market. The increasing adoption of electric vehicles (EVs) and advanced driver assistance systems (ADAS) has created a demand for specialized packaging solutions that can withstand harsh environments and ensure long-term reliability. This has led to the development of robust packaging materials and designs that can handle high temperatures, vibrations, and electromagnetic interference.

In terms of regional trends, Asia-Pacific continues to dominate the e-packaging market, with countries like China, Japan, South Korea, and Taiwan leading in both production and consumption. However, other regions such as North America and Europe are also experiencing growth, particularly in high-value segments such as advanced packaging for AI and 5G applications.

The investigation of conductive polypropylene for electronic packaging aligns well with these market trends. As a lightweight, cost-effective, and potentially recyclable material, conductive polypropylene could address several key market demands, including miniaturization, improved thermal management, and sustainability. Its potential applications in various industries, particularly automotive and consumer electronics, make it an attractive area for research and development in the evolving e-packaging landscape.

One of the key factors fueling this growth is the rapid advancement of technologies such as 5G, Internet of Things (IoT), artificial intelligence (AI), and edge computing. These technologies require more sophisticated and high-performance electronic packaging solutions to support their complex functionalities and increased data processing capabilities. As a result, there is a growing demand for advanced packaging materials and techniques that can provide better thermal management, electrical performance, and reliability.

The miniaturization trend in electronics has also been a significant driver for the e-packaging market. As devices become smaller and more compact, there is a need for packaging solutions that can accommodate higher component densities while maintaining or improving performance. This has led to the development of innovative packaging technologies such as 3D packaging, system-in-package (SiP), and wafer-level packaging (WLP).

Sustainability has emerged as a crucial consideration in the e-packaging market. With increasing environmental concerns and stricter regulations, there is a growing emphasis on developing eco-friendly packaging materials and processes. This includes the use of recyclable and biodegradable materials, as well as the implementation of more energy-efficient manufacturing techniques.

The automotive industry has become a significant driver of growth in the e-packaging market. The increasing adoption of electric vehicles (EVs) and advanced driver assistance systems (ADAS) has created a demand for specialized packaging solutions that can withstand harsh environments and ensure long-term reliability. This has led to the development of robust packaging materials and designs that can handle high temperatures, vibrations, and electromagnetic interference.

In terms of regional trends, Asia-Pacific continues to dominate the e-packaging market, with countries like China, Japan, South Korea, and Taiwan leading in both production and consumption. However, other regions such as North America and Europe are also experiencing growth, particularly in high-value segments such as advanced packaging for AI and 5G applications.

The investigation of conductive polypropylene for electronic packaging aligns well with these market trends. As a lightweight, cost-effective, and potentially recyclable material, conductive polypropylene could address several key market demands, including miniaturization, improved thermal management, and sustainability. Its potential applications in various industries, particularly automotive and consumer electronics, make it an attractive area for research and development in the evolving e-packaging landscape.

Conductive PP Challenges

The development of conductive polypropylene (PP) for electronic packaging faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is achieving consistent and uniform conductivity throughout the material. Polypropylene, being inherently an insulator, requires the incorporation of conductive fillers or additives to impart electrical conductivity. However, ensuring a homogeneous distribution of these conductive elements within the polymer matrix remains a complex task, often resulting in inconsistent electrical properties across the material.

Another major challenge lies in maintaining the desirable mechanical properties of polypropylene while enhancing its conductivity. The addition of conductive fillers often leads to a trade-off between electrical performance and mechanical strength. As the concentration of conductive additives increases to improve conductivity, it can simultaneously compromise the material's flexibility, impact resistance, and overall durability. Striking the right balance between conductivity and mechanical integrity is crucial for electronic packaging applications, where both electrical performance and physical protection are essential.

The thermal management of conductive polypropylene presents another significant hurdle. Electronic components generate heat during operation, and the packaging material must efficiently dissipate this heat to prevent overheating and potential failure. While the addition of conductive fillers can improve thermal conductivity to some extent, achieving the level of heat dissipation required for high-performance electronic applications remains challenging. This limitation can restrict the use of conductive PP in scenarios involving high-power or thermally demanding electronic components.

Furthermore, the long-term stability and reliability of conductive polypropylene in electronic packaging applications pose ongoing concerns. Environmental factors such as temperature fluctuations, humidity, and exposure to various chemicals can potentially degrade the material's conductive properties over time. Ensuring that the conductivity remains stable throughout the product's lifecycle is critical for maintaining consistent performance and reliability in electronic devices.

The manufacturing process for conductive polypropylene also presents challenges in terms of scalability and cost-effectiveness. Achieving uniform dispersion of conductive additives in large-scale production while maintaining quality control can be technically demanding and economically challenging. Additionally, the cost of conductive fillers and the complexity of the manufacturing process can significantly increase the overall production costs, potentially limiting the economic viability of conductive PP in certain electronic packaging applications.

Lastly, the environmental impact and recyclability of conductive polypropylene remain areas of concern. As the electronics industry increasingly focuses on sustainability, developing conductive PP formulations that are both environmentally friendly and easily recyclable without compromising performance becomes crucial. This challenge involves finding alternative, eco-friendly conductive additives and developing recycling processes that can effectively separate and recover the conductive components from the polymer matrix.

Another major challenge lies in maintaining the desirable mechanical properties of polypropylene while enhancing its conductivity. The addition of conductive fillers often leads to a trade-off between electrical performance and mechanical strength. As the concentration of conductive additives increases to improve conductivity, it can simultaneously compromise the material's flexibility, impact resistance, and overall durability. Striking the right balance between conductivity and mechanical integrity is crucial for electronic packaging applications, where both electrical performance and physical protection are essential.

The thermal management of conductive polypropylene presents another significant hurdle. Electronic components generate heat during operation, and the packaging material must efficiently dissipate this heat to prevent overheating and potential failure. While the addition of conductive fillers can improve thermal conductivity to some extent, achieving the level of heat dissipation required for high-performance electronic applications remains challenging. This limitation can restrict the use of conductive PP in scenarios involving high-power or thermally demanding electronic components.

Furthermore, the long-term stability and reliability of conductive polypropylene in electronic packaging applications pose ongoing concerns. Environmental factors such as temperature fluctuations, humidity, and exposure to various chemicals can potentially degrade the material's conductive properties over time. Ensuring that the conductivity remains stable throughout the product's lifecycle is critical for maintaining consistent performance and reliability in electronic devices.

The manufacturing process for conductive polypropylene also presents challenges in terms of scalability and cost-effectiveness. Achieving uniform dispersion of conductive additives in large-scale production while maintaining quality control can be technically demanding and economically challenging. Additionally, the cost of conductive fillers and the complexity of the manufacturing process can significantly increase the overall production costs, potentially limiting the economic viability of conductive PP in certain electronic packaging applications.

Lastly, the environmental impact and recyclability of conductive polypropylene remain areas of concern. As the electronics industry increasingly focuses on sustainability, developing conductive PP formulations that are both environmentally friendly and easily recyclable without compromising performance becomes crucial. This challenge involves finding alternative, eco-friendly conductive additives and developing recycling processes that can effectively separate and recover the conductive components from the polymer matrix.

Current Conductive PP

01 Conductive fillers for polypropylene

Various conductive fillers can be incorporated into polypropylene to enhance its conductivity. These fillers include carbon-based materials, metal particles, and conductive polymers. The type and concentration of the filler significantly affect the final conductivity of the composite.- Conductive fillers for polypropylene: Various conductive fillers can be incorporated into polypropylene to enhance its conductivity. These fillers may include carbon-based materials, metal particles, or conductive polymers. The type and concentration of the filler can be adjusted to achieve the desired level of conductivity while maintaining other properties of the polypropylene matrix.

- Surface modification of polypropylene: Surface modification techniques can be applied to polypropylene to improve its conductivity. These methods may involve chemical treatments, plasma treatments, or grafting of conductive molecules onto the polymer surface. Such modifications can enhance the interaction between the polymer and conductive additives, leading to improved overall conductivity.

- Blending with conductive polymers: Polypropylene can be blended with inherently conductive polymers to create conductive composites. This approach allows for the combination of the desirable properties of polypropylene with the conductivity of specialized polymers. The ratio of the blend components can be adjusted to achieve the required conductivity while maintaining processability and mechanical properties.

- Nanocomposite formulations: Incorporating conductive nanoparticles or nanostructures into polypropylene can significantly enhance its conductivity. These nanocomposites may utilize materials such as carbon nanotubes, graphene, or metal nanowires. The high aspect ratio and unique properties of nanomaterials can create conductive networks within the polymer matrix at relatively low loading levels.

- Processing techniques for conductivity enhancement: Specific processing techniques can be employed to optimize the conductivity of polypropylene composites. These may include methods to improve filler dispersion, orientation of conductive particles, or creation of segregated network structures. Advanced processing approaches can lead to enhanced conductivity at lower filler loadings, preserving other important properties of the polymer.

02 Surface modification of polypropylene

Surface modification techniques can be applied to polypropylene to improve its conductivity. These methods include plasma treatment, chemical grafting, and coating with conductive materials. Surface modification can enhance the compatibility between the polymer and conductive additives.Expand Specific Solutions03 Blending with conductive polymers

Blending polypropylene with inherently conductive polymers can significantly increase its conductivity. Common conductive polymers used for this purpose include polyaniline, polypyrrole, and polythiophene. The ratio of the blend and processing conditions are crucial factors in determining the final conductivity.Expand Specific Solutions04 Nanocomposite formulations

Incorporating conductive nanoparticles or nanostructures into polypropylene can enhance its conductivity while maintaining other desirable properties. Nanomaterials such as carbon nanotubes, graphene, and metal nanowires are commonly used. The dispersion and orientation of these nanofillers play a crucial role in the conductivity of the final composite.Expand Specific Solutions05 Processing techniques for conductivity enhancement

Various processing techniques can be employed to improve the conductivity of polypropylene composites. These include melt mixing, in-situ polymerization, and solution blending. The choice of processing method affects the dispersion of conductive additives and the overall conductivity of the material.Expand Specific Solutions

E-Packaging Key Players

The conductive polypropylene market for electronic packaging is in a growth phase, driven by increasing demand for lightweight, cost-effective, and sustainable packaging solutions in the electronics industry. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is advancing rapidly, with companies like Kingfa Sci. & Tech., DuPont, and Eastman Chemical leading innovation. These firms are developing enhanced formulations to improve conductivity, thermal management, and processability of conductive polypropylene. Emerging players such as GLOBALFOUNDRIES and Hefei Genius Advanced Material are also contributing to technological advancements, focusing on specialized applications and novel manufacturing techniques.

Kingfa Sci. & Tech. Co., Ltd.

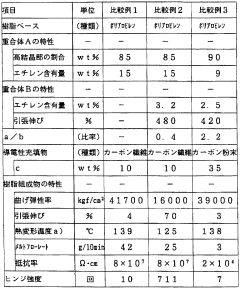

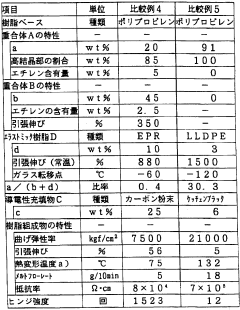

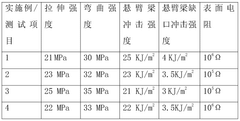

Technical Solution: Kingfa has focused on developing conductive polypropylene compounds using a combination of carbon-based fillers and innovative processing techniques. Their approach involves the use of specially modified carbon nanotubes (CNTs) and graphene nanoplatelets, which are incorporated into the polypropylene matrix using a proprietary extrusion process. This process ensures uniform dispersion of the conductive fillers and creates a three-dimensional conductive network within the polymer. Kingfa's conductive polypropylene materials have achieved volume resistivities in the range of 10^2 to 10^6 ohm-cm, depending on the filler content and type[7]. The company has also developed a range of grades with varying levels of antistatic and EMI shielding properties, catering to different electronic packaging applications[8].

Strengths: Wide range of conductivity options, good EMI shielding properties, uniform filler dispersion. Weaknesses: Potential for increased brittleness at higher filler loadings, may require specialized processing equipment.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a range of conductive polypropylene compounds for electronic packaging applications. Their technology involves incorporating conductive fillers such as carbon black, carbon nanotubes, or metallic particles into the polypropylene matrix. The company has optimized the dispersion and distribution of these fillers to achieve a balance between conductivity and mechanical properties. DuPont's conductive polypropylene materials offer tailored resistivity levels ranging from 10^2 to 10^10 ohm-cm, allowing for customization based on specific application requirements[1]. The company has also implemented surface modification techniques to enhance the adhesion between the conductive fillers and the polypropylene matrix, resulting in improved long-term stability and performance[2].

Strengths: Wide range of conductivity options, customizable for various applications, improved long-term stability. Weaknesses: Potential for increased cost due to specialized fillers, possible impact on mechanical properties at higher filler loadings.

Conductive PP Patents

Conductive propylene resin composition and parts container

PatentWO1997043338A1

Innovation

- A conductive polypropylene resin composition with specific physical properties, including a high flexural modulus, tensile elongation, and heat distortion temperature, combined with a conductive filler, to ensure rigidity, hinge strength, and heat resistance, allowing for reusable and recyclable electronic component storage containers.

Conductive polypropylene composite and preparation method therefor

PatentWO2019100746A1

Innovation

- A composite material made of polypropylene resin, superconducting carbon black, alumina, graphite powder, heat stabilizer, antioxidant and compatibilizer is synthesized by copolymerization and prepared by twin-screw extrusion process to ensure the conductivity and resistance of the material. Electrostatic properties.

Environmental Impact

The environmental impact of conductive polypropylene in electronic packaging is a critical consideration as the industry moves towards more sustainable practices. Conductive polypropylene offers several environmental advantages over traditional materials used in electronic packaging, such as metals and other plastics.

One of the primary benefits of conductive polypropylene is its recyclability. Unlike many composite materials used in electronics, polypropylene can be easily recycled and reprocessed without significant loss of properties. This characteristic aligns with the growing emphasis on circular economy principles in the electronics industry, potentially reducing the overall environmental footprint of electronic devices.

The production of conductive polypropylene also generally requires less energy compared to the manufacturing of metal-based packaging materials. This lower energy demand translates to reduced carbon emissions during the production phase, contributing to a smaller carbon footprint for electronic products that utilize this material.

Furthermore, conductive polypropylene is lightweight compared to metal alternatives, which can lead to reduced fuel consumption and emissions during transportation of both raw materials and finished products. This weight reduction can have a cascading positive effect throughout the supply chain and product lifecycle.

However, the environmental impact of conductive polypropylene is not without challenges. The addition of conductive fillers to achieve the desired electrical properties may complicate the recycling process and potentially introduce new environmental concerns. The type and amount of conductive additives used can affect the material's overall recyclability and biodegradability.

Another consideration is the potential for microplastic pollution. As with all plastic materials, there is a risk of conductive polypropylene breaking down into microplastics if not properly disposed of or recycled. This issue requires careful management and consideration of end-of-life scenarios for electronic products using this material.

The durability and longevity of conductive polypropylene in electronic packaging applications also play a role in its environmental impact. If the material can extend the lifespan of electronic devices by providing better protection against environmental factors, it could indirectly contribute to reducing electronic waste.

In conclusion, while conductive polypropylene presents several environmental benefits in electronic packaging, particularly in terms of recyclability and energy efficiency, its overall environmental impact depends on various factors including production methods, additive composition, and end-of-life management. As the technology evolves, ongoing research and life cycle assessments will be crucial to fully understand and optimize the environmental performance of conductive polypropylene in electronic packaging applications.

One of the primary benefits of conductive polypropylene is its recyclability. Unlike many composite materials used in electronics, polypropylene can be easily recycled and reprocessed without significant loss of properties. This characteristic aligns with the growing emphasis on circular economy principles in the electronics industry, potentially reducing the overall environmental footprint of electronic devices.

The production of conductive polypropylene also generally requires less energy compared to the manufacturing of metal-based packaging materials. This lower energy demand translates to reduced carbon emissions during the production phase, contributing to a smaller carbon footprint for electronic products that utilize this material.

Furthermore, conductive polypropylene is lightweight compared to metal alternatives, which can lead to reduced fuel consumption and emissions during transportation of both raw materials and finished products. This weight reduction can have a cascading positive effect throughout the supply chain and product lifecycle.

However, the environmental impact of conductive polypropylene is not without challenges. The addition of conductive fillers to achieve the desired electrical properties may complicate the recycling process and potentially introduce new environmental concerns. The type and amount of conductive additives used can affect the material's overall recyclability and biodegradability.

Another consideration is the potential for microplastic pollution. As with all plastic materials, there is a risk of conductive polypropylene breaking down into microplastics if not properly disposed of or recycled. This issue requires careful management and consideration of end-of-life scenarios for electronic products using this material.

The durability and longevity of conductive polypropylene in electronic packaging applications also play a role in its environmental impact. If the material can extend the lifespan of electronic devices by providing better protection against environmental factors, it could indirectly contribute to reducing electronic waste.

In conclusion, while conductive polypropylene presents several environmental benefits in electronic packaging, particularly in terms of recyclability and energy efficiency, its overall environmental impact depends on various factors including production methods, additive composition, and end-of-life management. As the technology evolves, ongoing research and life cycle assessments will be crucial to fully understand and optimize the environmental performance of conductive polypropylene in electronic packaging applications.

Regulatory Compliance

Regulatory compliance is a critical aspect of developing and implementing conductive polypropylene for electronic packaging. As this innovative material gains traction in the industry, manufacturers and end-users must navigate a complex landscape of regulations and standards to ensure product safety, environmental protection, and market acceptance.

In the United States, the primary regulatory body overseeing electronic packaging materials is the Food and Drug Administration (FDA). The FDA's regulations focus on the safety of materials that come into contact with food or pharmaceuticals. For conductive polypropylene used in electronic packaging, compliance with FDA regulations is essential, particularly for applications in the food and medical industries. Manufacturers must demonstrate that their conductive polypropylene formulations do not leach harmful substances and meet the requirements outlined in 21 CFR 177.1520 for olefin polymers.

The European Union's regulatory framework is equally stringent, with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation playing a central role. REACH requires manufacturers and importers to register chemical substances and provide safety data. For conductive polypropylene, this means thoroughly documenting the material's composition, including any additives or fillers used to enhance conductivity. Additionally, the Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment, which may impact the formulation of conductive polypropylene.

Environmental considerations are also paramount in regulatory compliance. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive mandates the proper disposal and recycling of electronic products. Manufacturers using conductive polypropylene in electronic packaging must ensure their products can be easily disassembled and recycled at the end of their lifecycle. This requirement may influence the design and composition of conductive polypropylene formulations to facilitate recycling processes.

Industry-specific standards further complicate the regulatory landscape. For instance, the automotive industry has its own set of stringent requirements, such as the GADSL (Global Automotive Declarable Substance List) and IMDS (International Material Data System). These standards govern the use of materials in automotive components, including electronic packaging. Conductive polypropylene manufacturers targeting this sector must ensure compliance with these industry-specific regulations.

Electromagnetic compatibility (EMC) regulations are another crucial area of compliance for conductive polypropylene in electronic packaging. The material's conductive properties must not interfere with the proper functioning of electronic devices or cause electromagnetic interference. Compliance with standards set by organizations such as the International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC) is essential for market acceptance.

As the regulatory landscape continues to evolve, manufacturers and researchers working on conductive polypropylene for electronic packaging must stay informed of new developments and potential changes in regulations. This proactive approach will ensure ongoing compliance and facilitate the successful adoption of this innovative material in various electronic packaging applications.

In the United States, the primary regulatory body overseeing electronic packaging materials is the Food and Drug Administration (FDA). The FDA's regulations focus on the safety of materials that come into contact with food or pharmaceuticals. For conductive polypropylene used in electronic packaging, compliance with FDA regulations is essential, particularly for applications in the food and medical industries. Manufacturers must demonstrate that their conductive polypropylene formulations do not leach harmful substances and meet the requirements outlined in 21 CFR 177.1520 for olefin polymers.

The European Union's regulatory framework is equally stringent, with the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation playing a central role. REACH requires manufacturers and importers to register chemical substances and provide safety data. For conductive polypropylene, this means thoroughly documenting the material's composition, including any additives or fillers used to enhance conductivity. Additionally, the Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment, which may impact the formulation of conductive polypropylene.

Environmental considerations are also paramount in regulatory compliance. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive mandates the proper disposal and recycling of electronic products. Manufacturers using conductive polypropylene in electronic packaging must ensure their products can be easily disassembled and recycled at the end of their lifecycle. This requirement may influence the design and composition of conductive polypropylene formulations to facilitate recycling processes.

Industry-specific standards further complicate the regulatory landscape. For instance, the automotive industry has its own set of stringent requirements, such as the GADSL (Global Automotive Declarable Substance List) and IMDS (International Material Data System). These standards govern the use of materials in automotive components, including electronic packaging. Conductive polypropylene manufacturers targeting this sector must ensure compliance with these industry-specific regulations.

Electromagnetic compatibility (EMC) regulations are another crucial area of compliance for conductive polypropylene in electronic packaging. The material's conductive properties must not interfere with the proper functioning of electronic devices or cause electromagnetic interference. Compliance with standards set by organizations such as the International Electrotechnical Commission (IEC) and the Federal Communications Commission (FCC) is essential for market acceptance.

As the regulatory landscape continues to evolve, manufacturers and researchers working on conductive polypropylene for electronic packaging must stay informed of new developments and potential changes in regulations. This proactive approach will ensure ongoing compliance and facilitate the successful adoption of this innovative material in various electronic packaging applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!