How Crystallization Control Improves Polypropylene Clarity

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Clarity Evolution and Objectives

Polypropylene (PP) has undergone significant evolution in terms of clarity since its inception in the 1950s. Initially, PP was known for its opaque appearance, limiting its applications in packaging and consumer goods where transparency was desired. The journey towards improving PP clarity has been driven by the growing demand for clear, lightweight, and cost-effective materials in various industries.

The primary objective in enhancing PP clarity has been to achieve a balance between transparency and the inherent properties that make PP attractive, such as its low density, high chemical resistance, and excellent mechanical properties. This goal has led to extensive research and development efforts focused on controlling the crystallization process of PP, which is key to improving its optical properties.

Over the decades, several milestones have marked the progress in PP clarity. The introduction of nucleating agents in the 1970s was a significant breakthrough, allowing for the creation of smaller, more uniform crystals that reduced light scattering and improved transparency. The 1990s saw the development of advanced clarifying agents, which further enhanced PP's optical properties by promoting the formation of smaller spherulites during crystallization.

The current objectives in PP clarity research are multifaceted. Researchers and industry professionals are striving to develop PP grades that can compete with other transparent plastics like PET and PS in terms of clarity, while maintaining PP's advantageous properties. There is a focus on creating PP with higher light transmission, reduced haze, and improved gloss, all while ensuring that the material remains recyclable and environmentally friendly.

Another key objective is to expand the application range of clear PP. This includes developing grades suitable for hot-fill applications, improving the clarity of PP in thick-walled parts, and enhancing the material's performance in extreme temperature conditions. The industry is also working towards reducing the cost of clarifying agents and optimizing processing conditions to make clear PP more economically viable for a wider range of applications.

The evolution of PP clarity is closely tied to advancements in polymer science and processing technologies. Current research is exploring novel approaches such as the use of nanotechnology, the development of new copolymer structures, and the application of advanced crystallization control techniques. These efforts aim not only to improve clarity but also to enhance other properties like impact resistance and barrier performance, making PP an even more versatile material.

The primary objective in enhancing PP clarity has been to achieve a balance between transparency and the inherent properties that make PP attractive, such as its low density, high chemical resistance, and excellent mechanical properties. This goal has led to extensive research and development efforts focused on controlling the crystallization process of PP, which is key to improving its optical properties.

Over the decades, several milestones have marked the progress in PP clarity. The introduction of nucleating agents in the 1970s was a significant breakthrough, allowing for the creation of smaller, more uniform crystals that reduced light scattering and improved transparency. The 1990s saw the development of advanced clarifying agents, which further enhanced PP's optical properties by promoting the formation of smaller spherulites during crystallization.

The current objectives in PP clarity research are multifaceted. Researchers and industry professionals are striving to develop PP grades that can compete with other transparent plastics like PET and PS in terms of clarity, while maintaining PP's advantageous properties. There is a focus on creating PP with higher light transmission, reduced haze, and improved gloss, all while ensuring that the material remains recyclable and environmentally friendly.

Another key objective is to expand the application range of clear PP. This includes developing grades suitable for hot-fill applications, improving the clarity of PP in thick-walled parts, and enhancing the material's performance in extreme temperature conditions. The industry is also working towards reducing the cost of clarifying agents and optimizing processing conditions to make clear PP more economically viable for a wider range of applications.

The evolution of PP clarity is closely tied to advancements in polymer science and processing technologies. Current research is exploring novel approaches such as the use of nanotechnology, the development of new copolymer structures, and the application of advanced crystallization control techniques. These efforts aim not only to improve clarity but also to enhance other properties like impact resistance and barrier performance, making PP an even more versatile material.

Market Demand for High-Clarity Polypropylene

The demand for high-clarity polypropylene has been steadily increasing across various industries due to its unique combination of transparency, cost-effectiveness, and versatile properties. Packaging remains the primary driver of this demand, with food and beverage containers, personal care products, and household goods leading the way. Consumers increasingly prefer transparent packaging that allows them to see the contents, perceiving it as more trustworthy and of higher quality.

In the food packaging sector, high-clarity polypropylene is particularly sought after for its ability to showcase products while maintaining their freshness and extending shelf life. The material's clarity rivals that of more expensive alternatives like PET, making it an attractive option for manufacturers looking to balance cost and aesthetics. Additionally, the growing trend towards sustainable packaging solutions has further boosted the demand for high-clarity polypropylene, as it is recyclable and can be produced with lower energy consumption compared to some other plastics.

The automotive industry has also emerged as a significant market for high-clarity polypropylene. As vehicle designs evolve to incorporate more transparent elements, there is an increasing need for lightweight, durable, and clear materials for interior components such as instrument panels, lighting covers, and decorative trims. The material's ability to withstand high temperatures and resist chemicals makes it ideal for these applications.

In the medical and healthcare sectors, the demand for high-clarity polypropylene continues to grow, driven by the need for transparent, sterilizable containers and devices. The material's clarity allows for easy visual inspection of contents, crucial in medical settings where accuracy and safety are paramount. The COVID-19 pandemic has further accelerated this trend, with increased demand for clear face shields, diagnostic equipment, and laboratory consumables.

The electronics industry is another area where high-clarity polypropylene is gaining traction. As consumer electronics become more aesthetically focused, there is a growing demand for transparent or translucent components that can showcase internal elements or create unique visual effects. This trend is particularly evident in gaming peripherals, smart home devices, and wearable technology.

Market analysts project that the global demand for high-clarity polypropylene will continue to grow at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is expected to be driven by innovations in crystallization control techniques that further enhance the material's optical properties, as well as the development of new applications across various industries. As manufacturers continue to invest in research and development to improve the clarity and performance of polypropylene, the material is poised to capture an even larger share of the transparent plastics market in the coming years.

In the food packaging sector, high-clarity polypropylene is particularly sought after for its ability to showcase products while maintaining their freshness and extending shelf life. The material's clarity rivals that of more expensive alternatives like PET, making it an attractive option for manufacturers looking to balance cost and aesthetics. Additionally, the growing trend towards sustainable packaging solutions has further boosted the demand for high-clarity polypropylene, as it is recyclable and can be produced with lower energy consumption compared to some other plastics.

The automotive industry has also emerged as a significant market for high-clarity polypropylene. As vehicle designs evolve to incorporate more transparent elements, there is an increasing need for lightweight, durable, and clear materials for interior components such as instrument panels, lighting covers, and decorative trims. The material's ability to withstand high temperatures and resist chemicals makes it ideal for these applications.

In the medical and healthcare sectors, the demand for high-clarity polypropylene continues to grow, driven by the need for transparent, sterilizable containers and devices. The material's clarity allows for easy visual inspection of contents, crucial in medical settings where accuracy and safety are paramount. The COVID-19 pandemic has further accelerated this trend, with increased demand for clear face shields, diagnostic equipment, and laboratory consumables.

The electronics industry is another area where high-clarity polypropylene is gaining traction. As consumer electronics become more aesthetically focused, there is a growing demand for transparent or translucent components that can showcase internal elements or create unique visual effects. This trend is particularly evident in gaming peripherals, smart home devices, and wearable technology.

Market analysts project that the global demand for high-clarity polypropylene will continue to grow at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is expected to be driven by innovations in crystallization control techniques that further enhance the material's optical properties, as well as the development of new applications across various industries. As manufacturers continue to invest in research and development to improve the clarity and performance of polypropylene, the material is poised to capture an even larger share of the transparent plastics market in the coming years.

Current Challenges in Polypropylene Crystallization Control

Despite significant advancements in polypropylene (PP) production, controlling crystallization to enhance clarity remains a persistent challenge in the industry. The primary obstacle lies in managing the complex interplay between molecular structure, processing conditions, and crystallization kinetics. One of the key issues is the inherent tendency of PP to form large, opaque spherulites during crystallization, which significantly reduces transparency.

The nucleation and growth of crystals in PP are highly sensitive to processing parameters such as cooling rate, shear stress, and thermal history. Achieving consistent and uniform nucleation across the polymer matrix is particularly challenging, as inconsistencies can lead to variations in optical properties. Moreover, the presence of additives and stabilizers, while necessary for other performance attributes, can interfere with crystallization control mechanisms, further complicating the process.

Another significant challenge is balancing clarity with other desirable properties such as stiffness and impact resistance. Efforts to enhance clarity often come at the expense of mechanical properties, creating a trade-off that manufacturers must carefully navigate. This balance is particularly crucial in applications where both optical and mechanical performance are critical, such as in packaging and automotive components.

The development of effective nucleating agents remains an ongoing challenge. While numerous nucleating agents have been introduced, finding ones that can simultaneously promote fine, uniform crystal structures and maintain compatibility with PP without negatively impacting other properties is still an area of active research. Additionally, the effectiveness of nucleating agents can vary depending on the specific grade of PP and processing conditions, making it difficult to develop universal solutions.

Environmental concerns and sustainability requirements add another layer of complexity to crystallization control. As the industry moves towards more eco-friendly materials and processes, there is a growing need for crystallization control methods that are compatible with recycled PP and bio-based alternatives. These materials often have more variable compositions and molecular weight distributions, making consistent crystallization control even more challenging.

Lastly, the scalability of laboratory-developed crystallization control techniques to industrial production remains a significant hurdle. Techniques that show promise in small-scale experiments may not translate effectively to high-volume manufacturing environments, where factors such as heat transfer rates and shear forces can differ significantly. Bridging this gap requires extensive research and development efforts, as well as substantial investment in process optimization and equipment modification.

The nucleation and growth of crystals in PP are highly sensitive to processing parameters such as cooling rate, shear stress, and thermal history. Achieving consistent and uniform nucleation across the polymer matrix is particularly challenging, as inconsistencies can lead to variations in optical properties. Moreover, the presence of additives and stabilizers, while necessary for other performance attributes, can interfere with crystallization control mechanisms, further complicating the process.

Another significant challenge is balancing clarity with other desirable properties such as stiffness and impact resistance. Efforts to enhance clarity often come at the expense of mechanical properties, creating a trade-off that manufacturers must carefully navigate. This balance is particularly crucial in applications where both optical and mechanical performance are critical, such as in packaging and automotive components.

The development of effective nucleating agents remains an ongoing challenge. While numerous nucleating agents have been introduced, finding ones that can simultaneously promote fine, uniform crystal structures and maintain compatibility with PP without negatively impacting other properties is still an area of active research. Additionally, the effectiveness of nucleating agents can vary depending on the specific grade of PP and processing conditions, making it difficult to develop universal solutions.

Environmental concerns and sustainability requirements add another layer of complexity to crystallization control. As the industry moves towards more eco-friendly materials and processes, there is a growing need for crystallization control methods that are compatible with recycled PP and bio-based alternatives. These materials often have more variable compositions and molecular weight distributions, making consistent crystallization control even more challenging.

Lastly, the scalability of laboratory-developed crystallization control techniques to industrial production remains a significant hurdle. Techniques that show promise in small-scale experiments may not translate effectively to high-volume manufacturing environments, where factors such as heat transfer rates and shear forces can differ significantly. Bridging this gap requires extensive research and development efforts, as well as substantial investment in process optimization and equipment modification.

Existing Crystallization Control Methods

01 Nucleating agents for improving clarity

Nucleating agents can be added to polypropylene to improve its clarity. These agents promote the formation of smaller, more uniform crystals in the polymer structure, resulting in increased transparency and reduced haze. Common nucleating agents include sorbitol derivatives and organic phosphates.- Nucleating agents for improving clarity: Nucleating agents are added to polypropylene to enhance its clarity. These agents promote the formation of smaller, more uniform crystals in the polymer structure, resulting in improved transparency and reduced haze. Common nucleating agents include sorbitol derivatives and organic phosphates.

- Polymer blending for clarity enhancement: Blending polypropylene with other polymers can improve its clarity. This technique involves combining polypropylene with compatible polymers that have better optical properties, such as polyethylene or certain copolymers. The resulting blend often exhibits improved transparency while maintaining desirable mechanical properties.

- Processing techniques for clarity improvement: Various processing techniques can be employed to enhance the clarity of polypropylene. These include controlled cooling rates during molding, orientation of polymer chains, and the use of specific extrusion or injection molding parameters. Such techniques can significantly impact the optical properties of the final product.

- Additives for haze reduction: Certain additives can be incorporated into polypropylene to reduce haze and improve overall clarity. These may include clarifying agents, antioxidants, and specific types of stabilizers. The additives work by modifying the polymer structure or preventing degradation that could lead to reduced transparency.

- Optical measurement and analysis techniques: Advanced optical measurement and analysis techniques are used to assess and improve polypropylene clarity. These may involve spectroscopic methods, image analysis, or specialized instruments designed to quantify transparency, haze, and other optical properties. Such techniques aid in the development and quality control of clear polypropylene products.

02 Polymer blending for enhanced clarity

Blending polypropylene with other polymers can improve its clarity. Certain polymer blends can disrupt the crystallization process of polypropylene, leading to smaller crystal sizes and improved light transmission. Compatible polymers like polyethylene or certain copolymers are often used for this purpose.Expand Specific Solutions03 Processing techniques for clarity enhancement

Specific processing techniques can be employed to improve the clarity of polypropylene. These may include controlled cooling rates during molding, orientation of polymer chains, or the use of rapid cooling methods. Such techniques can influence the crystal structure and size, thereby affecting the optical properties of the final product.Expand Specific Solutions04 Additives for optical property improvement

Various additives can be incorporated into polypropylene to enhance its clarity. These may include clarifying agents, light stabilizers, or specific fillers that can improve the overall transparency and reduce haze. The choice and concentration of additives are crucial for achieving the desired optical properties.Expand Specific Solutions05 Molecular weight and distribution control

Controlling the molecular weight and its distribution in polypropylene can significantly impact its clarity. Lower molecular weight and narrower molecular weight distribution often lead to improved clarity. This can be achieved through careful selection of catalysts and polymerization conditions during the manufacturing process.Expand Specific Solutions

Key Players in Polypropylene Clarity Enhancement

The crystallization control technology for improving polypropylene clarity is in a mature development stage, with significant market potential due to growing demand for transparent plastics. The global polypropylene market size exceeds $70 billion annually, with clarity-enhanced grades representing a high-value segment. Major petrochemical companies like China Petroleum & Chemical Corp., Total Petrochemicals, and LG Chem are actively involved in developing and commercializing advanced polypropylene grades with enhanced optical properties. Research institutions such as SINOPEC Beijing Research Institute and Hiroshima University are also contributing to technological advancements in this field. The competitive landscape is characterized by ongoing innovation in nucleating agents, processing techniques, and polymer design to achieve optimal clarity while maintaining other desirable properties.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced crystallization control techniques for improving polypropylene clarity. Their approach involves the use of nucleating agents and processing conditions optimization. Sinopec's method includes adding specific nucleating agents, such as sorbitol derivatives or organophosphates, at controlled concentrations to promote the formation of smaller, more uniform crystals[1]. They also employ precise temperature control during the cooling phase of polypropylene production, utilizing a step-wise cooling profile that allows for better crystal structure formation[3]. Additionally, Sinopec has implemented a proprietary extrusion process that applies controlled shear and elongational forces to the polymer melt, further enhancing crystal orientation and size distribution[5].

Strengths: Improved optical properties, enhanced stiffness, and better processability. Weaknesses: Potential increase in production costs due to additives and specialized equipment requirements.

BASF Corp.

Technical Solution: BASF Corp. has developed a multi-faceted approach to crystallization control for improving polypropylene clarity. Their technology involves a combination of innovative nucleating agents and process engineering. BASF's proprietary nucleating agents, based on organic phosphates and sorbitol derivatives, are designed to promote the formation of smaller, more uniform crystals[2]. They have also developed a controlled cooling system that implements a precise temperature gradient during the solidification process, allowing for optimal crystal growth[4]. Furthermore, BASF has introduced a novel bimodal molecular weight distribution technique for polypropylene, which enhances both clarity and mechanical properties by creating a synergistic effect between different polymer chain lengths[6].

Strengths: Excellent balance between clarity and mechanical properties, versatile application in various polypropylene grades. Weaknesses: Complex formulation process, potential challenges in maintaining consistency across large production volumes.

Innovative Approaches to Polypropylene Clarity

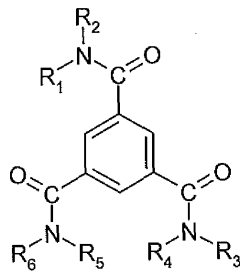

Polypropylene compositions with improved clarity

PatentPendingUS20240043669A1

Innovation

- Incorporating a combination of a nonitol-based or trisamide-based clarifying agent and a phosphate ester-based nucleating agent into the polypropylene composition, which synergistically reduces haze value and increases tensile modulus, thereby enhancing clarity and mechanical properties.

Clarified polypropylene articles with improved optical properties and/or increased temperature of crystallization

PatentWO2011071718A2

Innovation

- Incorporating uniformly dispersed polycyclic organic pigments (blue, green, magenta, red, yellow, orange, and violet) at low levels (1-10 ppm) along with aromatic trisamide nucleating agents (50-250 ppm) into polypropylene resin to enhance optical properties and increase the temperature of crystallization.

Environmental Impact of Clarity-Enhanced Polypropylene

The environmental impact of clarity-enhanced polypropylene is a crucial consideration in the development and application of this advanced material. As crystallization control techniques improve polypropylene clarity, it is essential to assess the ecological implications of these processes and the resulting products.

One of the primary environmental benefits of clarity-enhanced polypropylene is its potential to reduce material usage. The improved optical properties allow for thinner packaging designs, which can lead to a significant reduction in overall plastic consumption. This reduction in material usage translates to lower energy requirements for production and transportation, thereby decreasing the carbon footprint associated with polypropylene products.

However, the crystallization control processes used to enhance clarity may introduce additional environmental concerns. Some methods involve the use of nucleating agents or other additives, which could potentially impact the recyclability of the final product. It is crucial to ensure that these additives do not hinder the material's ability to be recycled or reprocessed, as this would counteract the environmental benefits gained from reduced material usage.

The improved clarity of polypropylene also opens up new possibilities for replacing less environmentally friendly materials in certain applications. For instance, clarity-enhanced polypropylene could potentially substitute for PVC or PET in some packaging applications, offering a more recyclable alternative with a lower environmental impact throughout its lifecycle.

Energy consumption during the production of clarity-enhanced polypropylene is another important factor to consider. While the crystallization control processes may require additional energy inputs, the overall energy balance should be evaluated against the potential savings from reduced material usage and improved product performance.

The durability and longevity of clarity-enhanced polypropylene products also contribute to their environmental profile. If these products demonstrate increased resistance to degradation or improved mechanical properties, they may have longer service lives, reducing the frequency of replacement and, consequently, the overall environmental impact.

End-of-life considerations for clarity-enhanced polypropylene are critical. The material's compatibility with existing recycling streams must be thoroughly assessed to ensure that it does not disrupt established recycling processes. Additionally, research into biodegradable or compostable variants of clarity-enhanced polypropylene could further improve its environmental credentials, particularly for single-use applications.

In conclusion, while clarity-enhanced polypropylene offers several potential environmental benefits, a comprehensive life cycle assessment is necessary to fully understand its ecological impact. This assessment should consider raw material sourcing, production processes, use phase, and end-of-life scenarios to provide a holistic view of the material's environmental footprint.

One of the primary environmental benefits of clarity-enhanced polypropylene is its potential to reduce material usage. The improved optical properties allow for thinner packaging designs, which can lead to a significant reduction in overall plastic consumption. This reduction in material usage translates to lower energy requirements for production and transportation, thereby decreasing the carbon footprint associated with polypropylene products.

However, the crystallization control processes used to enhance clarity may introduce additional environmental concerns. Some methods involve the use of nucleating agents or other additives, which could potentially impact the recyclability of the final product. It is crucial to ensure that these additives do not hinder the material's ability to be recycled or reprocessed, as this would counteract the environmental benefits gained from reduced material usage.

The improved clarity of polypropylene also opens up new possibilities for replacing less environmentally friendly materials in certain applications. For instance, clarity-enhanced polypropylene could potentially substitute for PVC or PET in some packaging applications, offering a more recyclable alternative with a lower environmental impact throughout its lifecycle.

Energy consumption during the production of clarity-enhanced polypropylene is another important factor to consider. While the crystallization control processes may require additional energy inputs, the overall energy balance should be evaluated against the potential savings from reduced material usage and improved product performance.

The durability and longevity of clarity-enhanced polypropylene products also contribute to their environmental profile. If these products demonstrate increased resistance to degradation or improved mechanical properties, they may have longer service lives, reducing the frequency of replacement and, consequently, the overall environmental impact.

End-of-life considerations for clarity-enhanced polypropylene are critical. The material's compatibility with existing recycling streams must be thoroughly assessed to ensure that it does not disrupt established recycling processes. Additionally, research into biodegradable or compostable variants of clarity-enhanced polypropylene could further improve its environmental credentials, particularly for single-use applications.

In conclusion, while clarity-enhanced polypropylene offers several potential environmental benefits, a comprehensive life cycle assessment is necessary to fully understand its ecological impact. This assessment should consider raw material sourcing, production processes, use phase, and end-of-life scenarios to provide a holistic view of the material's environmental footprint.

Regulatory Framework for Polymer Additives

The regulatory framework for polymer additives plays a crucial role in ensuring the safety and quality of polypropylene products, particularly those requiring enhanced clarity. This framework encompasses a complex set of regulations, standards, and guidelines that govern the use of additives in polymer manufacturing, including those used for crystallization control in polypropylene.

At the international level, organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) provide standardized testing methods and specifications for polymer additives. These standards help ensure consistency and reliability in the evaluation of additive performance and safety across different jurisdictions.

In the United States, the Food and Drug Administration (FDA) regulates polymer additives used in food contact materials through the Code of Federal Regulations (CFR), specifically 21 CFR 174-179. These regulations outline the permitted substances and their limitations for use in polymers that may come into contact with food. For polypropylene clarity enhancement, additives must comply with these regulations to ensure consumer safety.

The European Union has established the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including polymer additives. REACH requires manufacturers and importers to register chemicals and provide safety data, ensuring a high level of protection for human health and the environment. Additionally, the EU Plastics Regulation (EU) No 10/2011 specifically addresses materials and articles intended to come into contact with food, setting migration limits for various substances used in polymer production.

In Asia, countries like China and Japan have their own regulatory frameworks. China's GB standards (Guobiao standards) cover various aspects of polymer additives, including testing methods and safety requirements. Japan's Ministry of Health, Labour and Welfare (MHLW) regulates food contact materials, including polymer additives, through the Food Sanitation Act.

Compliance with these regulatory frameworks often requires extensive testing and documentation. Manufacturers must demonstrate that their additives meet specific purity criteria, do not exceed migration limits, and do not pose health risks when used as intended. This may involve toxicological assessments, migration studies, and long-term stability tests.

As the understanding of polymer additives' environmental impact grows, regulatory bodies are increasingly focusing on sustainability aspects. This includes regulations on biodegradability, recyclability, and the use of bio-based materials. Manufacturers developing crystallization control additives for polypropylene clarity must consider these evolving regulatory trends to ensure long-term compliance and market acceptance.

At the international level, organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) provide standardized testing methods and specifications for polymer additives. These standards help ensure consistency and reliability in the evaluation of additive performance and safety across different jurisdictions.

In the United States, the Food and Drug Administration (FDA) regulates polymer additives used in food contact materials through the Code of Federal Regulations (CFR), specifically 21 CFR 174-179. These regulations outline the permitted substances and their limitations for use in polymers that may come into contact with food. For polypropylene clarity enhancement, additives must comply with these regulations to ensure consumer safety.

The European Union has established the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to all chemical substances, including polymer additives. REACH requires manufacturers and importers to register chemicals and provide safety data, ensuring a high level of protection for human health and the environment. Additionally, the EU Plastics Regulation (EU) No 10/2011 specifically addresses materials and articles intended to come into contact with food, setting migration limits for various substances used in polymer production.

In Asia, countries like China and Japan have their own regulatory frameworks. China's GB standards (Guobiao standards) cover various aspects of polymer additives, including testing methods and safety requirements. Japan's Ministry of Health, Labour and Welfare (MHLW) regulates food contact materials, including polymer additives, through the Food Sanitation Act.

Compliance with these regulatory frameworks often requires extensive testing and documentation. Manufacturers must demonstrate that their additives meet specific purity criteria, do not exceed migration limits, and do not pose health risks when used as intended. This may involve toxicological assessments, migration studies, and long-term stability tests.

As the understanding of polymer additives' environmental impact grows, regulatory bodies are increasingly focusing on sustainability aspects. This includes regulations on biodegradability, recyclability, and the use of bio-based materials. Manufacturers developing crystallization control additives for polypropylene clarity must consider these evolving regulatory trends to ensure long-term compliance and market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!