Exploring Polypropylene Particle Applications in Biomedical Fields

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Biomedical Applications Overview

Polypropylene (PP) has emerged as a versatile material with significant potential in biomedical applications. Its unique properties, including biocompatibility, chemical resistance, and mechanical strength, make it an attractive choice for various medical devices and implants. In recent years, the use of PP particles has gained particular attention in the biomedical field due to their ability to be tailored for specific applications.

One of the primary areas where PP particles have shown promise is in drug delivery systems. The particles can be engineered to encapsulate and release drugs in a controlled manner, improving therapeutic efficacy and reducing side effects. This application is particularly beneficial for targeted drug delivery in cancer treatment and chronic disease management.

In tissue engineering, PP particles serve as scaffolds for cell growth and tissue regeneration. Their porous structure and customizable surface properties allow for effective cell adhesion and proliferation. This has led to advancements in the development of artificial organs and tissue repair techniques, offering new possibilities for regenerative medicine.

PP particles have also found applications in medical diagnostics. Their use in biosensors and immunoassays has improved the sensitivity and accuracy of various diagnostic tests. The particles can be functionalized with specific biomolecules, enabling the detection of disease markers with high precision.

In the field of orthopedics, PP particles are being explored for their potential in bone cement formulations. When combined with other materials, they can enhance the mechanical properties and biocompatibility of bone cements used in joint replacements and fracture repairs.

The use of PP particles in wound healing applications is another area of active research. These particles can be incorporated into wound dressings to promote faster healing and reduce the risk of infection. Their ability to absorb exudates while maintaining a moist wound environment makes them particularly effective in chronic wound management.

As research in this field progresses, new applications for PP particles continue to emerge. Their potential in areas such as gene therapy, vaccine delivery, and 3D bioprinting is being actively explored. The versatility of PP particles, combined with advancements in surface modification techniques, opens up possibilities for addressing complex biomedical challenges.

However, it is important to note that the use of PP particles in biomedical applications is not without challenges. Concerns regarding long-term biocompatibility, potential inflammatory responses, and environmental impact need to be carefully addressed. Ongoing research focuses on optimizing particle properties and developing strategies to mitigate these concerns, ensuring the safe and effective use of PP particles in medical applications.

One of the primary areas where PP particles have shown promise is in drug delivery systems. The particles can be engineered to encapsulate and release drugs in a controlled manner, improving therapeutic efficacy and reducing side effects. This application is particularly beneficial for targeted drug delivery in cancer treatment and chronic disease management.

In tissue engineering, PP particles serve as scaffolds for cell growth and tissue regeneration. Their porous structure and customizable surface properties allow for effective cell adhesion and proliferation. This has led to advancements in the development of artificial organs and tissue repair techniques, offering new possibilities for regenerative medicine.

PP particles have also found applications in medical diagnostics. Their use in biosensors and immunoassays has improved the sensitivity and accuracy of various diagnostic tests. The particles can be functionalized with specific biomolecules, enabling the detection of disease markers with high precision.

In the field of orthopedics, PP particles are being explored for their potential in bone cement formulations. When combined with other materials, they can enhance the mechanical properties and biocompatibility of bone cements used in joint replacements and fracture repairs.

The use of PP particles in wound healing applications is another area of active research. These particles can be incorporated into wound dressings to promote faster healing and reduce the risk of infection. Their ability to absorb exudates while maintaining a moist wound environment makes them particularly effective in chronic wound management.

As research in this field progresses, new applications for PP particles continue to emerge. Their potential in areas such as gene therapy, vaccine delivery, and 3D bioprinting is being actively explored. The versatility of PP particles, combined with advancements in surface modification techniques, opens up possibilities for addressing complex biomedical challenges.

However, it is important to note that the use of PP particles in biomedical applications is not without challenges. Concerns regarding long-term biocompatibility, potential inflammatory responses, and environmental impact need to be carefully addressed. Ongoing research focuses on optimizing particle properties and developing strategies to mitigate these concerns, ensuring the safe and effective use of PP particles in medical applications.

Market Analysis for Biomedical Polypropylene

The biomedical polypropylene market has experienced significant growth in recent years, driven by the increasing demand for medical devices, implants, and other healthcare applications. Polypropylene's unique properties, including its biocompatibility, chemical resistance, and low cost, have made it a preferred material in various biomedical fields.

The global market for biomedical polypropylene is projected to expand at a compound annual growth rate (CAGR) of 7.2% from 2021 to 2026. This growth is primarily attributed to the rising prevalence of chronic diseases, an aging population, and advancements in medical technology. North America currently holds the largest market share, followed by Europe and Asia-Pacific regions.

In the medical device sector, polypropylene particles find extensive applications in surgical instruments, syringes, and diagnostic equipment. The increasing adoption of minimally invasive surgical procedures has further boosted the demand for polypropylene-based medical devices. Additionally, the growing trend towards disposable medical supplies to prevent cross-contamination has contributed to market expansion.

The pharmaceutical packaging industry represents another significant market segment for biomedical polypropylene. The material's excellent barrier properties and resistance to moisture make it ideal for drug packaging and storage. With the pharmaceutical industry experiencing rapid growth, particularly in emerging economies, the demand for polypropylene packaging solutions is expected to surge.

Tissue engineering and regenerative medicine have emerged as promising areas for polypropylene particle applications. Researchers are exploring the use of polypropylene scaffolds for tissue regeneration and cell culture, opening new avenues for market growth. The increasing focus on personalized medicine and bioprinting technologies is likely to drive further innovation in this sector.

However, the market faces challenges such as stringent regulatory requirements and growing environmental concerns regarding plastic waste. Manufacturers are investing in research and development to address these issues, focusing on biodegradable alternatives and improved recycling technologies for polypropylene products.

The COVID-19 pandemic has had a mixed impact on the biomedical polypropylene market. While it initially disrupted supply chains and manufacturing processes, the increased demand for personal protective equipment (PPE) and medical supplies has subsequently boosted market growth. This trend is expected to continue in the post-pandemic era, as healthcare systems worldwide prioritize stockpiling essential medical supplies.

The global market for biomedical polypropylene is projected to expand at a compound annual growth rate (CAGR) of 7.2% from 2021 to 2026. This growth is primarily attributed to the rising prevalence of chronic diseases, an aging population, and advancements in medical technology. North America currently holds the largest market share, followed by Europe and Asia-Pacific regions.

In the medical device sector, polypropylene particles find extensive applications in surgical instruments, syringes, and diagnostic equipment. The increasing adoption of minimally invasive surgical procedures has further boosted the demand for polypropylene-based medical devices. Additionally, the growing trend towards disposable medical supplies to prevent cross-contamination has contributed to market expansion.

The pharmaceutical packaging industry represents another significant market segment for biomedical polypropylene. The material's excellent barrier properties and resistance to moisture make it ideal for drug packaging and storage. With the pharmaceutical industry experiencing rapid growth, particularly in emerging economies, the demand for polypropylene packaging solutions is expected to surge.

Tissue engineering and regenerative medicine have emerged as promising areas for polypropylene particle applications. Researchers are exploring the use of polypropylene scaffolds for tissue regeneration and cell culture, opening new avenues for market growth. The increasing focus on personalized medicine and bioprinting technologies is likely to drive further innovation in this sector.

However, the market faces challenges such as stringent regulatory requirements and growing environmental concerns regarding plastic waste. Manufacturers are investing in research and development to address these issues, focusing on biodegradable alternatives and improved recycling technologies for polypropylene products.

The COVID-19 pandemic has had a mixed impact on the biomedical polypropylene market. While it initially disrupted supply chains and manufacturing processes, the increased demand for personal protective equipment (PPE) and medical supplies has subsequently boosted market growth. This trend is expected to continue in the post-pandemic era, as healthcare systems worldwide prioritize stockpiling essential medical supplies.

Current Challenges in Biomedical Polypropylene

Despite the widespread use of polypropylene in biomedical applications, several challenges persist in its implementation. One of the primary concerns is the material's inherent hydrophobicity, which can lead to poor cell adhesion and reduced biocompatibility. This characteristic often necessitates surface modifications to enhance cell attachment and proliferation, adding complexity and cost to manufacturing processes.

Another significant challenge lies in the long-term stability of polypropylene particles in biological environments. While the material is generally considered inert, prolonged exposure to physiological conditions can potentially lead to degradation and the release of microplastics. This raises concerns about the long-term safety and efficacy of polypropylene-based medical devices and implants.

The sterilization of polypropylene particles for biomedical use presents another hurdle. Common sterilization methods, such as ethylene oxide treatment or gamma irradiation, can potentially alter the material's properties, affecting its performance and longevity. Developing sterilization protocols that maintain the integrity of polypropylene particles without compromising their intended function remains an ongoing challenge.

Furthermore, the controlled release of drugs or bioactive compounds from polypropylene particles poses difficulties due to the material's non-porous nature. Achieving sustained and predictable drug release profiles often requires complex formulation strategies or surface modifications, which can be challenging to implement consistently at scale.

The biocompatibility of polypropylene particles, particularly in terms of immune response and inflammation, continues to be a subject of investigation. While generally considered biocompatible, there are concerns about potential long-term effects and variations in individual patient responses, especially in applications involving direct contact with blood or tissue.

Additionally, the development of polypropylene particles with specific sizes, shapes, and surface properties for targeted biomedical applications remains challenging. Precise control over these parameters is crucial for optimizing performance in various biomedical contexts, from drug delivery to tissue engineering scaffolds.

Lastly, the environmental impact of polypropylene particles in biomedical applications is an emerging concern. As the healthcare industry moves towards more sustainable practices, finding ways to recycle or safely dispose of polypropylene-based medical devices and materials at the end of their lifecycle presents a significant challenge that requires innovative solutions and regulatory considerations.

Another significant challenge lies in the long-term stability of polypropylene particles in biological environments. While the material is generally considered inert, prolonged exposure to physiological conditions can potentially lead to degradation and the release of microplastics. This raises concerns about the long-term safety and efficacy of polypropylene-based medical devices and implants.

The sterilization of polypropylene particles for biomedical use presents another hurdle. Common sterilization methods, such as ethylene oxide treatment or gamma irradiation, can potentially alter the material's properties, affecting its performance and longevity. Developing sterilization protocols that maintain the integrity of polypropylene particles without compromising their intended function remains an ongoing challenge.

Furthermore, the controlled release of drugs or bioactive compounds from polypropylene particles poses difficulties due to the material's non-porous nature. Achieving sustained and predictable drug release profiles often requires complex formulation strategies or surface modifications, which can be challenging to implement consistently at scale.

The biocompatibility of polypropylene particles, particularly in terms of immune response and inflammation, continues to be a subject of investigation. While generally considered biocompatible, there are concerns about potential long-term effects and variations in individual patient responses, especially in applications involving direct contact with blood or tissue.

Additionally, the development of polypropylene particles with specific sizes, shapes, and surface properties for targeted biomedical applications remains challenging. Precise control over these parameters is crucial for optimizing performance in various biomedical contexts, from drug delivery to tissue engineering scaffolds.

Lastly, the environmental impact of polypropylene particles in biomedical applications is an emerging concern. As the healthcare industry moves towards more sustainable practices, finding ways to recycle or safely dispose of polypropylene-based medical devices and materials at the end of their lifecycle presents a significant challenge that requires innovative solutions and regulatory considerations.

Existing Polypropylene Particle Solutions

01 Synthesis and modification of polypropylene particles

Various methods for synthesizing and modifying polypropylene particles are described. These include techniques for controlling particle size, shape, and surface properties. Modifications can enhance the particles' performance in specific applications, such as improving dispersion or adding functional groups.- Synthesis and modification of polypropylene particles: This category focuses on methods for synthesizing polypropylene particles and modifying their properties. Techniques may include controlled polymerization, surface treatments, or incorporation of additives to enhance specific characteristics such as size distribution, morphology, or functionality.

- Applications of polypropylene particles in composites: Polypropylene particles are utilized in various composite materials to improve mechanical properties, thermal stability, or specific functionalities. This may involve blending with other polymers, reinforcing fillers, or creating novel composite structures for applications in automotive, construction, or consumer goods industries.

- Polypropylene particles in medical and pharmaceutical applications: This category covers the use of polypropylene particles in medical devices, drug delivery systems, or diagnostic applications. The particles may be functionalized or modified to enhance biocompatibility, drug loading capacity, or controlled release properties.

- Processing and manufacturing techniques for polypropylene particles: Various methods for processing and manufacturing polypropylene particles are explored, including extrusion, spray drying, emulsion techniques, or melt blowing. These processes aim to control particle size, shape, and uniformity for specific industrial applications.

- Environmental and sustainability aspects of polypropylene particles: This category addresses the environmental impact and sustainability of polypropylene particles, including biodegradability, recycling methods, and the development of eco-friendly alternatives. It may also cover strategies to reduce microplastic pollution and improve the overall lifecycle assessment of products containing these particles.

02 Applications of polypropylene particles in composites

Polypropylene particles are utilized in composite materials to enhance mechanical properties, thermal stability, and other characteristics. The particles can be incorporated into various matrices, including other polymers, to create materials with improved performance for specific industrial applications.Expand Specific Solutions03 Surface treatment of polypropylene particles

Surface treatment techniques for polypropylene particles are explored to modify their properties. These treatments can improve compatibility with other materials, enhance adhesion, or add specific functionalities. Methods may include chemical modifications, plasma treatments, or coating processes.Expand Specific Solutions04 Polypropylene particles in filtration and separation

The use of polypropylene particles in filtration and separation processes is described. These particles can be employed in various forms, such as membranes or as components in filter media, to improve efficiency in liquid or gas separation applications.Expand Specific Solutions05 Biodegradable and sustainable polypropylene particles

Development of biodegradable or more environmentally friendly versions of polypropylene particles is discussed. This includes research into additives or modifications that can enhance the degradability of the particles, as well as exploration of bio-based alternatives that maintain similar properties to traditional polypropylene.Expand Specific Solutions

Key Players in Biomedical Polypropylene

The field of polypropylene particle applications in biomedicine is in a growth phase, with increasing market potential and technological advancements. The global market for biomedical polymers is expanding, driven by rising healthcare demands and innovative material solutions. While the technology is maturing, there's still room for significant developments. Key players like PetroChina, DSM IP Assets, and Sumitomo Bakelite are leveraging their expertise in materials science to develop advanced polypropylene-based solutions. Academic institutions such as MIT and Johns Hopkins University are contributing to fundamental research, while companies like Borealis AG and Mitsui Chemicals are focusing on commercial applications, indicating a collaborative ecosystem driving innovation in this field.

DSM IP Assets BV

Technical Solution: DSM has developed innovative polypropylene (PP) particles for biomedical applications, focusing on controlled drug delivery systems. Their technology involves creating porous PP microspheres with tailored surface properties for enhanced drug loading and release profiles[1]. These particles are engineered to have specific sizes ranging from 10 to 200 micrometers, allowing for versatile applications in various biomedical fields[2]. DSM's approach includes surface modification techniques to improve biocompatibility and cellular interactions, making the PP particles suitable for tissue engineering scaffolds and cell culture substrates[3].

Strengths: Customizable particle properties, high drug loading capacity, and controlled release profiles. Weaknesses: Potential limitations in biodegradability and long-term biocompatibility.

Borealis AG

Technical Solution: Borealis AG has pioneered the development of polypropylene particles for biomedical applications, focusing on their use in advanced drug delivery systems and medical devices. Their proprietary technology involves creating spherical PP particles with controlled porosity and surface chemistry, enabling precise drug encapsulation and release kinetics[1]. Borealis has also developed a range of PP grades specifically designed for medical applications, featuring enhanced purity and biocompatibility[2]. These materials are utilized in the production of various medical devices, including syringes, inhalers, and diagnostic equipment[3].

Strengths: High-purity PP grades, versatile applications in medical devices, and advanced particle engineering capabilities. Weaknesses: Limited biodegradability and potential regulatory challenges for novel applications.

Core Innovations in Polypropylene Bioengineering

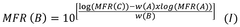

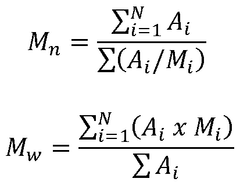

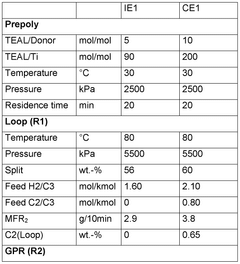

Propylene compositions with improved sealing and barrier properties

PatentWO2025021580A1

Innovation

- A polypropylene composition comprising a homopolymer of propylene with specific properties, including a melt flow rate, xylene cold soluble content, ethylene content, molecular weight ratio, melting temperature, and crystallization temperature, is developed. This composition is used in a multi-stage polymerization process and can be compounded with additives to enhance sealing and barrier properties.

A polymeric material for use in biomedical applications

PatentInactiveIN595DEL2005A

Innovation

- Use of polypropylene or styrene acrylonitrile for biomedical applications, specifically for disposable vaginal speculums.

- Modification of polypropylene with stabilizers such as hindered phenols, hydroxy phenol benzotriazole, and organic phosphite.

- Modification of styrene acrylonitrile with stabilizers such as butylated hydroxytoluene and hindered phenols.

Regulatory Framework for Biomedical Materials

The regulatory framework for biomedical materials plays a crucial role in ensuring the safety and efficacy of polypropylene particle applications in the biomedical field. As these particles are increasingly explored for various medical uses, it is essential to understand the complex landscape of regulations governing their development, testing, and commercialization.

In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing biomedical materials. The FDA classifies medical devices into three categories based on their risk level, with Class III devices being subject to the most stringent controls. Polypropylene particles, depending on their specific application, may fall under different classifications, necessitating varying levels of regulatory scrutiny.

The European Union employs the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) to govern biomedical materials. These regulations emphasize a life-cycle approach to product safety and performance, requiring manufacturers to implement robust quality management systems and conduct post-market surveillance.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) oversees the regulation of biomedical materials. The Japanese regulatory framework places significant emphasis on quality control and manufacturing processes, often requiring detailed documentation and on-site inspections.

International standards, such as those developed by the International Organization for Standardization (ISO), play a vital role in harmonizing regulatory requirements across different regions. ISO 10993, for instance, provides guidelines for the biological evaluation of medical devices, which is particularly relevant for polypropylene particle applications.

Regulatory bodies typically require extensive preclinical and clinical testing to demonstrate the safety and efficacy of biomedical materials. This includes in vitro studies, animal testing, and human clinical trials. For polypropylene particles, specific considerations may include biocompatibility, degradation profiles, and potential long-term effects on surrounding tissues.

As the field of biomedical materials continues to evolve, regulatory frameworks are adapting to keep pace with technological advancements. This includes the development of new guidance documents and regulatory pathways for emerging technologies, such as nanotechnology-based medical devices, which may be relevant to certain polypropylene particle applications.

Manufacturers and researchers working with polypropylene particles in biomedical applications must navigate this complex regulatory landscape carefully. Compliance with relevant regulations and standards is not only a legal requirement but also essential for ensuring patient safety and gaining market acceptance. Early engagement with regulatory authorities and thorough understanding of applicable guidelines can significantly streamline the development and approval process for novel polypropylene particle-based biomedical products.

In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing biomedical materials. The FDA classifies medical devices into three categories based on their risk level, with Class III devices being subject to the most stringent controls. Polypropylene particles, depending on their specific application, may fall under different classifications, necessitating varying levels of regulatory scrutiny.

The European Union employs the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) to govern biomedical materials. These regulations emphasize a life-cycle approach to product safety and performance, requiring manufacturers to implement robust quality management systems and conduct post-market surveillance.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) oversees the regulation of biomedical materials. The Japanese regulatory framework places significant emphasis on quality control and manufacturing processes, often requiring detailed documentation and on-site inspections.

International standards, such as those developed by the International Organization for Standardization (ISO), play a vital role in harmonizing regulatory requirements across different regions. ISO 10993, for instance, provides guidelines for the biological evaluation of medical devices, which is particularly relevant for polypropylene particle applications.

Regulatory bodies typically require extensive preclinical and clinical testing to demonstrate the safety and efficacy of biomedical materials. This includes in vitro studies, animal testing, and human clinical trials. For polypropylene particles, specific considerations may include biocompatibility, degradation profiles, and potential long-term effects on surrounding tissues.

As the field of biomedical materials continues to evolve, regulatory frameworks are adapting to keep pace with technological advancements. This includes the development of new guidance documents and regulatory pathways for emerging technologies, such as nanotechnology-based medical devices, which may be relevant to certain polypropylene particle applications.

Manufacturers and researchers working with polypropylene particles in biomedical applications must navigate this complex regulatory landscape carefully. Compliance with relevant regulations and standards is not only a legal requirement but also essential for ensuring patient safety and gaining market acceptance. Early engagement with regulatory authorities and thorough understanding of applicable guidelines can significantly streamline the development and approval process for novel polypropylene particle-based biomedical products.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations are paramount when exploring polypropylene particle applications in biomedical fields. The interaction between these particles and biological systems must be thoroughly evaluated to ensure patient safety and regulatory compliance.

Polypropylene particles, despite their widespread use in various industries, require careful assessment for biomedical applications. The primary concern is the potential for adverse reactions when these particles come into contact with living tissues or bodily fluids. Factors such as particle size, surface chemistry, and degradation products play crucial roles in determining biocompatibility.

One of the key aspects to consider is the immune response triggered by polypropylene particles. Studies have shown that the size and shape of these particles can influence the extent of inflammatory reactions. Smaller particles may be more likely to be engulfed by immune cells, potentially leading to chronic inflammation or granuloma formation. Conversely, larger particles might pose less risk of cellular uptake but could still elicit a foreign body response.

Surface modifications of polypropylene particles can significantly impact their biocompatibility. Techniques such as plasma treatment or chemical functionalization can alter the surface properties, potentially improving cell adhesion and reducing the risk of adverse reactions. However, these modifications must be carefully evaluated to ensure they do not introduce new safety concerns or compromise the mechanical properties of the particles.

The potential for polypropylene particles to release harmful substances over time is another critical safety consideration. While polypropylene is generally considered chemically inert, prolonged exposure to biological environments may lead to degradation or leaching of additives used in the manufacturing process. Rigorous testing is necessary to assess the long-term stability of these particles under physiological conditions.

Regulatory bodies, such as the FDA and EMA, have established guidelines for evaluating the biocompatibility of medical devices and materials. These guidelines typically include a battery of tests, including cytotoxicity assays, sensitization studies, and implantation tests. Compliance with these regulatory requirements is essential for the successful development and approval of polypropylene particle-based biomedical applications.

In conclusion, while polypropylene particles show promise in various biomedical applications, their biocompatibility and safety must be rigorously evaluated. A comprehensive understanding of the interactions between these particles and biological systems is crucial for developing safe and effective biomedical technologies. Ongoing research and adherence to regulatory standards will be key in realizing the full potential of polypropylene particles in the biomedical field.

Polypropylene particles, despite their widespread use in various industries, require careful assessment for biomedical applications. The primary concern is the potential for adverse reactions when these particles come into contact with living tissues or bodily fluids. Factors such as particle size, surface chemistry, and degradation products play crucial roles in determining biocompatibility.

One of the key aspects to consider is the immune response triggered by polypropylene particles. Studies have shown that the size and shape of these particles can influence the extent of inflammatory reactions. Smaller particles may be more likely to be engulfed by immune cells, potentially leading to chronic inflammation or granuloma formation. Conversely, larger particles might pose less risk of cellular uptake but could still elicit a foreign body response.

Surface modifications of polypropylene particles can significantly impact their biocompatibility. Techniques such as plasma treatment or chemical functionalization can alter the surface properties, potentially improving cell adhesion and reducing the risk of adverse reactions. However, these modifications must be carefully evaluated to ensure they do not introduce new safety concerns or compromise the mechanical properties of the particles.

The potential for polypropylene particles to release harmful substances over time is another critical safety consideration. While polypropylene is generally considered chemically inert, prolonged exposure to biological environments may lead to degradation or leaching of additives used in the manufacturing process. Rigorous testing is necessary to assess the long-term stability of these particles under physiological conditions.

Regulatory bodies, such as the FDA and EMA, have established guidelines for evaluating the biocompatibility of medical devices and materials. These guidelines typically include a battery of tests, including cytotoxicity assays, sensitization studies, and implantation tests. Compliance with these regulatory requirements is essential for the successful development and approval of polypropylene particle-based biomedical applications.

In conclusion, while polypropylene particles show promise in various biomedical applications, their biocompatibility and safety must be rigorously evaluated. A comprehensive understanding of the interactions between these particles and biological systems is crucial for developing safe and effective biomedical technologies. Ongoing research and adherence to regulatory standards will be key in realizing the full potential of polypropylene particles in the biomedical field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!