Exploring Laser Welding Techniques for Polypropylene Components

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Welding Evolution

Laser welding technology has undergone significant evolution since its inception in the 1960s. Initially developed for industrial applications in metal joining, laser welding has expanded its capabilities to include various materials, including polymers like polypropylene. The progression of laser welding techniques for polypropylene components can be traced through several key stages.

In the early stages, CO2 lasers were predominantly used for welding metals. However, as the technology advanced, researchers began exploring its potential for joining thermoplastics. The 1980s saw the introduction of Nd:YAG lasers, which offered improved beam quality and higher power densities, making them suitable for welding thinner materials, including some plastics.

The 1990s marked a significant milestone in laser welding of polymers, with the development of diode lasers. These compact and efficient lasers provided wavelengths more readily absorbed by many plastics, including polypropylene. This breakthrough enabled more precise and controlled welding of polymer components, opening up new possibilities in industries such as automotive and consumer electronics.

The early 2000s witnessed the emergence of fiber lasers, which offered even greater precision and energy efficiency. These lasers, with their excellent beam quality and high power output, further enhanced the capabilities of laser welding for polypropylene components. Concurrently, advancements in beam delivery systems and process control technologies led to improved weld quality and consistency.

In recent years, the focus has shifted towards developing specialized laser welding techniques for specific polymer applications. For polypropylene, which presents challenges due to its low absorption of laser energy, researchers have explored various approaches. These include the use of additives to enhance laser absorption, the development of dual-beam welding systems, and the integration of real-time monitoring and control systems to optimize weld parameters.

The latest developments in laser welding for polypropylene components involve the use of ultra-short pulse lasers and hybrid welding techniques. These advanced methods aim to address the limitations of traditional laser welding, such as thermal damage and material degradation, while improving weld strength and aesthetics.

As we look to the future, the evolution of laser welding techniques for polypropylene components is likely to continue, driven by demands for higher precision, increased automation, and improved energy efficiency. Emerging trends include the integration of artificial intelligence for process optimization, the development of multi-material welding capabilities, and the exploration of new laser sources tailored specifically for polymer welding applications.

In the early stages, CO2 lasers were predominantly used for welding metals. However, as the technology advanced, researchers began exploring its potential for joining thermoplastics. The 1980s saw the introduction of Nd:YAG lasers, which offered improved beam quality and higher power densities, making them suitable for welding thinner materials, including some plastics.

The 1990s marked a significant milestone in laser welding of polymers, with the development of diode lasers. These compact and efficient lasers provided wavelengths more readily absorbed by many plastics, including polypropylene. This breakthrough enabled more precise and controlled welding of polymer components, opening up new possibilities in industries such as automotive and consumer electronics.

The early 2000s witnessed the emergence of fiber lasers, which offered even greater precision and energy efficiency. These lasers, with their excellent beam quality and high power output, further enhanced the capabilities of laser welding for polypropylene components. Concurrently, advancements in beam delivery systems and process control technologies led to improved weld quality and consistency.

In recent years, the focus has shifted towards developing specialized laser welding techniques for specific polymer applications. For polypropylene, which presents challenges due to its low absorption of laser energy, researchers have explored various approaches. These include the use of additives to enhance laser absorption, the development of dual-beam welding systems, and the integration of real-time monitoring and control systems to optimize weld parameters.

The latest developments in laser welding for polypropylene components involve the use of ultra-short pulse lasers and hybrid welding techniques. These advanced methods aim to address the limitations of traditional laser welding, such as thermal damage and material degradation, while improving weld strength and aesthetics.

As we look to the future, the evolution of laser welding techniques for polypropylene components is likely to continue, driven by demands for higher precision, increased automation, and improved energy efficiency. Emerging trends include the integration of artificial intelligence for process optimization, the development of multi-material welding capabilities, and the exploration of new laser sources tailored specifically for polymer welding applications.

Market Demand Analysis

The market demand for laser welding techniques in polypropylene components has been steadily increasing in recent years, driven by the growing use of polypropylene in various industries. Polypropylene, known for its versatility, low cost, and excellent chemical resistance, is widely used in automotive, packaging, consumer goods, and medical device manufacturing.

In the automotive sector, there is a significant push towards lightweight materials to improve fuel efficiency and reduce emissions. Polypropylene components, such as bumpers, interior panels, and fluid reservoirs, are increasingly being used to replace heavier materials. This trend has created a strong demand for efficient and reliable joining methods, with laser welding emerging as a preferred technique due to its precision and speed.

The packaging industry has also shown a growing interest in laser welding for polypropylene. As sustainability concerns drive the adoption of mono-material packaging solutions, the ability to effectively weld polypropylene components becomes crucial. Laser welding offers advantages in creating hermetic seals for food packaging and pharmaceutical containers, ensuring product integrity and extending shelf life.

In the medical device industry, the demand for laser welding of polypropylene components is driven by the need for sterile, contamination-free manufacturing processes. Laser welding provides a non-contact method that minimizes the risk of contamination, making it ideal for producing medical devices, diagnostic equipment, and laboratory consumables.

The consumer goods sector has also contributed to the market demand for laser welding of polypropylene. Products such as household appliances, toys, and electronic enclosures often incorporate polypropylene components that require secure and aesthetically pleasing joints. Laser welding offers the advantage of creating strong, visually appealing welds without the need for additional materials or post-processing.

Market analysis indicates that the global laser welding equipment market is expected to grow significantly in the coming years, with a substantial portion of this growth attributed to the increasing use of polymers, including polypropylene. The Asia-Pacific region, particularly China and India, is anticipated to be a major driver of this growth due to rapid industrialization and increasing adoption of advanced manufacturing technologies.

However, challenges remain in the widespread adoption of laser welding for polypropylene components. These include the need for specialized equipment, the complexity of process parameters, and the initial investment required. Despite these challenges, the market demand continues to grow as manufacturers recognize the long-term benefits of laser welding in terms of production efficiency, joint quality, and design flexibility.

As environmental regulations become more stringent, the demand for laser welding of polypropylene is expected to further increase. This technique aligns well with sustainability goals by enabling the production of easily recyclable mono-material products and reducing material waste compared to traditional joining methods.

In the automotive sector, there is a significant push towards lightweight materials to improve fuel efficiency and reduce emissions. Polypropylene components, such as bumpers, interior panels, and fluid reservoirs, are increasingly being used to replace heavier materials. This trend has created a strong demand for efficient and reliable joining methods, with laser welding emerging as a preferred technique due to its precision and speed.

The packaging industry has also shown a growing interest in laser welding for polypropylene. As sustainability concerns drive the adoption of mono-material packaging solutions, the ability to effectively weld polypropylene components becomes crucial. Laser welding offers advantages in creating hermetic seals for food packaging and pharmaceutical containers, ensuring product integrity and extending shelf life.

In the medical device industry, the demand for laser welding of polypropylene components is driven by the need for sterile, contamination-free manufacturing processes. Laser welding provides a non-contact method that minimizes the risk of contamination, making it ideal for producing medical devices, diagnostic equipment, and laboratory consumables.

The consumer goods sector has also contributed to the market demand for laser welding of polypropylene. Products such as household appliances, toys, and electronic enclosures often incorporate polypropylene components that require secure and aesthetically pleasing joints. Laser welding offers the advantage of creating strong, visually appealing welds without the need for additional materials or post-processing.

Market analysis indicates that the global laser welding equipment market is expected to grow significantly in the coming years, with a substantial portion of this growth attributed to the increasing use of polymers, including polypropylene. The Asia-Pacific region, particularly China and India, is anticipated to be a major driver of this growth due to rapid industrialization and increasing adoption of advanced manufacturing technologies.

However, challenges remain in the widespread adoption of laser welding for polypropylene components. These include the need for specialized equipment, the complexity of process parameters, and the initial investment required. Despite these challenges, the market demand continues to grow as manufacturers recognize the long-term benefits of laser welding in terms of production efficiency, joint quality, and design flexibility.

As environmental regulations become more stringent, the demand for laser welding of polypropylene is expected to further increase. This technique aligns well with sustainability goals by enabling the production of easily recyclable mono-material products and reducing material waste compared to traditional joining methods.

Technical Challenges

Laser welding of polypropylene components presents several significant technical challenges that researchers and engineers must overcome to achieve reliable and high-quality welds. One of the primary difficulties lies in the material properties of polypropylene itself. As a semi-crystalline thermoplastic, polypropylene has a low melting point and high thermal expansion coefficient, making it susceptible to warping and distortion during the welding process. This characteristic necessitates precise control of heat input and cooling rates to maintain dimensional stability and prevent material degradation.

Another major challenge is the poor absorption of laser energy by polypropylene at common laser wavelengths. Unlike metals, which readily absorb laser radiation, polypropylene is highly transmissive to many laser wavelengths, particularly in the near-infrared region. This low absorption efficiency can lead to insufficient melting at the weld interface, resulting in weak bonds. Researchers have explored various strategies to enhance laser absorption, including the use of additives or surface treatments, but these methods often introduce additional complexities and potential material property alterations.

The formation of a consistent and strong weld seam is further complicated by the rapid solidification of polypropylene upon cooling. This quick transition from molten to solid state can trap air bubbles or create voids within the weld, compromising its structural integrity. Additionally, the low surface energy of polypropylene makes it inherently difficult to achieve good wetting and adhesion between the welded surfaces, potentially leading to poor bond strength and reduced durability of the welded joint.

Controlling the weld pool dynamics during laser welding of polypropylene is also challenging due to the material's low viscosity in its molten state. This property can result in excessive flow or splashing of the molten material, leading to inconsistent weld bead geometry and potential defects such as undercuts or porosity. Precise control of laser parameters, including power, speed, and beam profile, is crucial to manage the melt pool behavior and achieve consistent weld quality.

Furthermore, the sensitivity of polypropylene to thermal degradation poses a significant challenge in laser welding. Excessive heat input or prolonged exposure to high temperatures can lead to polymer chain scission, oxidation, or other forms of material degradation, which can severely compromise the mechanical properties and long-term performance of the welded components. Balancing the need for sufficient heat input to achieve fusion with the requirement to minimize thermal damage requires sophisticated process control and optimization strategies.

Lastly, the development of robust and reliable quality control methods for laser-welded polypropylene joints remains a technical hurdle. Traditional non-destructive testing techniques used for metal welds may not be directly applicable or effective for polymer welds, necessitating the development of specialized inspection and testing protocols tailored to the unique characteristics of polypropylene and other thermoplastics.

Another major challenge is the poor absorption of laser energy by polypropylene at common laser wavelengths. Unlike metals, which readily absorb laser radiation, polypropylene is highly transmissive to many laser wavelengths, particularly in the near-infrared region. This low absorption efficiency can lead to insufficient melting at the weld interface, resulting in weak bonds. Researchers have explored various strategies to enhance laser absorption, including the use of additives or surface treatments, but these methods often introduce additional complexities and potential material property alterations.

The formation of a consistent and strong weld seam is further complicated by the rapid solidification of polypropylene upon cooling. This quick transition from molten to solid state can trap air bubbles or create voids within the weld, compromising its structural integrity. Additionally, the low surface energy of polypropylene makes it inherently difficult to achieve good wetting and adhesion between the welded surfaces, potentially leading to poor bond strength and reduced durability of the welded joint.

Controlling the weld pool dynamics during laser welding of polypropylene is also challenging due to the material's low viscosity in its molten state. This property can result in excessive flow or splashing of the molten material, leading to inconsistent weld bead geometry and potential defects such as undercuts or porosity. Precise control of laser parameters, including power, speed, and beam profile, is crucial to manage the melt pool behavior and achieve consistent weld quality.

Furthermore, the sensitivity of polypropylene to thermal degradation poses a significant challenge in laser welding. Excessive heat input or prolonged exposure to high temperatures can lead to polymer chain scission, oxidation, or other forms of material degradation, which can severely compromise the mechanical properties and long-term performance of the welded components. Balancing the need for sufficient heat input to achieve fusion with the requirement to minimize thermal damage requires sophisticated process control and optimization strategies.

Lastly, the development of robust and reliable quality control methods for laser-welded polypropylene joints remains a technical hurdle. Traditional non-destructive testing techniques used for metal welds may not be directly applicable or effective for polymer welds, necessitating the development of specialized inspection and testing protocols tailored to the unique characteristics of polypropylene and other thermoplastics.

Current Techniques

01 Laser power and beam control

Precise control of laser power and beam characteristics is crucial for achieving high-quality welds. This includes adjusting parameters such as power density, pulse duration, and focus to optimize the welding process for different materials and thicknesses. Advanced beam shaping and power modulation techniques can enhance weld penetration and reduce defects.- Laser power and focus control: Precise control of laser power and focus is crucial for achieving high-quality welds. Adjusting these parameters allows for optimal energy distribution, penetration depth, and weld bead formation. Advanced systems may incorporate real-time monitoring and adjustment capabilities to maintain consistent welding quality across various materials and thicknesses.

- Shielding gas optimization: The use of appropriate shielding gases is essential for protecting the weld pool from atmospheric contamination and improving overall weld quality. Different gas compositions and flow rates can be optimized for specific materials and welding conditions to enhance weld appearance, reduce porosity, and improve mechanical properties.

- Seam tracking and adaptive control: Advanced laser welding systems incorporate seam tracking technologies and adaptive control algorithms to maintain precise alignment between the laser beam and the weld joint. These systems can compensate for part variations, thermal distortions, and positioning errors, ensuring consistent weld quality even in complex geometries or high-speed applications.

- Weld pool monitoring and analysis: Real-time monitoring of the weld pool using various sensors and imaging techniques allows for immediate detection of weld defects and quality issues. Advanced systems can analyze weld pool dynamics, temperature distribution, and solidification patterns to optimize welding parameters on-the-fly and ensure consistent weld quality throughout the process.

- Post-weld quality assessment: Non-destructive testing methods and automated inspection systems are employed to assess weld quality after the welding process. These may include visual inspection, ultrasonic testing, radiography, or other advanced techniques to detect internal defects, ensure proper fusion, and verify compliance with quality standards.

02 Monitoring and quality control systems

Implementing real-time monitoring and quality control systems can significantly improve welding quality. These systems use sensors and advanced algorithms to detect and analyze weld defects, thermal profiles, and process deviations during welding. This allows for immediate adjustments and ensures consistent weld quality across production runs.Expand Specific Solutions03 Material preparation and joint design

Proper material preparation and joint design are essential for high-quality laser welds. This includes cleaning and degreasing surfaces, ensuring precise fit-up, and optimizing joint geometries to enhance laser coupling and reduce the risk of defects such as porosity or incomplete fusion. Specialized joint designs can improve weld strength and appearance.Expand Specific Solutions04 Shielding gas optimization

Optimizing shielding gas composition and flow is critical for protecting the weld pool and achieving high-quality welds. Different gas mixtures can be used to control the weld pool dynamics, reduce oxidation, and improve the overall weld quality. Proper gas delivery systems and nozzle designs ensure effective shielding during the welding process.Expand Specific Solutions05 Post-weld treatment techniques

Various post-weld treatment techniques can enhance the quality and properties of laser-welded joints. These may include heat treatment to relieve residual stresses, surface finishing to improve appearance, and non-destructive testing methods to verify weld integrity. Such treatments can significantly improve the mechanical properties and longevity of welded components.Expand Specific Solutions

Industry Leaders

The laser welding of polypropylene components is an emerging technology in an early development stage, with a growing market driven by increasing demand for lightweight materials in automotive and consumer goods industries. The global market size for this specific application is still relatively small but expected to expand rapidly. Technologically, the process is moderately mature, with ongoing research to improve weld quality and efficiency. Key players like DuPont, Solvay, and SABIC are investing in R&D to enhance their polymer formulations for laser welding. Automotive manufacturers such as Toyota and Hyundai are also exploring this technology to reduce vehicle weight. While challenges remain in optimizing process parameters and material properties, collaborative efforts between material suppliers and end-users are accelerating progress in this field.

DuPont de Nemours, Inc.

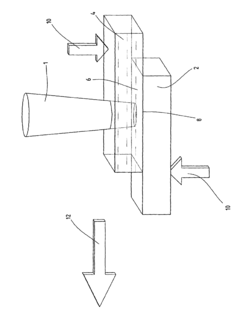

Technical Solution: DuPont has developed advanced laser welding techniques for polypropylene components, focusing on their Zytel® and Crastin® polymer families. Their approach utilizes a specialized laser-absorbing additive that enhances the energy absorption at the weld interface, allowing for precise and controlled welding of polypropylene parts[1]. The company has also introduced a novel through-transmission laser welding (TTLW) process, which enables the joining of dissimilar plastics, including polypropylene, without the need for additional absorbers or pigments[3]. This technology employs a dual-beam laser system that creates a more uniform heat distribution, resulting in stronger and more reliable welds[5].

Strengths: Innovative additive technology for enhanced laser absorption; Ability to weld dissimilar plastics; Improved weld strength and reliability. Weaknesses: May require specialized equipment; Potential for increased material costs due to additives.

SABIC Global Technologies BV

Technical Solution: SABIC has developed innovative laser welding techniques for polypropylene components, focusing on their STAMAX and SABIC PP compound families. Their approach involves the use of a proprietary laser-absorbing additive system that enhances energy absorption at the weld interface without affecting the bulk properties of the polypropylene[15]. SABIC has also introduced a novel laser welding process that utilizes a combination of fiber and diode lasers, allowing for improved control over heat distribution and weld penetration[17]. The company's technology incorporates advanced process monitoring and control systems, including real-time thermal imaging and closed-loop feedback mechanisms, to ensure consistent weld quality across various part geometries and thicknesses[19]. Additionally, SABIC has developed a specialized surface treatment process that enhances the weldability of polypropylene components, particularly for joining dissimilar materials or components with complex geometries[21].

Strengths: Proprietary laser-absorbing additive system; Advanced fiber and diode laser welding technology; Sophisticated process monitoring and control systems. Weaknesses: May require specific SABIC materials; Potential for increased production costs due to specialized equipment and additives.

Key Innovations

Method of welding two elements made from a polymer material which are opaque and resistant to high temperatures

PatentInactiveEP2047970A2

Innovation

- A process involving an upper element made opaque to visible light and transparent to laser radiation using a high-temperature resistant pigment, combined with a lower element containing micrometric carbon powder, allowing laser welding at the interface without altering the polymer material properties, using a laser source to scan and weld the assembly zone, ensuring a continuous and sealed joint.

Material Compatibility

Laser welding of polypropylene components presents unique challenges due to the material's specific properties. Polypropylene, a thermoplastic polymer, is known for its low density, high chemical resistance, and good fatigue resistance. However, its semi-crystalline structure and low surface energy can make it difficult to achieve strong and durable welds.

The compatibility of polypropylene with laser welding techniques depends on several factors. Firstly, the absorption of laser energy is crucial. Polypropylene naturally has low absorption in the near-infrared region, which is the typical wavelength range for many industrial lasers. To overcome this, additives or surface treatments may be necessary to enhance laser absorption and improve weldability.

Another critical aspect is the thermal behavior of polypropylene during the welding process. The material has a relatively low melting point and a narrow processing window, which requires precise control of laser parameters to avoid overheating or degradation. The high thermal expansion coefficient of polypropylene can also lead to residual stresses in the weld zone, potentially affecting the joint's long-term performance.

The molecular weight and crystallinity of the polypropylene grade used can significantly impact weldability. Higher molecular weight grades generally exhibit better weld strength but may require higher energy input. The degree of crystallinity affects both the melting behavior and the mechanical properties of the welded joint.

Surface preparation plays a vital role in achieving good material compatibility. Polypropylene's low surface energy can hinder wetting and adhesion at the weld interface. Techniques such as plasma treatment or chemical etching may be employed to modify the surface properties and enhance weldability.

The presence of fillers or reinforcements in polypropylene compounds can also influence laser welding compatibility. While some additives may improve laser absorption, others can interfere with the welding process or affect the final weld quality. Careful consideration of the compound formulation is essential for successful laser welding.

Lastly, the geometry and design of the components to be welded must be taken into account. Proper joint design, including features like energy directors or shear joints, can significantly improve the efficiency of laser energy transfer and the overall weld quality in polypropylene components.

The compatibility of polypropylene with laser welding techniques depends on several factors. Firstly, the absorption of laser energy is crucial. Polypropylene naturally has low absorption in the near-infrared region, which is the typical wavelength range for many industrial lasers. To overcome this, additives or surface treatments may be necessary to enhance laser absorption and improve weldability.

Another critical aspect is the thermal behavior of polypropylene during the welding process. The material has a relatively low melting point and a narrow processing window, which requires precise control of laser parameters to avoid overheating or degradation. The high thermal expansion coefficient of polypropylene can also lead to residual stresses in the weld zone, potentially affecting the joint's long-term performance.

The molecular weight and crystallinity of the polypropylene grade used can significantly impact weldability. Higher molecular weight grades generally exhibit better weld strength but may require higher energy input. The degree of crystallinity affects both the melting behavior and the mechanical properties of the welded joint.

Surface preparation plays a vital role in achieving good material compatibility. Polypropylene's low surface energy can hinder wetting and adhesion at the weld interface. Techniques such as plasma treatment or chemical etching may be employed to modify the surface properties and enhance weldability.

The presence of fillers or reinforcements in polypropylene compounds can also influence laser welding compatibility. While some additives may improve laser absorption, others can interfere with the welding process or affect the final weld quality. Careful consideration of the compound formulation is essential for successful laser welding.

Lastly, the geometry and design of the components to be welded must be taken into account. Proper joint design, including features like energy directors or shear joints, can significantly improve the efficiency of laser energy transfer and the overall weld quality in polypropylene components.

Environmental Impact

Laser welding of polypropylene components has gained significant attention due to its potential environmental benefits compared to traditional joining methods. The process offers reduced material waste, lower energy consumption, and decreased use of harmful chemicals, aligning with sustainable manufacturing practices.

One of the primary environmental advantages of laser welding for polypropylene is the elimination of adhesives and solvents typically used in conventional bonding techniques. This reduction in chemical usage not only minimizes the release of volatile organic compounds (VOCs) into the atmosphere but also simplifies the recycling process of polypropylene products at the end of their lifecycle.

The precision of laser welding contributes to material efficiency by minimizing scrap and rework. The highly focused energy input allows for localized heating, reducing the overall thermal impact on the surrounding material. This targeted approach results in less material degradation and potentially extends the lifespan of polypropylene components, thereby reducing waste generation over time.

Energy efficiency is another crucial aspect of laser welding's environmental impact. Compared to traditional welding methods, laser welding consumes less energy per unit of weld, particularly in high-volume production scenarios. The rapid processing speeds and reduced heat-affected zones contribute to lower overall energy requirements, potentially decreasing the carbon footprint associated with manufacturing processes.

However, it is essential to consider the environmental implications of laser equipment production and maintenance. The manufacturing of laser systems and their components, such as rare earth elements used in certain laser types, may have environmental consequences that should be factored into a comprehensive lifecycle assessment.

The durability and quality of laser-welded polypropylene joints can lead to improved product longevity, indirectly benefiting the environment by reducing the frequency of replacements and associated waste. Additionally, the ability to create complex, lightweight structures through laser welding can contribute to material reduction in various applications, such as automotive components, potentially leading to improved fuel efficiency and reduced emissions.

As industries increasingly prioritize circular economy principles, the recyclability of laser-welded polypropylene products becomes a critical consideration. The clean, contaminant-free welds produced by laser technology may facilitate easier separation and recycling of polypropylene components, supporting closed-loop material systems and reducing reliance on virgin plastics.

One of the primary environmental advantages of laser welding for polypropylene is the elimination of adhesives and solvents typically used in conventional bonding techniques. This reduction in chemical usage not only minimizes the release of volatile organic compounds (VOCs) into the atmosphere but also simplifies the recycling process of polypropylene products at the end of their lifecycle.

The precision of laser welding contributes to material efficiency by minimizing scrap and rework. The highly focused energy input allows for localized heating, reducing the overall thermal impact on the surrounding material. This targeted approach results in less material degradation and potentially extends the lifespan of polypropylene components, thereby reducing waste generation over time.

Energy efficiency is another crucial aspect of laser welding's environmental impact. Compared to traditional welding methods, laser welding consumes less energy per unit of weld, particularly in high-volume production scenarios. The rapid processing speeds and reduced heat-affected zones contribute to lower overall energy requirements, potentially decreasing the carbon footprint associated with manufacturing processes.

However, it is essential to consider the environmental implications of laser equipment production and maintenance. The manufacturing of laser systems and their components, such as rare earth elements used in certain laser types, may have environmental consequences that should be factored into a comprehensive lifecycle assessment.

The durability and quality of laser-welded polypropylene joints can lead to improved product longevity, indirectly benefiting the environment by reducing the frequency of replacements and associated waste. Additionally, the ability to create complex, lightweight structures through laser welding can contribute to material reduction in various applications, such as automotive components, potentially leading to improved fuel efficiency and reduced emissions.

As industries increasingly prioritize circular economy principles, the recyclability of laser-welded polypropylene products becomes a critical consideration. The clean, contaminant-free welds produced by laser technology may facilitate easier separation and recycling of polypropylene components, supporting closed-loop material systems and reducing reliance on virgin plastics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!