How Polypropylene Underpins Flexible Electronics Advancements

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene in Flexible Electronics: Background and Objectives

Polypropylene, a versatile thermoplastic polymer, has emerged as a key material in the rapidly evolving field of flexible electronics. The journey of polypropylene in this domain traces back to the early 2000s when researchers began exploring its potential as a substrate for flexible electronic devices. As the demand for lightweight, bendable, and durable electronic components grew, polypropylene's unique properties caught the attention of scientists and engineers alike.

The development of flexible electronics represents a paradigm shift from traditional rigid circuit boards to malleable, conformable systems that can be integrated into various form factors. This transition has been driven by the increasing need for wearable devices, foldable displays, and IoT sensors that can adapt to non-planar surfaces. Polypropylene's role in this evolution has been pivotal, offering a combination of flexibility, chemical resistance, and low cost that makes it an attractive option for manufacturers.

The primary objective of incorporating polypropylene into flexible electronics is to create a new generation of devices that can withstand mechanical stress while maintaining electrical performance. Researchers aim to leverage polypropylene's inherent properties to develop substrates that can support conductive inks, thin-film transistors, and other electronic components without compromising functionality under bending or stretching conditions.

Another critical goal is to enhance the durability and longevity of flexible electronic devices. Polypropylene's resistance to moisture and chemicals makes it an ideal candidate for protecting sensitive electronic components from environmental factors, potentially extending the lifespan of flexible devices and broadening their application scope.

Furthermore, the integration of polypropylene in flexible electronics aligns with the broader trend towards sustainable and recyclable materials in technology. As environmental concerns become increasingly prominent, the ability to create eco-friendly electronic devices using recyclable polymers like polypropylene has become a significant focus for researchers and manufacturers alike.

The technological trajectory of polypropylene in flexible electronics is characterized by continuous improvements in material properties and processing techniques. Scientists are exploring methods to enhance polypropylene's surface properties, increase its thermal stability, and improve its compatibility with various electronic materials. These advancements aim to push the boundaries of what's possible in flexible electronics, enabling the creation of more sophisticated and reliable devices.

The development of flexible electronics represents a paradigm shift from traditional rigid circuit boards to malleable, conformable systems that can be integrated into various form factors. This transition has been driven by the increasing need for wearable devices, foldable displays, and IoT sensors that can adapt to non-planar surfaces. Polypropylene's role in this evolution has been pivotal, offering a combination of flexibility, chemical resistance, and low cost that makes it an attractive option for manufacturers.

The primary objective of incorporating polypropylene into flexible electronics is to create a new generation of devices that can withstand mechanical stress while maintaining electrical performance. Researchers aim to leverage polypropylene's inherent properties to develop substrates that can support conductive inks, thin-film transistors, and other electronic components without compromising functionality under bending or stretching conditions.

Another critical goal is to enhance the durability and longevity of flexible electronic devices. Polypropylene's resistance to moisture and chemicals makes it an ideal candidate for protecting sensitive electronic components from environmental factors, potentially extending the lifespan of flexible devices and broadening their application scope.

Furthermore, the integration of polypropylene in flexible electronics aligns with the broader trend towards sustainable and recyclable materials in technology. As environmental concerns become increasingly prominent, the ability to create eco-friendly electronic devices using recyclable polymers like polypropylene has become a significant focus for researchers and manufacturers alike.

The technological trajectory of polypropylene in flexible electronics is characterized by continuous improvements in material properties and processing techniques. Scientists are exploring methods to enhance polypropylene's surface properties, increase its thermal stability, and improve its compatibility with various electronic materials. These advancements aim to push the boundaries of what's possible in flexible electronics, enabling the creation of more sophisticated and reliable devices.

Market Demand Analysis for Flexible Electronic Devices

The flexible electronics market has been experiencing significant growth, driven by increasing demand for wearable devices, foldable smartphones, and other innovative applications. This surge in demand is largely attributed to the unique properties of flexible electronic devices, such as their lightweight nature, bendability, and potential for integration into various form factors.

Consumer electronics represent a major segment driving the market demand for flexible electronic devices. The global smartwatch market, for instance, is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is fueled by rising health consciousness among consumers and the integration of advanced features like fitness tracking and ECG monitoring.

The healthcare sector is another key driver of demand for flexible electronics. The market for flexible medical sensors and wearable health monitoring devices is expanding rapidly, with applications ranging from continuous glucose monitoring to smart bandages for wound care. The ability of these devices to conform to the human body and provide real-time health data is revolutionizing patient care and preventive medicine.

In the automotive industry, flexible electronics are gaining traction for applications such as touch-sensitive control panels, heads-up displays, and advanced driver assistance systems. The integration of these technologies is expected to enhance user experience and safety features in vehicles, contributing to the overall market growth.

The energy sector is also showing increased interest in flexible electronic devices, particularly in the form of flexible solar cells and batteries. These technologies offer the potential for more efficient and versatile energy harvesting and storage solutions, which could have significant implications for renewable energy adoption and portable power applications.

Geographically, Asia-Pacific is expected to dominate the flexible electronics market, with countries like China, South Korea, and Japan leading in both production and consumption. North America and Europe are also significant markets, driven by technological advancements and high consumer adoption rates of wearable devices.

Despite the positive outlook, challenges such as high production costs and technical limitations in certain applications may impact market growth. However, ongoing research and development efforts, particularly in materials science and manufacturing processes, are expected to address these challenges and further expand the market potential for flexible electronic devices.

Consumer electronics represent a major segment driving the market demand for flexible electronic devices. The global smartwatch market, for instance, is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is fueled by rising health consciousness among consumers and the integration of advanced features like fitness tracking and ECG monitoring.

The healthcare sector is another key driver of demand for flexible electronics. The market for flexible medical sensors and wearable health monitoring devices is expanding rapidly, with applications ranging from continuous glucose monitoring to smart bandages for wound care. The ability of these devices to conform to the human body and provide real-time health data is revolutionizing patient care and preventive medicine.

In the automotive industry, flexible electronics are gaining traction for applications such as touch-sensitive control panels, heads-up displays, and advanced driver assistance systems. The integration of these technologies is expected to enhance user experience and safety features in vehicles, contributing to the overall market growth.

The energy sector is also showing increased interest in flexible electronic devices, particularly in the form of flexible solar cells and batteries. These technologies offer the potential for more efficient and versatile energy harvesting and storage solutions, which could have significant implications for renewable energy adoption and portable power applications.

Geographically, Asia-Pacific is expected to dominate the flexible electronics market, with countries like China, South Korea, and Japan leading in both production and consumption. North America and Europe are also significant markets, driven by technological advancements and high consumer adoption rates of wearable devices.

Despite the positive outlook, challenges such as high production costs and technical limitations in certain applications may impact market growth. However, ongoing research and development efforts, particularly in materials science and manufacturing processes, are expected to address these challenges and further expand the market potential for flexible electronic devices.

Current Challenges in Polypropylene-based Flexible Electronics

Despite the promising advancements in polypropylene-based flexible electronics, several significant challenges persist in this field. One of the primary obstacles is the inherent rigidity of polypropylene, which limits its flexibility and stretchability. While polypropylene offers excellent chemical resistance and low cost, its molecular structure results in a relatively high Young's modulus, making it less pliable compared to other polymers used in flexible electronics.

Another critical challenge lies in the integration of electronic components with polypropylene substrates. The low surface energy of polypropylene makes it difficult to achieve strong adhesion between the polymer and conductive materials, such as metal inks or nanoparticles. This poor adhesion can lead to delamination and failure of the electronic devices under mechanical stress or repeated bending cycles.

The thermal stability of polypropylene-based flexible electronics also presents a significant hurdle. Polypropylene has a relatively low melting point, which can cause issues during the manufacturing process and limit the operating temperature range of the final devices. This thermal sensitivity can result in performance degradation or device failure when exposed to high temperatures or rapid temperature fluctuations.

Furthermore, the barrier properties of polypropylene against moisture and oxygen permeation are not as effective as some other polymers used in flexible electronics. This can lead to reduced longevity and reliability of the electronic components, especially in applications where exposure to environmental factors is a concern.

The development of efficient and scalable manufacturing processes for polypropylene-based flexible electronics remains a challenge. Current techniques often involve complex multi-step processes, which can be time-consuming and costly. Achieving high-throughput production while maintaining consistent quality and performance across large areas is an ongoing area of research and development.

Lastly, the environmental impact and recyclability of polypropylene-based flexible electronics pose challenges in the context of sustainable technology development. While polypropylene itself is recyclable, the integration of electronic components and additives can complicate the recycling process, potentially limiting the eco-friendliness of these devices.

Addressing these challenges requires interdisciplinary research efforts, combining materials science, electrical engineering, and manufacturing technologies. Innovations in polymer chemistry, surface modification techniques, and novel device architectures are crucial for overcoming the current limitations and unlocking the full potential of polypropylene in flexible electronics applications.

Another critical challenge lies in the integration of electronic components with polypropylene substrates. The low surface energy of polypropylene makes it difficult to achieve strong adhesion between the polymer and conductive materials, such as metal inks or nanoparticles. This poor adhesion can lead to delamination and failure of the electronic devices under mechanical stress or repeated bending cycles.

The thermal stability of polypropylene-based flexible electronics also presents a significant hurdle. Polypropylene has a relatively low melting point, which can cause issues during the manufacturing process and limit the operating temperature range of the final devices. This thermal sensitivity can result in performance degradation or device failure when exposed to high temperatures or rapid temperature fluctuations.

Furthermore, the barrier properties of polypropylene against moisture and oxygen permeation are not as effective as some other polymers used in flexible electronics. This can lead to reduced longevity and reliability of the electronic components, especially in applications where exposure to environmental factors is a concern.

The development of efficient and scalable manufacturing processes for polypropylene-based flexible electronics remains a challenge. Current techniques often involve complex multi-step processes, which can be time-consuming and costly. Achieving high-throughput production while maintaining consistent quality and performance across large areas is an ongoing area of research and development.

Lastly, the environmental impact and recyclability of polypropylene-based flexible electronics pose challenges in the context of sustainable technology development. While polypropylene itself is recyclable, the integration of electronic components and additives can complicate the recycling process, potentially limiting the eco-friendliness of these devices.

Addressing these challenges requires interdisciplinary research efforts, combining materials science, electrical engineering, and manufacturing technologies. Innovations in polymer chemistry, surface modification techniques, and novel device architectures are crucial for overcoming the current limitations and unlocking the full potential of polypropylene in flexible electronics applications.

Existing Polypropylene-based Solutions for Flexible Electronics

01 Copolymerization with other monomers

Improving polypropylene flexibility through copolymerization with other monomers such as ethylene or alpha-olefins. This method can create a balance between rigidity and flexibility, enhancing the overall properties of the polymer.- Copolymerization with other monomers: Improving polypropylene flexibility through copolymerization with other monomers such as ethylene or alpha-olefins. This method can create a balance between flexibility and other desirable properties like strength and impact resistance.

- Incorporation of elastomeric components: Enhancing polypropylene flexibility by blending with elastomeric components or rubber-like materials. This approach can significantly improve the overall flexibility and impact resistance of the resulting polymer composite.

- Use of plasticizers: Adding plasticizers to polypropylene to increase its flexibility. Plasticizers work by reducing the intermolecular forces between polymer chains, allowing for greater mobility and flexibility in the material.

- Modification of molecular structure: Altering the molecular structure of polypropylene through various techniques such as controlled branching, stereoregularity adjustment, or molecular weight distribution modification to enhance flexibility while maintaining other key properties.

- Nanocomposite formulation: Incorporating nanoparticles or nanofillers into polypropylene to create nanocomposites with improved flexibility. This method can also enhance other properties such as strength, barrier properties, and thermal stability.

02 Addition of elastomers or plastomers

Incorporating elastomers or plastomers into polypropylene to increase its flexibility. These additives can improve impact resistance and reduce brittleness while maintaining other desirable properties of polypropylene.Expand Specific Solutions03 Nucleating agents and crystal structure modification

Using nucleating agents or modifying the crystal structure of polypropylene to enhance its flexibility. This approach can lead to improved mechanical properties and processability of the polymer.Expand Specific Solutions04 Blending with other polymers

Blending polypropylene with other polymers to achieve desired flexibility. This method allows for tailoring the properties of the final material by combining the characteristics of different polymers.Expand Specific Solutions05 Processing techniques and additives

Employing specific processing techniques or incorporating additives to enhance the flexibility of polypropylene. This can include the use of plasticizers, compatibilizers, or specialized extrusion and molding processes to achieve the desired flexibility.Expand Specific Solutions

Key Players in Polypropylene and Flexible Electronics Industries

The flexible electronics market is in a growth phase, with polypropylene playing a crucial role in advancing the technology. The market size is expanding rapidly, driven by increasing demand for wearable devices and IoT applications. Technologically, the field is progressing from early-stage development to more mature applications. Companies like Mitsui Chemicals, SABIC, and Borealis AG are at the forefront, developing innovative polypropylene-based materials for flexible electronics. Research institutions such as the University of Illinois and Industrial Technology Research Institute are contributing significantly to technological advancements. The competitive landscape is diverse, with both established chemical companies and emerging tech firms vying for market share in this promising sector.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced polypropylene (PP) grades specifically tailored for flexible electronics applications. Their proprietary catalyst technology enables the production of ultra-high melt strength PP with enhanced flexibility and durability[1]. This material exhibits excellent bendability and folding endurance, crucial for flexible displays and wearable devices. Sinopec's PP formulations incorporate nanofillers to improve thermal stability and electrical conductivity, addressing key challenges in flexible electronics[3]. The company has also pioneered a solvent-free extrusion process for PP-based flexible substrates, reducing environmental impact and production costs[5].

Strengths: Extensive R&D capabilities, vertically integrated production, and strong market presence in Asia. Weaknesses: Potential concerns over intellectual property protection and international expansion challenges.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed a series of specialty polypropylene grades under their TAFMER™ brand, specifically designed for flexible electronics applications. These materials feature ultra-low modulus and high elasticity, allowing for repeated bending and folding without compromising electrical performance[2]. Mitsui's PP-based compounds incorporate proprietary additives that enhance adhesion to metal layers, crucial for creating durable flexible circuits[4]. The company has also introduced a novel PP-based composite material that combines flexibility with improved barrier properties, addressing moisture sensitivity issues in flexible electronics[6].

Strengths: Strong expertise in polymer science, established global supply chain, and diverse product portfolio. Weaknesses: Relatively higher production costs and potential limitations in extreme temperature applications.

Core Innovations in Polypropylene for Flexible Electronics

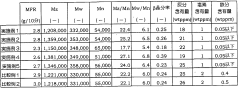

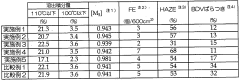

Polypropylene and application of said polypropylene to electric material

PatentWO2006057066A1

Innovation

- Development of a polypropylene with tightly controlled properties, including a melt flow rate of 0.1 to 30 g/10 minutes, mesopentad fraction of 0.90 to 0.99, and reduced titanium, iron, and chlorine content, achieved through advanced polymerization processes and post-treatment methods to minimize impurities and ensure consistent molecular weight distribution.

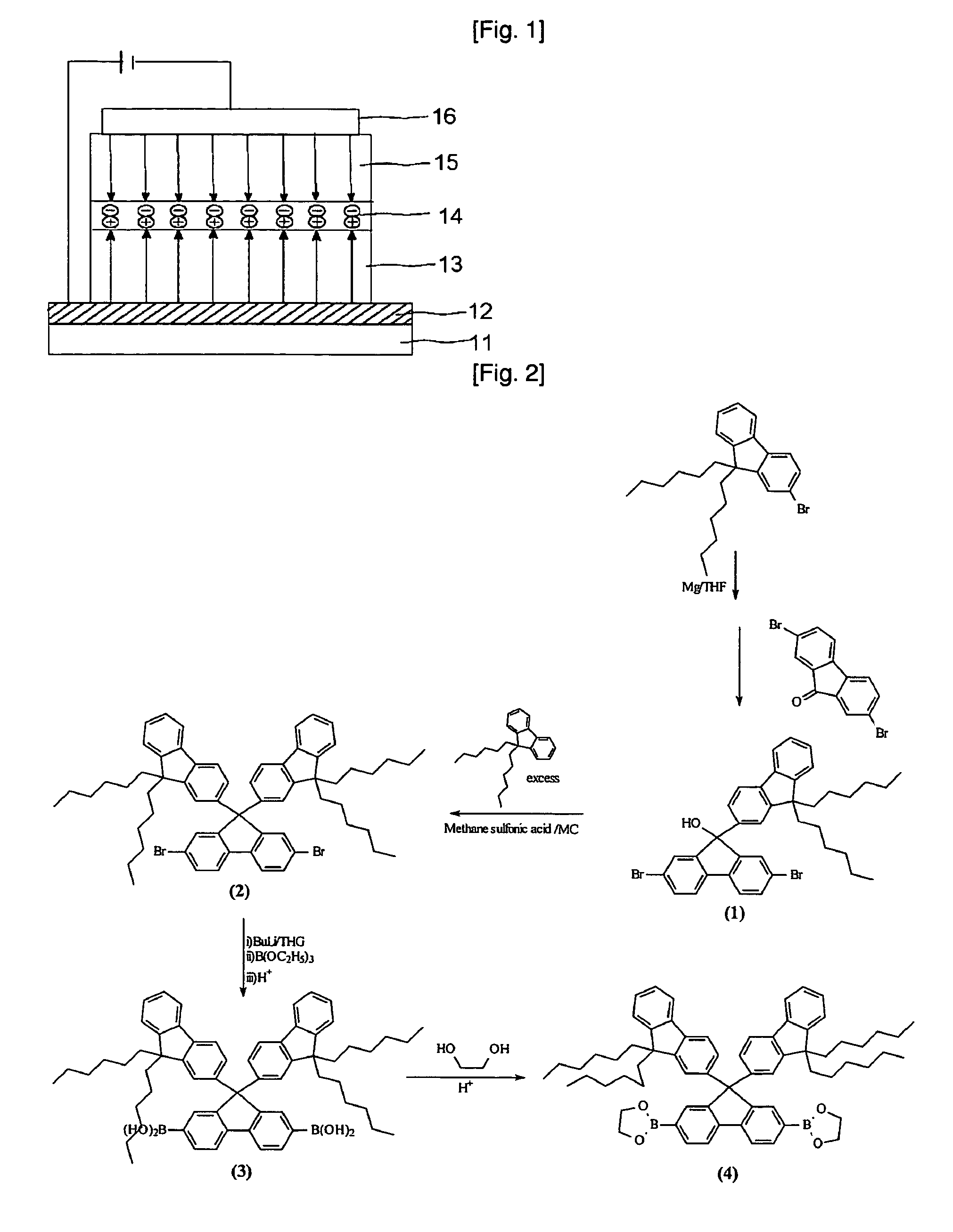

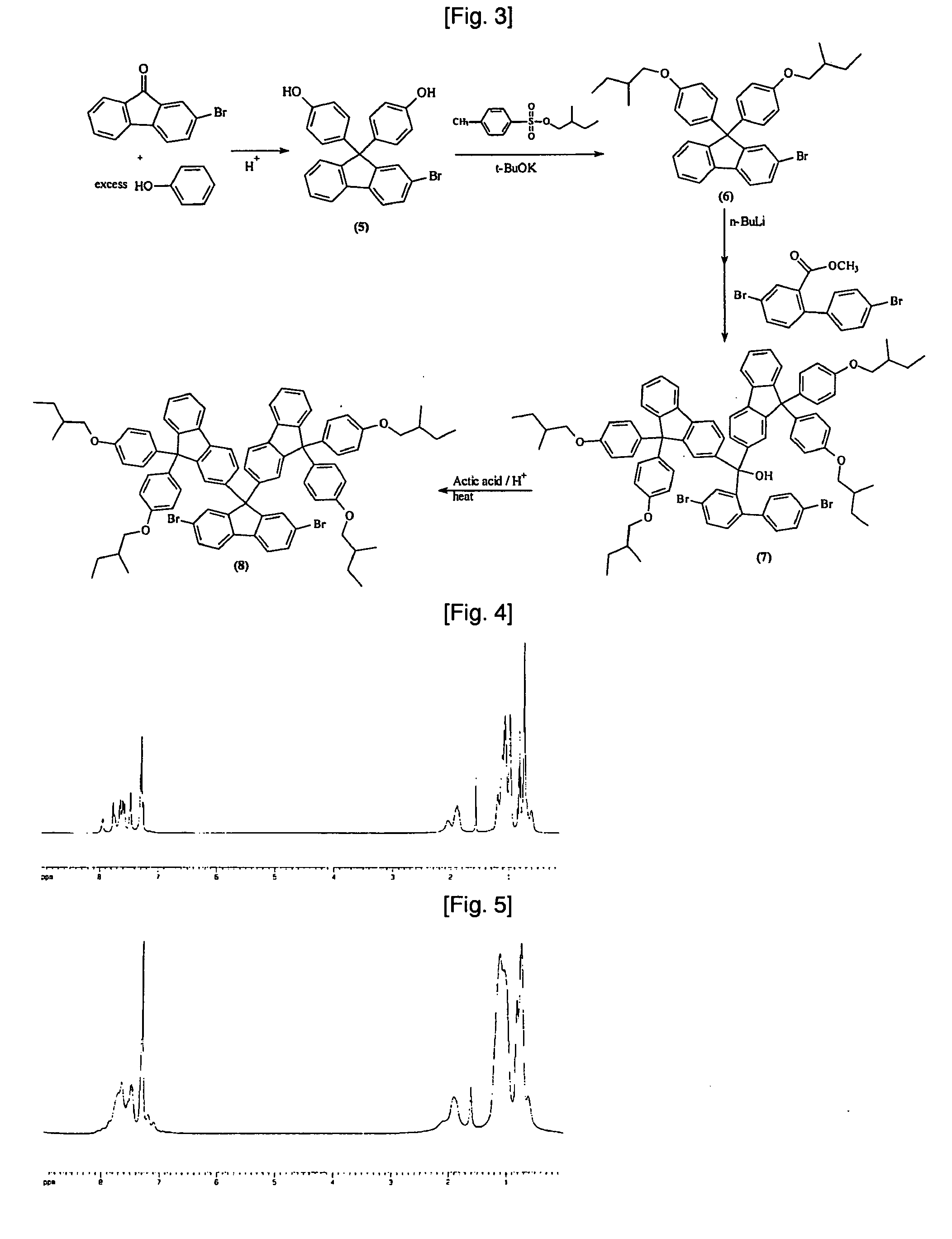

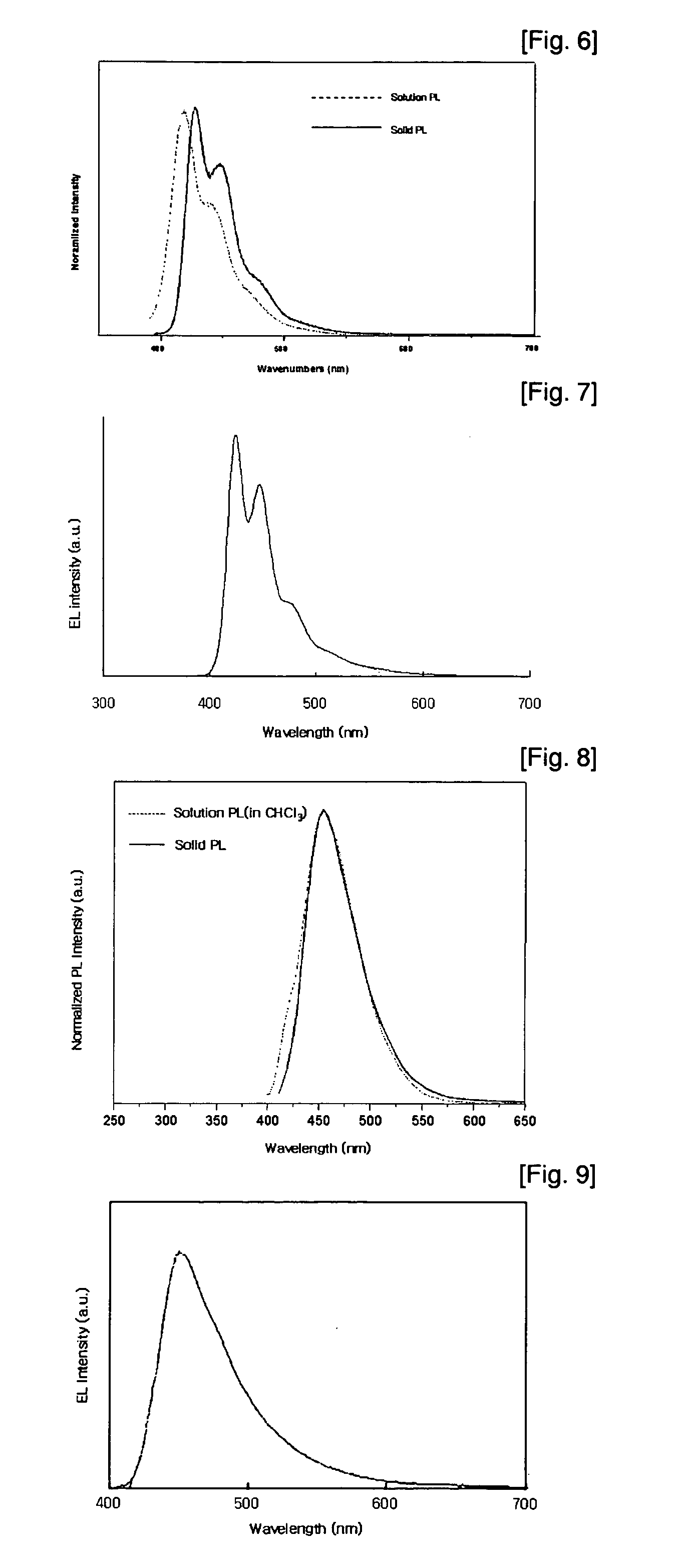

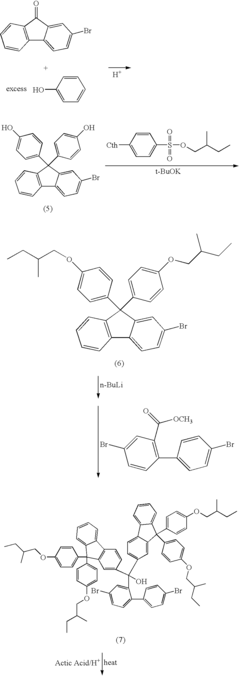

Organic electroluminescent polymer having 9,9-di(fluorenyl)-2,7-fluorenyl unit and organic electroluminescent device manufactured using the same

PatentInactiveUS20070093643A1

Innovation

- An organic electroluminescent polymer with a 9,9-di(fluorenyl)-2,7-fluorenyl unit is developed, which serves as a host material for blue, green, and red luminescence, offering high heat stability, solubility, and minimized molecule interaction through the introduction of a bulky fluorenyl substituent at the 9-position of fluorene, inhibiting excimer formation and allowing efficient energy transfer.

Environmental Impact of Polypropylene in Electronics

The environmental impact of polypropylene in flexible electronics is a critical consideration as the industry continues to advance. Polypropylene, a versatile thermoplastic polymer, has become increasingly prevalent in electronic applications due to its favorable properties. However, its widespread use raises concerns about sustainability and ecological consequences.

One of the primary environmental challenges associated with polypropylene in electronics is its end-of-life management. As a petroleum-based plastic, polypropylene is not biodegradable and can persist in the environment for hundreds of years. When electronic devices containing polypropylene components are discarded improperly, they contribute to the growing problem of electronic waste (e-waste). This accumulation of non-biodegradable materials in landfills poses long-term risks to ecosystems and wildlife.

The production process of polypropylene also has significant environmental implications. The extraction and refining of petroleum, the raw material for polypropylene, contribute to greenhouse gas emissions and potential environmental degradation. Additionally, the manufacturing of polypropylene involves energy-intensive processes, further increasing its carbon footprint.

However, it is important to note that polypropylene's use in flexible electronics can also have positive environmental impacts. The lightweight nature of polypropylene-based components can lead to reduced energy consumption during transportation and use of electronic devices. Furthermore, the durability and flexibility of polypropylene can extend the lifespan of electronic products, potentially reducing the frequency of replacements and, consequently, e-waste generation.

Efforts are being made to mitigate the environmental impact of polypropylene in electronics. Recycling initiatives are becoming more prevalent, with advanced sorting and processing technologies enabling the recovery and reuse of polypropylene from electronic waste. Some manufacturers are exploring bio-based alternatives to traditional polypropylene, derived from renewable resources, which could reduce reliance on fossil fuels and decrease overall environmental impact.

The electronics industry is also investigating ways to design products for easier disassembly and recycling, incorporating principles of circular economy. This approach aims to maximize the recovery and reuse of materials, including polypropylene, at the end of a product's life cycle. Additionally, research is ongoing to develop more environmentally friendly additives and processing methods for polypropylene, which could further reduce its ecological footprint in electronic applications.

As the flexible electronics sector continues to grow, balancing the benefits of polypropylene with its environmental impact remains a crucial challenge. Addressing this issue will require collaborative efforts from manufacturers, researchers, policymakers, and consumers to develop and implement sustainable practices throughout the lifecycle of polypropylene-based electronic components.

One of the primary environmental challenges associated with polypropylene in electronics is its end-of-life management. As a petroleum-based plastic, polypropylene is not biodegradable and can persist in the environment for hundreds of years. When electronic devices containing polypropylene components are discarded improperly, they contribute to the growing problem of electronic waste (e-waste). This accumulation of non-biodegradable materials in landfills poses long-term risks to ecosystems and wildlife.

The production process of polypropylene also has significant environmental implications. The extraction and refining of petroleum, the raw material for polypropylene, contribute to greenhouse gas emissions and potential environmental degradation. Additionally, the manufacturing of polypropylene involves energy-intensive processes, further increasing its carbon footprint.

However, it is important to note that polypropylene's use in flexible electronics can also have positive environmental impacts. The lightweight nature of polypropylene-based components can lead to reduced energy consumption during transportation and use of electronic devices. Furthermore, the durability and flexibility of polypropylene can extend the lifespan of electronic products, potentially reducing the frequency of replacements and, consequently, e-waste generation.

Efforts are being made to mitigate the environmental impact of polypropylene in electronics. Recycling initiatives are becoming more prevalent, with advanced sorting and processing technologies enabling the recovery and reuse of polypropylene from electronic waste. Some manufacturers are exploring bio-based alternatives to traditional polypropylene, derived from renewable resources, which could reduce reliance on fossil fuels and decrease overall environmental impact.

The electronics industry is also investigating ways to design products for easier disassembly and recycling, incorporating principles of circular economy. This approach aims to maximize the recovery and reuse of materials, including polypropylene, at the end of a product's life cycle. Additionally, research is ongoing to develop more environmentally friendly additives and processing methods for polypropylene, which could further reduce its ecological footprint in electronic applications.

As the flexible electronics sector continues to grow, balancing the benefits of polypropylene with its environmental impact remains a crucial challenge. Addressing this issue will require collaborative efforts from manufacturers, researchers, policymakers, and consumers to develop and implement sustainable practices throughout the lifecycle of polypropylene-based electronic components.

Scalability and Manufacturing Processes

The scalability and manufacturing processes of polypropylene-based flexible electronics are critical factors in their widespread adoption and commercial viability. Polypropylene's inherent properties, such as flexibility, durability, and low cost, make it an attractive substrate for large-scale production of flexible electronic devices.

One of the key advantages of polypropylene in flexible electronics manufacturing is its compatibility with roll-to-roll (R2R) processing. This continuous production method allows for high-throughput fabrication of flexible electronic components on large-area substrates. R2R processing enables the deposition of conductive materials, semiconductors, and protective layers onto polypropylene films in a continuous manner, significantly reducing production time and costs compared to batch processing methods.

The scalability of polypropylene-based flexible electronics is further enhanced by the material's ability to withstand various deposition and patterning techniques. These include physical vapor deposition, solution-based printing methods, and laser ablation. The versatility of polypropylene in accommodating different manufacturing processes allows for the integration of diverse electronic components on a single substrate, facilitating the production of complex, multi-functional devices.

Another important aspect of scalability is the potential for additive manufacturing techniques in polypropylene-based flexible electronics. 3D printing technologies, such as fused deposition modeling (FDM) and selective laser sintering (SLS), can be adapted to work with polypropylene materials. This opens up possibilities for rapid prototyping and customization of flexible electronic devices, potentially revolutionizing small-scale production and personalized electronics.

The manufacturing processes for polypropylene-based flexible electronics also benefit from the material's excellent chemical resistance. This property allows for the use of a wide range of solvents and chemicals during fabrication without compromising the substrate's integrity. Consequently, manufacturers can employ various etching, cleaning, and surface modification techniques to optimize device performance and yield.

However, challenges remain in scaling up production while maintaining consistent quality and performance. One such challenge is ensuring uniform surface properties across large-area polypropylene substrates. Variations in surface energy or roughness can affect the adhesion and uniformity of deposited materials, potentially leading to device failures or inconsistencies. To address this, researchers are developing advanced surface treatment methods and quality control processes specific to polypropylene substrates.

In conclusion, the scalability and manufacturing processes of polypropylene-based flexible electronics show great promise for large-scale production. The material's compatibility with R2R processing, versatility in accommodating various fabrication techniques, and potential for additive manufacturing make it a strong candidate for driving advancements in flexible electronics. As research continues to address remaining challenges, polypropylene is poised to play a crucial role in the future of scalable, cost-effective flexible electronic devices.

One of the key advantages of polypropylene in flexible electronics manufacturing is its compatibility with roll-to-roll (R2R) processing. This continuous production method allows for high-throughput fabrication of flexible electronic components on large-area substrates. R2R processing enables the deposition of conductive materials, semiconductors, and protective layers onto polypropylene films in a continuous manner, significantly reducing production time and costs compared to batch processing methods.

The scalability of polypropylene-based flexible electronics is further enhanced by the material's ability to withstand various deposition and patterning techniques. These include physical vapor deposition, solution-based printing methods, and laser ablation. The versatility of polypropylene in accommodating different manufacturing processes allows for the integration of diverse electronic components on a single substrate, facilitating the production of complex, multi-functional devices.

Another important aspect of scalability is the potential for additive manufacturing techniques in polypropylene-based flexible electronics. 3D printing technologies, such as fused deposition modeling (FDM) and selective laser sintering (SLS), can be adapted to work with polypropylene materials. This opens up possibilities for rapid prototyping and customization of flexible electronic devices, potentially revolutionizing small-scale production and personalized electronics.

The manufacturing processes for polypropylene-based flexible electronics also benefit from the material's excellent chemical resistance. This property allows for the use of a wide range of solvents and chemicals during fabrication without compromising the substrate's integrity. Consequently, manufacturers can employ various etching, cleaning, and surface modification techniques to optimize device performance and yield.

However, challenges remain in scaling up production while maintaining consistent quality and performance. One such challenge is ensuring uniform surface properties across large-area polypropylene substrates. Variations in surface energy or roughness can affect the adhesion and uniformity of deposited materials, potentially leading to device failures or inconsistencies. To address this, researchers are developing advanced surface treatment methods and quality control processes specific to polypropylene substrates.

In conclusion, the scalability and manufacturing processes of polypropylene-based flexible electronics show great promise for large-scale production. The material's compatibility with R2R processing, versatility in accommodating various fabrication techniques, and potential for additive manufacturing make it a strong candidate for driving advancements in flexible electronics. As research continues to address remaining challenges, polypropylene is poised to play a crucial role in the future of scalable, cost-effective flexible electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!