How Polypropylene Additives Improve Frictional Properties

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Additives Background and Objectives

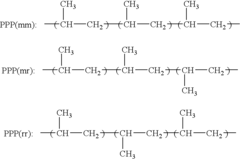

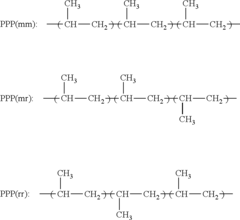

Polypropylene (PP) has been a cornerstone in the plastics industry since its discovery in the 1950s. As a versatile thermoplastic polymer, it has found applications across various sectors, from packaging to automotive parts. However, one of the inherent challenges with PP has been its frictional properties, which can limit its performance in certain applications.

The evolution of PP additives marks a significant milestone in addressing these limitations. Over the years, researchers and industry professionals have been working tirelessly to enhance the frictional properties of PP through the strategic use of additives. This technological advancement aims to expand the material's applicability and improve its overall performance in diverse environments.

The primary objective of incorporating additives into PP is to modify its surface characteristics, thereby altering its frictional behavior. This modification can lead to reduced wear, improved slip properties, and enhanced durability of PP-based products. The goal is to achieve a balance between maintaining the inherent strengths of PP while addressing its frictional limitations.

Recent trends in the field of PP additives have focused on developing more environmentally friendly and cost-effective solutions. There is a growing emphasis on bio-based additives and those that can be easily recycled along with the base polymer. This aligns with the global push towards sustainability in materials science and manufacturing.

The technological trajectory in this domain is moving towards smart additives that can respond to environmental stimuli, providing dynamic frictional properties. This could potentially lead to PP materials that adapt their surface characteristics based on usage conditions, opening up new avenues for application in advanced engineering and consumer products.

As we delve deeper into this topic, it's crucial to understand the interplay between the chemical structure of PP, the mechanisms of various additives, and their combined effect on frictional properties. This understanding forms the foundation for future innovations in the field, potentially leading to breakthroughs in material science and polymer engineering.

The ongoing research in this area not only aims to improve the performance of PP but also to expand its applicability in high-performance applications where frictional properties play a critical role. This includes sectors such as automotive, aerospace, and advanced manufacturing, where the demands on material properties are increasingly stringent.

The evolution of PP additives marks a significant milestone in addressing these limitations. Over the years, researchers and industry professionals have been working tirelessly to enhance the frictional properties of PP through the strategic use of additives. This technological advancement aims to expand the material's applicability and improve its overall performance in diverse environments.

The primary objective of incorporating additives into PP is to modify its surface characteristics, thereby altering its frictional behavior. This modification can lead to reduced wear, improved slip properties, and enhanced durability of PP-based products. The goal is to achieve a balance between maintaining the inherent strengths of PP while addressing its frictional limitations.

Recent trends in the field of PP additives have focused on developing more environmentally friendly and cost-effective solutions. There is a growing emphasis on bio-based additives and those that can be easily recycled along with the base polymer. This aligns with the global push towards sustainability in materials science and manufacturing.

The technological trajectory in this domain is moving towards smart additives that can respond to environmental stimuli, providing dynamic frictional properties. This could potentially lead to PP materials that adapt their surface characteristics based on usage conditions, opening up new avenues for application in advanced engineering and consumer products.

As we delve deeper into this topic, it's crucial to understand the interplay between the chemical structure of PP, the mechanisms of various additives, and their combined effect on frictional properties. This understanding forms the foundation for future innovations in the field, potentially leading to breakthroughs in material science and polymer engineering.

The ongoing research in this area not only aims to improve the performance of PP but also to expand its applicability in high-performance applications where frictional properties play a critical role. This includes sectors such as automotive, aerospace, and advanced manufacturing, where the demands on material properties are increasingly stringent.

Market Demand for Enhanced Frictional Properties

The market demand for enhanced frictional properties in polypropylene (PP) materials has been steadily growing across various industries. This demand is primarily driven by the need for improved safety, performance, and efficiency in a wide range of applications. In the automotive sector, there is a significant push for materials with better grip and wear resistance, particularly for interior components such as dashboards, door panels, and seat covers. These enhanced properties contribute to improved user experience and safety features in vehicles.

The packaging industry also shows a strong interest in PP materials with enhanced frictional properties. Manufacturers seek solutions that provide better stackability and handling of containers, reducing the risk of slippage during transportation and storage. This demand extends to food packaging, where improved friction control can enhance the sealing performance of containers, ensuring better product protection and longer shelf life.

In the construction sector, there is a growing need for PP materials with enhanced frictional properties for applications such as geotextiles and synthetic turf. These materials require specific friction characteristics to ensure stability and durability in various environmental conditions. The demand is further amplified by the increasing use of PP in roofing membranes and waterproofing systems, where slip resistance is crucial for safety during installation and maintenance.

The textile industry represents another significant market for PP with improved frictional properties. Manufacturers of sportswear and outdoor gear are particularly interested in materials that offer better grip and abrasion resistance. This demand is driven by consumer preferences for high-performance apparel that can withstand rigorous use in diverse environments.

In the medical and healthcare sectors, there is a growing demand for PP materials with enhanced frictional properties for use in medical devices, surgical instruments, and personal protective equipment. These applications require materials that provide a secure grip, even in wet or contaminated conditions, to ensure safety and precision during medical procedures.

The consumer goods industry also contributes to the market demand, with manufacturers seeking PP materials that offer improved tactile properties and surface textures for products ranging from household appliances to personal care items. This demand is often driven by the desire to enhance user experience and product differentiation in competitive markets.

As sustainability becomes an increasingly important factor in material selection, there is a growing interest in environmentally friendly additives that can enhance the frictional properties of PP without compromising its recyclability or increasing its environmental footprint. This trend is likely to shape future market demands and drive innovation in additive technologies for PP.

The packaging industry also shows a strong interest in PP materials with enhanced frictional properties. Manufacturers seek solutions that provide better stackability and handling of containers, reducing the risk of slippage during transportation and storage. This demand extends to food packaging, where improved friction control can enhance the sealing performance of containers, ensuring better product protection and longer shelf life.

In the construction sector, there is a growing need for PP materials with enhanced frictional properties for applications such as geotextiles and synthetic turf. These materials require specific friction characteristics to ensure stability and durability in various environmental conditions. The demand is further amplified by the increasing use of PP in roofing membranes and waterproofing systems, where slip resistance is crucial for safety during installation and maintenance.

The textile industry represents another significant market for PP with improved frictional properties. Manufacturers of sportswear and outdoor gear are particularly interested in materials that offer better grip and abrasion resistance. This demand is driven by consumer preferences for high-performance apparel that can withstand rigorous use in diverse environments.

In the medical and healthcare sectors, there is a growing demand for PP materials with enhanced frictional properties for use in medical devices, surgical instruments, and personal protective equipment. These applications require materials that provide a secure grip, even in wet or contaminated conditions, to ensure safety and precision during medical procedures.

The consumer goods industry also contributes to the market demand, with manufacturers seeking PP materials that offer improved tactile properties and surface textures for products ranging from household appliances to personal care items. This demand is often driven by the desire to enhance user experience and product differentiation in competitive markets.

As sustainability becomes an increasingly important factor in material selection, there is a growing interest in environmentally friendly additives that can enhance the frictional properties of PP without compromising its recyclability or increasing its environmental footprint. This trend is likely to shape future market demands and drive innovation in additive technologies for PP.

Current Challenges in Polypropylene Friction Modification

Despite the widespread use of polypropylene in various industries, improving its frictional properties remains a significant challenge. The inherent nature of polypropylene, characterized by its low surface energy and non-polar structure, contributes to high friction coefficients and poor wear resistance. This poses difficulties in applications where smooth sliding or low friction is crucial, such as in automotive components, packaging materials, and consumer goods.

One of the primary challenges in polypropylene friction modification is achieving a balance between reducing friction and maintaining other desirable properties. Additives that effectively lower friction may negatively impact mechanical strength, thermal stability, or processability. For instance, some lubricating additives can migrate to the surface over time, leading to inconsistent performance and potential contamination issues in sensitive applications.

The development of durable friction-modifying solutions presents another hurdle. Many current additives provide only temporary improvements, as they can be worn away or degraded under prolonged use or harsh environmental conditions. This necessitates the creation of more robust, long-lasting friction modifiers that can withstand various operational stresses without compromising their effectiveness.

Environmental concerns and regulatory pressures add another layer of complexity to polypropylene friction modification. Traditional additives, such as certain types of silicones or fluoropolymers, may face restrictions due to their potential environmental impact or health concerns. This drives the need for eco-friendly alternatives that can deliver comparable or superior friction-reducing performance while meeting stringent sustainability criteria.

The heterogeneous nature of polypropylene formulations across different grades and applications further complicates the development of universal friction-modifying solutions. Additives that work well in one type of polypropylene may not be as effective in another, necessitating tailored approaches for specific end-use requirements. This challenge is particularly evident in industries with diverse product portfolios, where a one-size-fits-all solution is rarely feasible.

Lastly, the integration of friction-modifying additives into existing manufacturing processes without significant disruption or cost increase remains a persistent challenge. New additives often require adjustments to processing parameters, which can be costly and time-consuming to implement at scale. Balancing the benefits of improved frictional properties against the potential complications in production and increased material costs is a critical consideration for manufacturers.

One of the primary challenges in polypropylene friction modification is achieving a balance between reducing friction and maintaining other desirable properties. Additives that effectively lower friction may negatively impact mechanical strength, thermal stability, or processability. For instance, some lubricating additives can migrate to the surface over time, leading to inconsistent performance and potential contamination issues in sensitive applications.

The development of durable friction-modifying solutions presents another hurdle. Many current additives provide only temporary improvements, as they can be worn away or degraded under prolonged use or harsh environmental conditions. This necessitates the creation of more robust, long-lasting friction modifiers that can withstand various operational stresses without compromising their effectiveness.

Environmental concerns and regulatory pressures add another layer of complexity to polypropylene friction modification. Traditional additives, such as certain types of silicones or fluoropolymers, may face restrictions due to their potential environmental impact or health concerns. This drives the need for eco-friendly alternatives that can deliver comparable or superior friction-reducing performance while meeting stringent sustainability criteria.

The heterogeneous nature of polypropylene formulations across different grades and applications further complicates the development of universal friction-modifying solutions. Additives that work well in one type of polypropylene may not be as effective in another, necessitating tailored approaches for specific end-use requirements. This challenge is particularly evident in industries with diverse product portfolios, where a one-size-fits-all solution is rarely feasible.

Lastly, the integration of friction-modifying additives into existing manufacturing processes without significant disruption or cost increase remains a persistent challenge. New additives often require adjustments to processing parameters, which can be costly and time-consuming to implement at scale. Balancing the benefits of improved frictional properties against the potential complications in production and increased material costs is a critical consideration for manufacturers.

Existing Friction Modification Solutions

01 Slip agents for improved frictional properties

Slip agents are additives incorporated into polypropylene to reduce surface friction and improve processing. These agents migrate to the surface of the polymer, creating a lubricating effect that enhances the material's slip characteristics. Common slip agents include fatty acid amides, silicone-based additives, and certain waxes. The addition of these agents can significantly reduce the coefficient of friction, leading to improved handling and processing of polypropylene products.- Slip agents for improved frictional properties: Slip agents are additives incorporated into polypropylene to reduce surface friction and improve processing. These agents migrate to the surface of the polymer, creating a lubricating effect that enhances the material's slip characteristics. Common slip agents include fatty acid amides, which can significantly reduce the coefficient of friction in polypropylene products.

- Inorganic fillers for enhanced mechanical properties: Inorganic fillers such as talc, calcium carbonate, and glass fibers are added to polypropylene to improve its mechanical properties, including stiffness and dimensional stability. These fillers can also affect the frictional properties of the polymer, often increasing surface roughness and altering the coefficient of friction.

- Polymer blends for optimized frictional characteristics: Blending polypropylene with other polymers or elastomers can modify its frictional properties. These blends can create a balance between slip and anti-slip characteristics, depending on the application requirements. The addition of elastomeric components, for instance, can increase the coefficient of friction for improved grip in certain products.

- Surface modification techniques: Various surface modification techniques can be applied to polypropylene to alter its frictional properties. These include plasma treatment, corona discharge, and the application of functional coatings. Such treatments can increase surface energy, improve adhesion, or create micro-textures that influence the material's frictional behavior.

- Antistatic additives for friction control: Antistatic additives are incorporated into polypropylene to reduce static charge buildup, which can indirectly affect frictional properties. By minimizing electrostatic attraction between surfaces, these additives can help maintain consistent frictional characteristics in applications where static electricity might otherwise cause sticking or irregular surface interactions.

02 Anti-static additives for friction reduction

Anti-static additives are used in polypropylene to dissipate static charge and indirectly improve frictional properties. These additives work by increasing the surface conductivity of the polymer, which helps prevent the accumulation of static electricity. By reducing static charge, these additives can minimize the attraction of dust and other particles to the surface, thereby maintaining smoother surfaces with lower friction. Common anti-static additives include quaternary ammonium compounds and certain types of polyethylene glycols.Expand Specific Solutions03 Surface modifiers for enhanced tribological properties

Surface modifiers are additives that alter the surface characteristics of polypropylene to improve its tribological properties, including friction and wear resistance. These additives can create a more uniform surface texture or form a protective layer on the polymer surface. Examples include certain fluoropolymers, silicone-based additives, and nanoparticles. By modifying the surface properties, these additives can significantly reduce the coefficient of friction and improve the overall performance of polypropylene in applications where low friction is critical.Expand Specific Solutions04 Lubricating additives for reduced friction

Lubricating additives are incorporated into polypropylene to reduce internal friction and improve flow properties during processing. These additives work by decreasing the melt viscosity and enhancing the polymer chain mobility. Common lubricating additives include metal stearates, certain waxes, and low molecular weight polyolefins. The use of these additives can lead to improved processability, reduced energy consumption during manufacturing, and enhanced surface finish of the final product.Expand Specific Solutions05 Nanocomposites for improved frictional characteristics

Nanocomposites formed by incorporating nanoparticles into polypropylene can significantly enhance its frictional properties. These nanoparticles, such as clay, silica, or carbon nanotubes, can improve the mechanical strength, thermal stability, and tribological properties of the polymer. The presence of nanoparticles can create a smoother surface at the nanoscale, reducing friction and wear. Additionally, some nanoparticles can act as solid lubricants, further enhancing the frictional characteristics of the polypropylene composite.Expand Specific Solutions

Key Players in Polypropylene Additive Industry

The competitive landscape for polypropylene additives improving frictional properties is in a mature stage, with a well-established market and steady growth. The global market size for these additives is estimated to be in the billions of dollars, driven by increasing demand in automotive, packaging, and consumer goods industries. Technologically, the field is relatively mature but continues to evolve, with companies like ExxonMobil Chemical Patents, Chevron Phillips Chemical, and Afton Chemical leading in innovation. Chinese players such as Sinopec and PetroChina are also making significant strides, leveraging their scale and research capabilities. European firms like Evonik and Solvay contribute advanced solutions, while Japanese companies like Mitsui Chemicals bring specialized expertise to the market.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced polypropylene additives to improve frictional properties. Their approach involves incorporating nano-scale inorganic particles, such as silica or titanium dioxide, into the polypropylene matrix. These nanoparticles create a surface roughness that reduces the contact area between the polymer and other surfaces, thereby lowering friction. Additionally, Sinopec has implemented a proprietary surface modification technique for these nanoparticles, enhancing their compatibility with the polypropylene and ensuring uniform dispersion[1][3]. The company has also explored the use of organic additives, such as fatty acid amides, which migrate to the surface of the polymer during processing, forming a lubricating layer that further reduces friction[2].

Strengths: Excellent friction reduction, improved wear resistance, and enhanced mechanical properties. Weaknesses: Potential increase in production costs and complexity in processing due to the incorporation of nanoparticles.

Chevron Phillips Chemical Co. LP

Technical Solution: Chevron Phillips Chemical Co. LP has developed a novel approach to improving the frictional properties of polypropylene through the use of specially designed copolymer additives. Their technology involves the synthesis of propylene-ethylene copolymers with controlled molecular weight and composition distribution. These copolymers are then blended with the base polypropylene resin at specific ratios. The copolymer additives migrate to the surface of the polypropylene during processing, creating a low-friction layer without significantly altering the bulk properties of the material[4]. Additionally, Chevron Phillips has incorporated slip agents, such as erucamide, into their formulations to further enhance the surface lubricity of the polypropylene[5]. The company has also explored the use of fluoropolymer additives in small quantities to achieve exceptional friction reduction in high-performance applications[6].

Strengths: Highly effective friction reduction, minimal impact on other material properties, and versatility across various applications. Weaknesses: Potential for higher costs due to the use of specialized copolymers and fluoropolymer additives.

Core Innovations in Polypropylene Additives

Polypropylene based fibers and nonwovens

PatentInactiveUS7998579B2

Innovation

- A polyolefin composition comprising polypropylene, a non-functionalized plasticizer with a viscosity index of 120 or more, and a functionalized slip agent, which is a fast bloom type, to enhance condrapability and flexibility without affecting melting temperature or clarity, and can be melt blended to avoid additional processing steps.

Polypropylene Based Fibers and Nonwovens

PatentInactiveUS20110253152A1

Innovation

- A polyolefin composition comprising polypropylene, a non-functionalized plasticizer with a viscosity index of 120 or more, and a functionalized slip agent, which enhances condrapability and flexibility without affecting melting temperature or clarity, and can be melt-blended for simplified processing.

Environmental Impact of Friction-Modifying Additives

The environmental impact of friction-modifying additives in polypropylene is a critical consideration in the development and application of these materials. These additives, while improving the frictional properties of polypropylene, can have both positive and negative effects on the environment throughout their lifecycle.

One of the primary environmental benefits of friction-modifying additives is their potential to reduce energy consumption. By lowering the coefficient of friction in polypropylene products, these additives can decrease the energy required for various applications, such as in automotive components or industrial machinery. This reduction in energy usage can lead to lower greenhouse gas emissions and a smaller carbon footprint for products utilizing these additives.

However, the production of friction-modifying additives often involves complex chemical processes that may have their own environmental implications. The synthesis of these additives can require significant energy inputs and may generate chemical waste that needs proper management and disposal. Additionally, some additives may be derived from non-renewable resources, raising concerns about long-term sustainability.

The use phase of products containing friction-modifying additives presents another set of environmental considerations. While these additives can extend the lifespan of products by reducing wear and tear, they may also alter the material properties of polypropylene in ways that affect its recyclability. Some additives may make it more challenging to separate and recycle polypropylene at the end of its life cycle, potentially increasing the amount of plastic waste that ends up in landfills or the environment.

Furthermore, the potential leaching of friction-modifying additives from polypropylene products during use or disposal is a growing concern. Some additives may be released into the environment over time, particularly when exposed to heat, UV radiation, or mechanical stress. These released chemicals could potentially accumulate in ecosystems, affecting wildlife and potentially entering the food chain.

To address these environmental challenges, researchers and manufacturers are exploring more sustainable alternatives for friction-modifying additives. This includes the development of bio-based additives derived from renewable resources, as well as additives designed to be more easily recyclable or biodegradable. Additionally, efforts are being made to optimize additive formulations to achieve the desired frictional properties with minimal environmental impact.

As regulations around plastic additives become more stringent, there is an increasing focus on life cycle assessments to evaluate the overall environmental impact of friction-modifying additives in polypropylene. These assessments consider factors such as raw material sourcing, production processes, use-phase benefits, and end-of-life disposal to provide a comprehensive view of the environmental implications of these additives.

One of the primary environmental benefits of friction-modifying additives is their potential to reduce energy consumption. By lowering the coefficient of friction in polypropylene products, these additives can decrease the energy required for various applications, such as in automotive components or industrial machinery. This reduction in energy usage can lead to lower greenhouse gas emissions and a smaller carbon footprint for products utilizing these additives.

However, the production of friction-modifying additives often involves complex chemical processes that may have their own environmental implications. The synthesis of these additives can require significant energy inputs and may generate chemical waste that needs proper management and disposal. Additionally, some additives may be derived from non-renewable resources, raising concerns about long-term sustainability.

The use phase of products containing friction-modifying additives presents another set of environmental considerations. While these additives can extend the lifespan of products by reducing wear and tear, they may also alter the material properties of polypropylene in ways that affect its recyclability. Some additives may make it more challenging to separate and recycle polypropylene at the end of its life cycle, potentially increasing the amount of plastic waste that ends up in landfills or the environment.

Furthermore, the potential leaching of friction-modifying additives from polypropylene products during use or disposal is a growing concern. Some additives may be released into the environment over time, particularly when exposed to heat, UV radiation, or mechanical stress. These released chemicals could potentially accumulate in ecosystems, affecting wildlife and potentially entering the food chain.

To address these environmental challenges, researchers and manufacturers are exploring more sustainable alternatives for friction-modifying additives. This includes the development of bio-based additives derived from renewable resources, as well as additives designed to be more easily recyclable or biodegradable. Additionally, efforts are being made to optimize additive formulations to achieve the desired frictional properties with minimal environmental impact.

As regulations around plastic additives become more stringent, there is an increasing focus on life cycle assessments to evaluate the overall environmental impact of friction-modifying additives in polypropylene. These assessments consider factors such as raw material sourcing, production processes, use-phase benefits, and end-of-life disposal to provide a comprehensive view of the environmental implications of these additives.

Regulatory Landscape for Polymer Additives

The regulatory landscape for polymer additives, particularly those used in polypropylene to improve frictional properties, is complex and constantly evolving. Regulatory bodies worldwide are increasingly focusing on the safety and environmental impact of these additives, leading to stricter guidelines and standards.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating polymer additives used in food contact materials. The FDA's Code of Federal Regulations Title 21, Part 177 specifically addresses polymers and additives in food packaging. For polypropylene additives, manufacturers must ensure compliance with these regulations, particularly when the end product is intended for food contact applications.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which significantly impacts the use of polymer additives. Under REACH, manufacturers and importers are required to register chemicals, including those used as additives in polypropylene, and provide safety data. This regulation has led to increased scrutiny of certain additives and, in some cases, restrictions or phase-outs of substances deemed to pose potential risks.

In Asia, countries like China and Japan have their own regulatory frameworks. China's GB standards for food contact materials are becoming increasingly stringent, while Japan's Positive List System for food contact materials sets specific requirements for additives used in polymers like polypropylene.

Environmental regulations are also shaping the landscape for polymer additives. The growing focus on sustainability and circular economy principles has led to increased pressure on manufacturers to develop additives that enhance recyclability and reduce environmental impact. This trend is reflected in regulations such as the EU's Circular Economy Action Plan, which aims to promote the use of recyclable and sustainable materials.

Occupational health and safety regulations further influence the development and use of polypropylene additives. Organizations like the Occupational Safety and Health Administration (OSHA) in the US set exposure limits and safety guidelines for workers handling these materials during manufacturing processes.

As concerns about microplastics and their environmental impact grow, regulators are beginning to consider new restrictions on polymer additives that may contribute to microplastic formation. This emerging area of regulation could have significant implications for the development of future friction-modifying additives for polypropylene.

The global nature of supply chains in the polymer industry necessitates compliance with multiple regulatory frameworks. Manufacturers must navigate this complex landscape to ensure their products meet the requirements of various markets, often leading to the adoption of the most stringent standards to ensure global compliance.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating polymer additives used in food contact materials. The FDA's Code of Federal Regulations Title 21, Part 177 specifically addresses polymers and additives in food packaging. For polypropylene additives, manufacturers must ensure compliance with these regulations, particularly when the end product is intended for food contact applications.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which significantly impacts the use of polymer additives. Under REACH, manufacturers and importers are required to register chemicals, including those used as additives in polypropylene, and provide safety data. This regulation has led to increased scrutiny of certain additives and, in some cases, restrictions or phase-outs of substances deemed to pose potential risks.

In Asia, countries like China and Japan have their own regulatory frameworks. China's GB standards for food contact materials are becoming increasingly stringent, while Japan's Positive List System for food contact materials sets specific requirements for additives used in polymers like polypropylene.

Environmental regulations are also shaping the landscape for polymer additives. The growing focus on sustainability and circular economy principles has led to increased pressure on manufacturers to develop additives that enhance recyclability and reduce environmental impact. This trend is reflected in regulations such as the EU's Circular Economy Action Plan, which aims to promote the use of recyclable and sustainable materials.

Occupational health and safety regulations further influence the development and use of polypropylene additives. Organizations like the Occupational Safety and Health Administration (OSHA) in the US set exposure limits and safety guidelines for workers handling these materials during manufacturing processes.

As concerns about microplastics and their environmental impact grow, regulators are beginning to consider new restrictions on polymer additives that may contribute to microplastic formation. This emerging area of regulation could have significant implications for the development of future friction-modifying additives for polypropylene.

The global nature of supply chains in the polymer industry necessitates compliance with multiple regulatory frameworks. Manufacturers must navigate this complex landscape to ensure their products meet the requirements of various markets, often leading to the adoption of the most stringent standards to ensure global compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!