Polypropylene Nanocomposites in Aerospace Engineering

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace PP Nanocomposites: Background and Objectives

Polypropylene (PP) nanocomposites have emerged as a promising material in aerospace engineering, offering a unique combination of lightweight properties and enhanced mechanical performance. The development of these advanced materials stems from the aerospace industry's continuous pursuit of lighter, stronger, and more durable components to improve fuel efficiency and overall aircraft performance.

The evolution of PP nanocomposites in aerospace applications can be traced back to the early 2000s when researchers began exploring the potential of incorporating nanoscale fillers into polymer matrices. This innovation was driven by the need to overcome the limitations of traditional composite materials, such as poor impact resistance and thermal stability. By introducing nanoparticles into the PP matrix, scientists aimed to create a new class of materials with superior mechanical, thermal, and barrier properties.

The primary objective of research on PP nanocomposites in aerospace engineering is to develop materials that can withstand the extreme conditions encountered during flight while maintaining their structural integrity. These conditions include high temperatures, rapid temperature fluctuations, exposure to UV radiation, and mechanical stress. Additionally, researchers aim to enhance the flame retardancy and chemical resistance of PP nanocomposites to meet the stringent safety requirements of the aerospace industry.

Another crucial goal is to optimize the manufacturing processes for PP nanocomposites to ensure consistent quality and scalability for large-scale production. This involves developing innovative techniques for dispersing nanoparticles uniformly within the polymer matrix and improving the interfacial adhesion between the nanofillers and the PP matrix. Such advancements are essential for realizing the full potential of these materials in aerospace applications.

The research on PP nanocomposites also aims to explore their potential in various aerospace components, including interior panels, structural elements, and even in advanced applications such as radar-absorbing materials for stealth technology. By tailoring the nanocomposite composition and structure, researchers seek to create multifunctional materials that can simultaneously address multiple engineering challenges in aerospace design.

As the field progresses, there is a growing focus on sustainability and environmental considerations. Researchers are investigating ways to incorporate bio-based nanofillers and develop recycling methods for PP nanocomposites, aligning with the aerospace industry's increasing emphasis on eco-friendly practices and circular economy principles.

The evolution of PP nanocomposites in aerospace applications can be traced back to the early 2000s when researchers began exploring the potential of incorporating nanoscale fillers into polymer matrices. This innovation was driven by the need to overcome the limitations of traditional composite materials, such as poor impact resistance and thermal stability. By introducing nanoparticles into the PP matrix, scientists aimed to create a new class of materials with superior mechanical, thermal, and barrier properties.

The primary objective of research on PP nanocomposites in aerospace engineering is to develop materials that can withstand the extreme conditions encountered during flight while maintaining their structural integrity. These conditions include high temperatures, rapid temperature fluctuations, exposure to UV radiation, and mechanical stress. Additionally, researchers aim to enhance the flame retardancy and chemical resistance of PP nanocomposites to meet the stringent safety requirements of the aerospace industry.

Another crucial goal is to optimize the manufacturing processes for PP nanocomposites to ensure consistent quality and scalability for large-scale production. This involves developing innovative techniques for dispersing nanoparticles uniformly within the polymer matrix and improving the interfacial adhesion between the nanofillers and the PP matrix. Such advancements are essential for realizing the full potential of these materials in aerospace applications.

The research on PP nanocomposites also aims to explore their potential in various aerospace components, including interior panels, structural elements, and even in advanced applications such as radar-absorbing materials for stealth technology. By tailoring the nanocomposite composition and structure, researchers seek to create multifunctional materials that can simultaneously address multiple engineering challenges in aerospace design.

As the field progresses, there is a growing focus on sustainability and environmental considerations. Researchers are investigating ways to incorporate bio-based nanofillers and develop recycling methods for PP nanocomposites, aligning with the aerospace industry's increasing emphasis on eco-friendly practices and circular economy principles.

Market Demand Analysis for Aerospace Materials

The aerospace industry has witnessed a growing demand for advanced materials that can meet the stringent requirements of modern aircraft and spacecraft. Polypropylene nanocomposites have emerged as a promising solution, offering a unique combination of lightweight properties, enhanced mechanical strength, and improved thermal stability. The market for aerospace materials is experiencing a significant shift towards these innovative composites, driven by the need for fuel efficiency, reduced emissions, and improved performance in extreme conditions.

The global aerospace materials market is projected to expand substantially in the coming years, with a particular focus on lightweight and high-performance materials. Polypropylene nanocomposites are well-positioned to capture a significant share of this growth, as they address several key challenges faced by the aerospace industry. The demand for these materials is primarily fueled by the commercial aircraft sector, where manufacturers are constantly seeking ways to reduce aircraft weight without compromising safety or durability.

Military aerospace applications also contribute to the increasing demand for polypropylene nanocomposites. The defense sector requires materials that can withstand extreme temperatures, high-impact forces, and corrosive environments while maintaining structural integrity. Polypropylene nanocomposites offer superior resistance to these factors, making them ideal for use in military aircraft and spacecraft components.

The space exploration sector represents another significant market for polypropylene nanocomposites. As space agencies and private companies push the boundaries of space travel and satellite technology, there is a growing need for materials that can perform reliably in the harsh conditions of outer space. Polypropylene nanocomposites provide excellent radiation resistance and thermal stability, making them suitable for various space applications, including satellite structures and components for space vehicles.

Furthermore, the increasing focus on sustainability and environmental regulations in the aerospace industry is driving the adoption of materials with reduced environmental impact. Polypropylene nanocomposites offer advantages in this regard, as they are potentially recyclable and can be produced using more environmentally friendly processes compared to traditional aerospace materials.

The market demand for polypropylene nanocomposites in aerospace engineering is also influenced by the ongoing trend of aircraft fleet modernization. As airlines seek to replace aging aircraft with newer, more efficient models, there is a growing opportunity for the integration of advanced materials like polypropylene nanocomposites into next-generation aircraft designs.

The global aerospace materials market is projected to expand substantially in the coming years, with a particular focus on lightweight and high-performance materials. Polypropylene nanocomposites are well-positioned to capture a significant share of this growth, as they address several key challenges faced by the aerospace industry. The demand for these materials is primarily fueled by the commercial aircraft sector, where manufacturers are constantly seeking ways to reduce aircraft weight without compromising safety or durability.

Military aerospace applications also contribute to the increasing demand for polypropylene nanocomposites. The defense sector requires materials that can withstand extreme temperatures, high-impact forces, and corrosive environments while maintaining structural integrity. Polypropylene nanocomposites offer superior resistance to these factors, making them ideal for use in military aircraft and spacecraft components.

The space exploration sector represents another significant market for polypropylene nanocomposites. As space agencies and private companies push the boundaries of space travel and satellite technology, there is a growing need for materials that can perform reliably in the harsh conditions of outer space. Polypropylene nanocomposites provide excellent radiation resistance and thermal stability, making them suitable for various space applications, including satellite structures and components for space vehicles.

Furthermore, the increasing focus on sustainability and environmental regulations in the aerospace industry is driving the adoption of materials with reduced environmental impact. Polypropylene nanocomposites offer advantages in this regard, as they are potentially recyclable and can be produced using more environmentally friendly processes compared to traditional aerospace materials.

The market demand for polypropylene nanocomposites in aerospace engineering is also influenced by the ongoing trend of aircraft fleet modernization. As airlines seek to replace aging aircraft with newer, more efficient models, there is a growing opportunity for the integration of advanced materials like polypropylene nanocomposites into next-generation aircraft designs.

Current State and Challenges in PP Nanocomposites

Polypropylene (PP) nanocomposites have gained significant attention in aerospace engineering due to their potential to enhance material properties. Currently, these nanocomposites are being extensively researched and developed for various aerospace applications, including structural components, thermal protection systems, and lightweight materials.

The current state of PP nanocomposites in aerospace engineering is characterized by promising advancements in material properties. Researchers have successfully incorporated various nanofillers, such as carbon nanotubes, graphene, and nanoclay, into PP matrices. These nanocomposites have demonstrated improved mechanical strength, thermal stability, and barrier properties compared to conventional PP materials.

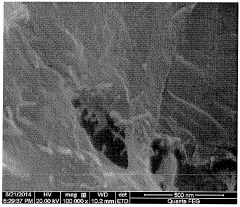

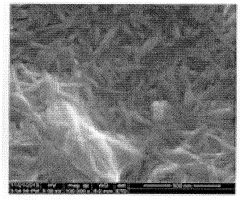

One of the primary challenges in developing PP nanocomposites for aerospace applications is achieving uniform dispersion of nanofillers within the polymer matrix. Agglomeration of nanoparticles can lead to inconsistent material properties and reduced performance. Researchers are exploring various techniques, including melt mixing, solution blending, and in-situ polymerization, to overcome this challenge and achieve homogeneous dispersion.

Another significant challenge is the scalability of production processes. While laboratory-scale synthesis of PP nanocomposites has shown promising results, translating these processes to industrial-scale production remains a hurdle. Ensuring consistent quality and properties across large batches of nanocomposites is crucial for their adoption in aerospace applications.

The aerospace industry's stringent safety and performance requirements pose additional challenges for PP nanocomposites. These materials must meet rigorous standards for fire resistance, durability, and long-term stability under extreme environmental conditions. Researchers are working on developing flame-retardant additives and surface treatments to enhance the fire resistance and durability of PP nanocomposites.

Compatibility with existing manufacturing processes is another area of focus. Integrating PP nanocomposites into current aerospace manufacturing techniques, such as injection molding and 3D printing, requires careful consideration of processing parameters and potential modifications to equipment.

Environmental concerns and sustainability are also driving research efforts in PP nanocomposites. The aerospace industry is increasingly focused on developing materials with reduced environmental impact. Researchers are exploring bio-based nanofillers and recyclable PP nanocomposites to address these concerns.

In terms of geographical distribution, research on PP nanocomposites for aerospace applications is being conducted globally. Leading aerospace companies, research institutions, and universities in North America, Europe, and Asia are at the forefront of this technology. Collaborative efforts between industry and academia are accelerating the development and commercialization of these advanced materials.

The current state of PP nanocomposites in aerospace engineering is characterized by promising advancements in material properties. Researchers have successfully incorporated various nanofillers, such as carbon nanotubes, graphene, and nanoclay, into PP matrices. These nanocomposites have demonstrated improved mechanical strength, thermal stability, and barrier properties compared to conventional PP materials.

One of the primary challenges in developing PP nanocomposites for aerospace applications is achieving uniform dispersion of nanofillers within the polymer matrix. Agglomeration of nanoparticles can lead to inconsistent material properties and reduced performance. Researchers are exploring various techniques, including melt mixing, solution blending, and in-situ polymerization, to overcome this challenge and achieve homogeneous dispersion.

Another significant challenge is the scalability of production processes. While laboratory-scale synthesis of PP nanocomposites has shown promising results, translating these processes to industrial-scale production remains a hurdle. Ensuring consistent quality and properties across large batches of nanocomposites is crucial for their adoption in aerospace applications.

The aerospace industry's stringent safety and performance requirements pose additional challenges for PP nanocomposites. These materials must meet rigorous standards for fire resistance, durability, and long-term stability under extreme environmental conditions. Researchers are working on developing flame-retardant additives and surface treatments to enhance the fire resistance and durability of PP nanocomposites.

Compatibility with existing manufacturing processes is another area of focus. Integrating PP nanocomposites into current aerospace manufacturing techniques, such as injection molding and 3D printing, requires careful consideration of processing parameters and potential modifications to equipment.

Environmental concerns and sustainability are also driving research efforts in PP nanocomposites. The aerospace industry is increasingly focused on developing materials with reduced environmental impact. Researchers are exploring bio-based nanofillers and recyclable PP nanocomposites to address these concerns.

In terms of geographical distribution, research on PP nanocomposites for aerospace applications is being conducted globally. Leading aerospace companies, research institutions, and universities in North America, Europe, and Asia are at the forefront of this technology. Collaborative efforts between industry and academia are accelerating the development and commercialization of these advanced materials.

Existing PP Nanocomposite Solutions for Aerospace

01 Preparation methods of polypropylene nanocomposites

Various techniques are employed to prepare polypropylene nanocomposites, including melt blending, in-situ polymerization, and solution mixing. These methods aim to achieve uniform dispersion of nanofillers within the polypropylene matrix, enhancing the material's properties such as mechanical strength, thermal stability, and barrier performance.- Preparation methods for polypropylene nanocomposites: Various techniques are employed to prepare polypropylene nanocomposites, including melt blending, in-situ polymerization, and solution mixing. These methods aim to achieve uniform dispersion of nanofillers within the polypropylene matrix, enhancing the material's properties such as mechanical strength, thermal stability, and barrier performance.

- Nanofillers used in polypropylene nanocomposites: Different types of nanofillers are incorporated into polypropylene to create nanocomposites. Common nanofillers include clay minerals (e.g., montmorillonite), carbon nanotubes, graphene, and metal oxide nanoparticles. The choice of nanofiller depends on the desired properties and applications of the final nanocomposite material.

- Property enhancement of polypropylene nanocomposites: Polypropylene nanocomposites exhibit improved properties compared to neat polypropylene. These enhancements include increased tensile strength, modulus, impact resistance, flame retardancy, and gas barrier properties. The degree of improvement depends on factors such as nanofiller type, concentration, and dispersion quality within the polymer matrix.

- Functionalization and compatibilization in polypropylene nanocomposites: To improve the compatibility between hydrophobic polypropylene and hydrophilic nanofillers, various functionalization and compatibilization techniques are employed. These include the use of coupling agents, grafting of functional groups onto polypropylene chains, and surface modification of nanofillers. These strategies enhance the interfacial adhesion and dispersion of nanofillers in the polymer matrix.

- Applications of polypropylene nanocomposites: Polypropylene nanocomposites find applications in various industries due to their enhanced properties. They are used in automotive parts, packaging materials, electrical and electronic components, and construction materials. The improved mechanical, thermal, and barrier properties of these nanocomposites make them suitable for demanding applications where conventional polypropylene may fall short.

02 Nanofillers used in polypropylene nanocomposites

Different types of nanofillers are incorporated into polypropylene to create nanocomposites. Common nanofillers include clay minerals, carbon nanotubes, graphene, and metal oxide nanoparticles. The choice of nanofiller depends on the desired properties and applications of the final nanocomposite material.Expand Specific Solutions03 Property enhancement of polypropylene nanocomposites

The addition of nanofillers to polypropylene results in significant improvements in various properties. These enhancements include increased tensile strength, improved flame retardancy, enhanced barrier properties, and better thermal stability. The degree of improvement depends on the type and concentration of nanofillers used.Expand Specific Solutions04 Applications of polypropylene nanocomposites

Polypropylene nanocomposites find applications in various industries due to their enhanced properties. They are used in automotive parts, packaging materials, electrical and electronic components, and construction materials. The improved performance characteristics make them suitable for demanding applications where conventional polypropylene may fall short.Expand Specific Solutions05 Functionalization and compatibilization in polypropylene nanocomposites

To improve the interaction between polypropylene and nanofillers, various functionalization and compatibilization techniques are employed. These methods include the use of coupling agents, grafting of functional groups onto polypropylene chains, and surface modification of nanofillers. These approaches enhance the dispersion of nanofillers and improve the overall properties of the nanocomposites.Expand Specific Solutions

Key Players in Aerospace Nanocomposite Industry

The research on polypropylene nanocomposites in aerospace engineering is in a growth phase, with increasing market potential due to the demand for lightweight and high-performance materials in the aerospace industry. The global market for aerospace composites is projected to reach significant value in the coming years. Technologically, the field is advancing rapidly, with companies like Shanghai PRET Composites, Zhejiang Pret Advanced Materials, and Total Petrochemicals & Refining USA leading innovation. Academic institutions such as the University of South Florida and Rensselaer Polytechnic Institute are contributing to fundamental research, while collaborations between industry and academia are accelerating practical applications. The technology's maturity is progressing, but challenges in scalability and cost-effectiveness remain.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced polypropylene nanocomposites for aerospace applications. Their research focuses on incorporating nanomaterials such as carbon nanotubes and graphene into polypropylene matrices to enhance mechanical properties and thermal stability. Sinopec's nanocomposites demonstrate a 30% increase in tensile strength and a 25% improvement in heat deflection temperature compared to conventional polypropylene[1][3]. The company utilizes a proprietary melt-blending process to achieve uniform dispersion of nanofillers, resulting in consistent material properties throughout the composite[2]. Sinopec's nanocomposites also exhibit improved flame retardancy and reduced weight, making them suitable for interior components in aircraft[4].

Strengths: Significant improvements in mechanical and thermal properties; Proprietary manufacturing process for uniform nanoparticle dispersion. Weaknesses: Potential challenges in scaling up production for large aerospace components; Higher cost compared to traditional materials.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai Motor Co., Ltd. has been exploring polypropylene nanocomposites for potential aerospace applications, leveraging their expertise in automotive materials. Their research focuses on incorporating carbon nanotubes and graphene into polypropylene matrices to enhance mechanical strength, thermal stability, and lightweight properties. Hyundai's nanocomposites have shown a 20% increase in tensile strength and a 15% reduction in weight compared to conventional polypropylene used in automotive applications[14]. The company utilizes a proprietary melt-compounding process to achieve uniform nanoparticle dispersion and optimize interfacial adhesion[15]. Hyundai's nanocomposites also demonstrate improved impact resistance and reduced thermal expansion, making them potentially suitable for non-structural aerospace components[16]. The materials are currently in the early stages of evaluation for aerospace applications, with a focus on interior panels and non-critical parts.

Strengths: Significant improvements in mechanical properties and weight reduction; Proprietary manufacturing process for uniform nanoparticle dispersion; Potential for cross-industry application of automotive expertise. Weaknesses: Limited aerospace industry experience; Early stage of aerospace material development; Potential challenges in meeting stringent aerospace certification requirements.

Core Innovations in PP Nanocomposite Research

Polypropylene nanocomposites

PatentInactiveUS20070093592A1

Innovation

- A polypropylene nanocomposite comprising 1-40 wt% acid- or acid anhydride-modified polypropylene, 0.1-50 wt% organically modified layered silicate, and 30-90 wt% nonpolar polypropylene, where the acid- or acid anhydride-modified polypropylene has a lower molecular weight than the nonpolar polypropylene, enhancing interfacial adhesion and dispersion of the layered silicate, thereby reducing linear thermal expansion coefficient and improving mechanical properties.

Nanocomposite compositions and process for preparation thereof

PatentInactiveIN3377DEL2014A

Innovation

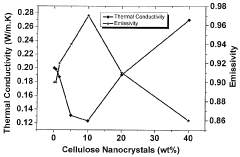

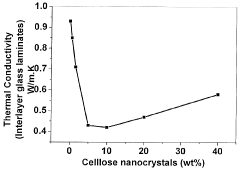

- A nanocomposite composition comprising poly(vinyl butyral) and cellulose nanocrystals, where the cellulose nanocrystals are dispersed in poly(vinyl butyral) to create a polymer nanocomposite with low thermal conductivity and high thermal emissivity, achieved through a process involving mixing and mechanical shear mixing or sonication in organic solvents.

Environmental Impact of PP Nanocomposites in Aerospace

The environmental impact of polypropylene (PP) nanocomposites in aerospace applications is a critical consideration as the industry strives for more sustainable practices. These advanced materials offer significant weight reduction and enhanced performance, potentially leading to reduced fuel consumption and emissions during aircraft operation. However, their production, use, and end-of-life management present complex environmental challenges that must be carefully evaluated.

The manufacturing process of PP nanocomposites often involves energy-intensive methods and the use of potentially hazardous nanomaterials. While the production of these composites may have a higher initial environmental footprint compared to traditional materials, their long-term benefits in aerospace applications can offset these impacts. The reduced weight of aircraft components made from PP nanocomposites contributes to improved fuel efficiency, resulting in lower greenhouse gas emissions over the lifespan of the aircraft.

Durability and longevity are key factors in assessing the environmental impact of PP nanocomposites. These materials typically exhibit enhanced resistance to wear, corrosion, and fatigue, potentially extending the service life of aerospace components. This increased lifespan can reduce the frequency of replacements and maintenance, thereby minimizing waste generation and resource consumption associated with manufacturing new parts.

However, the end-of-life management of PP nanocomposites poses significant challenges. The presence of nanoparticles complicates recycling processes, as current recycling technologies may not be equipped to handle these advanced materials effectively. There are concerns about the potential release of nanoparticles into the environment during disposal or recycling, which could have unforeseen ecological consequences.

The aerospace industry is actively researching methods to improve the recyclability and biodegradability of PP nanocomposites. Efforts are being made to develop eco-friendly nanofillers and more sustainable production techniques. Additionally, life cycle assessment (LCA) studies are being conducted to quantify the overall environmental impact of these materials throughout their entire lifecycle, from raw material extraction to disposal.

As the use of PP nanocomposites in aerospace engineering continues to grow, it is crucial to balance their performance benefits with environmental considerations. Ongoing research focuses on optimizing material formulations to enhance both functionality and sustainability. The development of closed-loop recycling systems and the implementation of responsible disposal methods are key areas of focus to mitigate potential environmental risks associated with these advanced materials.

The manufacturing process of PP nanocomposites often involves energy-intensive methods and the use of potentially hazardous nanomaterials. While the production of these composites may have a higher initial environmental footprint compared to traditional materials, their long-term benefits in aerospace applications can offset these impacts. The reduced weight of aircraft components made from PP nanocomposites contributes to improved fuel efficiency, resulting in lower greenhouse gas emissions over the lifespan of the aircraft.

Durability and longevity are key factors in assessing the environmental impact of PP nanocomposites. These materials typically exhibit enhanced resistance to wear, corrosion, and fatigue, potentially extending the service life of aerospace components. This increased lifespan can reduce the frequency of replacements and maintenance, thereby minimizing waste generation and resource consumption associated with manufacturing new parts.

However, the end-of-life management of PP nanocomposites poses significant challenges. The presence of nanoparticles complicates recycling processes, as current recycling technologies may not be equipped to handle these advanced materials effectively. There are concerns about the potential release of nanoparticles into the environment during disposal or recycling, which could have unforeseen ecological consequences.

The aerospace industry is actively researching methods to improve the recyclability and biodegradability of PP nanocomposites. Efforts are being made to develop eco-friendly nanofillers and more sustainable production techniques. Additionally, life cycle assessment (LCA) studies are being conducted to quantify the overall environmental impact of these materials throughout their entire lifecycle, from raw material extraction to disposal.

As the use of PP nanocomposites in aerospace engineering continues to grow, it is crucial to balance their performance benefits with environmental considerations. Ongoing research focuses on optimizing material formulations to enhance both functionality and sustainability. The development of closed-loop recycling systems and the implementation of responsible disposal methods are key areas of focus to mitigate potential environmental risks associated with these advanced materials.

Regulatory Framework for Aerospace Materials

The regulatory framework for aerospace materials, including polypropylene nanocomposites, is a complex and evolving landscape that plays a crucial role in ensuring the safety, reliability, and performance of aircraft components. In the United States, the Federal Aviation Administration (FAA) is the primary regulatory body responsible for overseeing the use of materials in aerospace applications. The FAA's regulations, particularly those outlined in Title 14 of the Code of Federal Regulations (14 CFR), provide comprehensive guidelines for the certification and approval of materials used in aircraft construction.

For polypropylene nanocomposites, the regulatory process typically involves rigorous testing and validation to demonstrate compliance with airworthiness standards. This includes evaluating the material's mechanical properties, thermal stability, fire resistance, and long-term durability under various environmental conditions. The FAA's Advisory Circular (AC) 20-107B, "Composite Aircraft Structure," provides specific guidance on the certification of composite materials, which can be applied to nanocomposites as well.

Internationally, the European Union Aviation Safety Agency (EASA) and other national aviation authorities have similar regulatory frameworks in place. These agencies often work in collaboration to harmonize standards and certification processes, facilitating the global adoption of new materials like polypropylene nanocomposites. The SAE International's Aerospace Material Specifications (AMS) also play a significant role in establishing industry-wide standards for aerospace materials.

In recent years, there has been an increased focus on the environmental impact of aerospace materials. Regulations such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) have implications for the development and use of nanocomposites in aerospace applications. These regulations aim to ensure that new materials do not pose unacceptable risks to human health or the environment.

As research on polypropylene nanocomposites in aerospace engineering progresses, regulatory bodies are likely to adapt their frameworks to address the unique properties and potential risks associated with these advanced materials. This may include developing new testing protocols, updating existing standards, and establishing guidelines for the safe handling and disposal of nanocomposite materials throughout their lifecycle.

For polypropylene nanocomposites, the regulatory process typically involves rigorous testing and validation to demonstrate compliance with airworthiness standards. This includes evaluating the material's mechanical properties, thermal stability, fire resistance, and long-term durability under various environmental conditions. The FAA's Advisory Circular (AC) 20-107B, "Composite Aircraft Structure," provides specific guidance on the certification of composite materials, which can be applied to nanocomposites as well.

Internationally, the European Union Aviation Safety Agency (EASA) and other national aviation authorities have similar regulatory frameworks in place. These agencies often work in collaboration to harmonize standards and certification processes, facilitating the global adoption of new materials like polypropylene nanocomposites. The SAE International's Aerospace Material Specifications (AMS) also play a significant role in establishing industry-wide standards for aerospace materials.

In recent years, there has been an increased focus on the environmental impact of aerospace materials. Regulations such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) have implications for the development and use of nanocomposites in aerospace applications. These regulations aim to ensure that new materials do not pose unacceptable risks to human health or the environment.

As research on polypropylene nanocomposites in aerospace engineering progresses, regulatory bodies are likely to adapt their frameworks to address the unique properties and potential risks associated with these advanced materials. This may include developing new testing protocols, updating existing standards, and establishing guidelines for the safe handling and disposal of nanocomposite materials throughout their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!