Investigating Sound Attenuation in Polypropylene Composite Doors

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acoustic Challenges in Composite Door Design

The design of composite doors presents unique acoustic challenges that require careful consideration and innovative solutions. Polypropylene composite doors, while offering advantages in terms of durability and cost-effectiveness, face particular difficulties in achieving optimal sound attenuation.

One of the primary challenges lies in the inherent properties of polypropylene composites. These materials, while lightweight and resistant to moisture, often lack the density and mass necessary for effective sound insulation. The low density of polypropylene can allow sound waves to pass through more easily compared to traditional door materials like solid wood or metal.

Another significant issue is the potential for resonance within the composite structure. The layered nature of composite materials can create cavities or air pockets that may resonate at certain frequencies, potentially amplifying rather than attenuating sound. This phenomenon requires careful engineering to mitigate, often involving the strategic placement of damping materials or the modification of the composite's internal structure.

The interface between the door and its frame presents additional acoustic challenges. Even small gaps or imperfect seals can significantly reduce the door's overall sound insulation performance. Designing effective sealing systems that maintain their integrity over time, while still allowing for smooth operation of the door, is a complex task that demands precision engineering.

Temperature and humidity fluctuations pose another set of challenges for composite doors. These environmental factors can cause slight dimensional changes in the door, potentially affecting its acoustic properties and the effectiveness of its seals. Ensuring consistent performance across a range of environmental conditions is crucial for maintaining acoustic integrity.

The integration of hardware, such as locks, hinges, and handles, into composite doors can create weak points in the acoustic barrier. These components often require cutouts or modifications to the door structure, which can compromise its sound-attenuating properties if not carefully designed and implemented.

Balancing acoustic performance with other desirable characteristics of composite doors, such as fire resistance, thermal insulation, and aesthetic appeal, adds another layer of complexity to the design process. Optimizing for one property may come at the expense of others, necessitating a holistic approach to door design that considers all performance criteria simultaneously.

Lastly, the manufacturing process itself can impact the acoustic properties of composite doors. Ensuring consistency in production, particularly in the distribution of materials and the formation of the composite structure, is essential for achieving reliable acoustic performance across all produced units.

One of the primary challenges lies in the inherent properties of polypropylene composites. These materials, while lightweight and resistant to moisture, often lack the density and mass necessary for effective sound insulation. The low density of polypropylene can allow sound waves to pass through more easily compared to traditional door materials like solid wood or metal.

Another significant issue is the potential for resonance within the composite structure. The layered nature of composite materials can create cavities or air pockets that may resonate at certain frequencies, potentially amplifying rather than attenuating sound. This phenomenon requires careful engineering to mitigate, often involving the strategic placement of damping materials or the modification of the composite's internal structure.

The interface between the door and its frame presents additional acoustic challenges. Even small gaps or imperfect seals can significantly reduce the door's overall sound insulation performance. Designing effective sealing systems that maintain their integrity over time, while still allowing for smooth operation of the door, is a complex task that demands precision engineering.

Temperature and humidity fluctuations pose another set of challenges for composite doors. These environmental factors can cause slight dimensional changes in the door, potentially affecting its acoustic properties and the effectiveness of its seals. Ensuring consistent performance across a range of environmental conditions is crucial for maintaining acoustic integrity.

The integration of hardware, such as locks, hinges, and handles, into composite doors can create weak points in the acoustic barrier. These components often require cutouts or modifications to the door structure, which can compromise its sound-attenuating properties if not carefully designed and implemented.

Balancing acoustic performance with other desirable characteristics of composite doors, such as fire resistance, thermal insulation, and aesthetic appeal, adds another layer of complexity to the design process. Optimizing for one property may come at the expense of others, necessitating a holistic approach to door design that considers all performance criteria simultaneously.

Lastly, the manufacturing process itself can impact the acoustic properties of composite doors. Ensuring consistency in production, particularly in the distribution of materials and the formation of the composite structure, is essential for achieving reliable acoustic performance across all produced units.

Market Demand for Soundproof Doors

The market demand for soundproof doors has been steadily increasing in recent years, driven by various factors across residential, commercial, and industrial sectors. In urban areas, the rise of noise pollution due to increased population density and traffic has led to a growing awareness of the importance of sound insulation in living and working spaces. This has resulted in a surge of interest in soundproof doors, particularly in apartment buildings, hotels, and office complexes.

In the residential sector, homeowners are increasingly seeking ways to create quieter living environments, especially in multi-family dwellings. The trend towards open-plan living spaces has also contributed to the need for better sound insulation between rooms. Soundproof doors are seen as an effective solution to maintain privacy and reduce noise transmission within homes.

The commercial sector, including hotels, conference centers, and educational institutions, has shown significant demand for soundproof doors. These establishments prioritize creating comfortable and distraction-free environments for their occupants. Hotels, in particular, view soundproof doors as a key feature to enhance guest experience and maintain high customer satisfaction ratings.

In the industrial sector, the demand for soundproof doors is driven by stringent workplace safety regulations and the need to contain noise from machinery and equipment. Manufacturing plants, power generation facilities, and research laboratories are among the primary consumers of high-performance soundproof doors.

The healthcare industry has emerged as a notable market for soundproof doors, with hospitals and medical facilities requiring noise control to ensure patient comfort and privacy. The growing emphasis on patient-centered care has led to increased investment in soundproofing solutions, including specialized doors for patient rooms, operating theaters, and consultation areas.

The global market for soundproof doors is expected to continue its growth trajectory, with a particular focus on innovative materials and designs that offer superior sound attenuation properties. Polypropylene composite doors represent a promising segment within this market, as they combine lightweight properties with effective sound insulation capabilities.

As environmental concerns gain prominence, there is a growing demand for eco-friendly soundproof door solutions. This trend is likely to drive research and development efforts towards sustainable materials and manufacturing processes in the soundproof door industry.

In the residential sector, homeowners are increasingly seeking ways to create quieter living environments, especially in multi-family dwellings. The trend towards open-plan living spaces has also contributed to the need for better sound insulation between rooms. Soundproof doors are seen as an effective solution to maintain privacy and reduce noise transmission within homes.

The commercial sector, including hotels, conference centers, and educational institutions, has shown significant demand for soundproof doors. These establishments prioritize creating comfortable and distraction-free environments for their occupants. Hotels, in particular, view soundproof doors as a key feature to enhance guest experience and maintain high customer satisfaction ratings.

In the industrial sector, the demand for soundproof doors is driven by stringent workplace safety regulations and the need to contain noise from machinery and equipment. Manufacturing plants, power generation facilities, and research laboratories are among the primary consumers of high-performance soundproof doors.

The healthcare industry has emerged as a notable market for soundproof doors, with hospitals and medical facilities requiring noise control to ensure patient comfort and privacy. The growing emphasis on patient-centered care has led to increased investment in soundproofing solutions, including specialized doors for patient rooms, operating theaters, and consultation areas.

The global market for soundproof doors is expected to continue its growth trajectory, with a particular focus on innovative materials and designs that offer superior sound attenuation properties. Polypropylene composite doors represent a promising segment within this market, as they combine lightweight properties with effective sound insulation capabilities.

As environmental concerns gain prominence, there is a growing demand for eco-friendly soundproof door solutions. This trend is likely to drive research and development efforts towards sustainable materials and manufacturing processes in the soundproof door industry.

Current State of Polypropylene Composite Acoustics

The current state of polypropylene composite acoustics represents a significant area of research and development in the field of sound attenuation for doors and other building components. Polypropylene composites have gained attention due to their potential to combine lightweight properties with enhanced acoustic performance.

Recent studies have shown that polypropylene composites can achieve sound transmission loss (STL) values comparable to traditional materials like wood or metal, particularly in the mid to high-frequency ranges. This performance is attributed to the composite's ability to dissipate sound energy through its complex internal structure.

One of the key advancements in polypropylene composite acoustics is the incorporation of various fillers and reinforcements. Researchers have experimented with adding materials such as natural fibers, glass fibers, and mineral particles to enhance the acoustic properties of polypropylene. These additives can significantly alter the composite's density, stiffness, and damping characteristics, leading to improved sound attenuation.

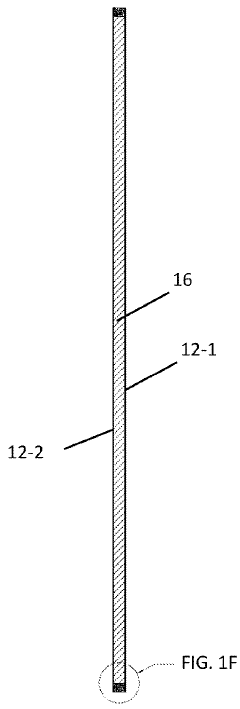

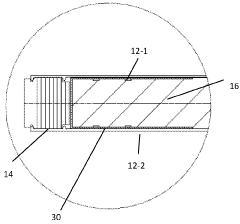

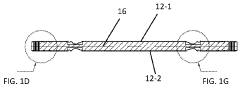

The development of multi-layer polypropylene composite structures has also shown promise in acoustic applications. By combining layers with different densities and mechanical properties, manufacturers can create doors that effectively attenuate sound across a broader frequency spectrum. This approach allows for customization of acoustic performance to meet specific requirements for different environments.

Another area of focus has been the optimization of the composite's surface properties. Researchers have explored various texturing and patterning techniques to enhance sound diffusion and absorption at the material's surface. These modifications can contribute to improved overall acoustic performance without significantly increasing the door's weight or thickness.

The integration of acoustic metamaterials into polypropylene composites represents a cutting-edge development in the field. These engineered structures can manipulate sound waves in ways that natural materials cannot, potentially leading to unprecedented levels of sound attenuation in specific frequency ranges.

Despite these advancements, challenges remain in achieving consistent acoustic performance across all frequency ranges, particularly at lower frequencies. Additionally, balancing acoustic properties with other essential characteristics such as fire resistance, durability, and cost-effectiveness continues to be an area of ongoing research and development in the polypropylene composite industry.

Recent studies have shown that polypropylene composites can achieve sound transmission loss (STL) values comparable to traditional materials like wood or metal, particularly in the mid to high-frequency ranges. This performance is attributed to the composite's ability to dissipate sound energy through its complex internal structure.

One of the key advancements in polypropylene composite acoustics is the incorporation of various fillers and reinforcements. Researchers have experimented with adding materials such as natural fibers, glass fibers, and mineral particles to enhance the acoustic properties of polypropylene. These additives can significantly alter the composite's density, stiffness, and damping characteristics, leading to improved sound attenuation.

The development of multi-layer polypropylene composite structures has also shown promise in acoustic applications. By combining layers with different densities and mechanical properties, manufacturers can create doors that effectively attenuate sound across a broader frequency spectrum. This approach allows for customization of acoustic performance to meet specific requirements for different environments.

Another area of focus has been the optimization of the composite's surface properties. Researchers have explored various texturing and patterning techniques to enhance sound diffusion and absorption at the material's surface. These modifications can contribute to improved overall acoustic performance without significantly increasing the door's weight or thickness.

The integration of acoustic metamaterials into polypropylene composites represents a cutting-edge development in the field. These engineered structures can manipulate sound waves in ways that natural materials cannot, potentially leading to unprecedented levels of sound attenuation in specific frequency ranges.

Despite these advancements, challenges remain in achieving consistent acoustic performance across all frequency ranges, particularly at lower frequencies. Additionally, balancing acoustic properties with other essential characteristics such as fire resistance, durability, and cost-effectiveness continues to be an area of ongoing research and development in the polypropylene composite industry.

Existing Sound Attenuation Solutions

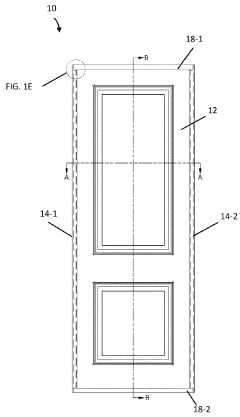

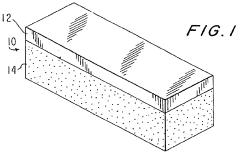

01 Composite door structure with sound-absorbing layers

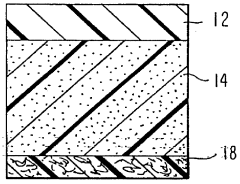

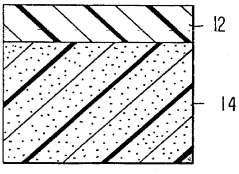

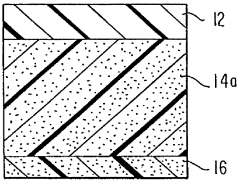

Polypropylene composite doors can be designed with multiple layers, including sound-absorbing materials, to enhance sound attenuation. These layers may include foam, fibrous materials, or other acoustic dampening components sandwiched between polypropylene sheets.- Composite door structure with sound-absorbing layers: Polypropylene composite doors can be designed with multiple layers, including sound-absorbing materials, to enhance sound attenuation. These layers may include foam, fibrous materials, or other acoustic insulators sandwiched between polypropylene sheets, creating a barrier that reduces sound transmission.

- Incorporation of sound-dampening fillers in polypropylene: Adding specific fillers to the polypropylene matrix can improve its sound-dampening properties. Materials such as mineral powders, glass fibers, or recycled materials can be mixed with polypropylene to create a composite that absorbs and dissipates sound waves more effectively than pure polypropylene.

- Honeycomb or cellular structure for improved acoustics: Designing polypropylene composite doors with a honeycomb or cellular internal structure can enhance sound attenuation. These structures create air pockets that trap sound waves, reducing their transmission through the door. The design can be optimized for specific frequency ranges to improve overall acoustic performance.

- Surface treatments for enhanced sound absorption: Applying specific surface treatments or textures to polypropylene composite doors can improve their sound-absorbing capabilities. These treatments may include micro-perforations, embossed patterns, or the application of sound-absorbing coatings, which increase the surface area available for sound absorption.

- Integration of acoustic seals and gaskets: Incorporating specialized acoustic seals and gaskets around the edges of polypropylene composite doors can significantly improve their sound attenuation properties. These components help to close gaps and reduce sound leakage, enhancing the overall acoustic performance of the door system.

02 Incorporation of sound-absorbing fillers in polypropylene matrix

Sound attenuation in polypropylene composite doors can be improved by incorporating sound-absorbing fillers into the polypropylene matrix. These fillers may include materials such as mineral powders, hollow microspheres, or recycled materials that help to dissipate sound energy.Expand Specific Solutions03 Surface treatments and texturing for sound diffusion

The surface of polypropylene composite doors can be treated or textured to enhance sound diffusion and reduce sound transmission. This may involve creating patterns, grooves, or irregular surfaces that scatter sound waves and reduce their energy.Expand Specific Solutions04 Integration of air gaps and cavities for acoustic insulation

Polypropylene composite doors can be designed with strategically placed air gaps and cavities to improve sound attenuation. These spaces act as additional barriers to sound transmission and can be filled with sound-absorbing materials for enhanced performance.Expand Specific Solutions05 Use of multi-component polypropylene blends for improved acoustics

Sound attenuation in composite doors can be enhanced by using multi-component polypropylene blends. These blends may combine different grades of polypropylene or incorporate other polymers to create a material with improved acoustic properties.Expand Specific Solutions

Key Players in Composite Door Industry

The sound attenuation in polypropylene composite doors market is in a growth phase, driven by increasing demand for noise reduction solutions in various sectors. The global market size for acoustic materials is projected to reach $16.55 billion by 2025, with a CAGR of 6.2%. Technologically, the field is advancing rapidly, with companies like Honeywell International Technologies, 3M Innovative Properties, and Owens Corning Intellectual Capital leading innovation. These firms are developing advanced composite materials and manufacturing techniques to enhance sound attenuation properties. Emerging players such as Zhejiang Yimeida Door Industry and Hefei Genius Advanced Material are also contributing to the competitive landscape, particularly in the Asian market. The technology's maturity is moderate, with ongoing research focusing on improving performance and cost-effectiveness.

Owens Corning Intellectual Capital LLC

Technical Solution: Owens Corning has developed a multi-layer composite door structure utilizing polypropylene and fiberglass materials. Their approach involves a sandwich construction with a polypropylene core reinforced with long glass fibers, surrounded by outer layers of fiberglass-reinforced polypropylene. This structure creates micro-voids and interfaces that effectively scatter and absorb sound waves[1]. The company has also implemented a proprietary manufacturing process that optimizes the distribution of fibers within the polypropylene matrix, enhancing both acoustic and mechanical properties[3]. Recent advancements include the incorporation of nano-sized particles into the composite, which has shown to improve sound attenuation across a broader frequency range[5].

Strengths: Excellent balance of acoustic performance and structural integrity. Lightweight compared to traditional materials. Weaknesses: Higher production costs. Potential for delamination in extreme conditions.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has pioneered a novel approach to sound attenuation in polypropylene composite doors through their Vistamaxx™ performance polymers. This technology involves blending specially designed elastomeric polypropylene with conventional polypropylene to create a material with enhanced damping properties[2]. The company has developed a multi-phase system where the elastomeric component forms discrete domains within the polypropylene matrix, effectively dissipating acoustic energy[4]. Additionally, ExxonMobil has introduced a chemical foaming process that creates a microcellular structure within the composite, further improving sound absorption characteristics[6]. Recent research has focused on optimizing the interface between the elastomeric and rigid phases to maximize sound attenuation across a wide temperature range.

Strengths: Excellent sound damping properties. Versatile processing options. Weaknesses: May have lower stiffness compared to pure polypropylene. Potential for increased material costs.

Core Innovations in Acoustic Materials

Door comprising vermiculite-containing core, and method of making the same

PatentActiveUS20180179807A1

Innovation

- A sound-attenuating door comprising a core made of a composition containing expanded vermiculite and an inorganic bonding agent, with a density of at least 600 Kg/m3, and a structure consisting of two skins and a reinforcing structure, which provides a high STC or OITC rating by attenuating airborne sound and reducing noise levels.

Method for forming a sound attenuation composite

PatentInactiveUS5622662A

Innovation

- A composite sound attenuation material comprising a dense, resilient, elastic polymer barrier layer and a fractured open cell foam layer, loaded with barium sulfate and glass microspheres, which absorbs, traps, and dissipates sound energy, along with optional decoupling and reinforcing layers for enhanced performance.

Environmental Impact of Composite Materials

The environmental impact of composite materials used in polypropylene composite doors for sound attenuation is a critical consideration in the development and application of these technologies. Composite materials, while offering superior sound attenuation properties, can have significant environmental implications throughout their lifecycle.

The production of polypropylene, a key component in these composite doors, involves energy-intensive processes and relies on fossil fuel resources. This contributes to greenhouse gas emissions and the depletion of non-renewable resources. Additionally, the manufacturing of composite materials often requires the use of chemical additives and bonding agents, which can lead to the release of volatile organic compounds (VOCs) and other potentially harmful substances into the environment.

During the use phase, polypropylene composite doors generally demonstrate positive environmental attributes. Their durability and resistance to weathering and degradation result in longer lifespans compared to traditional materials, reducing the need for frequent replacements. The enhanced sound attenuation properties also contribute to improved energy efficiency in buildings by reducing the need for additional insulation or sound-proofing measures.

However, the end-of-life management of composite materials presents significant challenges. Polypropylene composite doors are often difficult to recycle due to the complex mixture of materials used in their construction. The separation of these components for recycling can be energy-intensive and economically unfeasible. As a result, many composite materials end up in landfills, contributing to long-term environmental pollution.

Recent advancements in material science have led to the development of more environmentally friendly composite materials. Researchers are exploring bio-based alternatives to traditional petroleum-based polymers, which could reduce the carbon footprint of composite door production. Additionally, efforts are being made to improve the recyclability of composite materials through the use of reversible bonding agents and design for disassembly principles.

The life cycle assessment (LCA) of polypropylene composite doors reveals a complex environmental profile. While they offer benefits in terms of energy efficiency and longevity, the environmental costs associated with production and disposal must be carefully weighed. Future developments in this field should focus on improving the sustainability of raw materials, enhancing recyclability, and minimizing the use of harmful additives in the manufacturing process.

As the demand for sound attenuation solutions in buildings continues to grow, it is crucial to consider the broader environmental implications of composite materials. Balancing the acoustic performance with environmental sustainability will be key to the future development and adoption of polypropylene composite doors in sound attenuation applications.

The production of polypropylene, a key component in these composite doors, involves energy-intensive processes and relies on fossil fuel resources. This contributes to greenhouse gas emissions and the depletion of non-renewable resources. Additionally, the manufacturing of composite materials often requires the use of chemical additives and bonding agents, which can lead to the release of volatile organic compounds (VOCs) and other potentially harmful substances into the environment.

During the use phase, polypropylene composite doors generally demonstrate positive environmental attributes. Their durability and resistance to weathering and degradation result in longer lifespans compared to traditional materials, reducing the need for frequent replacements. The enhanced sound attenuation properties also contribute to improved energy efficiency in buildings by reducing the need for additional insulation or sound-proofing measures.

However, the end-of-life management of composite materials presents significant challenges. Polypropylene composite doors are often difficult to recycle due to the complex mixture of materials used in their construction. The separation of these components for recycling can be energy-intensive and economically unfeasible. As a result, many composite materials end up in landfills, contributing to long-term environmental pollution.

Recent advancements in material science have led to the development of more environmentally friendly composite materials. Researchers are exploring bio-based alternatives to traditional petroleum-based polymers, which could reduce the carbon footprint of composite door production. Additionally, efforts are being made to improve the recyclability of composite materials through the use of reversible bonding agents and design for disassembly principles.

The life cycle assessment (LCA) of polypropylene composite doors reveals a complex environmental profile. While they offer benefits in terms of energy efficiency and longevity, the environmental costs associated with production and disposal must be carefully weighed. Future developments in this field should focus on improving the sustainability of raw materials, enhancing recyclability, and minimizing the use of harmful additives in the manufacturing process.

As the demand for sound attenuation solutions in buildings continues to grow, it is crucial to consider the broader environmental implications of composite materials. Balancing the acoustic performance with environmental sustainability will be key to the future development and adoption of polypropylene composite doors in sound attenuation applications.

Acoustic Testing Standards and Certifications

Acoustic testing standards and certifications play a crucial role in evaluating the sound attenuation performance of polypropylene composite doors. These standards provide a framework for consistent and reliable measurements, ensuring that doors meet specific acoustic requirements for various applications.

One of the most widely recognized standards for acoustic testing is ISO 10140, which outlines methods for measuring sound insulation in building elements, including doors. This standard consists of several parts, with ISO 10140-2 specifically addressing airborne sound insulation. It provides detailed procedures for laboratory measurements of sound reduction index (R) and weighted sound reduction index (Rw).

ASTM E90 is another important standard used in North America for measuring airborne sound transmission loss of building partitions and elements. This standard complements ISO 10140 and is often used in conjunction with ASTM E413, which describes the method for determining the Sound Transmission Class (STC) rating.

For on-site measurements, ISO 16283-1 is commonly employed to assess the airborne sound insulation between rooms in buildings. This standard is particularly relevant for evaluating the performance of installed doors in real-world conditions.

Certification programs, such as the European CE marking, often incorporate these acoustic testing standards as part of their requirements. The CE marking ensures that products meet essential health, safety, and environmental protection requirements within the European Economic Area.

In the United States, the Architectural Woodwork Institute (AWI) provides quality standards for architectural wood doors, including acoustic performance criteria. These standards are often referenced in specifications for commercial and institutional projects.

The Acoustical Society of America (ASA) also contributes to the development and maintenance of acoustic standards through its work with the American National Standards Institute (ANSI). These organizations collaborate to produce standards such as ANSI/ASA S12.60, which addresses acoustical performance criteria for learning spaces.

For polypropylene composite doors specifically, manufacturers may need to comply with additional standards related to material properties and fire resistance. For example, ASTM D7032 provides standard specifications for establishing performance ratings for wood-plastic composite deck boards and guardrail systems.

Compliance with these standards and certifications not only ensures the quality and performance of polypropylene composite doors but also facilitates market acceptance and regulatory approval. As acoustic requirements become increasingly stringent in various sectors, adherence to these standards will be essential for manufacturers to remain competitive and meet customer expectations.

One of the most widely recognized standards for acoustic testing is ISO 10140, which outlines methods for measuring sound insulation in building elements, including doors. This standard consists of several parts, with ISO 10140-2 specifically addressing airborne sound insulation. It provides detailed procedures for laboratory measurements of sound reduction index (R) and weighted sound reduction index (Rw).

ASTM E90 is another important standard used in North America for measuring airborne sound transmission loss of building partitions and elements. This standard complements ISO 10140 and is often used in conjunction with ASTM E413, which describes the method for determining the Sound Transmission Class (STC) rating.

For on-site measurements, ISO 16283-1 is commonly employed to assess the airborne sound insulation between rooms in buildings. This standard is particularly relevant for evaluating the performance of installed doors in real-world conditions.

Certification programs, such as the European CE marking, often incorporate these acoustic testing standards as part of their requirements. The CE marking ensures that products meet essential health, safety, and environmental protection requirements within the European Economic Area.

In the United States, the Architectural Woodwork Institute (AWI) provides quality standards for architectural wood doors, including acoustic performance criteria. These standards are often referenced in specifications for commercial and institutional projects.

The Acoustical Society of America (ASA) also contributes to the development and maintenance of acoustic standards through its work with the American National Standards Institute (ANSI). These organizations collaborate to produce standards such as ANSI/ASA S12.60, which addresses acoustical performance criteria for learning spaces.

For polypropylene composite doors specifically, manufacturers may need to comply with additional standards related to material properties and fire resistance. For example, ASTM D7032 provides standard specifications for establishing performance ratings for wood-plastic composite deck boards and guardrail systems.

Compliance with these standards and certifications not only ensures the quality and performance of polypropylene composite doors but also facilitates market acceptance and regulatory approval. As acoustic requirements become increasingly stringent in various sectors, adherence to these standards will be essential for manufacturers to remain competitive and meet customer expectations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!