Exploring Heat-Resistant Polypropylene in Pyrotechnics Safety Gear

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pyrotechnic Safety Evolution

The evolution of pyrotechnic safety has been a critical journey in the field of fireworks and explosives handling. Initially, safety measures were rudimentary, focusing primarily on physical barriers and distance to mitigate risks. As the industry grew, so did the awareness of potential hazards, leading to more sophisticated approaches to safety.

In the early 20th century, the emphasis was on protective clothing made from natural fibers like wool and leather, which offered limited protection against heat and sparks. The mid-century saw the introduction of synthetic materials, marking a significant leap in safety gear development. However, these early synthetic materials often lacked the necessary heat resistance for pyrotechnic applications.

The 1960s and 1970s witnessed a surge in research and development of flame-retardant fabrics, driven by increasing safety regulations and a better understanding of fire dynamics. This period saw the emergence of materials like Nomex and Kevlar, which offered improved heat and flame resistance compared to their predecessors.

The late 20th century brought about a paradigm shift in pyrotechnic safety with the advent of advanced polymer science. This era saw the development of specialized heat-resistant polymers, including modified polypropylene formulations. These materials offered a balance of heat resistance, flexibility, and durability, making them ideal for safety gear in pyrotechnic environments.

The turn of the millennium marked the beginning of a new age in pyrotechnic safety evolution. Nanotechnology began to play a crucial role, with researchers exploring ways to enhance the heat-resistant properties of polymers at the molecular level. This led to the development of nanocomposite materials that exhibited exceptional thermal stability and flame-retardant properties.

In recent years, the focus has shifted towards smart materials and integrated safety systems. Heat-resistant polypropylene is being combined with sensors and phase-change materials to create adaptive safety gear that can respond to changing thermal conditions. This integration of technology and materials science represents the cutting edge of pyrotechnic safety evolution.

The ongoing research in this field continues to push the boundaries of what's possible in heat-resistant materials. Scientists are now exploring bio-inspired designs and self-healing polymers that could revolutionize the next generation of pyrotechnic safety gear, promising even greater levels of protection and functionality for workers in high-risk environments.

In the early 20th century, the emphasis was on protective clothing made from natural fibers like wool and leather, which offered limited protection against heat and sparks. The mid-century saw the introduction of synthetic materials, marking a significant leap in safety gear development. However, these early synthetic materials often lacked the necessary heat resistance for pyrotechnic applications.

The 1960s and 1970s witnessed a surge in research and development of flame-retardant fabrics, driven by increasing safety regulations and a better understanding of fire dynamics. This period saw the emergence of materials like Nomex and Kevlar, which offered improved heat and flame resistance compared to their predecessors.

The late 20th century brought about a paradigm shift in pyrotechnic safety with the advent of advanced polymer science. This era saw the development of specialized heat-resistant polymers, including modified polypropylene formulations. These materials offered a balance of heat resistance, flexibility, and durability, making them ideal for safety gear in pyrotechnic environments.

The turn of the millennium marked the beginning of a new age in pyrotechnic safety evolution. Nanotechnology began to play a crucial role, with researchers exploring ways to enhance the heat-resistant properties of polymers at the molecular level. This led to the development of nanocomposite materials that exhibited exceptional thermal stability and flame-retardant properties.

In recent years, the focus has shifted towards smart materials and integrated safety systems. Heat-resistant polypropylene is being combined with sensors and phase-change materials to create adaptive safety gear that can respond to changing thermal conditions. This integration of technology and materials science represents the cutting edge of pyrotechnic safety evolution.

The ongoing research in this field continues to push the boundaries of what's possible in heat-resistant materials. Scientists are now exploring bio-inspired designs and self-healing polymers that could revolutionize the next generation of pyrotechnic safety gear, promising even greater levels of protection and functionality for workers in high-risk environments.

Market Demand Analysis

The market demand for heat-resistant polypropylene in pyrotechnics safety gear has been steadily increasing due to the growing emphasis on worker safety and stringent regulations in the pyrotechnics industry. This specialized material plays a crucial role in protecting personnel from extreme heat and potential fire hazards associated with pyrotechnic operations.

The global pyrotechnics market, which includes fireworks, special effects, and military applications, has been experiencing consistent growth. This expansion directly correlates with the demand for advanced safety equipment, including heat-resistant polypropylene gear. The market for pyrotechnic safety equipment is expected to grow significantly in the coming years, driven by factors such as increased safety awareness, technological advancements, and the expansion of the entertainment industry.

In the entertainment sector, the rise of large-scale events, concerts, and theme parks has led to a surge in demand for pyrotechnic effects, consequently boosting the need for high-performance safety gear. The film and television industry also contributes substantially to this demand, as special effects become more elaborate and safety standards more rigorous.

The military and defense sector represents another significant market for heat-resistant polypropylene safety gear. With ongoing research and development in military pyrotechnics for training, signaling, and combat applications, there is a constant need for improved protective equipment. This sector's demand is characterized by a focus on durability, reliability, and advanced heat-resistant properties.

Industrial applications, including mining, oil and gas, and chemical manufacturing, also contribute to the market demand. These industries often involve high-temperature processes or the risk of fire, necessitating the use of heat-resistant safety gear for workers.

Geographically, North America and Europe lead in market demand due to strict safety regulations and a well-established pyrotechnics industry. However, the Asia-Pacific region is showing the fastest growth, driven by the expanding entertainment industry and increasing adoption of safety standards in developing countries.

The market is also influenced by technological advancements in material science. Innovations in polymer chemistry are enabling the development of polypropylene with enhanced heat resistance and other desirable properties. This progress is opening new possibilities for safer, more comfortable, and more effective protective gear, further stimulating market demand.

Environmental concerns and sustainability initiatives are shaping the market as well. There is a growing demand for eco-friendly and recyclable materials in safety gear, presenting both challenges and opportunities for manufacturers of heat-resistant polypropylene products.

The global pyrotechnics market, which includes fireworks, special effects, and military applications, has been experiencing consistent growth. This expansion directly correlates with the demand for advanced safety equipment, including heat-resistant polypropylene gear. The market for pyrotechnic safety equipment is expected to grow significantly in the coming years, driven by factors such as increased safety awareness, technological advancements, and the expansion of the entertainment industry.

In the entertainment sector, the rise of large-scale events, concerts, and theme parks has led to a surge in demand for pyrotechnic effects, consequently boosting the need for high-performance safety gear. The film and television industry also contributes substantially to this demand, as special effects become more elaborate and safety standards more rigorous.

The military and defense sector represents another significant market for heat-resistant polypropylene safety gear. With ongoing research and development in military pyrotechnics for training, signaling, and combat applications, there is a constant need for improved protective equipment. This sector's demand is characterized by a focus on durability, reliability, and advanced heat-resistant properties.

Industrial applications, including mining, oil and gas, and chemical manufacturing, also contribute to the market demand. These industries often involve high-temperature processes or the risk of fire, necessitating the use of heat-resistant safety gear for workers.

Geographically, North America and Europe lead in market demand due to strict safety regulations and a well-established pyrotechnics industry. However, the Asia-Pacific region is showing the fastest growth, driven by the expanding entertainment industry and increasing adoption of safety standards in developing countries.

The market is also influenced by technological advancements in material science. Innovations in polymer chemistry are enabling the development of polypropylene with enhanced heat resistance and other desirable properties. This progress is opening new possibilities for safer, more comfortable, and more effective protective gear, further stimulating market demand.

Environmental concerns and sustainability initiatives are shaping the market as well. There is a growing demand for eco-friendly and recyclable materials in safety gear, presenting both challenges and opportunities for manufacturers of heat-resistant polypropylene products.

Current Challenges

The development of heat-resistant polypropylene for pyrotechnics safety gear faces several significant challenges. One of the primary obstacles is achieving the delicate balance between heat resistance and material flexibility. While increased heat resistance is crucial for protecting users from extreme temperatures, it often comes at the cost of reduced flexibility, which can impair the comfort and mobility of safety gear.

Another major challenge lies in maintaining the structural integrity of polypropylene under high-temperature conditions. As temperatures rise, conventional polypropylene tends to soften and lose its shape, compromising the protective properties of the safety equipment. This necessitates the development of advanced polymer formulations that can retain their form and protective qualities even when exposed to intense heat.

The incorporation of flame-retardant additives presents its own set of difficulties. These additives, while essential for enhancing fire resistance, can negatively impact the physical properties of the polypropylene, such as tensile strength and impact resistance. Finding the right balance of additives that improve heat resistance without significantly degrading other critical material properties remains a complex task for researchers and manufacturers.

Durability under repeated exposure to high temperatures is another key challenge. Pyrotechnics safety gear must withstand not only single instances of extreme heat but also maintain its protective capabilities over multiple uses. This requires the development of polypropylene formulations that resist thermal degradation and maintain their properties even after repeated heat cycles.

Cost-effectiveness presents an ongoing challenge in the development of heat-resistant polypropylene. Advanced materials and manufacturing processes often come with higher production costs, which can limit widespread adoption in the pyrotechnics industry. Balancing enhanced performance with economic viability is crucial for the successful implementation of these materials in safety gear.

Environmental concerns also pose challenges in the development process. As sustainability becomes increasingly important, there is a growing need to create heat-resistant polypropylene that is not only effective but also environmentally friendly. This includes considerations for recyclability and the use of non-toxic additives, which can sometimes conflict with achieving optimal heat resistance properties.

Lastly, meeting stringent regulatory standards and certifications for pyrotechnics safety gear adds another layer of complexity to the development process. Manufacturers must navigate a landscape of evolving safety regulations while pushing the boundaries of material science to create polypropylene that meets or exceeds these standards.

Another major challenge lies in maintaining the structural integrity of polypropylene under high-temperature conditions. As temperatures rise, conventional polypropylene tends to soften and lose its shape, compromising the protective properties of the safety equipment. This necessitates the development of advanced polymer formulations that can retain their form and protective qualities even when exposed to intense heat.

The incorporation of flame-retardant additives presents its own set of difficulties. These additives, while essential for enhancing fire resistance, can negatively impact the physical properties of the polypropylene, such as tensile strength and impact resistance. Finding the right balance of additives that improve heat resistance without significantly degrading other critical material properties remains a complex task for researchers and manufacturers.

Durability under repeated exposure to high temperatures is another key challenge. Pyrotechnics safety gear must withstand not only single instances of extreme heat but also maintain its protective capabilities over multiple uses. This requires the development of polypropylene formulations that resist thermal degradation and maintain their properties even after repeated heat cycles.

Cost-effectiveness presents an ongoing challenge in the development of heat-resistant polypropylene. Advanced materials and manufacturing processes often come with higher production costs, which can limit widespread adoption in the pyrotechnics industry. Balancing enhanced performance with economic viability is crucial for the successful implementation of these materials in safety gear.

Environmental concerns also pose challenges in the development process. As sustainability becomes increasingly important, there is a growing need to create heat-resistant polypropylene that is not only effective but also environmentally friendly. This includes considerations for recyclability and the use of non-toxic additives, which can sometimes conflict with achieving optimal heat resistance properties.

Lastly, meeting stringent regulatory standards and certifications for pyrotechnics safety gear adds another layer of complexity to the development process. Manufacturers must navigate a landscape of evolving safety regulations while pushing the boundaries of material science to create polypropylene that meets or exceeds these standards.

Existing Safety Solutions

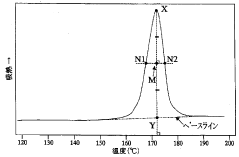

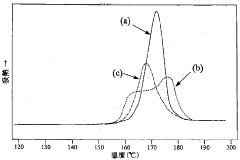

01 Nucleating agents for improved heat resistance

Incorporating nucleating agents into polypropylene compositions can enhance crystallization and improve heat resistance. These agents promote the formation of smaller, more uniform crystals, leading to better overall thermal stability and mechanical properties at elevated temperatures.- Nucleating agents for improved heat resistance: Incorporating nucleating agents into polypropylene compositions can enhance heat resistance. These agents promote the formation of smaller, more uniform crystalline structures, leading to improved thermal stability and mechanical properties at elevated temperatures.

- Blending with high-temperature resistant polymers: Blending polypropylene with other high-temperature resistant polymers, such as polyamides or polyesters, can significantly improve the overall heat resistance of the material. This approach combines the desirable properties of both polymers to create a more thermally stable composite.

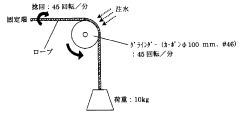

- Cross-linking for enhanced thermal stability: Cross-linking polypropylene molecules through various methods, such as electron beam irradiation or chemical agents, can greatly improve its heat resistance. This process creates a more stable network structure that maintains its integrity at higher temperatures.

- Incorporation of inorganic fillers: Adding inorganic fillers like talc, glass fibers, or mineral particles to polypropylene can enhance its heat resistance. These fillers act as reinforcing agents and heat dissipators, improving the material's ability to withstand high temperatures without deformation.

- Modification of polymer structure: Modifying the molecular structure of polypropylene through techniques such as copolymerization or grafting can lead to improved heat resistance. These modifications can introduce thermally stable functional groups or alter the crystalline structure, resulting in better performance at elevated temperatures.

02 Blending with high-temperature resistant polymers

Blending polypropylene with other high-temperature resistant polymers, such as polyamides or polyesters, can significantly improve the heat resistance of the resulting composite material. This approach combines the desirable properties of both polymers to create a more thermally stable product.Expand Specific Solutions03 Cross-linking for enhanced thermal stability

Cross-linking polypropylene chains through various methods, such as electron beam irradiation or chemical agents, can greatly improve its heat resistance. This process creates a more rigid molecular structure that maintains its integrity at higher temperatures.Expand Specific Solutions04 Incorporation of inorganic fillers

Adding inorganic fillers such as talc, glass fibers, or mineral particles to polypropylene can enhance its heat resistance. These fillers act as reinforcing agents and heat dissipators, improving the overall thermal stability of the composite material.Expand Specific Solutions05 Modification of polymer structure

Modifying the molecular structure of polypropylene through techniques such as copolymerization or grafting can improve its heat resistance. These modifications can introduce thermally stable functional groups or alter the crystalline structure, resulting in enhanced performance at elevated temperatures.Expand Specific Solutions

Key Industry Players

The heat-resistant polypropylene market for pyrotechnics safety gear is in a growth phase, driven by increasing safety regulations and demand for high-performance materials. The market size is expanding, with potential for further growth in specialized applications. Technologically, heat-resistant polypropylene is advancing, with companies like DuPont, Borealis, and Kingfa Sci. & Tech. leading innovation. These firms are developing enhanced formulations with improved thermal stability and flame-retardant properties. However, the technology is not yet fully mature, leaving room for further advancements in performance and cost-effectiveness. Collaboration between material suppliers and safety equipment manufacturers is likely to accelerate progress in this niche but critical market segment.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a heat-resistant polypropylene (PP) called Zytel® HTNHPA-LG2D which exhibits exceptional thermal stability and flame-retardant properties. This material incorporates advanced polymer technology and flame-retardant additives to achieve a UL94 V-0 rating at 0.8 mm thickness[1]. The Zytel® HTNHPA-LG2D maintains its mechanical properties at temperatures up to 200°C, making it suitable for pyrotechnics safety gear applications[2]. DuPont's solution also features a proprietary stabilization package that prevents degradation during processing and end-use, ensuring long-term performance in high-temperature environments[3].

Strengths: Superior heat resistance, excellent flame-retardant properties, and long-term stability. Weaknesses: Potentially higher cost compared to standard PP, may require specialized processing equipment.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed GORE® PYRAD® Fabric Technology, a heat and flame-resistant material suitable for pyrotechnics safety gear. This innovative fabric incorporates specially engineered polypropylene fibers with proprietary treatments to enhance heat resistance and flame retardancy[4]. The GORE® PYRAD® technology provides protection against heat fluxes up to 80 kW/m² while maintaining flexibility and breathability[5]. The fabric also features self-extinguishing properties and minimal shrinkage when exposed to high temperatures, crucial for maintaining protective coverage in pyrotechnic environments[6].

Strengths: High heat flux protection, flexibility, and breathability. Weaknesses: May be more expensive than traditional materials, potential limitations in extreme temperature scenarios.

Heat-Resistant Innovations

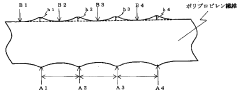

Polypropylene fiber, method of producing the same and utilization of the same

PatentWO2008123173A1

Innovation

- Development of polypropylene fibers with an isotactic pentad fraction of 94% or more, characterized by a uniform crystal structure, high fiber strength, and specific surface irregularities, which provide excellent heat resistance and water retention, and are produced through a method involving melt spinning, pre-stretching, and post-stretching under controlled conditions.

Flame-retardant Polypropylene Resin Composition with Excellent Rigidity and Heat Resistance

PatentActiveKR1020200071900A

Innovation

- A polypropylene resin composition comprising 38.0 to 93.8 parts by weight of a highly crystalline homo polypropylene resin, 1.0 to 30.0 parts by weight of a halogen-based flame retardant and metal-based flame retardant aid, 5.0 to 30.0 parts by weight of magnesium hydroxide-based filler, and optional additives like nucleating agents and antioxidants, which are mixed and molded to form a polypropylene resin molded article.

Regulatory Framework

The regulatory framework surrounding heat-resistant polypropylene in pyrotechnics safety gear is complex and multifaceted, involving various international, national, and industry-specific standards. At the international level, the United Nations' Recommendations on the Transport of Dangerous Goods provide guidelines for the safe handling and transportation of pyrotechnic materials, which indirectly influence the requirements for safety gear.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth standards for personal protective equipment (PPE) in hazardous environments, including those involving pyrotechnics. OSHA's standard 29 CFR 1910.132 mandates that employers provide appropriate PPE for employees exposed to workplace hazards. The National Fire Protection Association (NFPA) also plays a crucial role, with NFPA 1971 specifically addressing protective ensembles for structural fire fighting and proximity fire fighting.

The European Union has established the Personal Protective Equipment Regulation (EU) 2016/425, which sets out the essential health and safety requirements that PPE must fulfill. This regulation is particularly relevant for heat-resistant polypropylene used in pyrotechnics safety gear, as it covers equipment designed to protect against heat and flame.

In the context of material specifications, the International Organization for Standardization (ISO) provides several relevant standards. ISO 11612 outlines the performance requirements for protective clothing against heat and flame, while ISO 9151 specifies a test method for determining heat transmission through protective clothing or component assemblies exposed to flame.

Specific to pyrotechnics, the American Pyrotechnics Association (APA) has developed industry standards that complement federal regulations. These standards often reference the use of appropriate protective gear, including those made from heat-resistant materials like polypropylene.

It's important to note that regulations often lag behind technological advancements. As new heat-resistant polypropylene formulations are developed, there may be a period where existing standards do not fully address their unique properties. This creates both challenges and opportunities for manufacturers and regulatory bodies to collaborate on updating standards to ensure they remain relevant and effective.

Compliance with these regulations and standards is not only a legal requirement but also a critical factor in ensuring the safety of personnel working with pyrotechnics. Manufacturers of heat-resistant polypropylene safety gear must navigate this complex regulatory landscape, ensuring their products meet or exceed all applicable standards while also staying abreast of potential regulatory changes that may impact future product development and certification processes.

In the United States, the Occupational Safety and Health Administration (OSHA) sets forth standards for personal protective equipment (PPE) in hazardous environments, including those involving pyrotechnics. OSHA's standard 29 CFR 1910.132 mandates that employers provide appropriate PPE for employees exposed to workplace hazards. The National Fire Protection Association (NFPA) also plays a crucial role, with NFPA 1971 specifically addressing protective ensembles for structural fire fighting and proximity fire fighting.

The European Union has established the Personal Protective Equipment Regulation (EU) 2016/425, which sets out the essential health and safety requirements that PPE must fulfill. This regulation is particularly relevant for heat-resistant polypropylene used in pyrotechnics safety gear, as it covers equipment designed to protect against heat and flame.

In the context of material specifications, the International Organization for Standardization (ISO) provides several relevant standards. ISO 11612 outlines the performance requirements for protective clothing against heat and flame, while ISO 9151 specifies a test method for determining heat transmission through protective clothing or component assemblies exposed to flame.

Specific to pyrotechnics, the American Pyrotechnics Association (APA) has developed industry standards that complement federal regulations. These standards often reference the use of appropriate protective gear, including those made from heat-resistant materials like polypropylene.

It's important to note that regulations often lag behind technological advancements. As new heat-resistant polypropylene formulations are developed, there may be a period where existing standards do not fully address their unique properties. This creates both challenges and opportunities for manufacturers and regulatory bodies to collaborate on updating standards to ensure they remain relevant and effective.

Compliance with these regulations and standards is not only a legal requirement but also a critical factor in ensuring the safety of personnel working with pyrotechnics. Manufacturers of heat-resistant polypropylene safety gear must navigate this complex regulatory landscape, ensuring their products meet or exceed all applicable standards while also staying abreast of potential regulatory changes that may impact future product development and certification processes.

Environmental Impact

The development and use of heat-resistant polypropylene in pyrotechnics safety gear have significant environmental implications that warrant careful consideration. This material's enhanced thermal properties contribute to improved safety measures in pyrotechnic operations, potentially reducing the risk of accidents and associated environmental contamination. However, the production and disposal of heat-resistant polypropylene also present environmental challenges that must be addressed.

In terms of production, the manufacturing process of heat-resistant polypropylene typically involves the use of additives and specialized treatments to enhance its thermal properties. These processes may require additional energy inputs and chemical substances, potentially increasing the carbon footprint and environmental impact compared to standard polypropylene production. However, the extended lifespan and improved performance of heat-resistant polypropylene in safety gear applications may offset these initial environmental costs over time.

The durability and heat resistance of this material contribute to longer-lasting safety equipment, which can reduce the frequency of replacement and, consequently, the overall waste generated in the pyrotechnics industry. This longevity factor is particularly important in reducing the environmental burden associated with the disposal of safety gear. However, it is crucial to note that the additives used to enhance heat resistance may complicate recycling processes, potentially limiting the material's end-of-life options.

When considering the environmental impact of heat-resistant polypropylene in pyrotechnics safety gear, it is essential to evaluate its role in preventing accidents and containing potential environmental hazards. By providing superior protection against heat and flame, this material can help prevent the release of harmful substances into the environment during pyrotechnic events or accidents. This protective function indirectly contributes to environmental preservation by minimizing the risk of fires, explosions, or other incidents that could lead to ecological damage.

Furthermore, the use of heat-resistant polypropylene in safety gear may influence the design and execution of pyrotechnic displays and operations. Improved safety measures could potentially allow for more controlled and environmentally conscious practices in the industry, reducing the overall environmental footprint of pyrotechnic activities. This could include more precise and efficient use of pyrotechnic materials, leading to reduced waste and emissions.

However, it is important to consider the end-of-life management of heat-resistant polypropylene safety gear. While the material's durability is an asset during its use phase, it may pose challenges for disposal or recycling. Developing effective recycling methods or safe disposal protocols for this specialized material is crucial to mitigate its long-term environmental impact. Research into biodegradable alternatives or closed-loop recycling systems for heat-resistant polymers could provide future pathways to enhance the environmental sustainability of pyrotechnics safety gear.

In terms of production, the manufacturing process of heat-resistant polypropylene typically involves the use of additives and specialized treatments to enhance its thermal properties. These processes may require additional energy inputs and chemical substances, potentially increasing the carbon footprint and environmental impact compared to standard polypropylene production. However, the extended lifespan and improved performance of heat-resistant polypropylene in safety gear applications may offset these initial environmental costs over time.

The durability and heat resistance of this material contribute to longer-lasting safety equipment, which can reduce the frequency of replacement and, consequently, the overall waste generated in the pyrotechnics industry. This longevity factor is particularly important in reducing the environmental burden associated with the disposal of safety gear. However, it is crucial to note that the additives used to enhance heat resistance may complicate recycling processes, potentially limiting the material's end-of-life options.

When considering the environmental impact of heat-resistant polypropylene in pyrotechnics safety gear, it is essential to evaluate its role in preventing accidents and containing potential environmental hazards. By providing superior protection against heat and flame, this material can help prevent the release of harmful substances into the environment during pyrotechnic events or accidents. This protective function indirectly contributes to environmental preservation by minimizing the risk of fires, explosions, or other incidents that could lead to ecological damage.

Furthermore, the use of heat-resistant polypropylene in safety gear may influence the design and execution of pyrotechnic displays and operations. Improved safety measures could potentially allow for more controlled and environmentally conscious practices in the industry, reducing the overall environmental footprint of pyrotechnic activities. This could include more precise and efficient use of pyrotechnic materials, leading to reduced waste and emissions.

However, it is important to consider the end-of-life management of heat-resistant polypropylene safety gear. While the material's durability is an asset during its use phase, it may pose challenges for disposal or recycling. Developing effective recycling methods or safe disposal protocols for this specialized material is crucial to mitigate its long-term environmental impact. Research into biodegradable alternatives or closed-loop recycling systems for heat-resistant polymers could provide future pathways to enhance the environmental sustainability of pyrotechnics safety gear.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!