How Glycerol Contributes to Reduction of Plasticizer Use in Polymers

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glycerol in Plasticizers

Glycerol, a byproduct of biodiesel production, has emerged as a promising alternative to traditional plasticizers in polymer applications. Its unique chemical structure, consisting of three hydroxyl groups, allows for effective interaction with polymer chains, enhancing flexibility and processability. This natural, non-toxic compound addresses growing concerns over the environmental and health impacts of conventional plasticizers, particularly phthalates.

The incorporation of glycerol into polymer formulations has demonstrated significant potential in reducing the overall plasticizer content while maintaining or even improving material properties. Research has shown that glycerol can effectively plasticize a wide range of polymers, including starch-based materials, polyvinyl alcohol (PVA), and various biopolymers. Its hygroscopic nature contributes to moisture retention, which can be beneficial in certain applications but may require careful consideration in others.

One of the key advantages of using glycerol as a plasticizer is its ability to form hydrogen bonds with polymer chains. This interaction leads to increased free volume within the polymer matrix, resulting in enhanced chain mobility and reduced glass transition temperature. Consequently, polymers plasticized with glycerol often exhibit improved flexibility, elongation at break, and impact resistance compared to their unplasticized counterparts.

The effectiveness of glycerol as a plasticizer varies depending on the polymer type and the specific application requirements. In some cases, glycerol can be used as a sole plasticizer, while in others, it may be combined with traditional plasticizers to achieve optimal performance. The synergistic effects of glycerol with other plasticizers have been explored, showing promising results in terms of compatibility and overall plasticization efficiency.

Furthermore, the use of glycerol as a plasticizer aligns with the growing trend towards sustainable and bio-based materials. Its renewable nature and biodegradability contribute to the development of more environmentally friendly polymer products. This aspect is particularly relevant in industries such as packaging, where there is increasing pressure to reduce the environmental footprint of plastic materials.

However, challenges remain in the widespread adoption of glycerol as a plasticizer. These include potential migration issues, long-term stability concerns, and the need for optimized processing conditions. Ongoing research focuses on addressing these challenges through various strategies, such as chemical modification of glycerol, development of novel polymer blends, and exploration of innovative processing techniques.

The incorporation of glycerol into polymer formulations has demonstrated significant potential in reducing the overall plasticizer content while maintaining or even improving material properties. Research has shown that glycerol can effectively plasticize a wide range of polymers, including starch-based materials, polyvinyl alcohol (PVA), and various biopolymers. Its hygroscopic nature contributes to moisture retention, which can be beneficial in certain applications but may require careful consideration in others.

One of the key advantages of using glycerol as a plasticizer is its ability to form hydrogen bonds with polymer chains. This interaction leads to increased free volume within the polymer matrix, resulting in enhanced chain mobility and reduced glass transition temperature. Consequently, polymers plasticized with glycerol often exhibit improved flexibility, elongation at break, and impact resistance compared to their unplasticized counterparts.

The effectiveness of glycerol as a plasticizer varies depending on the polymer type and the specific application requirements. In some cases, glycerol can be used as a sole plasticizer, while in others, it may be combined with traditional plasticizers to achieve optimal performance. The synergistic effects of glycerol with other plasticizers have been explored, showing promising results in terms of compatibility and overall plasticization efficiency.

Furthermore, the use of glycerol as a plasticizer aligns with the growing trend towards sustainable and bio-based materials. Its renewable nature and biodegradability contribute to the development of more environmentally friendly polymer products. This aspect is particularly relevant in industries such as packaging, where there is increasing pressure to reduce the environmental footprint of plastic materials.

However, challenges remain in the widespread adoption of glycerol as a plasticizer. These include potential migration issues, long-term stability concerns, and the need for optimized processing conditions. Ongoing research focuses on addressing these challenges through various strategies, such as chemical modification of glycerol, development of novel polymer blends, and exploration of innovative processing techniques.

Market Demand Analysis

The market demand for glycerol as a plasticizer alternative in polymers has been steadily increasing due to growing environmental concerns and regulatory pressures. Traditional plasticizers, such as phthalates, have faced scrutiny for their potential health and environmental risks, leading to a shift towards more sustainable options. Glycerol, being a bio-based and non-toxic compound, has emerged as a promising candidate to meet this demand.

The global plasticizer market, valued at over $15 billion in 2020, is expected to grow at a CAGR of 5.5% from 2021 to 2028. Within this market, the demand for bio-based plasticizers is projected to grow at an even higher rate, driven by stringent regulations and consumer preferences for eco-friendly products. Glycerol, as a key player in this segment, is poised to capture a significant share of this growth.

Several industries are driving the demand for glycerol-based plasticizers. The packaging industry, particularly food packaging, is a major consumer due to the need for safe, non-toxic materials in contact with consumables. The automotive sector is also showing increased interest in glycerol-based polymer solutions for interior components, aiming to reduce the overall environmental impact of vehicles.

The construction industry is another significant market, with a growing demand for PVC products that utilize safer plasticizers. Glycerol's ability to enhance flexibility and durability in polymers makes it an attractive option for various building materials and components.

Medical and healthcare sectors are also contributing to the market demand, as glycerol-based plasticizers offer biocompatibility and reduced risk of leaching, crucial for medical devices and pharmaceutical packaging.

Geographically, Europe and North America are leading the adoption of glycerol-based plasticizers due to strict regulations on traditional plasticizers. However, Asia-Pacific is expected to show the highest growth rate in the coming years, driven by rapid industrialization and increasing awareness of environmental issues.

The market trend indicates a shift towards customized glycerol-based solutions that cater to specific polymer applications. This has led to increased research and development activities, focusing on optimizing glycerol's performance as a plasticizer in various polymer matrices.

Despite the positive outlook, challenges remain in scaling up production and ensuring cost-competitiveness with traditional plasticizers. However, as technology advances and production efficiencies improve, the cost gap is expected to narrow, further driving market growth for glycerol-based plasticizer alternatives in polymers.

The global plasticizer market, valued at over $15 billion in 2020, is expected to grow at a CAGR of 5.5% from 2021 to 2028. Within this market, the demand for bio-based plasticizers is projected to grow at an even higher rate, driven by stringent regulations and consumer preferences for eco-friendly products. Glycerol, as a key player in this segment, is poised to capture a significant share of this growth.

Several industries are driving the demand for glycerol-based plasticizers. The packaging industry, particularly food packaging, is a major consumer due to the need for safe, non-toxic materials in contact with consumables. The automotive sector is also showing increased interest in glycerol-based polymer solutions for interior components, aiming to reduce the overall environmental impact of vehicles.

The construction industry is another significant market, with a growing demand for PVC products that utilize safer plasticizers. Glycerol's ability to enhance flexibility and durability in polymers makes it an attractive option for various building materials and components.

Medical and healthcare sectors are also contributing to the market demand, as glycerol-based plasticizers offer biocompatibility and reduced risk of leaching, crucial for medical devices and pharmaceutical packaging.

Geographically, Europe and North America are leading the adoption of glycerol-based plasticizers due to strict regulations on traditional plasticizers. However, Asia-Pacific is expected to show the highest growth rate in the coming years, driven by rapid industrialization and increasing awareness of environmental issues.

The market trend indicates a shift towards customized glycerol-based solutions that cater to specific polymer applications. This has led to increased research and development activities, focusing on optimizing glycerol's performance as a plasticizer in various polymer matrices.

Despite the positive outlook, challenges remain in scaling up production and ensuring cost-competitiveness with traditional plasticizers. However, as technology advances and production efficiencies improve, the cost gap is expected to narrow, further driving market growth for glycerol-based plasticizer alternatives in polymers.

Current Challenges

The current challenges in reducing plasticizer use through glycerol incorporation in polymers are multifaceted and complex. One of the primary obstacles is achieving optimal compatibility between glycerol and various polymer matrices. While glycerol's hydrophilic nature can enhance certain polymer properties, it may also lead to phase separation or inconsistent distribution within hydrophobic polymers, potentially compromising the material's overall performance and stability.

Another significant challenge lies in maintaining the desired mechanical properties of polymers when substituting traditional plasticizers with glycerol. Plasticizers are crucial for imparting flexibility and reducing brittleness in many polymer applications. However, glycerol's molecular structure and interactions with polymer chains differ from conventional plasticizers, necessitating careful formulation adjustments to achieve comparable or superior mechanical characteristics.

The processing and manufacturing aspects of incorporating glycerol into polymers also present technical hurdles. Existing production lines and equipment may require modifications to accommodate the different rheological behavior and processing parameters associated with glycerol-containing polymer blends. This adaptation can be both costly and time-consuming for manufacturers, potentially slowing down the widespread adoption of glycerol as a plasticizer alternative.

Furthermore, the long-term stability and durability of glycerol-plasticized polymers remain areas of concern. Glycerol's hygroscopic nature may lead to moisture absorption over time, potentially affecting the polymer's dimensional stability, electrical properties, and resistance to environmental factors. Addressing these issues requires extensive research into stabilization techniques and protective measures to ensure the longevity of glycerol-containing polymer products.

The regulatory landscape and safety considerations also pose challenges to the widespread use of glycerol as a plasticizer replacement. While glycerol is generally recognized as safe for many applications, its use in certain polymer products, particularly those in contact with food or medical applications, may require additional testing and certification to meet stringent regulatory standards.

Lastly, the economic viability of using glycerol as a plasticizer alternative remains a significant challenge. Although glycerol is a byproduct of biodiesel production and potentially more sustainable than traditional plasticizers, the cost-effectiveness of its use in large-scale polymer manufacturing must be carefully evaluated. Factors such as raw material costs, processing modifications, and potential changes in product performance all contribute to the overall economic feasibility of this technological shift.

Another significant challenge lies in maintaining the desired mechanical properties of polymers when substituting traditional plasticizers with glycerol. Plasticizers are crucial for imparting flexibility and reducing brittleness in many polymer applications. However, glycerol's molecular structure and interactions with polymer chains differ from conventional plasticizers, necessitating careful formulation adjustments to achieve comparable or superior mechanical characteristics.

The processing and manufacturing aspects of incorporating glycerol into polymers also present technical hurdles. Existing production lines and equipment may require modifications to accommodate the different rheological behavior and processing parameters associated with glycerol-containing polymer blends. This adaptation can be both costly and time-consuming for manufacturers, potentially slowing down the widespread adoption of glycerol as a plasticizer alternative.

Furthermore, the long-term stability and durability of glycerol-plasticized polymers remain areas of concern. Glycerol's hygroscopic nature may lead to moisture absorption over time, potentially affecting the polymer's dimensional stability, electrical properties, and resistance to environmental factors. Addressing these issues requires extensive research into stabilization techniques and protective measures to ensure the longevity of glycerol-containing polymer products.

The regulatory landscape and safety considerations also pose challenges to the widespread use of glycerol as a plasticizer replacement. While glycerol is generally recognized as safe for many applications, its use in certain polymer products, particularly those in contact with food or medical applications, may require additional testing and certification to meet stringent regulatory standards.

Lastly, the economic viability of using glycerol as a plasticizer alternative remains a significant challenge. Although glycerol is a byproduct of biodiesel production and potentially more sustainable than traditional plasticizers, the cost-effectiveness of its use in large-scale polymer manufacturing must be carefully evaluated. Factors such as raw material costs, processing modifications, and potential changes in product performance all contribute to the overall economic feasibility of this technological shift.

Glycerol-based Solutions

01 Use of glycerol as a plasticizer in polymer compositions

Glycerol is utilized as a plasticizer in various polymer compositions to improve flexibility, processability, and overall performance. It is particularly effective in biodegradable and bio-based polymers, enhancing their mechanical properties and reducing brittleness.- Use of glycerol as a plasticizer in polymer compositions: Glycerol is utilized as a plasticizer in various polymer compositions to improve flexibility, processability, and overall performance. It is particularly effective in biodegradable and bio-based polymers, enhancing their mechanical properties and reducing brittleness. The addition of glycerol can also improve the thermal stability and moisture resistance of the polymer materials.

- Application of glycerol plasticizer in food packaging: Glycerol is employed as a plasticizer in food packaging materials, particularly in edible films and coatings. It helps improve the barrier properties, flexibility, and durability of the packaging while maintaining food safety. The use of glycerol in this context also contributes to the development of environmentally friendly packaging solutions.

- Glycerol as a plasticizer in pharmaceutical formulations: In pharmaceutical applications, glycerol serves as a plasticizer in various drug delivery systems and dosage forms. It enhances the flexibility and stability of film coatings, improves the dissolution properties of certain drugs, and contributes to the overall efficacy of pharmaceutical formulations. Glycerol's use in this field also extends to the production of soft gelatin capsules and transdermal patches.

- Glycerol plasticizer in personal care and cosmetic products: Glycerol is widely used as a plasticizer in personal care and cosmetic formulations. It helps improve the texture, spreadability, and moisture retention properties of various products such as creams, lotions, and gels. The plasticizing effect of glycerol also contributes to the stability and shelf life of these products while providing skin-conditioning benefits.

- Glycerol as a plasticizer in bioplastics and sustainable materials: In the development of bioplastics and sustainable materials, glycerol plays a crucial role as a plasticizer. It is often used in conjunction with bio-based polymers to create environmentally friendly alternatives to conventional plastics. Glycerol improves the processability, flexibility, and biodegradability of these materials, making them suitable for various applications in packaging, agriculture, and consumer goods.

02 Glycerol plasticizer in food packaging materials

Glycerol is employed as a plasticizer in the production of food packaging materials, particularly in edible films and coatings. It improves the barrier properties, flexibility, and durability of these materials while maintaining their biodegradability and food safety compliance.Expand Specific Solutions03 Glycerol as a plasticizer in pharmaceutical formulations

In pharmaceutical applications, glycerol serves as a plasticizer in various formulations, including tablet coatings, capsule shells, and transdermal patches. It enhances the flexibility and stability of these dosage forms, improving their performance and shelf life.Expand Specific Solutions04 Use of glycerol in plasticized starch compositions

Glycerol is widely used as a plasticizer in starch-based materials, improving their processability, flexibility, and moisture resistance. These plasticized starch compositions find applications in biodegradable packaging, disposable products, and agricultural films.Expand Specific Solutions05 Glycerol as a plasticizer in personal care and cosmetic products

In personal care and cosmetic formulations, glycerol acts as a plasticizer to improve the texture, spreadability, and stability of various products. It also provides moisturizing properties, making it a versatile ingredient in skincare, haircare, and color cosmetics.Expand Specific Solutions

Key Industry Players

The competition landscape for glycerol's contribution to reducing plasticizer use in polymers is evolving rapidly. The market is in a growth phase, driven by increasing demand for sustainable and eco-friendly plasticizer alternatives. Major players like BASF, ExxonMobil, and Eastman Chemical are investing heavily in research and development to capitalize on this trend. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing quickly, with companies like Plantic Technologies and Anhui Sealong Biotechnology making strides in developing innovative glycerol-based solutions. However, the technology is still maturing, with ongoing efforts to optimize performance and cost-effectiveness across various polymer applications.

BASF Corp.

Technical Solution: BASF has developed a novel approach to using glycerol as a bio-based plasticizer in polymer formulations. Their technology involves chemically modifying glycerol to enhance its compatibility with various polymers. The modified glycerol derivatives are designed to have improved miscibility and reduced migration compared to traditional plasticizers. BASF's process includes esterification of glycerol with fatty acids or other organic compounds to create tailored plasticizers for specific polymer applications[1]. These glycerol-based plasticizers have been shown to provide effective plasticization while maintaining or improving key polymer properties such as flexibility, durability, and thermal stability[3]. BASF has also developed methods to incorporate these glycerol-derived plasticizers into polymer processing at industrial scales, enabling seamless integration into existing manufacturing processes[5].

Strengths: Utilizes renewable resources, reduces reliance on petroleum-based plasticizers, and offers improved compatibility with various polymers. Weaknesses: May have higher production costs compared to traditional plasticizers and potential limitations in extreme temperature applications.

Eastman Chemical Co.

Technical Solution: Eastman Chemical has pioneered a glycerol-based plasticizer technology that focuses on enhancing the performance of biodegradable polymers. Their approach involves creating glycerol esters through a proprietary process that results in plasticizers with excellent compatibility with biopolymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA)[2]. These glycerol-derived plasticizers are designed to improve the flexibility and processability of biopolymers without compromising their biodegradability. Eastman's technology also addresses the issue of plasticizer migration by optimizing the molecular weight and polarity of the glycerol esters[4]. The company has demonstrated that their glycerol-based plasticizers can significantly reduce the glass transition temperature of biopolymers, enhancing their potential applications in packaging and consumer goods[6].

Strengths: Enhances properties of biodegradable polymers, maintains biodegradability, and offers improved performance in packaging applications. Weaknesses: May have limited effectiveness in non-biodegradable polymer systems and potential higher costs compared to conventional plasticizers.

Innovative Glycerol Tech

Process for treating thermoplasts or non-thermoplastic polymers and those containing amide and/or urethane groups

PatentInactiveEP0344681A2

Innovation

- A method involving the use of glycerol to liquefy polymers at temperatures between 120°C and 280°C, allowing for physical separation of polymers from metal surfaces and other materials, enabling effective cleaning, waste disposal, and recycling by floating or sinking components based on density differences.

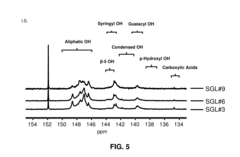

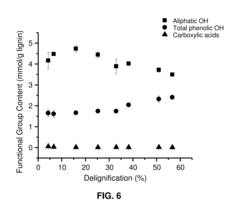

Melt compounding and fractionation of lignocellulosic biomass and products produced therefrom

PatentInactiveUS20160273010A1

Innovation

- A pretreatment process using thermal processing with glycerol as a solvent to shear biomass at elevated temperatures, disrupting inter- and intra-polymer linkages, thereby enhancing enzyme access and achieving high conversion rates of cellulose to glucose, while maintaining high molecular weight lignin for recovery.

Environmental Impact

The use of glycerol as a plasticizer in polymers has significant environmental implications, offering a more sustainable alternative to traditional petrochemical-based plasticizers. Glycerol, a byproduct of biodiesel production, is abundant, renewable, and biodegradable, making it an environmentally friendly option for polymer modification.

One of the primary environmental benefits of using glycerol as a plasticizer is the reduction of reliance on fossil fuel-derived materials. Traditional plasticizers, such as phthalates, are typically derived from petroleum, contributing to the depletion of non-renewable resources and increasing carbon footprint. In contrast, glycerol's renewable nature helps mitigate these issues, promoting a more circular economy approach in polymer production.

The biodegradability of glycerol-based plasticizers is another crucial environmental advantage. Unlike many synthetic plasticizers that persist in the environment for extended periods, glycerol-based alternatives break down more readily in natural conditions. This characteristic reduces the long-term environmental impact of plastic products, particularly in terms of waste management and potential ecosystem contamination.

Furthermore, the use of glycerol as a plasticizer can contribute to the reduction of volatile organic compound (VOC) emissions. Many traditional plasticizers are known to release VOCs over time, which can have detrimental effects on air quality and human health. Glycerol, being less volatile, minimizes these emissions, leading to improved indoor air quality and reduced environmental pollution.

The incorporation of glycerol into polymers can also enhance the overall recyclability of plastic products. As a natural compound, glycerol does not introduce complex chemical structures that might hinder recycling processes. This compatibility with existing recycling systems can lead to higher recycling rates and a more efficient circular economy for plastics.

Additionally, the use of glycerol as a plasticizer aligns with the growing trend of bio-based materials in various industries. This shift towards more sustainable raw materials can drive innovation in green chemistry and promote the development of environmentally friendly technologies across the polymer industry.

However, it is important to consider the potential environmental trade-offs. While glycerol itself is environmentally benign, its production through biodiesel manufacturing may have associated environmental impacts. These include land use changes for biofuel crops and the energy requirements of the biodiesel production process. A comprehensive life cycle assessment is necessary to fully understand the net environmental benefits of glycerol-based plasticizers compared to traditional alternatives.

One of the primary environmental benefits of using glycerol as a plasticizer is the reduction of reliance on fossil fuel-derived materials. Traditional plasticizers, such as phthalates, are typically derived from petroleum, contributing to the depletion of non-renewable resources and increasing carbon footprint. In contrast, glycerol's renewable nature helps mitigate these issues, promoting a more circular economy approach in polymer production.

The biodegradability of glycerol-based plasticizers is another crucial environmental advantage. Unlike many synthetic plasticizers that persist in the environment for extended periods, glycerol-based alternatives break down more readily in natural conditions. This characteristic reduces the long-term environmental impact of plastic products, particularly in terms of waste management and potential ecosystem contamination.

Furthermore, the use of glycerol as a plasticizer can contribute to the reduction of volatile organic compound (VOC) emissions. Many traditional plasticizers are known to release VOCs over time, which can have detrimental effects on air quality and human health. Glycerol, being less volatile, minimizes these emissions, leading to improved indoor air quality and reduced environmental pollution.

The incorporation of glycerol into polymers can also enhance the overall recyclability of plastic products. As a natural compound, glycerol does not introduce complex chemical structures that might hinder recycling processes. This compatibility with existing recycling systems can lead to higher recycling rates and a more efficient circular economy for plastics.

Additionally, the use of glycerol as a plasticizer aligns with the growing trend of bio-based materials in various industries. This shift towards more sustainable raw materials can drive innovation in green chemistry and promote the development of environmentally friendly technologies across the polymer industry.

However, it is important to consider the potential environmental trade-offs. While glycerol itself is environmentally benign, its production through biodiesel manufacturing may have associated environmental impacts. These include land use changes for biofuel crops and the energy requirements of the biodiesel production process. A comprehensive life cycle assessment is necessary to fully understand the net environmental benefits of glycerol-based plasticizers compared to traditional alternatives.

Regulatory Landscape

The regulatory landscape surrounding the use of glycerol as a plasticizer in polymers is evolving rapidly, driven by increasing environmental concerns and the push for sustainable alternatives. Governments and regulatory bodies worldwide are implementing stricter guidelines on the use of traditional plasticizers, particularly phthalates, due to their potential health and environmental risks. This shift has created a favorable environment for glycerol-based alternatives.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has placed significant restrictions on certain phthalates, creating opportunities for glycerol-based plasticizers. The EU has also set targets for increasing the use of bio-based materials in various industries, indirectly supporting the adoption of glycerol as a renewable plasticizer option.

The United States Environmental Protection Agency (EPA) has similarly tightened regulations on phthalates, particularly in children's toys and childcare articles. This has led to increased interest in alternative plasticizers, with glycerol gaining attention due to its non-toxic and biodegradable properties. The FDA has also recognized glycerol as Generally Recognized as Safe (GRAS), facilitating its use in food packaging applications.

In Asia, countries like China and Japan are following suit with their own regulatory frameworks. China's recent updates to its food contact materials regulations have opened doors for glycerol-based plasticizers in packaging applications. Japan's positive list system for food contact materials also favors the use of safer alternatives like glycerol.

The global trend towards circular economy principles is further shaping the regulatory landscape. Many countries are introducing extended producer responsibility (EPR) schemes, which incentivize the use of recyclable and biodegradable materials. Glycerol, being biodegradable and derived from renewable sources, aligns well with these circular economy goals.

Industry standards and certifications are also playing a crucial role. Organizations like ASTM International and ISO are developing new standards for bio-based plasticizers, providing a framework for the evaluation and adoption of glycerol-based solutions. These standards are likely to influence future regulatory decisions and market acceptance.

As the regulatory landscape continues to evolve, it is expected that the use of glycerol as a plasticizer will face fewer barriers compared to traditional options. However, manufacturers must remain vigilant of regional variations in regulations and ensure compliance across different markets. The ongoing shift towards sustainable and safe materials in regulations worldwide presents a significant opportunity for glycerol-based plasticizers to gain market share and contribute to the reduction of conventional plasticizer use in polymers.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has placed significant restrictions on certain phthalates, creating opportunities for glycerol-based plasticizers. The EU has also set targets for increasing the use of bio-based materials in various industries, indirectly supporting the adoption of glycerol as a renewable plasticizer option.

The United States Environmental Protection Agency (EPA) has similarly tightened regulations on phthalates, particularly in children's toys and childcare articles. This has led to increased interest in alternative plasticizers, with glycerol gaining attention due to its non-toxic and biodegradable properties. The FDA has also recognized glycerol as Generally Recognized as Safe (GRAS), facilitating its use in food packaging applications.

In Asia, countries like China and Japan are following suit with their own regulatory frameworks. China's recent updates to its food contact materials regulations have opened doors for glycerol-based plasticizers in packaging applications. Japan's positive list system for food contact materials also favors the use of safer alternatives like glycerol.

The global trend towards circular economy principles is further shaping the regulatory landscape. Many countries are introducing extended producer responsibility (EPR) schemes, which incentivize the use of recyclable and biodegradable materials. Glycerol, being biodegradable and derived from renewable sources, aligns well with these circular economy goals.

Industry standards and certifications are also playing a crucial role. Organizations like ASTM International and ISO are developing new standards for bio-based plasticizers, providing a framework for the evaluation and adoption of glycerol-based solutions. These standards are likely to influence future regulatory decisions and market acceptance.

As the regulatory landscape continues to evolve, it is expected that the use of glycerol as a plasticizer will face fewer barriers compared to traditional options. However, manufacturers must remain vigilant of regional variations in regulations and ensure compliance across different markets. The ongoing shift towards sustainable and safe materials in regulations worldwide presents a significant opportunity for glycerol-based plasticizers to gain market share and contribute to the reduction of conventional plasticizer use in polymers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!