How Hydrogen Embrittlement Interacts With Residual Stresses From Forming And Machining?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement Background and Research Objectives

Hydrogen embrittlement (HE) represents one of the most significant challenges in materials engineering, particularly for high-strength steels and other structural metals used in critical applications. This phenomenon, first documented in the late 19th century, occurs when hydrogen atoms penetrate a metal's microstructure, leading to a dramatic reduction in ductility and load-bearing capacity, ultimately resulting in premature and often catastrophic failure. The economic impact of hydrogen-induced failures across industries such as aerospace, automotive, energy, and infrastructure is estimated to exceed billions of dollars annually.

The interaction between hydrogen embrittlement and residual stresses presents a particularly complex technical challenge. Residual stresses—those that remain in a material after manufacturing processes like forming, machining, welding, or heat treatment—can significantly influence hydrogen diffusion pathways and trapping mechanisms within the material microstructure. These manufacturing-induced stresses can either mitigate or exacerbate hydrogen embrittlement effects, depending on their nature (tensile or compressive) and distribution throughout the component.

Recent technological advancements in high-strength materials for lightweight structures, hydrogen energy systems, and extreme environment applications have made understanding this interaction increasingly critical. The push toward hydrogen as a clean energy carrier further amplifies the importance of addressing hydrogen embrittlement challenges, as infrastructure for hydrogen production, storage, and transportation must maintain structural integrity under hydrogen-rich environments.

The evolution of this technical field has seen significant milestones, from early empirical observations to sophisticated multi-scale modeling approaches. Initial research focused primarily on phenomenological descriptions, while contemporary work leverages advanced characterization techniques such as neutron diffraction, synchrotron X-ray analysis, and atom probe tomography to provide unprecedented insights into hydrogen-material interactions at the atomic scale.

This technical pre-research aims to comprehensively examine how hydrogen embrittlement mechanisms interact with residual stresses from forming and machining processes. Specifically, our objectives include: (1) characterizing the fundamental mechanisms by which hydrogen and residual stresses interact at multiple length scales; (2) identifying critical manufacturing parameters that influence this interaction; (3) evaluating existing predictive models and their limitations; and (4) developing a roadmap for advanced mitigation strategies that can be implemented in industrial manufacturing processes.

By addressing these objectives, we seek to bridge the gap between theoretical understanding and practical applications, ultimately enabling the design of more resilient materials and manufacturing processes that can withstand hydrogen environments while maintaining structural integrity and performance requirements.

The interaction between hydrogen embrittlement and residual stresses presents a particularly complex technical challenge. Residual stresses—those that remain in a material after manufacturing processes like forming, machining, welding, or heat treatment—can significantly influence hydrogen diffusion pathways and trapping mechanisms within the material microstructure. These manufacturing-induced stresses can either mitigate or exacerbate hydrogen embrittlement effects, depending on their nature (tensile or compressive) and distribution throughout the component.

Recent technological advancements in high-strength materials for lightweight structures, hydrogen energy systems, and extreme environment applications have made understanding this interaction increasingly critical. The push toward hydrogen as a clean energy carrier further amplifies the importance of addressing hydrogen embrittlement challenges, as infrastructure for hydrogen production, storage, and transportation must maintain structural integrity under hydrogen-rich environments.

The evolution of this technical field has seen significant milestones, from early empirical observations to sophisticated multi-scale modeling approaches. Initial research focused primarily on phenomenological descriptions, while contemporary work leverages advanced characterization techniques such as neutron diffraction, synchrotron X-ray analysis, and atom probe tomography to provide unprecedented insights into hydrogen-material interactions at the atomic scale.

This technical pre-research aims to comprehensively examine how hydrogen embrittlement mechanisms interact with residual stresses from forming and machining processes. Specifically, our objectives include: (1) characterizing the fundamental mechanisms by which hydrogen and residual stresses interact at multiple length scales; (2) identifying critical manufacturing parameters that influence this interaction; (3) evaluating existing predictive models and their limitations; and (4) developing a roadmap for advanced mitigation strategies that can be implemented in industrial manufacturing processes.

By addressing these objectives, we seek to bridge the gap between theoretical understanding and practical applications, ultimately enabling the design of more resilient materials and manufacturing processes that can withstand hydrogen environments while maintaining structural integrity and performance requirements.

Industrial Demand Analysis for Hydrogen Embrittlement Solutions

The hydrogen embrittlement (HE) market is experiencing significant growth driven by increasing awareness of material failures in critical industries. The global market for hydrogen embrittlement solutions is projected to reach $3.2 billion by 2027, growing at a CAGR of 6.8% from 2022. This growth is primarily fueled by expanding applications in aerospace, automotive, energy, and infrastructure sectors where high-strength metals are increasingly utilized under hydrogen-rich environments.

Aerospace and defense industries represent the largest market segment, accounting for approximately 28% of the total demand for hydrogen embrittlement solutions. These sectors require materials that can withstand extreme conditions while maintaining structural integrity, particularly in fuel systems and engine components where hydrogen exposure is common.

The automotive industry follows closely, constituting about 24% of market demand, particularly with the rising adoption of hydrogen fuel cell vehicles. Toyota, Hyundai, and other major manufacturers investing in hydrogen propulsion technologies have significantly increased research funding for embrittlement-resistant materials and protective coatings.

Oil and gas operations contribute roughly 22% to market demand, where deep-sea drilling equipment, pipelines, and refinery components frequently encounter hydrogen-rich environments. The sector has reported that hydrogen-related failures cost the industry over $1.8 billion annually in maintenance, replacement, and downtime expenses.

Renewable energy, particularly the green hydrogen production sector, represents the fastest-growing segment with a 9.2% annual growth rate. As hydrogen production scales up globally, the demand for materials that can withstand hydrogen exposure during electrolysis, storage, and transportation is surging.

Regional analysis indicates North America leads with 35% market share, followed by Europe (30%) and Asia-Pacific (25%). However, Asia-Pacific is expected to witness the highest growth rate of 8.5% annually through 2027, driven by rapid industrialization and increasing hydrogen infrastructure investments in China, Japan, and South Korea.

Industry surveys reveal that 78% of manufacturing companies consider hydrogen embrittlement a significant concern in their material selection processes, with 65% reporting increased spending on preventive technologies and testing protocols over the past five years. The intersection of hydrogen embrittlement with residual stresses from manufacturing processes has become a particular focus area, with dedicated research initiatives increasing by 45% since 2019.

Aerospace and defense industries represent the largest market segment, accounting for approximately 28% of the total demand for hydrogen embrittlement solutions. These sectors require materials that can withstand extreme conditions while maintaining structural integrity, particularly in fuel systems and engine components where hydrogen exposure is common.

The automotive industry follows closely, constituting about 24% of market demand, particularly with the rising adoption of hydrogen fuel cell vehicles. Toyota, Hyundai, and other major manufacturers investing in hydrogen propulsion technologies have significantly increased research funding for embrittlement-resistant materials and protective coatings.

Oil and gas operations contribute roughly 22% to market demand, where deep-sea drilling equipment, pipelines, and refinery components frequently encounter hydrogen-rich environments. The sector has reported that hydrogen-related failures cost the industry over $1.8 billion annually in maintenance, replacement, and downtime expenses.

Renewable energy, particularly the green hydrogen production sector, represents the fastest-growing segment with a 9.2% annual growth rate. As hydrogen production scales up globally, the demand for materials that can withstand hydrogen exposure during electrolysis, storage, and transportation is surging.

Regional analysis indicates North America leads with 35% market share, followed by Europe (30%) and Asia-Pacific (25%). However, Asia-Pacific is expected to witness the highest growth rate of 8.5% annually through 2027, driven by rapid industrialization and increasing hydrogen infrastructure investments in China, Japan, and South Korea.

Industry surveys reveal that 78% of manufacturing companies consider hydrogen embrittlement a significant concern in their material selection processes, with 65% reporting increased spending on preventive technologies and testing protocols over the past five years. The intersection of hydrogen embrittlement with residual stresses from manufacturing processes has become a particular focus area, with dedicated research initiatives increasing by 45% since 2019.

Current Understanding and Technical Barriers in Hydrogen-Stress Interactions

The current understanding of hydrogen embrittlement (HE) and its interaction with residual stresses represents a complex metallurgical challenge that continues to evolve. Research has established that hydrogen atoms can penetrate metallic structures through various mechanisms including electrochemical processes, corrosion reactions, and during manufacturing operations. Once inside the material, hydrogen tends to accumulate at microstructural defects, grain boundaries, and areas of high stress concentration.

Residual stresses from forming and machining operations create preferential pathways for hydrogen diffusion and trapping. These stresses, whether tensile or compressive, significantly alter the material's susceptibility to hydrogen-induced damage. Tensile residual stresses are particularly problematic as they facilitate crack initiation and propagation when hydrogen is present, while compressive residual stresses may provide some protective effects by impeding crack growth.

The hydrogen-enhanced localized plasticity (HELP) mechanism has gained substantial acceptance in explaining how hydrogen reduces the energy required for dislocation movement, thereby facilitating localized deformation at lower stress levels. This mechanism operates synergistically with residual stresses, particularly accelerating damage in regions with high tensile residual stress concentrations.

Hydrogen-enhanced decohesion (HEDE) represents another critical mechanism wherein hydrogen reduces the cohesive strength between atoms, weakening atomic bonds and facilitating intergranular or transgranular fracture. The presence of residual stresses can significantly amplify this effect by providing the additional energy needed to initiate material separation.

Despite these advances, significant technical barriers persist in fully understanding these interactions. The multiscale nature of hydrogen embrittlement—spanning atomic, microscopic, and macroscopic levels—makes comprehensive modeling extremely challenging. Current computational models struggle to integrate all relevant parameters across these different scales.

Experimental validation faces substantial hurdles due to difficulties in accurately measuring hydrogen concentration and distribution in real-time within materials, particularly at stress concentration points. The transient nature of hydrogen movement further complicates these measurements, as hydrogen can rapidly redistribute during testing.

Material variability introduces additional complexity, as microstructural differences, even within the same material grade, can dramatically alter hydrogen-stress interactions. This variability makes it difficult to develop universal predictive models applicable across different manufacturing scenarios.

The time-dependent nature of hydrogen embrittlement presents another significant barrier, as the interaction between hydrogen and residual stresses evolves over time, making long-term prediction of material behavior particularly challenging for components with extended service lives.

Residual stresses from forming and machining operations create preferential pathways for hydrogen diffusion and trapping. These stresses, whether tensile or compressive, significantly alter the material's susceptibility to hydrogen-induced damage. Tensile residual stresses are particularly problematic as they facilitate crack initiation and propagation when hydrogen is present, while compressive residual stresses may provide some protective effects by impeding crack growth.

The hydrogen-enhanced localized plasticity (HELP) mechanism has gained substantial acceptance in explaining how hydrogen reduces the energy required for dislocation movement, thereby facilitating localized deformation at lower stress levels. This mechanism operates synergistically with residual stresses, particularly accelerating damage in regions with high tensile residual stress concentrations.

Hydrogen-enhanced decohesion (HEDE) represents another critical mechanism wherein hydrogen reduces the cohesive strength between atoms, weakening atomic bonds and facilitating intergranular or transgranular fracture. The presence of residual stresses can significantly amplify this effect by providing the additional energy needed to initiate material separation.

Despite these advances, significant technical barriers persist in fully understanding these interactions. The multiscale nature of hydrogen embrittlement—spanning atomic, microscopic, and macroscopic levels—makes comprehensive modeling extremely challenging. Current computational models struggle to integrate all relevant parameters across these different scales.

Experimental validation faces substantial hurdles due to difficulties in accurately measuring hydrogen concentration and distribution in real-time within materials, particularly at stress concentration points. The transient nature of hydrogen movement further complicates these measurements, as hydrogen can rapidly redistribute during testing.

Material variability introduces additional complexity, as microstructural differences, even within the same material grade, can dramatically alter hydrogen-stress interactions. This variability makes it difficult to develop universal predictive models applicable across different manufacturing scenarios.

The time-dependent nature of hydrogen embrittlement presents another significant barrier, as the interaction between hydrogen and residual stresses evolves over time, making long-term prediction of material behavior particularly challenging for components with extended service lives.

Existing Methodologies for Mitigating Hydrogen-Induced Damage

01 Techniques for reducing hydrogen embrittlement through residual stress control

Various methods can be employed to control residual stresses in materials to mitigate hydrogen embrittlement. These techniques include shot peening, laser peening, and other surface treatment processes that introduce compressive residual stresses in the material surface. The compressive stresses help counteract the tensile stresses that typically promote hydrogen-induced cracking, thereby enhancing the material's resistance to hydrogen embrittlement.- Methods to mitigate hydrogen embrittlement through residual stress control: Various techniques can be employed to control residual stresses and mitigate hydrogen embrittlement in metallic materials. These include heat treatment processes, shot peening, and specialized surface treatments that induce compressive residual stresses in the material surface. By creating compressive stresses, these methods can counteract the tensile stresses that typically facilitate hydrogen embrittlement, thereby enhancing the material's resistance to hydrogen-induced cracking.

- Measurement and analysis of hydrogen-induced residual stresses: Advanced techniques for measuring and analyzing residual stresses in materials susceptible to hydrogen embrittlement are essential for understanding the phenomenon. These methods include X-ray diffraction, neutron diffraction, and various non-destructive testing approaches that can quantify stress distributions within components. By accurately measuring residual stresses, engineers can better predict hydrogen embrittlement behavior and develop more effective prevention strategies.

- Material selection and composition to reduce hydrogen embrittlement susceptibility: The selection of appropriate materials and control of their composition can significantly reduce susceptibility to hydrogen embrittlement. Alloying elements, microstructural modifications, and grain boundary engineering can be employed to create materials with inherent resistance to hydrogen damage. These approaches focus on reducing hydrogen diffusion pathways, trapping hydrogen at benign locations, or creating microstructures that are less susceptible to hydrogen-induced stress cracking.

- Coating and surface treatment technologies for hydrogen embrittlement prevention: Specialized coatings and surface treatments can be applied to create barriers against hydrogen ingress while simultaneously managing residual stresses. These include metallic plating, ceramic coatings, and various surface modification techniques that either prevent hydrogen from entering the material or create favorable residual stress profiles. Such treatments are particularly important for components operating in hydrogen-rich environments or those subjected to cathodic protection systems.

- Manufacturing processes to control residual stresses and hydrogen content: Optimized manufacturing processes can be designed to control both residual stresses and hydrogen content in finished components. These include modified welding procedures, controlled cooling rates, and specialized forming operations that minimize hydrogen uptake while creating beneficial residual stress distributions. Post-processing treatments such as baking or degassing can also be employed to remove hydrogen before it causes embrittlement, particularly in high-strength steels and other susceptible alloys.

02 Heat treatment methods for hydrogen embrittlement prevention

Heat treatment processes can be effective in managing residual stresses and reducing susceptibility to hydrogen embrittlement. Techniques such as stress relief annealing, tempering, and controlled cooling help redistribute and reduce internal stresses in metallic components. These thermal processes also facilitate hydrogen diffusion out of the material, decreasing the concentration of trapped hydrogen that could potentially cause embrittlement.Expand Specific Solutions03 Measurement and analysis of hydrogen-induced residual stresses

Advanced techniques for measuring and analyzing residual stresses in materials susceptible to hydrogen embrittlement are crucial for understanding and preventing failure. These methods include X-ray diffraction, neutron diffraction, ultrasonic techniques, and computational modeling. By accurately quantifying residual stress distributions and their evolution in the presence of hydrogen, engineers can better predict material behavior and develop more effective prevention strategies.Expand Specific Solutions04 Material composition modifications to resist hydrogen embrittlement

Altering the composition of materials can significantly improve their resistance to hydrogen embrittlement under residual stress conditions. Approaches include adding alloying elements that trap hydrogen at harmless sites, developing microstructures that reduce hydrogen diffusion, and creating materials with inherently lower susceptibility to hydrogen damage. These compositional modifications help maintain material integrity even when residual stresses are present in hydrogen-rich environments.Expand Specific Solutions05 Coating and surface treatments for hydrogen embrittlement protection

Protective coatings and surface treatments can create barriers that prevent hydrogen ingress while managing residual stresses. These include metallic plating, ceramic coatings, and specialized surface conversion treatments. Such protective layers not only shield the base material from hydrogen exposure but can also be designed to introduce beneficial residual stress states that counteract the detrimental effects of hydrogen embrittlement in critical components.Expand Specific Solutions

Leading Research Institutions and Industrial Stakeholders

Hydrogen embrittlement's interaction with residual stresses represents a critical challenge in advanced manufacturing, currently in a growth phase with an estimated market value exceeding $2 billion annually. The technical landscape is moderately mature, with key players demonstrating varying levels of expertise. Industry leaders like NIPPON STEEL, JFE Steel, and Mitsubishi Heavy Industries have established robust research programs, while automotive manufacturers such as Toyota and BMW are actively developing mitigation strategies. Academic institutions including Tohoku University and University of Science & Technology Beijing contribute fundamental research. The field is witnessing increased collaboration between steel producers, automotive manufacturers, and research institutions, with emerging technologies focusing on predictive modeling and in-situ monitoring to address this complex metallurgical phenomenon.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has developed comprehensive approaches to address hydrogen embrittlement in high-strength steels, particularly focusing on the interaction with residual stresses. Their technology involves controlled heat treatment processes that minimize residual stresses from forming operations while simultaneously reducing hydrogen trapping sites. The company employs advanced microstructural engineering techniques to create fine-dispersed precipitates that act as benign hydrogen traps, preventing hydrogen from accumulating at critical stress concentration points. Their proprietary NANOHITEN® steel utilizes nano-precipitation strengthening mechanisms that maintain ductility while offering resistance to hydrogen embrittlement. NIPPON STEEL has also pioneered non-destructive evaluation methods that can detect potential hydrogen embrittlement risks by mapping residual stress distributions in formed components, allowing for targeted post-processing treatments to relieve harmful stress concentrations before hydrogen exposure occurs.

Strengths: Industry-leading expertise in microstructural control of steels to mitigate hydrogen effects; comprehensive testing capabilities across multiple scales; integration of computational modeling with experimental validation. Weaknesses: Solutions may be more applicable to new steel development rather than existing components; some techniques require specialized equipment not widely available in manufacturing environments.

The Japan Steel Works Ltd.

Technical Solution: The Japan Steel Works (JSW) has developed specialized technologies addressing hydrogen embrittlement in large-scale steel components subject to complex forming and machining processes. Their approach centers on a multi-stage stress management system that begins with controlled deformation during hot forming to minimize unfavorable residual stress patterns. JSW employs proprietary heat treatment protocols specifically designed to relieve residual stresses while preventing hydrogen ingress during processing. Their technology includes advanced surface treatment methods that create protective barrier layers to inhibit hydrogen penetration at vulnerable machined surfaces. JSW has pioneered the use of acoustic emission monitoring during manufacturing to detect potential microcrack formation associated with hydrogen-stress interactions in real-time. Additionally, they've developed specialized welding procedures that control heat input and cooling rates to minimize hydrogen trapping in heat-affected zones, particularly critical for large pressure vessel components where residual stresses from welding can interact with environmental hydrogen sources during service.

Strengths: Extensive experience with large-scale components under high-pressure hydrogen environments; integrated approach addressing both manufacturing and in-service conditions; proven track record in critical applications like nuclear and petrochemical industries. Weaknesses: Solutions often require significant capital investment; techniques may add considerable processing time to manufacturing operations; primarily focused on traditional steel compositions rather than newer alloys.

Critical Analysis of Hydrogen-Residual Stress Interaction Mechanisms

Method of making welded joints for large vessels subject to hydrogen embrittlement

PatentInactiveUS3861883A

Innovation

- The solution involves padding the heat-affected zones in welded joints with Cr-Mo steel or Mo steel containing Ti and/or Nb, which are only slightly hardenable by welding heat and resistant to hydrogen embrittlement, and using austenitic stainless steel or Inconel for inner surface welds, allowing for welding without complete annealing of the assembly.

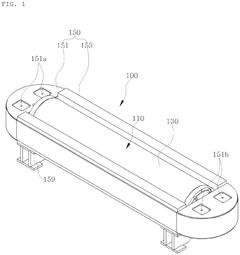

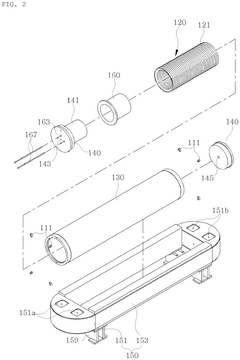

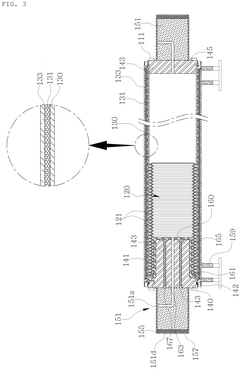

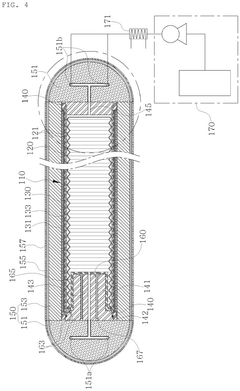

Variable volume hydrogen container or hydrogen compressor with improved hydrogen embrittlement resistance

PatentPendingEP4549804A1

Innovation

- A variable volume hydrogen container or hydrogen compressor is designed with a variable vessel installed in a pressure vessel, featuring an embrittlement blocking member at the vessel cap to prevent hydrogen penetration and an external pressure action recess for direct hydrogen discharge, allowing for uniform hydrogen discharge pressure and reduced material costs.

Material Selection Strategies for Hydrogen Service Environments

Material selection represents a critical factor in mitigating hydrogen embrittlement risks in industrial applications. When designing components for hydrogen service environments, engineers must carefully evaluate materials based on their susceptibility to hydrogen-induced damage, particularly when residual stresses from manufacturing processes are present.

Austenitic stainless steels (300 series) demonstrate superior resistance to hydrogen embrittlement compared to ferritic and martensitic grades due to their face-centered cubic crystal structure, which limits hydrogen diffusion. These materials are preferred for high-pressure hydrogen applications despite their higher cost, as they provide significant safety margins against catastrophic failure.

Nickel-based alloys, particularly those with nickel content exceeding 50%, offer exceptional resistance to hydrogen damage. Alloys such as Inconel 625 and Monel 400 are increasingly utilized in extreme hydrogen environments where both corrosion resistance and mechanical integrity are paramount. Their performance justifies the premium cost in critical applications.

Advanced aluminum alloys present an emerging alternative for hydrogen service. Their inherently low hydrogen solubility reduces embrittlement susceptibility, while their lightweight properties offer additional benefits for mobile hydrogen applications. However, careful consideration must be given to their lower strength compared to steels and potential galvanic corrosion issues.

Surface modification techniques can enhance hydrogen resistance of conventional materials. Coatings such as electroless nickel with phosphorus content exceeding 10% create effective hydrogen diffusion barriers. Similarly, nitriding and carburizing treatments can establish protective surface layers that impede hydrogen ingress while maintaining core material properties.

Composite materials, particularly carbon fiber reinforced polymers (CFRP), demonstrate promising hydrogen compatibility. Their anisotropic properties can be engineered to minimize hydrogen permeation while maintaining structural integrity. These materials are increasingly adopted in hydrogen storage vessels where weight reduction is critical.

Material selection must also consider manufacturing processes that introduce residual stresses. Cold-worked materials typically exhibit increased susceptibility to hydrogen embrittlement due to higher dislocation density and internal stresses. Post-processing heat treatments such as stress relief annealing can significantly reduce these risks by homogenizing the microstructure and relieving internal stresses before hydrogen exposure.

Austenitic stainless steels (300 series) demonstrate superior resistance to hydrogen embrittlement compared to ferritic and martensitic grades due to their face-centered cubic crystal structure, which limits hydrogen diffusion. These materials are preferred for high-pressure hydrogen applications despite their higher cost, as they provide significant safety margins against catastrophic failure.

Nickel-based alloys, particularly those with nickel content exceeding 50%, offer exceptional resistance to hydrogen damage. Alloys such as Inconel 625 and Monel 400 are increasingly utilized in extreme hydrogen environments where both corrosion resistance and mechanical integrity are paramount. Their performance justifies the premium cost in critical applications.

Advanced aluminum alloys present an emerging alternative for hydrogen service. Their inherently low hydrogen solubility reduces embrittlement susceptibility, while their lightweight properties offer additional benefits for mobile hydrogen applications. However, careful consideration must be given to their lower strength compared to steels and potential galvanic corrosion issues.

Surface modification techniques can enhance hydrogen resistance of conventional materials. Coatings such as electroless nickel with phosphorus content exceeding 10% create effective hydrogen diffusion barriers. Similarly, nitriding and carburizing treatments can establish protective surface layers that impede hydrogen ingress while maintaining core material properties.

Composite materials, particularly carbon fiber reinforced polymers (CFRP), demonstrate promising hydrogen compatibility. Their anisotropic properties can be engineered to minimize hydrogen permeation while maintaining structural integrity. These materials are increasingly adopted in hydrogen storage vessels where weight reduction is critical.

Material selection must also consider manufacturing processes that introduce residual stresses. Cold-worked materials typically exhibit increased susceptibility to hydrogen embrittlement due to higher dislocation density and internal stresses. Post-processing heat treatments such as stress relief annealing can significantly reduce these risks by homogenizing the microstructure and relieving internal stresses before hydrogen exposure.

Non-Destructive Testing Approaches for Hydrogen Damage Detection

Non-destructive testing (NDT) methodologies have become increasingly vital for detecting hydrogen damage in metallic components, particularly where hydrogen embrittlement interacts with residual stresses. Current NDT approaches can be categorized into several major techniques that offer varying capabilities for hydrogen damage assessment without compromising structural integrity.

Ultrasonic testing represents one of the most promising NDT methods for hydrogen damage detection. Advanced techniques such as phased array ultrasonics and time-of-flight diffraction can identify microcracking and internal defects caused by hydrogen embrittlement, especially in areas with high residual stress concentration. These methods can detect changes in material properties at depths conventional visual inspection cannot reach.

Acoustic emission testing provides real-time monitoring capabilities by detecting stress waves generated during crack initiation and propagation. This technique is particularly valuable for components under dynamic loading where hydrogen-enhanced localized plasticity may occur at residual stress points from forming operations.

Electromagnetic techniques, including eddy current testing and magnetic flux leakage, have demonstrated effectiveness in detecting surface and near-surface hydrogen damage. These methods are especially useful for identifying hydrogen-induced cracking in areas affected by machining-induced residual stresses, as they can detect changes in electrical conductivity and magnetic permeability associated with hydrogen presence.

Neutron diffraction and synchrotron X-ray diffraction techniques offer high-resolution mapping of both hydrogen concentration and residual stress distributions. Though requiring specialized facilities, these methods provide unparalleled insights into the interaction mechanisms between hydrogen and residual stresses at the microstructural level.

Infrared thermography has emerged as a rapid screening tool for detecting hydrogen damage by identifying thermal anomalies associated with stress concentration zones. This technique is particularly effective for large surface areas where residual stresses from forming processes may create preferential pathways for hydrogen ingress.

Recent developments in electrochemical hydrogen permeation techniques allow for in-situ monitoring of hydrogen diffusion through metallic structures. These methods can quantify hydrogen flux and trapping behavior in regions with varying residual stress profiles, providing critical data for lifetime prediction models.

Integration of multiple NDT techniques through data fusion approaches represents the frontier of hydrogen damage detection. Machine learning algorithms applied to combined NDT data sets have demonstrated improved detection reliability, particularly for complex geometries where forming and machining processes create intricate residual stress patterns.

Ultrasonic testing represents one of the most promising NDT methods for hydrogen damage detection. Advanced techniques such as phased array ultrasonics and time-of-flight diffraction can identify microcracking and internal defects caused by hydrogen embrittlement, especially in areas with high residual stress concentration. These methods can detect changes in material properties at depths conventional visual inspection cannot reach.

Acoustic emission testing provides real-time monitoring capabilities by detecting stress waves generated during crack initiation and propagation. This technique is particularly valuable for components under dynamic loading where hydrogen-enhanced localized plasticity may occur at residual stress points from forming operations.

Electromagnetic techniques, including eddy current testing and magnetic flux leakage, have demonstrated effectiveness in detecting surface and near-surface hydrogen damage. These methods are especially useful for identifying hydrogen-induced cracking in areas affected by machining-induced residual stresses, as they can detect changes in electrical conductivity and magnetic permeability associated with hydrogen presence.

Neutron diffraction and synchrotron X-ray diffraction techniques offer high-resolution mapping of both hydrogen concentration and residual stress distributions. Though requiring specialized facilities, these methods provide unparalleled insights into the interaction mechanisms between hydrogen and residual stresses at the microstructural level.

Infrared thermography has emerged as a rapid screening tool for detecting hydrogen damage by identifying thermal anomalies associated with stress concentration zones. This technique is particularly effective for large surface areas where residual stresses from forming processes may create preferential pathways for hydrogen ingress.

Recent developments in electrochemical hydrogen permeation techniques allow for in-situ monitoring of hydrogen diffusion through metallic structures. These methods can quantify hydrogen flux and trapping behavior in regions with varying residual stress profiles, providing critical data for lifetime prediction models.

Integration of multiple NDT techniques through data fusion approaches represents the frontier of hydrogen damage detection. Machine learning algorithms applied to combined NDT data sets have demonstrated improved detection reliability, particularly for complex geometries where forming and machining processes create intricate residual stress patterns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!