Hydrogen Embrittlement In Pipeline Steels: Microstructure Control, Weld Zones And Sour Media

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement Background and Objectives

Hydrogen embrittlement (HE) represents one of the most significant challenges in pipeline steel applications, particularly in oil and gas transportation systems. This phenomenon, first documented in the late 19th century, has evolved from a peripheral concern to a central issue in materials engineering as industrial demands for high-strength steels have increased. The progressive understanding of hydrogen's detrimental effects on steel microstructure has paralleled the expansion of global energy infrastructure, with research intensity accelerating notably since the 1970s oil crisis.

The evolution of pipeline steel technology has been marked by several distinct phases, beginning with basic carbon steels and progressing through multiple generations of high-strength low-alloy (HSLA) steels. Each advancement has brought improved mechanical properties but often increased susceptibility to hydrogen-induced damage, creating an ongoing technological challenge. Recent developments in X70, X80, and X100 grade pipeline steels have pushed the boundaries of strength-to-weight ratios while simultaneously demanding enhanced hydrogen resistance.

Current industry trends indicate a growing deployment of pipelines in increasingly harsh environments, including deep-sea installations, arctic regions, and sour gas fields with high H2S content. These operational conditions significantly elevate the risk of hydrogen embrittlement, necessitating more sophisticated approaches to material design and protection. The economic impact of hydrogen-related failures is substantial, with industry reports estimating costs exceeding $2 billion annually in maintenance, replacement, and downtime.

The primary objective of this technical investigation is to comprehensively analyze the mechanisms of hydrogen embrittlement in modern pipeline steels, with particular emphasis on microstructural control strategies. This includes examining the relationship between steel composition, processing parameters, and resultant microstructures that either promote or inhibit hydrogen diffusion and trapping. Special attention will be given to weld zones, which represent critical vulnerability points due to their heterogeneous microstructures and residual stresses.

Additionally, this research aims to evaluate the specific challenges posed by sour media environments, where the combination of hydrogen sulfide and moisture creates particularly aggressive conditions for hydrogen generation and absorption. The investigation will establish quantitative correlations between environmental parameters and embrittlement susceptibility, providing a foundation for predictive modeling of pipeline integrity in varied service conditions.

The ultimate goal is to develop actionable guidelines for optimizing pipeline steel microstructures and welding protocols that maximize resistance to hydrogen embrittlement while maintaining the mechanical properties required for safe, efficient operation in demanding environments. These findings will support the industry's transition toward more resilient infrastructure systems capable of meeting growing global energy demands.

The evolution of pipeline steel technology has been marked by several distinct phases, beginning with basic carbon steels and progressing through multiple generations of high-strength low-alloy (HSLA) steels. Each advancement has brought improved mechanical properties but often increased susceptibility to hydrogen-induced damage, creating an ongoing technological challenge. Recent developments in X70, X80, and X100 grade pipeline steels have pushed the boundaries of strength-to-weight ratios while simultaneously demanding enhanced hydrogen resistance.

Current industry trends indicate a growing deployment of pipelines in increasingly harsh environments, including deep-sea installations, arctic regions, and sour gas fields with high H2S content. These operational conditions significantly elevate the risk of hydrogen embrittlement, necessitating more sophisticated approaches to material design and protection. The economic impact of hydrogen-related failures is substantial, with industry reports estimating costs exceeding $2 billion annually in maintenance, replacement, and downtime.

The primary objective of this technical investigation is to comprehensively analyze the mechanisms of hydrogen embrittlement in modern pipeline steels, with particular emphasis on microstructural control strategies. This includes examining the relationship between steel composition, processing parameters, and resultant microstructures that either promote or inhibit hydrogen diffusion and trapping. Special attention will be given to weld zones, which represent critical vulnerability points due to their heterogeneous microstructures and residual stresses.

Additionally, this research aims to evaluate the specific challenges posed by sour media environments, where the combination of hydrogen sulfide and moisture creates particularly aggressive conditions for hydrogen generation and absorption. The investigation will establish quantitative correlations between environmental parameters and embrittlement susceptibility, providing a foundation for predictive modeling of pipeline integrity in varied service conditions.

The ultimate goal is to develop actionable guidelines for optimizing pipeline steel microstructures and welding protocols that maximize resistance to hydrogen embrittlement while maintaining the mechanical properties required for safe, efficient operation in demanding environments. These findings will support the industry's transition toward more resilient infrastructure systems capable of meeting growing global energy demands.

Market Demand for Hydrogen-Resistant Pipeline Steels

The global demand for hydrogen-resistant pipeline steels has been experiencing significant growth, driven by the expanding hydrogen economy and the increasing need for safe transportation of hydrogen and hydrogen-containing gases. The market for these specialized steels is projected to grow substantially over the next decade as countries worldwide invest in hydrogen infrastructure as part of their decarbonization strategies.

Energy transition initiatives across major economies are creating unprecedented demand for pipeline infrastructure capable of safely transporting hydrogen. The European Union's Hydrogen Strategy aims to install at least 40 GW of renewable hydrogen electrolyzers by 2030, requiring extensive pipeline networks. Similarly, countries like Japan, South Korea, and Australia have announced ambitious hydrogen roadmaps that will necessitate significant pipeline construction using hydrogen-resistant materials.

The oil and gas sector represents another major market driver, particularly in regions with sour gas fields containing hydrogen sulfide (H2S). Middle Eastern countries, parts of North America, and specific regions in Asia with high H2S content in natural gas reserves require pipelines with enhanced resistance to hydrogen embrittlement. This segment alone accounts for a substantial portion of the current market demand.

Industrial applications constitute a growing market segment, with chemical processing, refining, and manufacturing facilities requiring hydrogen-resistant piping systems. As industrial decarbonization accelerates, many facilities are incorporating hydrogen as a feedstock or fuel, further driving demand for resistant materials.

Market analysis indicates that pipeline operators are increasingly willing to invest in premium steel grades that offer superior hydrogen embrittlement resistance, recognizing the long-term cost benefits of reduced maintenance and prevention of catastrophic failures. This shift in procurement priorities has created opportunities for steel manufacturers who can demonstrate superior hydrogen resistance properties in their products.

Geographically, the Asia-Pacific region is expected to witness the highest growth rate in demand, primarily due to China's aggressive hydrogen infrastructure development plans and Japan's commitment to becoming a hydrogen-based society. North America follows closely, driven by natural gas infrastructure upgrades and hydrogen blending initiatives.

The market is also seeing increased demand for specialized solutions for retrofit applications, where existing pipeline infrastructure needs to be adapted for hydrogen transportation. This segment presents unique challenges related to weld zones and material compatibility, creating niche opportunities for specialized steel products and coating technologies designed specifically for hydrogen service in retrofitted systems.

Energy transition initiatives across major economies are creating unprecedented demand for pipeline infrastructure capable of safely transporting hydrogen. The European Union's Hydrogen Strategy aims to install at least 40 GW of renewable hydrogen electrolyzers by 2030, requiring extensive pipeline networks. Similarly, countries like Japan, South Korea, and Australia have announced ambitious hydrogen roadmaps that will necessitate significant pipeline construction using hydrogen-resistant materials.

The oil and gas sector represents another major market driver, particularly in regions with sour gas fields containing hydrogen sulfide (H2S). Middle Eastern countries, parts of North America, and specific regions in Asia with high H2S content in natural gas reserves require pipelines with enhanced resistance to hydrogen embrittlement. This segment alone accounts for a substantial portion of the current market demand.

Industrial applications constitute a growing market segment, with chemical processing, refining, and manufacturing facilities requiring hydrogen-resistant piping systems. As industrial decarbonization accelerates, many facilities are incorporating hydrogen as a feedstock or fuel, further driving demand for resistant materials.

Market analysis indicates that pipeline operators are increasingly willing to invest in premium steel grades that offer superior hydrogen embrittlement resistance, recognizing the long-term cost benefits of reduced maintenance and prevention of catastrophic failures. This shift in procurement priorities has created opportunities for steel manufacturers who can demonstrate superior hydrogen resistance properties in their products.

Geographically, the Asia-Pacific region is expected to witness the highest growth rate in demand, primarily due to China's aggressive hydrogen infrastructure development plans and Japan's commitment to becoming a hydrogen-based society. North America follows closely, driven by natural gas infrastructure upgrades and hydrogen blending initiatives.

The market is also seeing increased demand for specialized solutions for retrofit applications, where existing pipeline infrastructure needs to be adapted for hydrogen transportation. This segment presents unique challenges related to weld zones and material compatibility, creating niche opportunities for specialized steel products and coating technologies designed specifically for hydrogen service in retrofitted systems.

Current Challenges in Pipeline Steel Microstructure Control

The current landscape of pipeline steel microstructure control faces significant challenges due to the complex interplay between hydrogen embrittlement mechanisms and steel microstructure. One primary challenge is achieving optimal grain refinement while maintaining adequate strength and toughness. Ultra-high strength pipeline steels (X80 and above) require precise control of grain size distribution, which becomes increasingly difficult as strength requirements escalate. The conventional thermomechanical controlled processing (TMCP) approaches are reaching their physical limits in simultaneously addressing strength, toughness, and hydrogen resistance.

Precipitation control presents another formidable challenge. While precipitates are essential for strengthening, certain types and distributions can act as hydrogen trapping sites with varying binding energies. Engineering the precise nature of these traps requires nanoscale control that current industrial processes struggle to achieve consistently. The balance between reversible and irreversible trapping sites remains particularly elusive in production environments.

Phase balance optimization between ferrite, bainite, and martensite constitutes a critical challenge. Modern pipeline steels often employ multi-phase microstructures, but controlling phase transformations during accelerated cooling after hot rolling demands extremely tight process control windows that are difficult to maintain in full-scale production. The presence of retained austenite further complicates this balance, as it can either beneficially trap hydrogen or detrimentally transform under stress.

Inclusion and impurity control represents another significant hurdle. Non-metallic inclusions, particularly manganese sulfides and complex oxides, serve as preferential sites for hydrogen accumulation and crack initiation. Despite advances in steel cleanliness, complete elimination of these features remains impossible, necessitating strategies to modify their morphology and distribution instead.

The challenge of microstructural stability under service conditions cannot be overlooked. Pipeline steels may experience microstructural evolution during long-term exposure to operating temperatures and stresses, potentially altering hydrogen trapping characteristics over time. This dynamic behavior is particularly problematic in sour service environments where hydrogen generation is continuous.

Finally, achieving microstructural homogeneity across thick-walled pipes presents substantial difficulties. Cooling rate variations from surface to core inevitably create microstructural gradients that can lead to localized susceptibility to hydrogen embrittlement. This heterogeneity becomes even more pronounced in the heat-affected zones of welds, where rapid thermal cycles create complex microstructural regions with varying hydrogen susceptibility.

Precipitation control presents another formidable challenge. While precipitates are essential for strengthening, certain types and distributions can act as hydrogen trapping sites with varying binding energies. Engineering the precise nature of these traps requires nanoscale control that current industrial processes struggle to achieve consistently. The balance between reversible and irreversible trapping sites remains particularly elusive in production environments.

Phase balance optimization between ferrite, bainite, and martensite constitutes a critical challenge. Modern pipeline steels often employ multi-phase microstructures, but controlling phase transformations during accelerated cooling after hot rolling demands extremely tight process control windows that are difficult to maintain in full-scale production. The presence of retained austenite further complicates this balance, as it can either beneficially trap hydrogen or detrimentally transform under stress.

Inclusion and impurity control represents another significant hurdle. Non-metallic inclusions, particularly manganese sulfides and complex oxides, serve as preferential sites for hydrogen accumulation and crack initiation. Despite advances in steel cleanliness, complete elimination of these features remains impossible, necessitating strategies to modify their morphology and distribution instead.

The challenge of microstructural stability under service conditions cannot be overlooked. Pipeline steels may experience microstructural evolution during long-term exposure to operating temperatures and stresses, potentially altering hydrogen trapping characteristics over time. This dynamic behavior is particularly problematic in sour service environments where hydrogen generation is continuous.

Finally, achieving microstructural homogeneity across thick-walled pipes presents substantial difficulties. Cooling rate variations from surface to core inevitably create microstructural gradients that can lead to localized susceptibility to hydrogen embrittlement. This heterogeneity becomes even more pronounced in the heat-affected zones of welds, where rapid thermal cycles create complex microstructural regions with varying hydrogen susceptibility.

Existing Solutions for Weld Zone Protection

01 Composition control for hydrogen embrittlement resistance

Controlling the chemical composition of pipeline steels is crucial for improving resistance to hydrogen embrittlement. Specific elements such as chromium, molybdenum, and niobium can be added in controlled amounts to enhance the steel's microstructure and reduce susceptibility to hydrogen-induced cracking. Limiting harmful elements like phosphorus and sulfur while optimizing carbon content creates a more resistant steel matrix that can withstand hydrogen permeation and subsequent embrittlement.- Chemical composition optimization for hydrogen embrittlement resistance: Specific chemical compositions can be engineered in pipeline steels to enhance resistance to hydrogen embrittlement. These compositions typically involve controlling the levels of carbon, manganese, silicon, and microalloying elements such as niobium, titanium, and vanadium. The addition of certain elements like chromium and molybdenum can form stable carbides that trap hydrogen and prevent its diffusion to sensitive microstructural regions. Careful balance of these elements creates a microstructure that minimizes hydrogen trapping sites and improves overall resistance to hydrogen-induced cracking.

- Microstructure control techniques for improved hydrogen resistance: Controlling the microstructure of pipeline steels through specific heat treatment processes can significantly improve hydrogen embrittlement resistance. Techniques include controlled rolling followed by accelerated cooling to develop fine-grained structures with optimized distributions of ferrite, bainite, and/or martensite. The creation of fine precipitates and reduction of inclusion content helps minimize hydrogen trapping sites. Heat treatment parameters such as austenitizing temperature, cooling rate, and tempering conditions are carefully designed to create microstructures that limit hydrogen diffusion pathways and increase resistance to hydrogen-induced damage.

- Surface treatments and coatings for hydrogen barrier protection: Various surface treatments and coating technologies can be applied to pipeline steels to create effective barriers against hydrogen penetration. These include specialized metallic coatings, organic coatings, and multi-layer protection systems that reduce hydrogen permeation into the steel substrate. Surface modification techniques such as shot peening, nitriding, or carburizing can create compressive stresses in the surface layer that inhibit hydrogen entry. Advanced coating formulations may incorporate hydrogen scavengers or trapping compounds that capture hydrogen molecules before they can diffuse into the steel structure.

- Testing and evaluation methods for hydrogen embrittlement resistance: Specialized testing methodologies have been developed to evaluate the hydrogen embrittlement resistance of pipeline steels under various operating conditions. These include hydrogen charging tests, slow strain rate testing in hydrogen environments, electrochemical hydrogen permeation tests, and thermal desorption spectroscopy. Advanced non-destructive evaluation techniques can be used to monitor hydrogen-induced damage in pipeline steels during service. These testing protocols help in qualifying materials for hydrogen service and in developing predictive models for the long-term performance of pipeline steels exposed to hydrogen-containing environments.

- Novel steel alloy designs specifically for hydrogen service: Innovative steel alloy designs have been developed specifically for hydrogen service in pipeline applications. These include high-strength low-alloy (HSLA) steels with tailored compositions, advanced high-strength steels with controlled inclusion morphology, and new generation pipeline steels with optimized grain boundary characteristics. Some designs incorporate nano-scale precipitates that act as beneficial hydrogen traps, preventing hydrogen from reaching critical microstructural features. These novel alloys often balance multiple properties including strength, toughness, weldability, and corrosion resistance while maintaining superior resistance to hydrogen embrittlement.

02 Microstructure engineering for improved hydrogen resistance

The microstructure of pipeline steels significantly affects their resistance to hydrogen embrittlement. Developing fine-grained structures with controlled distributions of precipitates and phases can create effective hydrogen traps that prevent hydrogen from accumulating at critical locations. Heat treatments and thermomechanical processing techniques can be employed to achieve optimal microstructures such as tempered martensite, bainite, or dual-phase structures that provide superior resistance to hydrogen-induced degradation.Expand Specific Solutions03 Surface treatments and coatings for hydrogen barrier properties

Various surface treatments and coating technologies can be applied to pipeline steels to create effective barriers against hydrogen permeation. These include specialized metallic coatings, ceramic layers, or composite coatings that reduce hydrogen uptake into the steel substrate. Surface modification techniques such as shot peening, nitriding, or carburizing can also introduce compressive stresses and altered surface compositions that inhibit hydrogen entry and mitigate embrittlement effects in pipeline applications.Expand Specific Solutions04 Advanced manufacturing processes for hydrogen-resistant pipelines

Innovative manufacturing processes can significantly enhance the hydrogen embrittlement resistance of pipeline steels. Controlled rolling and cooling strategies, specialized welding techniques, and precise heat treatment protocols help develop optimized microstructures throughout the material. Advanced processing methods like thermo-mechanical controlled processing (TMCP) can produce pipeline steels with superior combinations of strength, toughness, and hydrogen resistance by carefully managing grain refinement and precipitation during production.Expand Specific Solutions05 Testing and qualification methods for hydrogen embrittlement resistance

Specialized testing methodologies are essential for evaluating and qualifying pipeline steels for hydrogen service. These include hydrogen charging tests, slow strain rate testing in hydrogen environments, and fracture mechanics approaches to quantify susceptibility to hydrogen-induced cracking. Non-destructive evaluation techniques and in-situ monitoring systems can be employed to detect early signs of hydrogen damage in pipeline steels during service, allowing for timely intervention before catastrophic failure occurs.Expand Specific Solutions

Key Industry Players in Pipeline Steel Manufacturing

Hydrogen embrittlement in pipeline steels represents a critical challenge in the energy infrastructure sector, currently in a mature development phase with established research foundations but ongoing innovation needs. The global market for hydrogen-resistant pipeline solutions is expanding rapidly, driven by increasing hydrogen infrastructure investments and estimated to reach $5-7 billion by 2030. Technical maturity varies across applications, with companies demonstrating different specialization levels. Major steel manufacturers like NIPPON STEEL, JFE Steel, and POSCO Holdings lead in microstructure control research, while Halliburton and China National Petroleum focus on field applications. Specialized players such as Tenaris Connections and Nexteel concentrate on weld zone integrity, particularly for sour media environments. Academic-industry partnerships with institutions like MIT and Tianjin University are accelerating solutions for this complex metallurgical challenge.

JFE Steel Corp.

Technical Solution: JFE Steel has developed a comprehensive approach to hydrogen embrittlement in pipeline steels focusing on microstructural optimization. Their HIPER (High Performance Environmental Resistance) steel technology utilizes controlled rolling and accelerated cooling processes to create a refined microstructure with evenly distributed nano-precipitates that act as hydrogen traps. For sour service environments, they've engineered steels with sulfide stress cracking (SSC) resistance through careful control of hardness distribution and inclusion morphology. Their weld zone protection strategy involves specialized heat input control and consumable design to maintain favorable microstructures in the heat-affected zone. JFE's X80 HIC-resistant pipes incorporate proprietary alloying elements including Ca treatment for inclusion shape control and Cu-Ni additions for enhanced resistance to hydrogen-induced degradation. Their recent innovations include ultra-low sulfur processing techniques and thermomechanical control processes (TMCP) that create optimized dislocation substructures serving as reversible hydrogen traps.

Strengths: Excellent balance between high strength and hydrogen resistance; proven track record in severe sour service applications; advanced inclusion shape control technology. Weaknesses: Some solutions require precise processing parameters that may be difficult to maintain consistently in large-scale production; higher alloying costs for premium grades; potential challenges in field welding of advanced grades.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed advanced hydrogen-resistant pipeline steels through microstructural engineering. Their technology focuses on creating fine-grained bainitic-ferritic microstructures with optimized carbide precipitation to act as hydrogen traps. They've pioneered the HIC (Hydrogen-Induced Cracking) resistant X70 and X80 grade steels specifically designed for sour service environments. Their proprietary HTUFF (Hydrogen Trap for Ultra Fine Ferrite) technology incorporates nano-sized titanium and niobium carbonitrides that serve as beneficial hydrogen trapping sites, reducing diffusible hydrogen that causes embrittlement. For weld zones, they've developed specialized welding consumables and procedures that maintain hydrogen resistance in the heat-affected zone (HAZ) through careful control of cooling rates and post-weld heat treatment protocols. Their X100 grade pipeline steels incorporate Cu-Ni-Mo alloying systems that provide superior resistance to hydrogen embrittlement even in high-pressure H2S environments.

Strengths: Superior microstructural control through advanced metallurgical techniques; comprehensive approach addressing base metal, weld zones, and sour service conditions simultaneously; extensive field validation in harsh environments. Weaknesses: Higher production costs compared to conventional pipeline steels; requires specialized welding procedures that may limit field applicability; some solutions may be overengineered for less demanding applications.

Critical Metallurgical Innovations for Sour Service

Steel pipe or tube for hydrogen gas, method for manufacturing steel pipe or tube for hydrogen gas, pressure vessel for hydrogen gas, and method for manufacturing pressure vessel for hydrogen gas

PatentPendingUS20240027022A1

Innovation

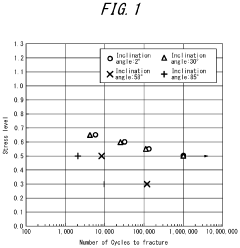

- Controlling the inclination angle of polishing traces on the inner surface of steel pipes or tubes to within 0° to 30° during finish polishing, which enhances hydrogen embrittlement resistance without the need for complex metallurgical adjustments, allowing for a variety of steel types and increased productivity.

Environmental Impact of Pipeline Failures

Pipeline failures due to hydrogen embrittlement present significant environmental risks that extend beyond immediate operational concerns. When pipelines transporting oil, gas, or other hazardous materials fail, they can release substantial quantities of contaminants into surrounding ecosystems. These releases may affect soil quality, groundwater resources, and surface water bodies, potentially causing long-term ecological damage.

The environmental impact varies depending on the pipeline's contents and the affected ecosystem. In sour media environments, where hydrogen sulfide is present, pipeline failures can release not only hydrocarbons but also toxic hydrogen sulfide gas, creating dual contamination scenarios. This is particularly concerning in sensitive ecological areas such as wetlands, protected habitats, or water crossings.

Remediation efforts following pipeline failures are often costly and may not fully restore affected ecosystems to their original state. Studies indicate that soil contaminated by pipeline leaks can remain impaired for decades, with persistent effects on microbial communities and vegetation regrowth patterns. Groundwater contamination presents even greater challenges, as subsurface remediation is technically difficult and extremely expensive.

The carbon footprint associated with pipeline failures must also be considered. Methane releases from natural gas pipeline failures contribute significantly to greenhouse gas emissions. Research suggests that even small, undetected leaks can have cumulative climate impacts equivalent to major failure events when considered over extended timeframes.

Wildlife impacts represent another critical environmental concern. Aquatic species are particularly vulnerable to pipeline failures near water bodies, with documented cases of mass mortality events following hydrocarbon releases. Terrestrial wildlife may suffer from both direct exposure to contaminants and habitat degradation following remediation activities that disturb natural landscapes.

Regulatory frameworks increasingly recognize these environmental risks, leading to stricter requirements for pipeline materials resistant to hydrogen embrittlement. Environmental impact assessments now routinely include evaluation of potential failure scenarios related to material degradation mechanisms, including hydrogen-induced cracking in sour service environments. This regulatory evolution reflects growing awareness of the connection between materials science challenges and environmental protection imperatives.

Preventive approaches focusing on microstructure control and improved weld zone integrity offer promising pathways to reduce environmental risks. By addressing the fundamental metallurgical factors that contribute to hydrogen embrittlement, particularly in sour media environments, the frequency and severity of environmentally damaging pipeline failures can be significantly reduced.

The environmental impact varies depending on the pipeline's contents and the affected ecosystem. In sour media environments, where hydrogen sulfide is present, pipeline failures can release not only hydrocarbons but also toxic hydrogen sulfide gas, creating dual contamination scenarios. This is particularly concerning in sensitive ecological areas such as wetlands, protected habitats, or water crossings.

Remediation efforts following pipeline failures are often costly and may not fully restore affected ecosystems to their original state. Studies indicate that soil contaminated by pipeline leaks can remain impaired for decades, with persistent effects on microbial communities and vegetation regrowth patterns. Groundwater contamination presents even greater challenges, as subsurface remediation is technically difficult and extremely expensive.

The carbon footprint associated with pipeline failures must also be considered. Methane releases from natural gas pipeline failures contribute significantly to greenhouse gas emissions. Research suggests that even small, undetected leaks can have cumulative climate impacts equivalent to major failure events when considered over extended timeframes.

Wildlife impacts represent another critical environmental concern. Aquatic species are particularly vulnerable to pipeline failures near water bodies, with documented cases of mass mortality events following hydrocarbon releases. Terrestrial wildlife may suffer from both direct exposure to contaminants and habitat degradation following remediation activities that disturb natural landscapes.

Regulatory frameworks increasingly recognize these environmental risks, leading to stricter requirements for pipeline materials resistant to hydrogen embrittlement. Environmental impact assessments now routinely include evaluation of potential failure scenarios related to material degradation mechanisms, including hydrogen-induced cracking in sour service environments. This regulatory evolution reflects growing awareness of the connection between materials science challenges and environmental protection imperatives.

Preventive approaches focusing on microstructure control and improved weld zone integrity offer promising pathways to reduce environmental risks. By addressing the fundamental metallurgical factors that contribute to hydrogen embrittlement, particularly in sour media environments, the frequency and severity of environmentally damaging pipeline failures can be significantly reduced.

Regulatory Standards for Hydrogen Service Pipelines

The regulatory landscape for hydrogen service pipelines has evolved significantly in response to the growing understanding of hydrogen embrittlement mechanisms. ASME B31.12, specifically developed for hydrogen piping and pipelines, stands as the primary international standard addressing the unique challenges posed by hydrogen service. This comprehensive standard incorporates specific material selection criteria, design factors, and inspection protocols that directly address hydrogen embrittlement concerns in pipeline steels.

In the United States, the Department of Transportation's Pipeline and Hazardous Materials Safety Administration (PHMSA) has established regulations under 49 CFR Part 192 for natural gas pipelines, which have been adapted to include hydrogen considerations. These regulations mandate rigorous integrity management programs, including regular inspection and testing protocols specifically designed to detect early signs of hydrogen-induced damage.

The European framework centers around the Pressure Equipment Directive (PED) 2014/68/EU, complemented by EN 13445 and EN 13480 standards, which provide specific requirements for hydrogen service equipment. The European Industrial Gases Association (EIGA) has further developed dedicated guidelines for hydrogen pipeline systems that address material compatibility issues in sour environments.

ISO 11114 specifically addresses the compatibility of materials with hydrogen, providing crucial guidance on material selection to minimize embrittlement risks. For sour service environments, NACE MR0175/ISO 15156 establishes critical parameters for materials used in hydrogen sulfide-containing environments, directly addressing the compounded challenges of hydrogen embrittlement in sour media.

Japanese regulations, governed by the High Pressure Gas Safety Act, incorporate specific provisions for hydrogen pipelines with particular attention to seismic considerations and material degradation mechanisms. Similarly, Canadian standards CSA Z662 for oil and gas pipeline systems have been updated to include hydrogen-specific requirements.

Regulatory standards increasingly emphasize the critical nature of weld zones, requiring enhanced non-destructive testing protocols and more stringent acceptance criteria for welds in hydrogen service. Recent regulatory updates have incorporated advanced understanding of microstructural factors, mandating specific heat treatment procedures and microstructure control parameters to enhance resistance to hydrogen embrittlement.

The global trend in regulatory development shows movement toward performance-based standards rather than prescriptive requirements, allowing for innovation in materials and designs while maintaining safety through rigorous validation protocols. This approach facilitates the implementation of novel microstructure control strategies that can significantly improve hydrogen embrittlement resistance in pipeline steels.

In the United States, the Department of Transportation's Pipeline and Hazardous Materials Safety Administration (PHMSA) has established regulations under 49 CFR Part 192 for natural gas pipelines, which have been adapted to include hydrogen considerations. These regulations mandate rigorous integrity management programs, including regular inspection and testing protocols specifically designed to detect early signs of hydrogen-induced damage.

The European framework centers around the Pressure Equipment Directive (PED) 2014/68/EU, complemented by EN 13445 and EN 13480 standards, which provide specific requirements for hydrogen service equipment. The European Industrial Gases Association (EIGA) has further developed dedicated guidelines for hydrogen pipeline systems that address material compatibility issues in sour environments.

ISO 11114 specifically addresses the compatibility of materials with hydrogen, providing crucial guidance on material selection to minimize embrittlement risks. For sour service environments, NACE MR0175/ISO 15156 establishes critical parameters for materials used in hydrogen sulfide-containing environments, directly addressing the compounded challenges of hydrogen embrittlement in sour media.

Japanese regulations, governed by the High Pressure Gas Safety Act, incorporate specific provisions for hydrogen pipelines with particular attention to seismic considerations and material degradation mechanisms. Similarly, Canadian standards CSA Z662 for oil and gas pipeline systems have been updated to include hydrogen-specific requirements.

Regulatory standards increasingly emphasize the critical nature of weld zones, requiring enhanced non-destructive testing protocols and more stringent acceptance criteria for welds in hydrogen service. Recent regulatory updates have incorporated advanced understanding of microstructural factors, mandating specific heat treatment procedures and microstructure control parameters to enhance resistance to hydrogen embrittlement.

The global trend in regulatory development shows movement toward performance-based standards rather than prescriptive requirements, allowing for innovation in materials and designs while maintaining safety through rigorous validation protocols. This approach facilitates the implementation of novel microstructure control strategies that can significantly improve hydrogen embrittlement resistance in pipeline steels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!