How Hydrogen Embrittlement Mitigation Balances Coating Permeation With Mechanical Integrity?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement Background and Mitigation Goals

Hydrogen embrittlement (HE) represents one of the most significant challenges in materials engineering, particularly affecting high-strength steels and other metal alloys used in critical applications. This phenomenon occurs when hydrogen atoms penetrate into a metal's microstructure, causing a reduction in ductility and load-bearing capacity, ultimately leading to catastrophic failure under stresses well below the material's normal yield strength. The historical recognition of hydrogen embrittlement dates back to the 19th century, but comprehensive understanding has evolved significantly in recent decades with advanced characterization techniques.

The evolution of hydrogen embrittlement research has progressed through several distinct phases. Initially, observations were primarily empirical, focusing on documenting failures. The mid-20th century saw the development of fundamental theories explaining hydrogen-metal interactions at the atomic level. Recent advancements have leveraged computational modeling, in-situ testing methods, and nanoscale characterization to provide unprecedented insights into hydrogen diffusion pathways and trapping mechanisms.

Current technological trends in this field include the development of advanced hydrogen sensors for real-time monitoring, novel alloy designs with intrinsic resistance to embrittlement, and sophisticated multi-scale modeling approaches that bridge atomic interactions with macroscopic mechanical behavior. These developments are particularly crucial as industries transition toward hydrogen-based energy systems, where material compatibility with hydrogen becomes a central concern.

The primary mitigation goal in addressing hydrogen embrittlement involves establishing an optimal balance between preventing hydrogen ingress through protective coatings while maintaining the mechanical integrity of the base material. This balance presents a fundamental engineering challenge: highly effective barrier coatings may introduce mechanical discontinuities or residual stresses that compromise structural integrity, while coatings optimized for mechanical compatibility may allow unacceptable levels of hydrogen permeation.

Secondary mitigation objectives include developing standardized testing protocols that accurately predict long-term hydrogen embrittlement susceptibility, creating cost-effective monitoring systems for in-service components, and establishing clear design guidelines that account for hydrogen effects across diverse operating environments. These goals must address both immediate safety concerns and long-term reliability requirements.

The technical objectives for hydrogen embrittlement mitigation must align with broader industry trends toward lightweighting, extended service life, and sustainability. As industries push toward higher-strength materials to improve efficiency, the inherent trade-off between strength and hydrogen resistance becomes increasingly critical, necessitating innovative approaches that transcend traditional material selection paradigms.

The evolution of hydrogen embrittlement research has progressed through several distinct phases. Initially, observations were primarily empirical, focusing on documenting failures. The mid-20th century saw the development of fundamental theories explaining hydrogen-metal interactions at the atomic level. Recent advancements have leveraged computational modeling, in-situ testing methods, and nanoscale characterization to provide unprecedented insights into hydrogen diffusion pathways and trapping mechanisms.

Current technological trends in this field include the development of advanced hydrogen sensors for real-time monitoring, novel alloy designs with intrinsic resistance to embrittlement, and sophisticated multi-scale modeling approaches that bridge atomic interactions with macroscopic mechanical behavior. These developments are particularly crucial as industries transition toward hydrogen-based energy systems, where material compatibility with hydrogen becomes a central concern.

The primary mitigation goal in addressing hydrogen embrittlement involves establishing an optimal balance between preventing hydrogen ingress through protective coatings while maintaining the mechanical integrity of the base material. This balance presents a fundamental engineering challenge: highly effective barrier coatings may introduce mechanical discontinuities or residual stresses that compromise structural integrity, while coatings optimized for mechanical compatibility may allow unacceptable levels of hydrogen permeation.

Secondary mitigation objectives include developing standardized testing protocols that accurately predict long-term hydrogen embrittlement susceptibility, creating cost-effective monitoring systems for in-service components, and establishing clear design guidelines that account for hydrogen effects across diverse operating environments. These goals must address both immediate safety concerns and long-term reliability requirements.

The technical objectives for hydrogen embrittlement mitigation must align with broader industry trends toward lightweighting, extended service life, and sustainability. As industries push toward higher-strength materials to improve efficiency, the inherent trade-off between strength and hydrogen resistance becomes increasingly critical, necessitating innovative approaches that transcend traditional material selection paradigms.

Market Demand for Hydrogen-Resistant Materials

The global market for hydrogen-resistant materials is experiencing significant growth, driven by the expanding hydrogen economy and increasing adoption of hydrogen as a clean energy carrier. As industries transition towards hydrogen-based solutions for energy storage, transportation, and industrial processes, the demand for materials that can withstand hydrogen embrittlement has become critical. Current market estimates value the hydrogen-resistant materials sector at several billion dollars, with projected annual growth rates exceeding 8% through 2030.

Key market segments driving this demand include the energy sector, automotive industry, aerospace applications, and industrial manufacturing. The energy sector, particularly hydrogen production, storage, and distribution infrastructure, represents the largest market share. With over 30 countries having established national hydrogen strategies, investments in hydrogen infrastructure are creating substantial demand for specialized materials that balance hydrogen permeation resistance with mechanical integrity.

The automotive industry presents another significant market opportunity, especially with the growing interest in hydrogen fuel cell vehicles. Major automotive manufacturers are investing heavily in hydrogen technology, creating demand for components that can safely contain and transport hydrogen while maintaining structural integrity under various operating conditions.

Industrial applications, including petrochemical processing, ammonia production, and metallurgical processes, constitute a stable and growing market segment. These industries require materials that can withstand hydrogen exposure at elevated temperatures and pressures while maintaining operational reliability and safety standards.

Geographically, Asia-Pacific represents the fastest-growing market for hydrogen-resistant materials, led by significant investments in hydrogen infrastructure in Japan, South Korea, and China. Europe follows closely, driven by ambitious decarbonization targets and substantial funding for hydrogen projects under the European Green Deal.

Market analysis indicates a shift in customer requirements toward materials that offer longer service life, reduced maintenance costs, and enhanced safety features. End-users are increasingly willing to pay premium prices for advanced materials that demonstrate superior resistance to hydrogen embrittlement while maintaining mechanical properties.

The market also shows growing demand for standardized testing and certification protocols for hydrogen-resistant materials, as industries seek reliable performance metrics and quality assurance. This trend is creating additional market opportunities for testing services and certification bodies specializing in hydrogen compatibility assessment.

Key market segments driving this demand include the energy sector, automotive industry, aerospace applications, and industrial manufacturing. The energy sector, particularly hydrogen production, storage, and distribution infrastructure, represents the largest market share. With over 30 countries having established national hydrogen strategies, investments in hydrogen infrastructure are creating substantial demand for specialized materials that balance hydrogen permeation resistance with mechanical integrity.

The automotive industry presents another significant market opportunity, especially with the growing interest in hydrogen fuel cell vehicles. Major automotive manufacturers are investing heavily in hydrogen technology, creating demand for components that can safely contain and transport hydrogen while maintaining structural integrity under various operating conditions.

Industrial applications, including petrochemical processing, ammonia production, and metallurgical processes, constitute a stable and growing market segment. These industries require materials that can withstand hydrogen exposure at elevated temperatures and pressures while maintaining operational reliability and safety standards.

Geographically, Asia-Pacific represents the fastest-growing market for hydrogen-resistant materials, led by significant investments in hydrogen infrastructure in Japan, South Korea, and China. Europe follows closely, driven by ambitious decarbonization targets and substantial funding for hydrogen projects under the European Green Deal.

Market analysis indicates a shift in customer requirements toward materials that offer longer service life, reduced maintenance costs, and enhanced safety features. End-users are increasingly willing to pay premium prices for advanced materials that demonstrate superior resistance to hydrogen embrittlement while maintaining mechanical properties.

The market also shows growing demand for standardized testing and certification protocols for hydrogen-resistant materials, as industries seek reliable performance metrics and quality assurance. This trend is creating additional market opportunities for testing services and certification bodies specializing in hydrogen compatibility assessment.

Current Challenges in Hydrogen Embrittlement Prevention

Hydrogen embrittlement (HE) prevention remains one of the most challenging aspects in materials engineering, particularly in high-strength steel applications. The fundamental challenge lies in the inherent trade-off between coating permeability and mechanical integrity. Current protective coatings that effectively block hydrogen penetration often compromise the mechanical properties of the substrate material, creating a complex engineering dilemma.

The industry faces significant technical barriers in developing coatings that simultaneously provide adequate hydrogen permeation resistance while maintaining or enhancing the mechanical properties of the base material. Conventional approaches using thick metallic coatings (such as cadmium or zinc) offer good hydrogen barrier properties but add substantial weight and can reduce fatigue performance in critical components.

Recent research has revealed that nano-structured coatings show promise in hydrogen mitigation but face challenges in scalable manufacturing and long-term stability under cyclic loading conditions. The inconsistency in testing protocols across the industry further complicates the assessment of coating effectiveness, with no standardized methodology to evaluate the balance between permeation resistance and mechanical integrity preservation.

Environmental regulations present additional challenges, as traditional effective coatings like cadmium are being phased out due to toxicity concerns. Alternative environmentally friendly coatings often demonstrate inferior hydrogen barrier properties or require more complex application processes, increasing production costs and complexity.

The aerospace and automotive industries particularly struggle with hydrogen embrittlement in high-strength fasteners and structural components. Current solutions often involve trade-offs: either accepting reduced mechanical properties with effective hydrogen barriers or risking hydrogen-induced delayed fracture with coatings that preserve mechanical integrity but offer insufficient permeation resistance.

Another significant challenge is the limited understanding of hydrogen-coating-substrate interactions at the atomic level. Without this fundamental knowledge, designing optimized coating systems remains largely empirical rather than scientifically driven. Computational modeling efforts are hampered by the multi-scale nature of hydrogen diffusion and trapping mechanisms.

The economic impact of these challenges is substantial, with industries reporting significant costs associated with component failures, overdesigned systems, and extensive testing requirements. The lack of predictive models for hydrogen embrittlement progression under various coating scenarios forces manufacturers to implement conservative design approaches, often resulting in heavier, more expensive components than theoretically necessary.

The industry faces significant technical barriers in developing coatings that simultaneously provide adequate hydrogen permeation resistance while maintaining or enhancing the mechanical properties of the base material. Conventional approaches using thick metallic coatings (such as cadmium or zinc) offer good hydrogen barrier properties but add substantial weight and can reduce fatigue performance in critical components.

Recent research has revealed that nano-structured coatings show promise in hydrogen mitigation but face challenges in scalable manufacturing and long-term stability under cyclic loading conditions. The inconsistency in testing protocols across the industry further complicates the assessment of coating effectiveness, with no standardized methodology to evaluate the balance between permeation resistance and mechanical integrity preservation.

Environmental regulations present additional challenges, as traditional effective coatings like cadmium are being phased out due to toxicity concerns. Alternative environmentally friendly coatings often demonstrate inferior hydrogen barrier properties or require more complex application processes, increasing production costs and complexity.

The aerospace and automotive industries particularly struggle with hydrogen embrittlement in high-strength fasteners and structural components. Current solutions often involve trade-offs: either accepting reduced mechanical properties with effective hydrogen barriers or risking hydrogen-induced delayed fracture with coatings that preserve mechanical integrity but offer insufficient permeation resistance.

Another significant challenge is the limited understanding of hydrogen-coating-substrate interactions at the atomic level. Without this fundamental knowledge, designing optimized coating systems remains largely empirical rather than scientifically driven. Computational modeling efforts are hampered by the multi-scale nature of hydrogen diffusion and trapping mechanisms.

The economic impact of these challenges is substantial, with industries reporting significant costs associated with component failures, overdesigned systems, and extensive testing requirements. The lack of predictive models for hydrogen embrittlement progression under various coating scenarios forces manufacturers to implement conservative design approaches, often resulting in heavier, more expensive components than theoretically necessary.

Current Coating Solutions for Hydrogen Permeation Control

01 Barrier coatings to prevent hydrogen permeation

Specialized barrier coatings can be applied to metal surfaces to prevent hydrogen permeation and subsequent embrittlement. These coatings create a physical barrier that blocks hydrogen atoms from diffusing into the metal substrate. Various materials such as metallic alloys, ceramics, and composite coatings have been developed with low hydrogen permeability characteristics. These barrier coatings are particularly effective in high-pressure hydrogen environments and can significantly reduce the risk of hydrogen-induced cracking and mechanical failure.- Metallic coating compositions for hydrogen embrittlement prevention: Specialized metallic coatings can be applied to surfaces to create a barrier against hydrogen permeation. These coatings typically include metals like nickel, chromium, aluminum, or their alloys that have low hydrogen diffusivity. The coatings can be applied through various methods such as electroplating, physical vapor deposition, or thermal spraying. These metallic layers effectively block hydrogen atoms from penetrating into the substrate material, thereby preventing hydrogen embrittlement while maintaining mechanical integrity of the base material.

- Polymer and composite barrier coatings: Polymer-based and composite coatings provide effective barriers against hydrogen permeation while offering flexibility and adhesion to various substrates. These coatings typically incorporate materials such as epoxy resins, polyurethanes, or fluoropolymers, often enhanced with additives like ceramic particles or nanomaterials. The polymer matrix creates a tortuous path for hydrogen molecules, significantly reducing permeation rates. These coatings can be applied as multi-layer systems to improve barrier properties while maintaining mechanical integrity under various service conditions.

- Surface treatment and modification techniques: Various surface treatment methods can be employed to modify the surface properties of materials to mitigate hydrogen embrittlement. These techniques include nitriding, carburizing, shot peening, and laser surface modification. Such treatments create compressive stresses in the surface layer, modify the microstructure, or form protective compounds that reduce hydrogen absorption and diffusion. These methods enhance the mechanical integrity of components while providing resistance to hydrogen permeation without significantly altering dimensional tolerances.

- Hydrogen trapping additives and mechanisms: Incorporating specific additives into coatings can create hydrogen trapping sites that immobilize hydrogen atoms, preventing them from causing embrittlement. These additives include certain transition metal compounds, rare earth elements, or nanoparticles that have high affinity for hydrogen. The trapped hydrogen becomes immobilized at these sites rather than diffusing into the substrate material. This approach allows for maintaining mechanical integrity while effectively managing hydrogen that penetrates the primary barrier, providing a secondary defense mechanism against embrittlement.

- Multi-layer and hybrid coating systems: Multi-layer and hybrid coating systems combine different materials and technologies to provide comprehensive protection against hydrogen embrittlement. These systems typically feature a combination of metallic, ceramic, and polymer layers, each serving specific functions such as hydrogen barrier, corrosion protection, or mechanical reinforcement. The layered approach creates multiple barriers against hydrogen permeation while maintaining overall mechanical integrity. These systems can be customized for specific operating environments and can self-heal minor damage through incorporated mechanisms.

02 Surface treatments to enhance mechanical integrity

Various surface treatment methods can be employed to enhance the mechanical integrity of materials susceptible to hydrogen embrittlement. These treatments include shot peening, laser shock peening, and surface hardening processes that introduce compressive stresses in the surface layer. By modifying the surface microstructure and creating compressive residual stresses, these treatments can significantly improve resistance to hydrogen-induced cracking. The treated surfaces show enhanced fatigue strength and better overall mechanical performance in hydrogen-rich environments.Expand Specific Solutions03 Multi-layer coating systems for hydrogen mitigation

Multi-layer coating systems have been developed to provide comprehensive protection against hydrogen embrittlement. These systems typically consist of a base layer that adheres strongly to the substrate, intermediate layers that provide barrier properties, and a top layer that offers additional protection against environmental factors. The combination of different materials with complementary properties creates a synergistic effect that enhances overall hydrogen resistance. These multi-layer systems can be tailored for specific applications and operating conditions to maximize protection while maintaining other required properties.Expand Specific Solutions04 Hydrogen trapping additives and mechanisms

Specialized additives can be incorporated into coatings to trap hydrogen atoms, preventing them from reaching the underlying metal substrate. These hydrogen trapping mechanisms involve the addition of elements or compounds that have high affinity for hydrogen, effectively creating benign sites where hydrogen can be immobilized. Common hydrogen trapping additives include rare earth elements, transition metals, and certain carbides. By strategically distributing these trapping sites throughout the coating, hydrogen atoms are captured before they can cause embrittlement, significantly improving the mechanical integrity of the protected components.Expand Specific Solutions05 Self-healing coating technologies for long-term protection

Self-healing coating technologies have been developed to provide long-term protection against hydrogen embrittlement. These innovative coatings contain encapsulated healing agents that are released when the coating is damaged, automatically repairing breaches that could allow hydrogen permeation. The self-healing mechanism can be triggered by mechanical damage, chemical reactions, or environmental factors. This approach ensures continuous protection even after the coating experiences wear or damage during service, extending the effective lifetime of the hydrogen barrier and maintaining mechanical integrity of the protected components over extended periods.Expand Specific Solutions

Leading Companies in Hydrogen-Resistant Materials

Hydrogen embrittlement mitigation is currently in a transitional phase, moving from experimental research to commercial implementation. The market is expanding rapidly, projected to reach significant growth as industries prioritize material integrity in hydrogen environments. Technologically, the field shows varying maturity levels across different sectors. Leading players like NIPPON STEEL, The Japan Steel Works, and BMW are developing advanced coating technologies that balance hydrogen permeation resistance with mechanical performance. Research institutions including MIT, Kyushu University, and NIMS are pioneering fundamental breakthroughs in coating formulations. Meanwhile, automotive manufacturers such as Nissan and BMW are implementing practical solutions for hydrogen-powered vehicles, focusing on the critical balance between coating effectiveness and maintaining structural integrity in high-stress applications.

BASF Coatings GmbH

Technical Solution: BASF Coatings has pioneered an innovative approach to hydrogen embrittlement mitigation through their advanced polymer-ceramic hybrid coating systems. Their technology utilizes a multi-layer architecture featuring a base layer of modified epoxy with engineered porosity to trap hydrogen molecules, followed by a dense ceramic-polymer composite layer that significantly reduces hydrogen permeation while maintaining excellent adhesion and flexibility. BASF's research has demonstrated permeation reduction rates exceeding 80% compared to conventional coatings. Their proprietary CeraShield technology incorporates nano-scale ceramic particles with tailored surface chemistry that act as hydrogen scavengers, effectively binding hydrogen molecules before they can reach the substrate. The company has developed specialized application processes that ensure uniform coating thickness and optimal cross-linking density, critical factors in maintaining mechanical integrity while maximizing hydrogen barrier properties. Additionally, BASF employs surface preparation techniques that create controlled roughness profiles, enhancing coating adhesion without introducing stress concentration points that could serve as crack initiation sites. Their coatings also feature self-healing capabilities through the incorporation of microencapsulated healing agents that are released upon microcrack formation.

Strengths: Exceptional hydrogen barrier properties; excellent flexibility and adhesion; compatibility with various substrate materials; good resistance to environmental degradation. Weaknesses: Higher material costs compared to conventional coatings; more complex application process requiring specialized equipment; potential thickness limitations for certain applications.

voestalpine Stahl GmbH

Technical Solution: voestalpine Stahl has developed an innovative dual-phase approach to hydrogen embrittlement mitigation that focuses on both microstructural optimization and advanced coating systems. Their technology employs a specialized heat treatment process that creates a gradient microstructure with varying grain sizes and phase distributions, strategically designed to provide hydrogen trapping sites away from critical stress regions. This is complemented by their proprietary PremCoat HD coating system, which incorporates aluminum-silicon diffusion layers beneath conventional zinc coatings, creating effective hydrogen barriers while maintaining excellent formability. Research has shown this combination reduces hydrogen permeation by up to 85% compared to standard galvanized coatings. voestalpine has also pioneered the use of nano-scale ceramic particles dispersed within the coating matrix, which serve as both mechanical reinforcement and hydrogen trapping sites, effectively preventing hydrogen accumulation at potential crack initiation points. Their process includes controlled cooling rates after coating application to minimize residual stresses and optimize the interface between coating and substrate.

Strengths: Exceptional balance between hydrogen barrier properties and mechanical flexibility; superior performance in high-stress applications; excellent long-term durability under cyclic loading conditions. Weaknesses: Higher initial implementation costs; requires specialized equipment for optimal application; more complex quality control procedures compared to conventional coatings.

Key Innovations in Hydrogen Barrier Technologies

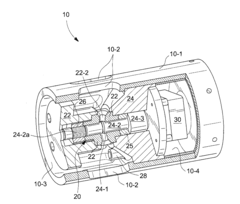

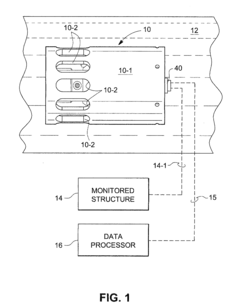

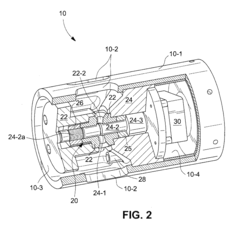

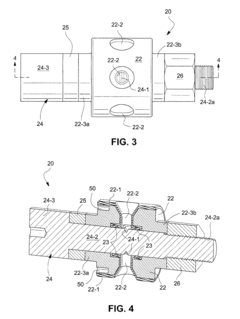

In-situ sensors and methods for monitoring environment assisted cracking of structural components

PatentActiveUS20110100131A1

Innovation

- A compact sensor system utilizing a circumferentially notched tensile (CNT) specimen with high-resolution strain gage instrumentation and a stiff sensor construction to measure crack depth in real-time, mimicking the loading conditions of the monitored structure, allowing for early detection of cracking and correlation with structural damage.

Material Testing Standards for Hydrogen Environments

The standardization of material testing in hydrogen environments is critical for ensuring the reliability and safety of materials used in hydrogen infrastructure. ASTM International has developed several key standards, including ASTM F1940 for hydrogen embrittlement testing of plated products and ASTM G142 for determining susceptibility of metals to embrittlement in hydrogen environments. These standards provide consistent methodologies for evaluating material performance under hydrogen exposure.

ISO standards complement these with ISO 11114 for compatibility testing of materials with gas contents and ISO 16573 for hydrogen embrittlement testing of steels. Together, these standards establish a comprehensive framework for material qualification in hydrogen service applications.

Testing protocols typically include slow strain rate testing (SSRT), which evaluates material degradation under simultaneous mechanical loading and hydrogen exposure. This method is particularly valuable for assessing the balance between coating permeation resistance and mechanical integrity. Fracture mechanics-based tests, such as those outlined in ASTM E1681, provide quantitative measures of crack growth rates in hydrogen environments.

For coated materials specifically, specialized testing standards have emerged to address the unique challenges of evaluating hydrogen barrier properties while maintaining mechanical performance. NACE TM0284 offers procedures for evaluating hydrogen-induced cracking resistance in pipeline steels, while ASTM G148 provides guidelines for hydrogen uptake, permeation, and transport measurements.

Environmental factors significantly impact test results, necessitating standardized environmental conditions. Temperature, pressure, and hydrogen purity must be carefully controlled according to specifications in standards like ASTM G129. These parameters directly influence hydrogen diffusion rates through coatings and subsequent embrittlement processes.

Recent developments in testing standards have focused on accelerated testing methodologies to predict long-term performance more efficiently. These include electrochemical hydrogen charging techniques standardized in ISO 17081 for measuring hydrogen permeation. Additionally, non-destructive evaluation methods are increasingly incorporated into standards to monitor hydrogen-induced damage progression without compromising structural integrity.

The harmonization of international standards remains an ongoing challenge, with efforts by organizations like the International Association for Hydrogen Safety (HySafe) to establish globally recognized testing protocols. This standardization is essential for facilitating the development of coatings that effectively balance hydrogen permeation resistance with the mechanical integrity requirements of hydrogen infrastructure components.

ISO standards complement these with ISO 11114 for compatibility testing of materials with gas contents and ISO 16573 for hydrogen embrittlement testing of steels. Together, these standards establish a comprehensive framework for material qualification in hydrogen service applications.

Testing protocols typically include slow strain rate testing (SSRT), which evaluates material degradation under simultaneous mechanical loading and hydrogen exposure. This method is particularly valuable for assessing the balance between coating permeation resistance and mechanical integrity. Fracture mechanics-based tests, such as those outlined in ASTM E1681, provide quantitative measures of crack growth rates in hydrogen environments.

For coated materials specifically, specialized testing standards have emerged to address the unique challenges of evaluating hydrogen barrier properties while maintaining mechanical performance. NACE TM0284 offers procedures for evaluating hydrogen-induced cracking resistance in pipeline steels, while ASTM G148 provides guidelines for hydrogen uptake, permeation, and transport measurements.

Environmental factors significantly impact test results, necessitating standardized environmental conditions. Temperature, pressure, and hydrogen purity must be carefully controlled according to specifications in standards like ASTM G129. These parameters directly influence hydrogen diffusion rates through coatings and subsequent embrittlement processes.

Recent developments in testing standards have focused on accelerated testing methodologies to predict long-term performance more efficiently. These include electrochemical hydrogen charging techniques standardized in ISO 17081 for measuring hydrogen permeation. Additionally, non-destructive evaluation methods are increasingly incorporated into standards to monitor hydrogen-induced damage progression without compromising structural integrity.

The harmonization of international standards remains an ongoing challenge, with efforts by organizations like the International Association for Hydrogen Safety (HySafe) to establish globally recognized testing protocols. This standardization is essential for facilitating the development of coatings that effectively balance hydrogen permeation resistance with the mechanical integrity requirements of hydrogen infrastructure components.

Economic Impact of Hydrogen Embrittlement Failures

Hydrogen embrittlement failures represent a significant economic burden across multiple industries, particularly in sectors where high-strength steels and other susceptible materials are extensively utilized. The direct costs associated with these failures include immediate material losses, replacement expenses, and production downtime. For instance, in the oil and gas industry, a single hydrogen-induced failure in a critical pipeline component can result in operational shutdowns costing upwards of $100,000 per hour.

Beyond immediate replacement costs, the secondary economic impacts often prove more substantial. These include production losses, contractual penalties for delivery delays, and increased insurance premiums following failure incidents. The automotive industry reports that hydrogen embrittlement-related recalls have cost manufacturers billions over the past decade, with individual campaigns sometimes exceeding $100 million in direct costs.

The preventive measures implemented to mitigate hydrogen embrittlement also carry significant economic implications. Companies must balance the costs of advanced coating technologies, material selection, and specialized heat treatments against the risk of potential failures. This preventive investment typically represents 2-5% of total production costs in high-risk applications but can reach 15% in aerospace and defense sectors where failure consequences are most severe.

Liability considerations further amplify the economic impact. Catastrophic failures resulting from hydrogen embrittlement can lead to substantial legal settlements, particularly when such failures result in safety incidents. Historical cases demonstrate settlements reaching tens of millions of dollars when hydrogen-induced failures have contributed to structural collapses or equipment malfunctions causing injury.

The research and development expenditure directed toward hydrogen embrittlement solutions represents another significant economic factor. Global R&D spending on hydrogen embrittlement mitigation technologies exceeds $500 million annually, reflecting the critical importance of this challenge to industrial operations.

From a competitive standpoint, organizations that effectively manage hydrogen embrittlement risks gain substantial market advantages. Companies demonstrating superior reliability records can command premium pricing and secure preferred supplier status. Conversely, those with documented failure histories face market penalties through reduced contract opportunities and heightened scrutiny from potential customers.

The economic calculus of hydrogen embrittlement mitigation ultimately centers on risk management. Decision-makers must weigh the upfront costs of prevention against the potentially catastrophic financial consequences of failures, considering both direct expenses and the less quantifiable impacts on reputation and future business opportunities.

Beyond immediate replacement costs, the secondary economic impacts often prove more substantial. These include production losses, contractual penalties for delivery delays, and increased insurance premiums following failure incidents. The automotive industry reports that hydrogen embrittlement-related recalls have cost manufacturers billions over the past decade, with individual campaigns sometimes exceeding $100 million in direct costs.

The preventive measures implemented to mitigate hydrogen embrittlement also carry significant economic implications. Companies must balance the costs of advanced coating technologies, material selection, and specialized heat treatments against the risk of potential failures. This preventive investment typically represents 2-5% of total production costs in high-risk applications but can reach 15% in aerospace and defense sectors where failure consequences are most severe.

Liability considerations further amplify the economic impact. Catastrophic failures resulting from hydrogen embrittlement can lead to substantial legal settlements, particularly when such failures result in safety incidents. Historical cases demonstrate settlements reaching tens of millions of dollars when hydrogen-induced failures have contributed to structural collapses or equipment malfunctions causing injury.

The research and development expenditure directed toward hydrogen embrittlement solutions represents another significant economic factor. Global R&D spending on hydrogen embrittlement mitigation technologies exceeds $500 million annually, reflecting the critical importance of this challenge to industrial operations.

From a competitive standpoint, organizations that effectively manage hydrogen embrittlement risks gain substantial market advantages. Companies demonstrating superior reliability records can command premium pricing and secure preferred supplier status. Conversely, those with documented failure histories face market penalties through reduced contract opportunities and heightened scrutiny from potential customers.

The economic calculus of hydrogen embrittlement mitigation ultimately centers on risk management. Decision-makers must weigh the upfront costs of prevention against the potentially catastrophic financial consequences of failures, considering both direct expenses and the less quantifiable impacts on reputation and future business opportunities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!