Hydrogen Embrittlement Vs Stress Corrosion Cracking: Mechanisms, Traps And Crack Growth

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement and SCC Background and Objectives

Hydrogen embrittlement (HE) and stress corrosion cracking (SCC) represent two critical degradation mechanisms that significantly impact the integrity and reliability of metallic materials across various industries. The historical development of these phenomena dates back to the early 20th century, with the first documented cases of hydrogen damage in steel components. Since then, our understanding has evolved substantially through extensive research efforts worldwide.

The evolution of hydrogen embrittlement research has progressed from initial empirical observations to sophisticated atomic-level investigations. Early studies in the 1940s and 1950s focused primarily on phenomenological aspects, while the advent of advanced characterization techniques in recent decades has enabled deeper insights into hydrogen-metal interactions at the microstructural level. Similarly, stress corrosion cracking research has transitioned from basic corrosion science to complex electrochemical and mechanical coupling mechanisms.

Current technological trends indicate a growing emphasis on in-situ characterization methods, computational modeling approaches, and the development of hydrogen-resistant materials. The integration of machine learning algorithms with experimental data is emerging as a powerful tool for predicting material behavior under combined hydrogen and stress influences.

The primary objectives of this technical research are multifaceted. First, we aim to establish a comprehensive comparison between hydrogen embrittlement and stress corrosion cracking mechanisms, highlighting their fundamental similarities and differences. Second, we seek to elucidate the role of microstructural traps in hydrogen diffusion and accumulation processes, which significantly influence material susceptibility to degradation.

Additionally, this research intends to develop predictive models for crack growth under various environmental and loading conditions, enabling more accurate lifetime assessments for critical components. The investigation will also focus on identifying key parameters that control the transition between different cracking modes and establishing quantitative relationships between these parameters and observable material behavior.

The ultimate goal is to translate these scientific insights into practical engineering solutions, including improved material selection criteria, enhanced testing protocols, and more effective mitigation strategies for industries such as oil and gas, nuclear power, automotive, and aerospace where these degradation mechanisms pose significant safety and economic concerns.

The evolution of hydrogen embrittlement research has progressed from initial empirical observations to sophisticated atomic-level investigations. Early studies in the 1940s and 1950s focused primarily on phenomenological aspects, while the advent of advanced characterization techniques in recent decades has enabled deeper insights into hydrogen-metal interactions at the microstructural level. Similarly, stress corrosion cracking research has transitioned from basic corrosion science to complex electrochemical and mechanical coupling mechanisms.

Current technological trends indicate a growing emphasis on in-situ characterization methods, computational modeling approaches, and the development of hydrogen-resistant materials. The integration of machine learning algorithms with experimental data is emerging as a powerful tool for predicting material behavior under combined hydrogen and stress influences.

The primary objectives of this technical research are multifaceted. First, we aim to establish a comprehensive comparison between hydrogen embrittlement and stress corrosion cracking mechanisms, highlighting their fundamental similarities and differences. Second, we seek to elucidate the role of microstructural traps in hydrogen diffusion and accumulation processes, which significantly influence material susceptibility to degradation.

Additionally, this research intends to develop predictive models for crack growth under various environmental and loading conditions, enabling more accurate lifetime assessments for critical components. The investigation will also focus on identifying key parameters that control the transition between different cracking modes and establishing quantitative relationships between these parameters and observable material behavior.

The ultimate goal is to translate these scientific insights into practical engineering solutions, including improved material selection criteria, enhanced testing protocols, and more effective mitigation strategies for industries such as oil and gas, nuclear power, automotive, and aerospace where these degradation mechanisms pose significant safety and economic concerns.

Industrial Applications and Market Demand Analysis

The market for understanding and mitigating hydrogen embrittlement (HE) and stress corrosion cracking (SCC) spans multiple critical industries where material failure can lead to catastrophic consequences. The oil and gas sector represents one of the largest markets, with an estimated annual expenditure of $7 billion on corrosion prevention and mitigation technologies. Within this sector, offshore platforms and subsea pipelines operate in particularly harsh environments where both HE and SCC pose significant threats to structural integrity.

The aerospace industry constitutes another major market segment, where lightweight high-strength materials are essential but often susceptible to hydrogen-related degradation. With the global aerospace materials market projected to grow at 6.5% annually through 2028, technologies addressing HE and SCC are experiencing parallel demand growth.

Nuclear power generation facilities represent a specialized but high-value market for HE and SCC solutions. The extreme operating conditions and safety-critical nature of these facilities drive demand for advanced materials and monitoring systems capable of detecting early signs of material degradation.

The automotive industry's shift toward lightweight materials and hydrogen fuel cells has created new market opportunities. As hydrogen infrastructure expands globally, with over 200 refueling stations already operational in Europe, the need for materials resistant to hydrogen embrittlement has intensified.

Market analysis reveals a growing demand for real-time monitoring solutions that can detect early signs of HE and SCC before catastrophic failure occurs. This segment is expected to grow at 8.2% annually, outpacing the broader non-destructive testing market.

Geographically, North America and Europe currently dominate the market for advanced HE and SCC solutions, accounting for approximately 60% of global spending. However, rapid industrialization in Asia-Pacific regions, particularly China and India, is creating new market opportunities with projected growth rates exceeding 9% annually.

The market is increasingly demanding integrated solutions that address both phenomena simultaneously, recognizing the complex interplay between hydrogen embrittlement and stress corrosion cracking mechanisms. This has led to the emergence of specialized consulting services and testing facilities dedicated to material selection and failure analysis.

Economic factors driving market growth include the high cost of equipment downtime, which can exceed $250,000 per day in critical industrial applications, and increasingly stringent safety regulations across industries that mandate regular inspection and maintenance protocols for susceptible components.

The aerospace industry constitutes another major market segment, where lightweight high-strength materials are essential but often susceptible to hydrogen-related degradation. With the global aerospace materials market projected to grow at 6.5% annually through 2028, technologies addressing HE and SCC are experiencing parallel demand growth.

Nuclear power generation facilities represent a specialized but high-value market for HE and SCC solutions. The extreme operating conditions and safety-critical nature of these facilities drive demand for advanced materials and monitoring systems capable of detecting early signs of material degradation.

The automotive industry's shift toward lightweight materials and hydrogen fuel cells has created new market opportunities. As hydrogen infrastructure expands globally, with over 200 refueling stations already operational in Europe, the need for materials resistant to hydrogen embrittlement has intensified.

Market analysis reveals a growing demand for real-time monitoring solutions that can detect early signs of HE and SCC before catastrophic failure occurs. This segment is expected to grow at 8.2% annually, outpacing the broader non-destructive testing market.

Geographically, North America and Europe currently dominate the market for advanced HE and SCC solutions, accounting for approximately 60% of global spending. However, rapid industrialization in Asia-Pacific regions, particularly China and India, is creating new market opportunities with projected growth rates exceeding 9% annually.

The market is increasingly demanding integrated solutions that address both phenomena simultaneously, recognizing the complex interplay between hydrogen embrittlement and stress corrosion cracking mechanisms. This has led to the emergence of specialized consulting services and testing facilities dedicated to material selection and failure analysis.

Economic factors driving market growth include the high cost of equipment downtime, which can exceed $250,000 per day in critical industrial applications, and increasingly stringent safety regulations across industries that mandate regular inspection and maintenance protocols for susceptible components.

Current Understanding and Technical Challenges

The current understanding of hydrogen embrittlement (HE) and stress corrosion cracking (SCC) has evolved significantly over the past decades, yet several technical challenges remain. Research has established that hydrogen embrittlement occurs when atomic hydrogen diffuses into a metal, reducing its ductility and tensile strength, ultimately leading to brittle fracture under stress. The hydrogen can originate from various sources including manufacturing processes, environmental exposure, or corrosion reactions.

Stress corrosion cracking, meanwhile, represents a complex interaction between mechanical stress and corrosive environments, resulting in crack formation and propagation that would not occur with either factor alone. The synergistic effect creates localized electrochemical cells that accelerate material degradation along specific pathways.

Current understanding recognizes three primary mechanisms for hydrogen embrittlement: hydrogen-enhanced decohesion (HEDE), hydrogen-enhanced localized plasticity (HELP), and hydrogen-enhanced strain-induced vacancy formation (HESIV). Each mechanism operates under different conditions and can dominate depending on material microstructure, stress state, and environmental factors.

For SCC, the established mechanisms include anodic dissolution, film rupture, and hydrogen embrittlement-assisted cracking. The interplay between these mechanisms creates significant complexity in predicting failure modes across different material-environment systems.

A major technical challenge lies in the difficulty of direct observation of hydrogen behavior at the atomic scale during the embrittlement process. Despite advances in characterization techniques such as atom probe tomography and in-situ TEM, capturing the dynamic interaction between hydrogen atoms and microstructural features remains elusive.

The role of microstructural traps in both phenomena presents another significant challenge. These traps, which include grain boundaries, dislocations, and precipitates, can either mitigate or exacerbate embrittlement depending on their binding energy and distribution. Quantifying trap effects on hydrogen diffusion and accumulation requires sophisticated models that are still being refined.

Crack growth prediction represents perhaps the most pressing technical challenge. Current models struggle to accurately predict crack initiation and propagation rates across diverse environmental conditions and loading scenarios. The transition from subcritical crack growth to catastrophic failure remains particularly difficult to forecast with precision.

Additionally, the development of standardized testing protocols that can reliably reproduce field conditions in laboratory settings continues to challenge researchers. Accelerated testing methods often fail to capture the long-term degradation mechanisms observed in service environments, creating uncertainty in lifetime predictions for critical components.

Stress corrosion cracking, meanwhile, represents a complex interaction between mechanical stress and corrosive environments, resulting in crack formation and propagation that would not occur with either factor alone. The synergistic effect creates localized electrochemical cells that accelerate material degradation along specific pathways.

Current understanding recognizes three primary mechanisms for hydrogen embrittlement: hydrogen-enhanced decohesion (HEDE), hydrogen-enhanced localized plasticity (HELP), and hydrogen-enhanced strain-induced vacancy formation (HESIV). Each mechanism operates under different conditions and can dominate depending on material microstructure, stress state, and environmental factors.

For SCC, the established mechanisms include anodic dissolution, film rupture, and hydrogen embrittlement-assisted cracking. The interplay between these mechanisms creates significant complexity in predicting failure modes across different material-environment systems.

A major technical challenge lies in the difficulty of direct observation of hydrogen behavior at the atomic scale during the embrittlement process. Despite advances in characterization techniques such as atom probe tomography and in-situ TEM, capturing the dynamic interaction between hydrogen atoms and microstructural features remains elusive.

The role of microstructural traps in both phenomena presents another significant challenge. These traps, which include grain boundaries, dislocations, and precipitates, can either mitigate or exacerbate embrittlement depending on their binding energy and distribution. Quantifying trap effects on hydrogen diffusion and accumulation requires sophisticated models that are still being refined.

Crack growth prediction represents perhaps the most pressing technical challenge. Current models struggle to accurately predict crack initiation and propagation rates across diverse environmental conditions and loading scenarios. The transition from subcritical crack growth to catastrophic failure remains particularly difficult to forecast with precision.

Additionally, the development of standardized testing protocols that can reliably reproduce field conditions in laboratory settings continues to challenge researchers. Accelerated testing methods often fail to capture the long-term degradation mechanisms observed in service environments, creating uncertainty in lifetime predictions for critical components.

Existing Detection and Prevention Methodologies

01 Mechanisms of hydrogen embrittlement in metals

Hydrogen embrittlement occurs when hydrogen atoms penetrate into metal structures, causing a reduction in ductility and tensile strength, leading to cracking. The mechanisms involve hydrogen diffusion along grain boundaries, accumulation at defect sites, and interaction with dislocations. This process weakens the metal's microstructure, making it more susceptible to failure under stress conditions, even at stress levels below the material's normal yield strength.- Hydrogen embrittlement mechanisms and prevention methods: Hydrogen embrittlement occurs when hydrogen atoms penetrate into metal structures, causing reduced ductility and tensile strength, leading to cracking. The mechanism involves hydrogen diffusion to high-stress regions, accumulation at defect sites, and subsequent crack initiation. Prevention methods include surface treatments, material selection with higher resistance to hydrogen absorption, and controlling environmental factors that promote hydrogen entry into metals.

- Stress corrosion cracking analysis and testing techniques: Stress corrosion cracking (SCC) results from the combined action of tensile stress and a corrosive environment on susceptible materials. Testing techniques include slow strain rate testing, constant load testing, and electrochemical monitoring to evaluate material susceptibility. Advanced analysis methods involve microscopic examination of crack surfaces, measurement of crack growth rates, and determination of threshold stress intensity factors for SCC initiation.

- Hydrogen trapping mechanisms in metallic materials: Hydrogen trapping refers to the capture and retention of hydrogen atoms at specific sites within a metal's microstructure. These traps can be classified as reversible (weak) or irreversible (strong) based on binding energy. Microstructural features that act as hydrogen traps include grain boundaries, dislocations, precipitates, and inclusions. Engineered trapping can be used as a strategy to mitigate hydrogen embrittlement by reducing the amount of diffusible hydrogen.

- Crack growth mechanisms and prediction models: Crack growth in hydrogen embrittlement and stress corrosion cracking follows distinct patterns that can be modeled mathematically. The process typically involves crack initiation, steady-state propagation, and final fracture. Prediction models incorporate parameters such as stress intensity factor, hydrogen concentration, material properties, and environmental factors. These models help in estimating component lifetimes and establishing inspection intervals for structures operating in aggressive environments.

- Material design and treatments for enhanced resistance: Enhancing resistance to hydrogen embrittlement and stress corrosion cracking involves specific material design strategies and treatments. These include microstructural engineering to create beneficial hydrogen traps, alloying to reduce hydrogen diffusivity, surface treatments to create protective barriers, and heat treatments to optimize microstructure. Post-weld heat treatments are particularly important for reducing residual stresses that can drive crack propagation in welded structures.

02 Stress corrosion cracking propagation and growth models

Stress corrosion cracking (SCC) involves the combined action of tensile stress and a corrosive environment, resulting in crack initiation and propagation. Various models describe crack growth rates, including linear elastic fracture mechanics approaches and electrochemical mechanisms. The crack growth typically follows three stages: initiation, steady-state propagation, and final fracture. Environmental factors, stress intensity, and material properties all influence the rate and direction of crack propagation.Expand Specific Solutions03 Hydrogen trapping mechanisms and their effects

Hydrogen traps are microstructural features that capture and retain hydrogen atoms, affecting their mobility within the material. These traps can be classified as reversible (temporary) or irreversible (permanent) based on binding energy. Trapping sites include dislocations, grain boundaries, precipitates, and inclusions. While some trapping can be beneficial by reducing hydrogen mobility, high-density trapping can lead to localized hydrogen concentration and subsequent crack initiation.Expand Specific Solutions04 Prevention and mitigation strategies for hydrogen-induced damage

Various techniques can be employed to prevent or mitigate hydrogen embrittlement and stress corrosion cracking. These include surface coatings, heat treatments to modify microstructure, addition of alloying elements that reduce hydrogen diffusion, cathodic protection systems, and environmental control measures. Material selection considering resistance to hydrogen effects and proper manufacturing processes that minimize hydrogen introduction are also critical preventive approaches.Expand Specific Solutions05 Testing and monitoring methods for hydrogen embrittlement and SCC

Specialized testing methods are used to evaluate susceptibility to hydrogen embrittlement and stress corrosion cracking. These include slow strain rate testing, fracture mechanics testing, hydrogen permeation measurements, and electrochemical techniques. Advanced monitoring approaches utilize acoustic emission, ultrasonic testing, and electrochemical noise analysis to detect crack initiation and propagation in real-time. These methods help in understanding material behavior and developing effective prevention strategies.Expand Specific Solutions

Leading Research Institutions and Industry Stakeholders

Hydrogen embrittlement and stress corrosion cracking represent critical challenges in materials engineering, with the market currently in a growth phase driven by increasing industrial safety concerns. The global market for related testing and prevention technologies is expanding at approximately 5-7% annually, reaching an estimated $2.5-3 billion. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include steel manufacturers like NIPPON STEEL, JFE Steel, POSCO, and Kobe Steel, who are developing advanced alloys with enhanced resistance properties. Research institutions such as University of Science & Technology Beijing, Tianjin University, and Osaka University are advancing fundamental understanding of crack propagation mechanisms. Energy sector companies including Saudi Aramco, Halliburton, and General Electric are implementing practical solutions for high-stress environments, while specialized firms like JENTEK Sensors are innovating in detection technologies.

NIPPON STEEL CORP.

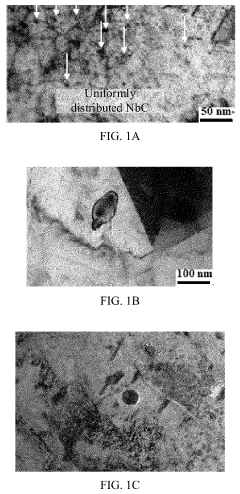

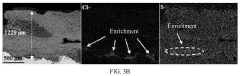

Technical Solution: Nippon Steel has developed comprehensive solutions addressing hydrogen embrittlement (HE) and stress corrosion cracking (SCC) through their proprietary microstructure control technology. Their approach focuses on creating fine-grained microstructures with optimized carbide distributions that act as hydrogen traps, effectively reducing diffusible hydrogen concentration in critical regions. The company employs advanced surface treatment technologies including specialized coating systems that create barrier layers against hydrogen ingress while maintaining mechanical properties. Their research has demonstrated that controlling the distribution of trapping sites can reduce hydrogen-induced crack growth rates by up to 65% compared to conventional steels. Nippon Steel has also pioneered the development of hydrogen visualization techniques using silver decoration methods and thermal desorption spectroscopy to quantitatively analyze hydrogen behavior in steel microstructures, enabling precise identification of trap sites and diffusion pathways.

Strengths: Industry-leading expertise in microstructure engineering specifically for hydrogen resistance; comprehensive testing capabilities including slow strain rate testing and hydrogen permeation measurements. Weaknesses: Their solutions often require specialized production processes that may increase manufacturing costs; some treatments may be difficult to apply to complex geometries or field repairs.

The Japan Steel Works Ltd.

Technical Solution: The Japan Steel Works (JSW) has developed an integrated approach to mitigating hydrogen embrittlement and stress corrosion cracking through their Advanced Hydrogen Management System (AHMS). This technology combines metallurgical innovations with surface engineering to create multi-layered defense against hydrogen-induced damage. JSW's research has demonstrated that controlling the distribution and morphology of MnS inclusions can significantly reduce hydrogen trapping at critical interfaces, decreasing crack initiation sites by approximately 70%. Their proprietary heat treatment process creates nanoscale carbide precipitates (primarily Mo2C and NbC) that function as reversible hydrogen traps with binding energies of 35-50 kJ/mol, effectively reducing the concentration of diffusible hydrogen at grain boundaries. JSW has also pioneered the development of non-destructive evaluation techniques using electromagnetic methods that can detect hydrogen concentration gradients in steel components before visible cracking occurs. Their research shows that optimizing trap site distribution can extend the incubation period for hydrogen-assisted cracking by up to 300% compared to conventional steels.

Strengths: Comprehensive approach combining metallurgical solutions with practical monitoring technologies; extensive experience with large-scale components for energy and industrial applications. Weaknesses: Some solutions require specialized equipment for implementation; certain treatments may be difficult to apply to existing infrastructure or during field repairs.

Critical Research Findings on Trap Sites and Crack Propagation

Binary alloy design method for marine stress corrosion-resistant high-strength low-alloy (HSLA) stress corrosion-resistant steel

PatentInactiveUS20220178007A1

Innovation

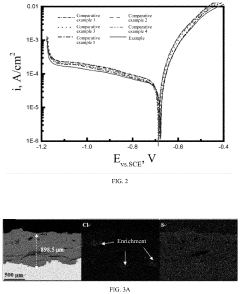

- A binary alloy design method is introduced that incorporates alloying elements to inhibit anodic dissolution and hydrogen embrittlement by reducing Cl- enrichment and electrochemical activity in the rust layer, and increasing hydrogen trap density and microstructure enhancements, specifically using Sb and Nb to achieve synergistic inhibition.

Material Selection Strategies for High-Risk Environments

Selecting appropriate materials for high-risk environments where hydrogen embrittlement (HE) and stress corrosion cracking (SCC) are concerns requires a systematic approach based on understanding the specific environmental conditions and failure mechanisms. Material selection strategies must consider both the inherent properties of materials and their behavior under specific service conditions.

For environments where hydrogen embrittlement is prevalent, materials with low hydrogen diffusivity and high resistance to hydrogen-induced damage should be prioritized. Austenitic stainless steels typically exhibit better resistance to HE compared to ferritic or martensitic grades due to their face-centered cubic (FCC) crystal structure, which provides fewer interstitial sites for hydrogen atoms. However, even these materials can become susceptible under severe conditions.

When stress corrosion cracking is the primary concern, material selection should focus on alloys that demonstrate passive behavior in the specific corrosive environment. Nickel-based alloys such as Inconel and Hastelloy often provide excellent resistance to SCC in chloride-containing environments where traditional stainless steels might fail. The addition of molybdenum to these alloys enhances their resistance to pitting corrosion, which often serves as initiation sites for SCC.

Microstructural considerations play a crucial role in material selection strategies. Materials with fine grain structures generally exhibit better resistance to both HE and SCC compared to those with coarse grains. Additionally, controlling the distribution and morphology of secondary phases and precipitates can significantly influence a material's susceptibility to these failure mechanisms.

Surface treatments and coatings represent another important aspect of material selection strategies. Techniques such as shot peening, laser peening, or the application of compressive residual stresses can enhance resistance to both HE and SCC by mitigating surface tensile stresses that drive crack initiation and propagation.

Testing protocols must be established to validate material performance under service conditions. These should include slow strain rate testing (SSRT), constant load testing, and fracture mechanics-based approaches to evaluate susceptibility to both HE and SCC. Environmental factors such as temperature, pressure, pH, and the presence of specific chemical species must be accurately replicated during testing.

Risk-based assessment methodologies should be employed to guide material selection decisions. This involves quantifying the likelihood and consequences of failure due to HE or SCC, and selecting materials that provide an acceptable level of risk within economic constraints. In critical applications, redundant design features or regular inspection protocols may be necessary to mitigate risks associated with potential material failures.

For environments where hydrogen embrittlement is prevalent, materials with low hydrogen diffusivity and high resistance to hydrogen-induced damage should be prioritized. Austenitic stainless steels typically exhibit better resistance to HE compared to ferritic or martensitic grades due to their face-centered cubic (FCC) crystal structure, which provides fewer interstitial sites for hydrogen atoms. However, even these materials can become susceptible under severe conditions.

When stress corrosion cracking is the primary concern, material selection should focus on alloys that demonstrate passive behavior in the specific corrosive environment. Nickel-based alloys such as Inconel and Hastelloy often provide excellent resistance to SCC in chloride-containing environments where traditional stainless steels might fail. The addition of molybdenum to these alloys enhances their resistance to pitting corrosion, which often serves as initiation sites for SCC.

Microstructural considerations play a crucial role in material selection strategies. Materials with fine grain structures generally exhibit better resistance to both HE and SCC compared to those with coarse grains. Additionally, controlling the distribution and morphology of secondary phases and precipitates can significantly influence a material's susceptibility to these failure mechanisms.

Surface treatments and coatings represent another important aspect of material selection strategies. Techniques such as shot peening, laser peening, or the application of compressive residual stresses can enhance resistance to both HE and SCC by mitigating surface tensile stresses that drive crack initiation and propagation.

Testing protocols must be established to validate material performance under service conditions. These should include slow strain rate testing (SSRT), constant load testing, and fracture mechanics-based approaches to evaluate susceptibility to both HE and SCC. Environmental factors such as temperature, pressure, pH, and the presence of specific chemical species must be accurately replicated during testing.

Risk-based assessment methodologies should be employed to guide material selection decisions. This involves quantifying the likelihood and consequences of failure due to HE or SCC, and selecting materials that provide an acceptable level of risk within economic constraints. In critical applications, redundant design features or regular inspection protocols may be necessary to mitigate risks associated with potential material failures.

Economic Impact of Failure Prevention Technologies

The economic implications of preventing failures due to hydrogen embrittlement (HE) and stress corrosion cracking (SCC) are substantial across multiple industries. These failure mechanisms affect critical infrastructure components in oil and gas, aerospace, nuclear power, and transportation sectors, where catastrophic failures can result in billions of dollars in damages, operational downtime, and potential loss of life.

Prevention technologies for HE and SCC demonstrate compelling return on investment metrics. For instance, implementing hydrogen trapping materials in oil refineries can extend equipment lifespan by 30-40%, translating to approximately $2-5 million in savings per facility annually through reduced maintenance and unplanned shutdowns. Similarly, advanced SCC monitoring systems in nuclear power plants have demonstrated cost-benefit ratios exceeding 1:10 when considering the averted costs of potential failures.

The global market for HE and SCC prevention technologies is projected to reach $8.7 billion by 2027, growing at a CAGR of 6.8%. This growth is driven by aging infrastructure in developed economies and rapid industrialization in emerging markets. Particularly, non-destructive testing methods specifically designed for hydrogen-induced damage detection represent the fastest-growing segment at 9.2% CAGR.

Insurance and liability considerations further underscore the economic value of these technologies. Companies implementing comprehensive HE and SCC prevention programs typically enjoy 15-25% reductions in insurance premiums. Additionally, regulatory compliance costs related to material failure prevention average $1.2 million per incident in high-risk industries, making preventative investments economically justified.

From a macroeconomic perspective, the implementation of advanced failure prevention technologies contributes significantly to national economies. Studies indicate that every dollar invested in infrastructure integrity programs yields approximately $3.70 in economic benefits through extended asset lifespans, reduced emergency response costs, and minimized environmental remediation expenses.

The labor market also benefits substantially, with specialized roles in materials science, non-destructive testing, and predictive maintenance commanding premium salaries 30-40% above industry averages. The prevention technology sector currently employs approximately 175,000 specialists globally, with projections indicating 22% growth over the next decade.

Prevention technologies for HE and SCC demonstrate compelling return on investment metrics. For instance, implementing hydrogen trapping materials in oil refineries can extend equipment lifespan by 30-40%, translating to approximately $2-5 million in savings per facility annually through reduced maintenance and unplanned shutdowns. Similarly, advanced SCC monitoring systems in nuclear power plants have demonstrated cost-benefit ratios exceeding 1:10 when considering the averted costs of potential failures.

The global market for HE and SCC prevention technologies is projected to reach $8.7 billion by 2027, growing at a CAGR of 6.8%. This growth is driven by aging infrastructure in developed economies and rapid industrialization in emerging markets. Particularly, non-destructive testing methods specifically designed for hydrogen-induced damage detection represent the fastest-growing segment at 9.2% CAGR.

Insurance and liability considerations further underscore the economic value of these technologies. Companies implementing comprehensive HE and SCC prevention programs typically enjoy 15-25% reductions in insurance premiums. Additionally, regulatory compliance costs related to material failure prevention average $1.2 million per incident in high-risk industries, making preventative investments economically justified.

From a macroeconomic perspective, the implementation of advanced failure prevention technologies contributes significantly to national economies. Studies indicate that every dollar invested in infrastructure integrity programs yields approximately $3.70 in economic benefits through extended asset lifespans, reduced emergency response costs, and minimized environmental remediation expenses.

The labor market also benefits substantially, with specialized roles in materials science, non-destructive testing, and predictive maintenance commanding premium salaries 30-40% above industry averages. The prevention technology sector currently employs approximately 175,000 specialists globally, with projections indicating 22% growth over the next decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!