Hydrogen Embrittlement Under Cathodic Protection: Potential Control, Coatings And Risk Windows

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement Background and Objectives

Hydrogen embrittlement (HE) represents one of the most significant challenges in materials science and engineering, particularly in industries where metals are exposed to hydrogen-rich environments. The phenomenon was first observed in the late 19th century, but comprehensive understanding has evolved significantly over the past five decades with advances in analytical techniques and computational modeling.

The evolution of hydrogen embrittlement research has progressed through several distinct phases. Initially, observations were primarily phenomenological, focusing on macroscopic effects. The 1970s-1980s saw the development of fundamental theories regarding hydrogen-metal interactions. The 1990s-2000s brought significant advances in experimental techniques allowing for nanoscale observations. Most recently, computational modeling has enabled predictive capabilities previously unattainable.

In the context of cathodic protection systems, hydrogen embrittlement presents a particular paradox. While cathodic protection effectively mitigates corrosion by imposing a negative electrical potential on metal structures, this same process can inadvertently generate hydrogen at the metal surface through water reduction reactions, potentially leading to embrittlement.

The technical objectives of this research focus on several critical aspects. First, establishing quantitative relationships between cathodic protection potentials and hydrogen generation rates across various environmental conditions. Second, determining precise "risk windows" where protection is achieved without significant hydrogen evolution. Third, evaluating coating technologies that can simultaneously permit cathodic protection while serving as hydrogen permeation barriers.

Additionally, this investigation aims to develop monitoring methodologies capable of detecting early-stage hydrogen ingress before structural integrity is compromised. This includes evaluating electrochemical hydrogen permeation techniques, acoustic emission monitoring, and in-situ hydrogen concentration measurements.

The ultimate goal is to establish comprehensive guidelines for cathodic protection implementation that minimize hydrogen embrittlement risk while maintaining effective corrosion protection. These guidelines would address potential control strategies, coating selection criteria, and environmental factors that influence the hydrogen embrittlement susceptibility of protected structures.

Understanding the fundamental mechanisms of hydrogen transport, trapping, and material degradation under cathodic protection conditions represents a critical knowledge gap that this research seeks to address, with significant implications for industries including offshore structures, pipelines, and critical infrastructure where both corrosion protection and structural integrity are paramount concerns.

The evolution of hydrogen embrittlement research has progressed through several distinct phases. Initially, observations were primarily phenomenological, focusing on macroscopic effects. The 1970s-1980s saw the development of fundamental theories regarding hydrogen-metal interactions. The 1990s-2000s brought significant advances in experimental techniques allowing for nanoscale observations. Most recently, computational modeling has enabled predictive capabilities previously unattainable.

In the context of cathodic protection systems, hydrogen embrittlement presents a particular paradox. While cathodic protection effectively mitigates corrosion by imposing a negative electrical potential on metal structures, this same process can inadvertently generate hydrogen at the metal surface through water reduction reactions, potentially leading to embrittlement.

The technical objectives of this research focus on several critical aspects. First, establishing quantitative relationships between cathodic protection potentials and hydrogen generation rates across various environmental conditions. Second, determining precise "risk windows" where protection is achieved without significant hydrogen evolution. Third, evaluating coating technologies that can simultaneously permit cathodic protection while serving as hydrogen permeation barriers.

Additionally, this investigation aims to develop monitoring methodologies capable of detecting early-stage hydrogen ingress before structural integrity is compromised. This includes evaluating electrochemical hydrogen permeation techniques, acoustic emission monitoring, and in-situ hydrogen concentration measurements.

The ultimate goal is to establish comprehensive guidelines for cathodic protection implementation that minimize hydrogen embrittlement risk while maintaining effective corrosion protection. These guidelines would address potential control strategies, coating selection criteria, and environmental factors that influence the hydrogen embrittlement susceptibility of protected structures.

Understanding the fundamental mechanisms of hydrogen transport, trapping, and material degradation under cathodic protection conditions represents a critical knowledge gap that this research seeks to address, with significant implications for industries including offshore structures, pipelines, and critical infrastructure where both corrosion protection and structural integrity are paramount concerns.

Market Analysis for Cathodic Protection Systems

The global cathodic protection systems market is experiencing robust growth, valued at approximately $6.9 billion in 2022 and projected to reach $10.2 billion by 2028, representing a compound annual growth rate (CAGR) of 6.7%. This growth is primarily driven by increasing investments in oil and gas infrastructure, expanding maritime industries, and the rising need to protect aging metal structures from corrosion.

The oil and gas sector remains the largest end-user segment, accounting for nearly 40% of the market share. This dominance stems from the extensive network of pipelines, offshore platforms, and storage facilities requiring protection against corrosive environments. The maritime industry follows closely, with ships, ports, and offshore structures constituting about 25% of the market demand.

Geographically, North America leads the market with approximately 32% share, followed by Asia-Pacific at 28% and Europe at 24%. The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth due to rapid industrialization and significant investments in energy infrastructure development.

The market is segmented by technology into impressed current cathodic protection (ICCP) and sacrificial anode cathodic protection (SACP) systems. ICCP systems currently dominate with 65% market share due to their effectiveness in protecting large structures and ability to provide adjustable protection levels. However, SACP systems are gaining traction in specific applications due to their simplicity and lower maintenance requirements.

A significant market trend is the growing concern about hydrogen embrittlement as a side effect of cathodic protection, particularly in high-strength steels used in critical infrastructure. This has created a specialized niche market for advanced monitoring systems and potential-controlling equipment, estimated at $450 million and growing at 8.3% annually.

The competitive landscape features established players like Aegion Corporation, Cathodic Protection Co., and MATCOR, who collectively hold about 35% market share. However, the market is witnessing increased competition from regional players and technology startups focusing on innovative solutions to address hydrogen embrittlement risks while maintaining effective corrosion protection.

Customer demand is increasingly shifting toward integrated solutions that combine cathodic protection with advanced monitoring systems, allowing for real-time adjustment of protection potentials to minimize hydrogen evolution while maintaining adequate corrosion protection. This segment is growing at nearly 10% annually, outpacing the overall market growth.

The oil and gas sector remains the largest end-user segment, accounting for nearly 40% of the market share. This dominance stems from the extensive network of pipelines, offshore platforms, and storage facilities requiring protection against corrosive environments. The maritime industry follows closely, with ships, ports, and offshore structures constituting about 25% of the market demand.

Geographically, North America leads the market with approximately 32% share, followed by Asia-Pacific at 28% and Europe at 24%. The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth due to rapid industrialization and significant investments in energy infrastructure development.

The market is segmented by technology into impressed current cathodic protection (ICCP) and sacrificial anode cathodic protection (SACP) systems. ICCP systems currently dominate with 65% market share due to their effectiveness in protecting large structures and ability to provide adjustable protection levels. However, SACP systems are gaining traction in specific applications due to their simplicity and lower maintenance requirements.

A significant market trend is the growing concern about hydrogen embrittlement as a side effect of cathodic protection, particularly in high-strength steels used in critical infrastructure. This has created a specialized niche market for advanced monitoring systems and potential-controlling equipment, estimated at $450 million and growing at 8.3% annually.

The competitive landscape features established players like Aegion Corporation, Cathodic Protection Co., and MATCOR, who collectively hold about 35% market share. However, the market is witnessing increased competition from regional players and technology startups focusing on innovative solutions to address hydrogen embrittlement risks while maintaining effective corrosion protection.

Customer demand is increasingly shifting toward integrated solutions that combine cathodic protection with advanced monitoring systems, allowing for real-time adjustment of protection potentials to minimize hydrogen evolution while maintaining adequate corrosion protection. This segment is growing at nearly 10% annually, outpacing the overall market growth.

Current Challenges in Hydrogen Embrittlement Control

Despite significant advancements in cathodic protection systems, hydrogen embrittlement remains a persistent challenge in corrosion prevention strategies. The fundamental paradox lies in the dual nature of cathodic protection: while it effectively mitigates corrosion, it simultaneously promotes hydrogen evolution at the metal surface, particularly when protection potentials are excessively negative.

One of the primary technical hurdles is achieving precise potential control across complex structures. Industrial systems often exhibit potential gradients due to geometric complexities, coating defects, and varying environmental conditions. These gradients create zones where hydrogen generation becomes problematic despite overall protection appearing adequate. Current monitoring technologies struggle to detect these localized risk areas with sufficient spatial resolution.

The development of hydrogen-resistant coatings presents another significant challenge. Conventional barrier coatings may reduce hydrogen permeation but often deteriorate under cathodic protection conditions. The industry lacks coatings specifically engineered to maintain integrity while simultaneously limiting hydrogen ingress under cathodic polarization. This technical gap is particularly evident in high-temperature and high-pressure service environments.

Quantitative risk assessment methodologies for hydrogen embrittlement remain underdeveloped. Engineers face difficulties in establishing reliable "safe windows" of cathodic protection potentials that effectively balance corrosion prevention against hydrogen damage risks. This challenge is compounded by material variability, with different steel grades and microstructures exhibiting vastly different susceptibilities to hydrogen damage.

Real-time monitoring of hydrogen activity represents a critical technological limitation. Current techniques cannot effectively measure hydrogen concentration at the metal-electrolyte interface during cathodic protection, forcing engineers to rely on indirect indicators or post-failure analysis. This reactive approach significantly hampers preventive strategies.

The synergistic effects between mechanical stress and hydrogen embrittlement under cathodic protection conditions are poorly understood. Structures under combined loading and cathodic polarization often exhibit accelerated degradation that exceeds theoretical predictions, suggesting complex interaction mechanisms that current models fail to capture adequately.

Finally, the industry faces challenges in translating laboratory findings to field applications. Controlled laboratory studies frequently fail to replicate the complex interplay of variables present in industrial environments, creating a significant gap between theoretical understanding and practical implementation of hydrogen embrittlement control strategies under cathodic protection.

One of the primary technical hurdles is achieving precise potential control across complex structures. Industrial systems often exhibit potential gradients due to geometric complexities, coating defects, and varying environmental conditions. These gradients create zones where hydrogen generation becomes problematic despite overall protection appearing adequate. Current monitoring technologies struggle to detect these localized risk areas with sufficient spatial resolution.

The development of hydrogen-resistant coatings presents another significant challenge. Conventional barrier coatings may reduce hydrogen permeation but often deteriorate under cathodic protection conditions. The industry lacks coatings specifically engineered to maintain integrity while simultaneously limiting hydrogen ingress under cathodic polarization. This technical gap is particularly evident in high-temperature and high-pressure service environments.

Quantitative risk assessment methodologies for hydrogen embrittlement remain underdeveloped. Engineers face difficulties in establishing reliable "safe windows" of cathodic protection potentials that effectively balance corrosion prevention against hydrogen damage risks. This challenge is compounded by material variability, with different steel grades and microstructures exhibiting vastly different susceptibilities to hydrogen damage.

Real-time monitoring of hydrogen activity represents a critical technological limitation. Current techniques cannot effectively measure hydrogen concentration at the metal-electrolyte interface during cathodic protection, forcing engineers to rely on indirect indicators or post-failure analysis. This reactive approach significantly hampers preventive strategies.

The synergistic effects between mechanical stress and hydrogen embrittlement under cathodic protection conditions are poorly understood. Structures under combined loading and cathodic polarization often exhibit accelerated degradation that exceeds theoretical predictions, suggesting complex interaction mechanisms that current models fail to capture adequately.

Finally, the industry faces challenges in translating laboratory findings to field applications. Controlled laboratory studies frequently fail to replicate the complex interplay of variables present in industrial environments, creating a significant gap between theoretical understanding and practical implementation of hydrogen embrittlement control strategies under cathodic protection.

Existing Solutions for Hydrogen Embrittlement Mitigation

01 Cathodic protection systems for controlling hydrogen embrittlement

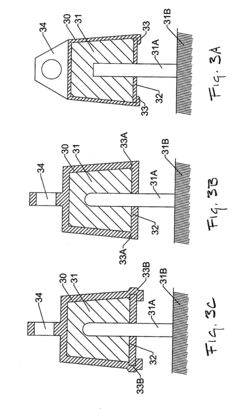

Cathodic protection systems can be designed with specific potential control mechanisms to minimize hydrogen embrittlement risks. These systems monitor and adjust the applied potential to maintain protection while keeping hydrogen generation below critical thresholds. Advanced control algorithms and feedback mechanisms ensure that the protective current remains within a safe operating window, preventing excessive hydrogen evolution at the metal surface while still providing adequate corrosion protection.- Cathodic protection systems for hydrogen embrittlement control: Cathodic protection systems can be designed to mitigate hydrogen embrittlement by controlling the potential within safe operating windows. These systems use specialized electrodes and monitoring equipment to maintain the protective potential at levels that prevent corrosion while minimizing hydrogen generation. By carefully controlling the applied potential, these systems can protect metal structures without causing hydrogen-induced damage to the protected material.

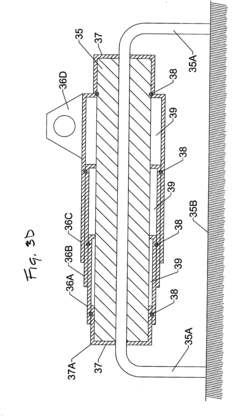

- Protective coatings to prevent hydrogen penetration: Specialized coatings can be applied to metal surfaces to create barriers against hydrogen penetration while maintaining cathodic protection effectiveness. These coatings typically contain compounds that either block hydrogen absorption or trap hydrogen atoms before they can diffuse into the metal substrate. Advanced coating technologies include multi-layer systems with specific functional layers designed to provide both corrosion protection and hydrogen embrittlement resistance.

- Monitoring and detection systems for hydrogen embrittlement risk: Monitoring systems can be employed to detect potential hydrogen embrittlement conditions in real-time. These systems use sensors to measure critical parameters such as potential levels, hydrogen concentration, and material response. Advanced monitoring technologies include electrochemical sensors, acoustic emission detection, and integrated data analysis systems that can identify when operating conditions approach critical risk windows for hydrogen embrittlement, allowing for preventive actions before damage occurs.

- Potential control strategies and risk window identification: Specific potential control strategies can be implemented to operate cathodic protection systems within safe windows that minimize hydrogen embrittlement risk. These strategies involve identifying the critical potential ranges where protection is achieved without excessive hydrogen generation. Methods include stepped potential control, intermittent protection cycles, and adaptive systems that adjust protection levels based on environmental conditions and material response, ensuring operation outside of high-risk potential windows.

- Material selection and treatment for hydrogen embrittlement resistance: Selecting appropriate materials and applying specific treatments can enhance resistance to hydrogen embrittlement under cathodic protection conditions. These approaches include using alloys with reduced susceptibility to hydrogen damage, applying thermal treatments to modify microstructure, and incorporating hydrogen trapping elements. Surface modification techniques can also be employed to create protective layers that maintain cathodic protection effectiveness while reducing hydrogen uptake into the base material.

02 Protective coatings to mitigate hydrogen permeation

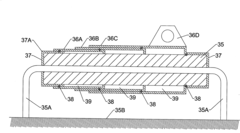

Specialized coatings can be applied to metal surfaces to create barriers against hydrogen permeation while maintaining cathodic protection effectiveness. These coatings include composite materials, metallic overlays, and polymer-based systems that reduce hydrogen absorption while allowing the cathodic protection current to function properly. The coatings can be engineered with specific permeability characteristics to control the rate of hydrogen diffusion into the substrate material.Expand Specific Solutions03 Monitoring and detection systems for hydrogen embrittlement risk

Advanced monitoring systems can be implemented to detect and assess hydrogen embrittlement risks in real-time during cathodic protection. These systems utilize electrochemical sensors, potential measurement devices, and data analysis algorithms to identify when operating conditions approach critical risk windows. Early warning capabilities allow for immediate adjustment of protection parameters to prevent hydrogen damage while maintaining effective corrosion protection.Expand Specific Solutions04 Identification of safe operating windows for cathodic protection

Research has established specific potential ranges and operating windows that minimize hydrogen embrittlement risk while maintaining effective cathodic protection. These safe operating windows consider factors such as material composition, environmental conditions, and stress states. By maintaining cathodic protection potentials within these defined ranges, operators can achieve corrosion protection while avoiding the critical thresholds that accelerate hydrogen generation and subsequent embrittlement.Expand Specific Solutions05 Material selection and treatment for hydrogen embrittlement resistance

Specific material selection and treatment methods can enhance resistance to hydrogen embrittlement under cathodic protection conditions. These include the use of low-susceptibility alloys, microstructural modifications, and surface treatments that reduce hydrogen trapping sites. Heat treatment processes and alloying elements can be optimized to create materials that maintain mechanical integrity even when exposed to hydrogen generated during cathodic protection.Expand Specific Solutions

Leading Companies in Corrosion Protection Industry

Hydrogen embrittlement under cathodic protection represents a critical challenge in the energy and industrial sectors, currently in a mature development phase with established research foundations. The global market for related technologies is expanding, driven by increasing infrastructure protection needs in oil and gas, marine, and automotive industries. Leading players demonstrate varying levels of technical sophistication: Industrie De Nora SpA and its subsidiary De Nora Permelec lead in electrochemical solutions and protective coatings; Saudi Aramco and CNPC focus on large-scale implementation; while research institutions like MIT, Tianjin University, and Fraunhofer-Gesellschaft advance fundamental understanding. Specialized service providers such as Farwest Corrosion Control and Corrosión y Protección Ingeniería offer targeted solutions, creating a diverse ecosystem of technology providers addressing this complex metallurgical phenomenon.

Industrie De Nora SpA

Technical Solution: De Nora has developed advanced mixed metal oxide (MMO) anode technology specifically designed to mitigate hydrogen embrittlement risks under cathodic protection systems. Their proprietary coating formulations incorporate platinum group metals (PGM) that optimize current distribution while minimizing hydrogen generation at the protected surface. The company's LIDA® anode systems feature specialized coating compositions that maintain protection potential within a narrow window (-850mV to -950mV vs Ag/AgCl) to prevent both corrosion and hydrogen evolution[1]. De Nora has also pioneered remote monitoring systems that continuously adjust protection current based on environmental conditions, ensuring potential remains in the safe zone between corrosion protection and hydrogen generation. Their integrated approach combines specialized anodes with intelligent control systems to maintain protection while minimizing embrittlement risks in critical infrastructure applications[3].

Strengths: Industry-leading expertise in electrochemical coatings with proven long-term performance in marine environments. Their systems offer precise potential control with minimal maintenance requirements. Weaknesses: Higher initial implementation costs compared to conventional cathodic protection systems, and requires specialized installation expertise for optimal performance.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed a comprehensive hydrogen embrittlement management system for their extensive offshore infrastructure under cathodic protection. Their approach integrates specialized coating systems with controlled-potential cathodic protection to create what they term "smart CP systems." These systems utilize reference electrodes strategically positioned throughout protected structures to continuously monitor protection potentials and automatically adjust current output to maintain potentials within a safe window (-800mV to -950mV vs Ag/AgCl)[2]. For critical high-strength steel components, Aramco employs proprietary multi-layer coating systems incorporating zinc-rich primers, epoxy intermediate layers, and polyurethane topcoats that work synergistically with cathodic protection while providing a barrier against hydrogen permeation. Their research has established specific "risk windows" for different steel grades, with tailored protection parameters for each application environment, from shallow water to deep subsea installations[5]. The company has also pioneered the use of hydrogen permeation monitoring sensors that provide real-time data on hydrogen uptake rates in protected structures.

Strengths: Extensive field validation across diverse environments with demonstrated long-term effectiveness in preventing both corrosion and hydrogen damage. Their integrated monitoring systems provide exceptional reliability for critical infrastructure. Weaknesses: Solutions are highly customized and may be difficult to implement in non-Aramco facilities without significant adaptation. The systems require sophisticated monitoring infrastructure and specialized maintenance protocols.

Key Innovations in Potential Control Mechanisms

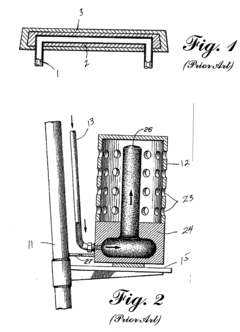

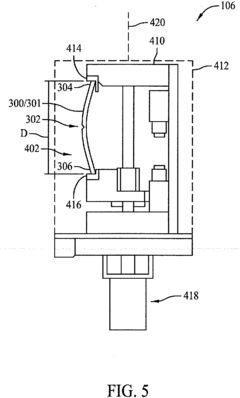

Cathodic protection method and apparatus

PatentInactiveUS20100270169A1

Innovation

- A cathodic protection system that uses readily available sacrificial anodes with a removable impermeable barrier, allowing in situ adjustment of exposed anode area to control cathodic potential and current density, facilitated by remotely operated vehicles (ROVs) for precise measurement and adjustment.

Method and systems for determining hydrogen embrittlement.

PatentActiveEP2772756A3

Innovation

- A testing system and method that positions a plated sample between two holding members, applying a static load by bending it to a predetermined percentage of its baseline ultimate failure distance, allowing for real-time determination of hydrogen embrittlement within 8 hours.

Risk Assessment Frameworks for Critical Infrastructure

Risk assessment frameworks for critical infrastructure protection against hydrogen embrittlement under cathodic protection conditions have evolved significantly in recent years. These frameworks integrate multiple methodologies to evaluate and mitigate risks associated with structural integrity compromises in critical assets such as pipelines, offshore platforms, and bridge supports.

The most comprehensive frameworks incorporate probabilistic risk assessment (PRA) models that quantify the likelihood of hydrogen-induced failures based on operational parameters, material properties, and environmental conditions. These models typically establish risk matrices that correlate cathodic protection potential levels with hydrogen generation rates and subsequent embrittlement susceptibility for various material types.

Industry standards such as NACE SP0169 and ISO 15589 provide baseline criteria for risk assessment, but advanced frameworks now extend beyond these by incorporating real-time monitoring data and predictive analytics. This evolution enables more dynamic risk profiling that accounts for temporal variations in protection potentials and environmental factors affecting hydrogen uptake.

Critical infrastructure operators increasingly implement multi-tiered assessment approaches that categorize assets based on consequence of failure, with heightened scrutiny applied to high-consequence areas. These frameworks typically define "risk windows" - operational boundaries within which hydrogen embrittlement risks remain acceptable while maintaining adequate cathodic protection against corrosion.

Material-specific vulnerability indices form another key component of modern frameworks, recognizing that susceptibility to hydrogen embrittlement varies significantly across different steel grades and microstructures. These indices help prioritize inspection and maintenance resources toward the most vulnerable components within complex infrastructure systems.

Coating performance evaluation has been integrated into these frameworks, acknowledging the critical role that coating integrity plays in both cathodic protection efficiency and hydrogen permeation barriers. Advanced frameworks now incorporate coating degradation models to predict evolving risk profiles throughout asset lifecycles.

Emerging risk assessment methodologies are increasingly incorporating machine learning algorithms that analyze historical failure data alongside operational parameters to identify previously unrecognized risk factors and interaction effects between variables such as protection potential, temperature fluctuations, and mechanical stress states.

The most comprehensive frameworks incorporate probabilistic risk assessment (PRA) models that quantify the likelihood of hydrogen-induced failures based on operational parameters, material properties, and environmental conditions. These models typically establish risk matrices that correlate cathodic protection potential levels with hydrogen generation rates and subsequent embrittlement susceptibility for various material types.

Industry standards such as NACE SP0169 and ISO 15589 provide baseline criteria for risk assessment, but advanced frameworks now extend beyond these by incorporating real-time monitoring data and predictive analytics. This evolution enables more dynamic risk profiling that accounts for temporal variations in protection potentials and environmental factors affecting hydrogen uptake.

Critical infrastructure operators increasingly implement multi-tiered assessment approaches that categorize assets based on consequence of failure, with heightened scrutiny applied to high-consequence areas. These frameworks typically define "risk windows" - operational boundaries within which hydrogen embrittlement risks remain acceptable while maintaining adequate cathodic protection against corrosion.

Material-specific vulnerability indices form another key component of modern frameworks, recognizing that susceptibility to hydrogen embrittlement varies significantly across different steel grades and microstructures. These indices help prioritize inspection and maintenance resources toward the most vulnerable components within complex infrastructure systems.

Coating performance evaluation has been integrated into these frameworks, acknowledging the critical role that coating integrity plays in both cathodic protection efficiency and hydrogen permeation barriers. Advanced frameworks now incorporate coating degradation models to predict evolving risk profiles throughout asset lifecycles.

Emerging risk assessment methodologies are increasingly incorporating machine learning algorithms that analyze historical failure data alongside operational parameters to identify previously unrecognized risk factors and interaction effects between variables such as protection potential, temperature fluctuations, and mechanical stress states.

Environmental Impact of Cathodic Protection Systems

Cathodic protection systems, while effective in preventing corrosion of metallic structures, have significant environmental implications that warrant careful consideration. The electrochemical processes involved in these systems can lead to various environmental impacts, including changes in water chemistry, effects on marine ecosystems, and potential contamination from sacrificial anodes.

The primary environmental concern with cathodic protection systems is the release of metal ions from sacrificial anodes into the surrounding environment. Zinc, aluminum, and magnesium anodes commonly used in marine applications gradually dissolve, introducing these metals into aquatic ecosystems. Research indicates that in areas with high densities of cathodically protected structures, such as harbors and offshore installations, elevated levels of these metals can be detected in sediments and water columns.

Hydrogen evolution, a byproduct of cathodic protection particularly relevant to hydrogen embrittlement concerns, also presents environmental challenges. The generation of hydrogen gas at protected surfaces can alter local pH levels and create microenvironments that affect benthic organisms. Studies have documented changes in microbial communities in sediments surrounding cathodically protected structures, with potential implications for broader ecosystem functioning.

The electrical fields generated by impressed current cathodic protection (ICCP) systems represent another environmental consideration. These fields can influence the behavior of certain marine species, particularly those that use electromagnetic sensing for navigation or prey detection. Research on elasmobranchs (sharks and rays) suggests that these species may detect and respond to the electrical fields associated with cathodic protection systems, potentially altering their natural behavior patterns.

Energy consumption constitutes a significant environmental footprint of ICCP systems. These systems require continuous electrical input, contributing to carbon emissions when powered by non-renewable energy sources. Recent innovations have explored integration with renewable energy sources, such as solar panels or wind turbines, to mitigate this impact, particularly for remote installations where grid connections are impractical.

Regulatory frameworks addressing the environmental impacts of cathodic protection vary globally, with more stringent requirements emerging in environmentally sensitive areas. Environmental impact assessments increasingly include evaluation of cathodic protection systems, particularly for large marine installations. Industry standards are evolving to incorporate environmentally optimized designs that maintain corrosion protection efficacy while minimizing ecological footprints.

The development of environmentally friendly anode materials represents a promising direction for reducing the environmental impact of cathodic protection systems. Research into biodegradable sacrificial anodes and less toxic metal alloys aims to maintain protection performance while reducing harmful environmental releases. Additionally, advanced monitoring systems enable more precise control of protection potentials, minimizing overprotection scenarios that exacerbate hydrogen evolution and unnecessary anode consumption.

The primary environmental concern with cathodic protection systems is the release of metal ions from sacrificial anodes into the surrounding environment. Zinc, aluminum, and magnesium anodes commonly used in marine applications gradually dissolve, introducing these metals into aquatic ecosystems. Research indicates that in areas with high densities of cathodically protected structures, such as harbors and offshore installations, elevated levels of these metals can be detected in sediments and water columns.

Hydrogen evolution, a byproduct of cathodic protection particularly relevant to hydrogen embrittlement concerns, also presents environmental challenges. The generation of hydrogen gas at protected surfaces can alter local pH levels and create microenvironments that affect benthic organisms. Studies have documented changes in microbial communities in sediments surrounding cathodically protected structures, with potential implications for broader ecosystem functioning.

The electrical fields generated by impressed current cathodic protection (ICCP) systems represent another environmental consideration. These fields can influence the behavior of certain marine species, particularly those that use electromagnetic sensing for navigation or prey detection. Research on elasmobranchs (sharks and rays) suggests that these species may detect and respond to the electrical fields associated with cathodic protection systems, potentially altering their natural behavior patterns.

Energy consumption constitutes a significant environmental footprint of ICCP systems. These systems require continuous electrical input, contributing to carbon emissions when powered by non-renewable energy sources. Recent innovations have explored integration with renewable energy sources, such as solar panels or wind turbines, to mitigate this impact, particularly for remote installations where grid connections are impractical.

Regulatory frameworks addressing the environmental impacts of cathodic protection vary globally, with more stringent requirements emerging in environmentally sensitive areas. Environmental impact assessments increasingly include evaluation of cathodic protection systems, particularly for large marine installations. Industry standards are evolving to incorporate environmentally optimized designs that maintain corrosion protection efficacy while minimizing ecological footprints.

The development of environmentally friendly anode materials represents a promising direction for reducing the environmental impact of cathodic protection systems. Research into biodegradable sacrificial anodes and less toxic metal alloys aims to maintain protection performance while reducing harmful environmental releases. Additionally, advanced monitoring systems enable more precise control of protection potentials, minimizing overprotection scenarios that exacerbate hydrogen evolution and unnecessary anode consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!