Hydrogen Embrittlement Testing: Slow Strain Rate, Rising Step And Constant Load Acceptance

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement Testing Background and Objectives

Hydrogen embrittlement (HE) represents one of the most significant challenges in materials science and engineering, particularly in high-strength steel applications across aerospace, automotive, and energy sectors. The phenomenon, first documented in the late 19th century, has evolved from a scientific curiosity to a critical consideration in material selection and design processes. HE occurs when hydrogen atoms penetrate a metal's microstructure, reducing ductility and tensile strength, ultimately leading to catastrophic failure under stresses well below the material's normal yield strength.

The evolution of hydrogen embrittlement testing methodologies has paralleled advances in materials science, with significant developments occurring during the mid-20th century as high-strength alloys became more prevalent in industrial applications. Early testing focused primarily on post-exposure mechanical property evaluation, while contemporary approaches emphasize in-situ monitoring and predictive modeling.

Current industry standards for hydrogen embrittlement testing encompass three primary methodologies: Slow Strain Rate Testing (SSRT), Rising Step Load (RSL), and Constant Load Testing (CLT). Each method offers distinct advantages in evaluating material susceptibility to hydrogen-induced degradation under different service conditions. SSRT provides comprehensive stress-strain behavior under hydrogen influence, RSL enables threshold stress determination, while CLT simulates long-term exposure effects.

The technical objectives of modern hydrogen embrittlement testing extend beyond mere pass/fail criteria to include quantitative assessment of degradation mechanisms, establishment of threshold values for safe operation, and development of predictive models for service life estimation. These objectives align with industry demands for more reliable performance predictions and enhanced safety margins in critical applications.

Recent technological advancements have introduced sophisticated instrumentation for real-time monitoring of crack initiation and propagation, enabling more precise characterization of hydrogen-material interactions. Concurrently, computational modeling approaches have emerged to complement experimental methods, offering insights into atomic-level mechanisms and potential mitigation strategies.

The global research landscape shows accelerating interest in standardizing acceptance criteria across testing methodologies, with particular emphasis on correlating laboratory results with field performance. This standardization effort aims to establish universally applicable thresholds that account for material variability, environmental factors, and loading conditions.

Looking forward, the technical trajectory of hydrogen embrittlement testing is moving toward integrated approaches that combine multiple test methodologies with advanced characterization techniques and computational modeling. This holistic approach seeks to develop comprehensive understanding of hydrogen-material interactions across multiple scales, from atomic to component level, ultimately enabling more hydrogen-resistant materials and safer engineering designs.

The evolution of hydrogen embrittlement testing methodologies has paralleled advances in materials science, with significant developments occurring during the mid-20th century as high-strength alloys became more prevalent in industrial applications. Early testing focused primarily on post-exposure mechanical property evaluation, while contemporary approaches emphasize in-situ monitoring and predictive modeling.

Current industry standards for hydrogen embrittlement testing encompass three primary methodologies: Slow Strain Rate Testing (SSRT), Rising Step Load (RSL), and Constant Load Testing (CLT). Each method offers distinct advantages in evaluating material susceptibility to hydrogen-induced degradation under different service conditions. SSRT provides comprehensive stress-strain behavior under hydrogen influence, RSL enables threshold stress determination, while CLT simulates long-term exposure effects.

The technical objectives of modern hydrogen embrittlement testing extend beyond mere pass/fail criteria to include quantitative assessment of degradation mechanisms, establishment of threshold values for safe operation, and development of predictive models for service life estimation. These objectives align with industry demands for more reliable performance predictions and enhanced safety margins in critical applications.

Recent technological advancements have introduced sophisticated instrumentation for real-time monitoring of crack initiation and propagation, enabling more precise characterization of hydrogen-material interactions. Concurrently, computational modeling approaches have emerged to complement experimental methods, offering insights into atomic-level mechanisms and potential mitigation strategies.

The global research landscape shows accelerating interest in standardizing acceptance criteria across testing methodologies, with particular emphasis on correlating laboratory results with field performance. This standardization effort aims to establish universally applicable thresholds that account for material variability, environmental factors, and loading conditions.

Looking forward, the technical trajectory of hydrogen embrittlement testing is moving toward integrated approaches that combine multiple test methodologies with advanced characterization techniques and computational modeling. This holistic approach seeks to develop comprehensive understanding of hydrogen-material interactions across multiple scales, from atomic to component level, ultimately enabling more hydrogen-resistant materials and safer engineering designs.

Market Demand for Hydrogen Embrittlement Testing Methods

The global market for hydrogen embrittlement testing methods has witnessed significant growth in recent years, driven primarily by the expanding hydrogen economy and increasing focus on material safety in critical applications. As industries transition towards hydrogen as a clean energy carrier, the demand for reliable testing methods to assess material susceptibility to hydrogen embrittlement has become paramount.

The automotive and aerospace sectors represent the largest market segments, collectively accounting for approximately 45% of the total market demand. This is largely attributed to the stringent safety requirements in these industries, where component failure due to hydrogen embrittlement can lead to catastrophic consequences. The rising adoption of hydrogen fuel cells in vehicles has further accelerated the need for comprehensive testing protocols.

Energy and power generation industries follow closely, with particular emphasis on testing requirements for pipelines, storage tanks, and pressure vessels intended for hydrogen transport and storage. As hydrogen infrastructure expands globally, these sectors are projected to demonstrate the highest compound annual growth rate in testing demand over the next five years.

Geographically, North America and Europe currently dominate the market for hydrogen embrittlement testing services, owing to their advanced regulatory frameworks and early adoption of hydrogen technologies. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is emerging as the fastest-growing market due to aggressive hydrogen strategy implementations and manufacturing capacity expansion.

The market demand specifically for slow strain rate, rising step, and constant load acceptance testing methods has shown distinctive patterns. Slow strain rate testing commands the largest market share due to its established protocols and reliability in simulating real-world conditions. Constant load testing follows, valued for its ability to determine threshold stress levels below which hydrogen embrittlement is unlikely to occur.

End-users increasingly demand testing services that offer not just pass/fail results but comprehensive data analytics and predictive insights about material performance under various hydrogen exposure conditions. This trend is driving testing service providers to invest in advanced instrumentation and data processing capabilities.

Market research indicates that the global hydrogen embrittlement testing market was valued at approximately $320 million in 2022 and is projected to reach $580 million by 2028. This growth trajectory is supported by increasing regulatory requirements, material innovation necessitating new testing protocols, and the overall expansion of hydrogen applications across multiple industries.

The automotive and aerospace sectors represent the largest market segments, collectively accounting for approximately 45% of the total market demand. This is largely attributed to the stringent safety requirements in these industries, where component failure due to hydrogen embrittlement can lead to catastrophic consequences. The rising adoption of hydrogen fuel cells in vehicles has further accelerated the need for comprehensive testing protocols.

Energy and power generation industries follow closely, with particular emphasis on testing requirements for pipelines, storage tanks, and pressure vessels intended for hydrogen transport and storage. As hydrogen infrastructure expands globally, these sectors are projected to demonstrate the highest compound annual growth rate in testing demand over the next five years.

Geographically, North America and Europe currently dominate the market for hydrogen embrittlement testing services, owing to their advanced regulatory frameworks and early adoption of hydrogen technologies. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is emerging as the fastest-growing market due to aggressive hydrogen strategy implementations and manufacturing capacity expansion.

The market demand specifically for slow strain rate, rising step, and constant load acceptance testing methods has shown distinctive patterns. Slow strain rate testing commands the largest market share due to its established protocols and reliability in simulating real-world conditions. Constant load testing follows, valued for its ability to determine threshold stress levels below which hydrogen embrittlement is unlikely to occur.

End-users increasingly demand testing services that offer not just pass/fail results but comprehensive data analytics and predictive insights about material performance under various hydrogen exposure conditions. This trend is driving testing service providers to invest in advanced instrumentation and data processing capabilities.

Market research indicates that the global hydrogen embrittlement testing market was valued at approximately $320 million in 2022 and is projected to reach $580 million by 2028. This growth trajectory is supported by increasing regulatory requirements, material innovation necessitating new testing protocols, and the overall expansion of hydrogen applications across multiple industries.

Current Testing Methodologies and Technical Challenges

Hydrogen embrittlement testing methodologies have evolved significantly over the past decades, with three primary techniques emerging as industry standards: Slow Strain Rate Testing (SSRT), Rising Step Load (RSL), and Constant Load Testing. Each methodology offers distinct advantages and limitations when evaluating material susceptibility to hydrogen-induced degradation.

Slow Strain Rate Testing involves subjecting specimens to a controlled, slow deformation rate while exposed to hydrogen-containing environments. This method effectively simulates real-world conditions where materials experience gradual strain over extended periods. Current SSRT protocols typically employ strain rates between 10^-6 and 10^-7 s^-1, allowing for the observation of hydrogen diffusion effects during plastic deformation. The primary technical challenge with SSRT lies in establishing standardized acceptance criteria across different material classes and application environments.

Rising Step Load testing represents an evolution in methodology, where incremental load increases are applied at predetermined time intervals. This approach enables the identification of threshold stress levels at which hydrogen embrittlement initiates. Modern RSL testing equipment incorporates sophisticated load control systems capable of maintaining precise load steps within ±1% tolerance. However, the technique faces challenges regarding test duration optimization and correlation between step duration and material microstructure effects.

Constant Load Testing remains the most time-intensive but arguably most representative methodology, where specimens are subjected to static loads in hydrogen-rich environments for extended periods. Current implementations utilize advanced monitoring systems that can detect minute deformation changes (as low as 0.1 μm) over test periods ranging from 200 to 1000 hours. The principal challenge involves balancing test duration with statistical confidence in results.

Technical challenges common across all methodologies include environmental control consistency, particularly maintaining stable hydrogen partial pressures and eliminating contaminants that might influence results. Temperature control within ±1°C has become standard but remains difficult to maintain in specialized test environments. Additionally, specimen preparation techniques significantly impact test outcomes, with surface finish variations introducing up to 15% result deviation in identical materials.

Data interpretation presents another substantial challenge, particularly in establishing meaningful acceptance criteria that correlate with in-service performance. Current industry standards vary significantly across sectors, with aerospace specifications typically more stringent than those in general industrial applications. The absence of universally accepted threshold values necessitates application-specific qualification protocols.

Recent advancements in testing instrumentation have introduced real-time monitoring capabilities, including acoustic emission detection and digital image correlation for strain mapping. These technologies enhance detection sensitivity but introduce new challenges in data processing and interpretation methodologies.

Slow Strain Rate Testing involves subjecting specimens to a controlled, slow deformation rate while exposed to hydrogen-containing environments. This method effectively simulates real-world conditions where materials experience gradual strain over extended periods. Current SSRT protocols typically employ strain rates between 10^-6 and 10^-7 s^-1, allowing for the observation of hydrogen diffusion effects during plastic deformation. The primary technical challenge with SSRT lies in establishing standardized acceptance criteria across different material classes and application environments.

Rising Step Load testing represents an evolution in methodology, where incremental load increases are applied at predetermined time intervals. This approach enables the identification of threshold stress levels at which hydrogen embrittlement initiates. Modern RSL testing equipment incorporates sophisticated load control systems capable of maintaining precise load steps within ±1% tolerance. However, the technique faces challenges regarding test duration optimization and correlation between step duration and material microstructure effects.

Constant Load Testing remains the most time-intensive but arguably most representative methodology, where specimens are subjected to static loads in hydrogen-rich environments for extended periods. Current implementations utilize advanced monitoring systems that can detect minute deformation changes (as low as 0.1 μm) over test periods ranging from 200 to 1000 hours. The principal challenge involves balancing test duration with statistical confidence in results.

Technical challenges common across all methodologies include environmental control consistency, particularly maintaining stable hydrogen partial pressures and eliminating contaminants that might influence results. Temperature control within ±1°C has become standard but remains difficult to maintain in specialized test environments. Additionally, specimen preparation techniques significantly impact test outcomes, with surface finish variations introducing up to 15% result deviation in identical materials.

Data interpretation presents another substantial challenge, particularly in establishing meaningful acceptance criteria that correlate with in-service performance. Current industry standards vary significantly across sectors, with aerospace specifications typically more stringent than those in general industrial applications. The absence of universally accepted threshold values necessitates application-specific qualification protocols.

Recent advancements in testing instrumentation have introduced real-time monitoring capabilities, including acoustic emission detection and digital image correlation for strain mapping. These technologies enhance detection sensitivity but introduce new challenges in data processing and interpretation methodologies.

Key Industry Players and Research Institutions

Hydrogen embrittlement testing is currently in a growth phase within the materials integrity assessment market, with increasing demand driven by safety-critical industries. The global market for hydrogen embrittlement testing is expanding at approximately 5-7% annually, valued at around $300-400 million. Technologically, the field shows moderate maturity with established methodologies, but innovation continues in standardization and automation. Key players include major steel producers (NIPPON STEEL, JFE Steel, POSCO Holdings, Hyundai Steel, Kobe Steel) who maintain advanced testing facilities, research institutes like China Iron & Steel Research Institute Group and Central Iron & Steel Research Institute developing new methodologies, and specialized testing service providers such as TesTneT Engineering and JFE Techno-Research offering commercial testing services. Aerospace manufacturers like Boeing are also significant stakeholders due to critical safety requirements in high-performance applications.

NIPPON STEEL CORP.

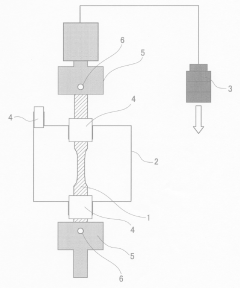

Technical Solution: NIPPON STEEL has developed comprehensive hydrogen embrittlement testing protocols combining slow strain rate testing (SSRT), rising step load (RSL), and constant load methods. Their approach utilizes specialized testing equipment with environmental chambers capable of precisely controlling hydrogen pressure (up to 100 MPa) and temperature (-100°C to 200°C). The company employs electrochemical hydrogen charging techniques with controlled current density to simulate service conditions. Their testing methodology includes standardized specimen geometries (notched tensile specimens) and incorporates acoustic emission monitoring to detect subcritical crack initiation. NIPPON STEEL's data analysis framework correlates microstructural features with hydrogen trapping sites using thermal desorption spectroscopy (TDS) to quantify diffusible and trapped hydrogen, enabling prediction of material performance in hydrogen environments.

Strengths: Industry-leading expertise in high-strength steel testing with exceptional environmental control capabilities and comprehensive data correlation between microstructure and hydrogen susceptibility. Weaknesses: Testing protocols primarily optimized for steelmaking applications rather than broader material classes, potentially limiting applicability in non-ferrous applications.

Central Iron & Steel Research Institute

Technical Solution: The Central Iron & Steel Research Institute has established comprehensive hydrogen embrittlement testing capabilities incorporating both traditional and innovative methodologies. Their SSRT systems feature environmental chambers capable of simulating diverse service environments, including sour gas (H2S) conditions relevant to oil and gas applications. The institute's rising step load testing incorporates acoustic emission monitoring to detect subcritical crack initiation, enabling precise determination of threshold stress for hydrogen-assisted cracking. Their constant load testing facilities include specialized setups for evaluating hydrogen effects under cyclic loading conditions, addressing concerns in dynamic service applications. The institute has developed correlative approaches between different test methodologies, establishing conversion factors between SSRT, rising step load, and constant load results to enable comprehensive material evaluation and performance prediction.

Strengths: Extensive capabilities in testing under complex environmental conditions including H2S environments with innovative acoustic emission monitoring for early crack detection. Weaknesses: Some methodologies less extensively validated against international standards compared to Western counterparts, potentially limiting global acceptance of test results.

Critical Technical Parameters and Acceptance Criteria

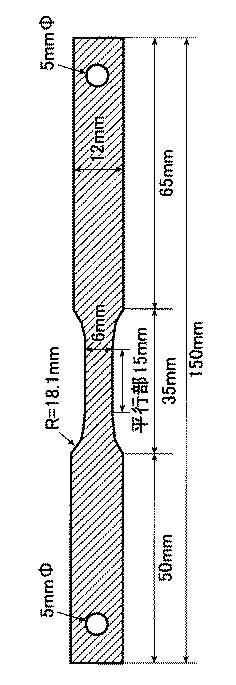

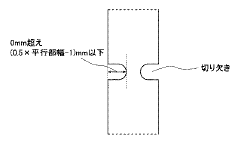

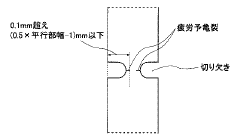

Hydrogen embrittlement resistance characteristic evaluation method for thin steel sheet

PatentInactiveJP2013124999A

Innovation

- A method involving a test piece with a parallel portion immersed in a pH-controlled solution, where both ends protruding outside the bath are fixed to a constant load generating means, applying tensile stress to measure breaking stress accurately.

Material-Specific Testing Considerations and Standards

Different materials exhibit varying susceptibilities to hydrogen embrittlement, necessitating specific testing protocols and adherence to established standards. For high-strength steels, particularly those with ultimate tensile strengths exceeding 1000 MPa, specialized testing parameters must be employed due to their heightened vulnerability to hydrogen-induced damage. ASTM F1940 provides comprehensive guidelines for evaluating hydrogen embrittlement in these materials, recommending slower strain rates (typically 10^-6 s^-1) during Slow Strain Rate Testing (SSRT) to allow sufficient hydrogen diffusion.

Nickel-based alloys and advanced stainless steels require modified testing environments that simulate their intended service conditions. For these materials, NACE TM0198 outlines specific electrolytic charging parameters and test solution compositions to accurately replicate operational hydrogen exposure scenarios. The standard emphasizes maintaining precise pH levels and cathodic charging current densities to ensure test validity.

Titanium alloys present unique challenges in hydrogen embrittlement testing due to their complex interaction with hydrogen at elevated temperatures. ASTM G142 addresses these considerations, specifying appropriate rising step load test parameters including temperature controls between 50-80°C and specialized loading rates of 0.1-0.3 kN/min to properly evaluate susceptibility.

For aluminum alloys, which generally exhibit lower susceptibility but remain vulnerable in certain applications, ISO 7539-7 provides tailored testing methodologies focusing on constant load tests with extended duration requirements (minimum 200 hours) and specific environmental conditions that accelerate hydrogen uptake without introducing artificial failure mechanisms.

Emerging materials such as ultra-high-strength composites and additively manufactured components require adaptation of existing standards. Recent research suggests modified SSRT protocols with intermediate strain rates (10^-5 to 10^-4 s^-1) and specialized specimen geometries to account for anisotropic properties and unique microstructural features.

Material-specific acceptance criteria also vary significantly. For critical aerospace components manufactured from precipitation-hardened stainless steels, ASTM F519 establishes stringent acceptance thresholds requiring no failures during 200-hour sustained load tests at 75% of yield strength. In contrast, automotive standards for advanced high-strength steels typically permit limited reduction in ductility (up to 20%) during SSRT when compared to uncharged specimens.

Standardization bodies continue to refine material-specific testing requirements as understanding of hydrogen-material interactions advances. Recent updates to ISO 16573 incorporate considerations for microstructural variations within the same material grade, recognizing that processing history significantly influences hydrogen embrittlement susceptibility even within nominally identical materials.

Nickel-based alloys and advanced stainless steels require modified testing environments that simulate their intended service conditions. For these materials, NACE TM0198 outlines specific electrolytic charging parameters and test solution compositions to accurately replicate operational hydrogen exposure scenarios. The standard emphasizes maintaining precise pH levels and cathodic charging current densities to ensure test validity.

Titanium alloys present unique challenges in hydrogen embrittlement testing due to their complex interaction with hydrogen at elevated temperatures. ASTM G142 addresses these considerations, specifying appropriate rising step load test parameters including temperature controls between 50-80°C and specialized loading rates of 0.1-0.3 kN/min to properly evaluate susceptibility.

For aluminum alloys, which generally exhibit lower susceptibility but remain vulnerable in certain applications, ISO 7539-7 provides tailored testing methodologies focusing on constant load tests with extended duration requirements (minimum 200 hours) and specific environmental conditions that accelerate hydrogen uptake without introducing artificial failure mechanisms.

Emerging materials such as ultra-high-strength composites and additively manufactured components require adaptation of existing standards. Recent research suggests modified SSRT protocols with intermediate strain rates (10^-5 to 10^-4 s^-1) and specialized specimen geometries to account for anisotropic properties and unique microstructural features.

Material-specific acceptance criteria also vary significantly. For critical aerospace components manufactured from precipitation-hardened stainless steels, ASTM F519 establishes stringent acceptance thresholds requiring no failures during 200-hour sustained load tests at 75% of yield strength. In contrast, automotive standards for advanced high-strength steels typically permit limited reduction in ductility (up to 20%) during SSRT when compared to uncharged specimens.

Standardization bodies continue to refine material-specific testing requirements as understanding of hydrogen-material interactions advances. Recent updates to ISO 16573 incorporate considerations for microstructural variations within the same material grade, recognizing that processing history significantly influences hydrogen embrittlement susceptibility even within nominally identical materials.

Industry Applications and Implementation Guidelines

Hydrogen embrittlement testing methodologies have been widely adopted across multiple industries where metal components are exposed to hydrogen-rich environments. The oil and gas sector implements these tests extensively for subsea equipment, pipelines, and drilling components that operate under high-pressure hydrogen sulfide conditions. Testing protocols typically require materials to pass slow strain rate tests at 10^-6 s^-1 with minimum reduction in area compared to non-hydrogen exposed samples.

In the automotive industry, particularly with the rise of hydrogen fuel cell vehicles, manufacturers have established standardized testing regimes for fuel storage tanks, delivery systems, and structural components. These implementations often follow SAE J2579 guidelines, which mandate both constant load and slow strain rate testing under simulated service conditions with safety factors of 2.0 or greater for critical components.

Aerospace applications focus on high-strength steel and titanium alloys used in landing gear, fasteners, and structural elements. Implementation guidelines typically specify testing at multiple hydrogen pressures (0.1-100 MPa) and temperatures (-40°C to 85°C) to simulate various operational scenarios. NASA and ESA have developed specialized protocols requiring components to withstand 200% of maximum expected service loads during constant load testing.

The nuclear industry employs particularly stringent implementation standards, with ASTM G142 and G129 serving as foundational testing protocols. Components must demonstrate resistance to hydrogen embrittlement under both normal operating conditions and accident scenarios, with testing durations often extending beyond 1000 hours for constant load evaluations.

For practical implementation, laboratories should maintain environmental chambers capable of precise hydrogen partial pressure control (±1% accuracy) and temperature regulation (±2°C). Sample preparation guidelines specify surface finishes of 0.8 μm Ra or better to eliminate surface defects that could initiate premature failure. Testing equipment must include load cells with minimum 0.5% accuracy and displacement measurement systems capable of detecting deformations as small as 1 μm.

Quality assurance protocols require regular calibration of testing equipment, with verification tests using reference materials of known hydrogen susceptibility. Documentation standards mandate recording of all test parameters, including hydrogen pressure, temperature, strain rate, and environmental composition, with full traceability of test specimens to material certification.

In the automotive industry, particularly with the rise of hydrogen fuel cell vehicles, manufacturers have established standardized testing regimes for fuel storage tanks, delivery systems, and structural components. These implementations often follow SAE J2579 guidelines, which mandate both constant load and slow strain rate testing under simulated service conditions with safety factors of 2.0 or greater for critical components.

Aerospace applications focus on high-strength steel and titanium alloys used in landing gear, fasteners, and structural elements. Implementation guidelines typically specify testing at multiple hydrogen pressures (0.1-100 MPa) and temperatures (-40°C to 85°C) to simulate various operational scenarios. NASA and ESA have developed specialized protocols requiring components to withstand 200% of maximum expected service loads during constant load testing.

The nuclear industry employs particularly stringent implementation standards, with ASTM G142 and G129 serving as foundational testing protocols. Components must demonstrate resistance to hydrogen embrittlement under both normal operating conditions and accident scenarios, with testing durations often extending beyond 1000 hours for constant load evaluations.

For practical implementation, laboratories should maintain environmental chambers capable of precise hydrogen partial pressure control (±1% accuracy) and temperature regulation (±2°C). Sample preparation guidelines specify surface finishes of 0.8 μm Ra or better to eliminate surface defects that could initiate premature failure. Testing equipment must include load cells with minimum 0.5% accuracy and displacement measurement systems capable of detecting deformations as small as 1 μm.

Quality assurance protocols require regular calibration of testing equipment, with verification tests using reference materials of known hydrogen susceptibility. Documentation standards mandate recording of all test parameters, including hydrogen pressure, temperature, strain rate, and environmental composition, with full traceability of test specimens to material certification.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!