How Hydrogen Embrittlement Risk Is Quantified For Cylinders, Valves And Piping?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement Fundamentals and Assessment Objectives

Hydrogen embrittlement (HE) represents a critical degradation mechanism that affects metallic components exposed to hydrogen environments. This phenomenon occurs when hydrogen atoms penetrate into the metal lattice, reducing ductility and tensile strength, which can lead to catastrophic failures even under normal operating conditions. The evolution of hydrogen energy systems has accelerated the need for comprehensive understanding of this phenomenon, particularly in pressure vessels, valves, and piping systems that form the backbone of hydrogen infrastructure.

The historical progression of hydrogen embrittlement research dates back to the early 20th century, with significant advancements occurring during the aerospace and nuclear industry developments in the 1950s and 1960s. Recent technological shifts toward hydrogen as a clean energy carrier have intensified research efforts, creating a convergence of materials science, mechanical engineering, and electrochemistry to address this multifaceted challenge.

Current technological trends focus on developing quantitative assessment methodologies that can accurately predict the susceptibility of materials to hydrogen embrittlement under various operating conditions. These methodologies incorporate advanced computational models, experimental validation techniques, and in-situ monitoring systems to provide real-time risk assessment capabilities.

The primary objective of hydrogen embrittlement quantification is to establish reliable predictive models that can determine the threshold conditions for crack initiation and propagation in hydrogen-containing environments. This involves characterizing the interaction between hydrogen and material microstructure, understanding the influence of mechanical loading conditions, and evaluating environmental factors that accelerate embrittlement processes.

Secondary objectives include developing standardized testing protocols that can be universally applied across different industries, creating material selection guidelines for hydrogen service, and establishing inspection intervals based on quantitative risk assessment rather than arbitrary time-based schedules.

The technical goals extend to establishing correlations between laboratory test results and actual field performance, which remains one of the most challenging aspects of hydrogen embrittlement research. This includes developing accelerated testing methodologies that can simulate long-term exposure effects within reasonable timeframes, enabling more efficient material qualification processes for hydrogen applications.

Emerging research directions are exploring the potential of novel materials and surface treatments that can inherently resist hydrogen penetration, thereby providing intrinsic protection against embrittlement. These innovations aim to shift the paradigm from managing hydrogen embrittlement to preventing it altogether through materials engineering approaches.

The historical progression of hydrogen embrittlement research dates back to the early 20th century, with significant advancements occurring during the aerospace and nuclear industry developments in the 1950s and 1960s. Recent technological shifts toward hydrogen as a clean energy carrier have intensified research efforts, creating a convergence of materials science, mechanical engineering, and electrochemistry to address this multifaceted challenge.

Current technological trends focus on developing quantitative assessment methodologies that can accurately predict the susceptibility of materials to hydrogen embrittlement under various operating conditions. These methodologies incorporate advanced computational models, experimental validation techniques, and in-situ monitoring systems to provide real-time risk assessment capabilities.

The primary objective of hydrogen embrittlement quantification is to establish reliable predictive models that can determine the threshold conditions for crack initiation and propagation in hydrogen-containing environments. This involves characterizing the interaction between hydrogen and material microstructure, understanding the influence of mechanical loading conditions, and evaluating environmental factors that accelerate embrittlement processes.

Secondary objectives include developing standardized testing protocols that can be universally applied across different industries, creating material selection guidelines for hydrogen service, and establishing inspection intervals based on quantitative risk assessment rather than arbitrary time-based schedules.

The technical goals extend to establishing correlations between laboratory test results and actual field performance, which remains one of the most challenging aspects of hydrogen embrittlement research. This includes developing accelerated testing methodologies that can simulate long-term exposure effects within reasonable timeframes, enabling more efficient material qualification processes for hydrogen applications.

Emerging research directions are exploring the potential of novel materials and surface treatments that can inherently resist hydrogen penetration, thereby providing intrinsic protection against embrittlement. These innovations aim to shift the paradigm from managing hydrogen embrittlement to preventing it altogether through materials engineering approaches.

Market Demand for Hydrogen Storage and Transport Solutions

The global hydrogen market is experiencing unprecedented growth, driven by the increasing focus on decarbonization and clean energy transition. As of 2023, the hydrogen storage and transport solutions market was valued at approximately $15 billion, with projections indicating a compound annual growth rate of 8% through 2030, potentially reaching $26 billion by the end of the decade.

The demand for safe hydrogen storage and transport infrastructure is primarily fueled by three key sectors: industrial applications, transportation, and energy storage. Industrial users, particularly in refining, ammonia production, and metallurgy, represent the largest current market segment, accounting for roughly 60% of hydrogen consumption globally.

Transportation sector demand is rapidly accelerating, with hydrogen fuel cell vehicles gaining traction in heavy-duty applications such as buses, trucks, and material handling equipment. This segment is expected to grow at 12-15% annually as infrastructure expands and vehicle costs decrease. Major automotive manufacturers including Toyota, Hyundai, and Daimler have made significant investments in hydrogen vehicle technology, signaling strong industry confidence.

Energy storage applications represent the fastest-growing segment, with green hydrogen increasingly viewed as a solution for long-duration energy storage to complement intermittent renewable power generation. Utility companies and grid operators are investing in hydrogen projects to address seasonal storage needs and grid balancing capabilities.

Geographically, Asia-Pacific leads market demand, with Japan, South Korea, and China implementing aggressive hydrogen strategies. Europe follows closely, driven by strong policy support through initiatives like the European Clean Hydrogen Alliance and substantial funding commitments exceeding €400 billion through 2030.

A critical market driver is the growing emphasis on safety standards and risk quantification for hydrogen infrastructure. End-users are increasingly demanding advanced materials and components that minimize hydrogen embrittlement risks, with willingness to pay premium prices for solutions that offer superior safety profiles and longer operational lifespans.

Market research indicates that 78% of hydrogen infrastructure operators cite safety concerns—particularly hydrogen embrittlement—as a primary consideration in procurement decisions. This has created a specialized market segment for advanced testing equipment, monitoring systems, and predictive maintenance solutions specifically designed to quantify and mitigate hydrogen embrittlement risks in storage and transport systems.

The demand for safe hydrogen storage and transport infrastructure is primarily fueled by three key sectors: industrial applications, transportation, and energy storage. Industrial users, particularly in refining, ammonia production, and metallurgy, represent the largest current market segment, accounting for roughly 60% of hydrogen consumption globally.

Transportation sector demand is rapidly accelerating, with hydrogen fuel cell vehicles gaining traction in heavy-duty applications such as buses, trucks, and material handling equipment. This segment is expected to grow at 12-15% annually as infrastructure expands and vehicle costs decrease. Major automotive manufacturers including Toyota, Hyundai, and Daimler have made significant investments in hydrogen vehicle technology, signaling strong industry confidence.

Energy storage applications represent the fastest-growing segment, with green hydrogen increasingly viewed as a solution for long-duration energy storage to complement intermittent renewable power generation. Utility companies and grid operators are investing in hydrogen projects to address seasonal storage needs and grid balancing capabilities.

Geographically, Asia-Pacific leads market demand, with Japan, South Korea, and China implementing aggressive hydrogen strategies. Europe follows closely, driven by strong policy support through initiatives like the European Clean Hydrogen Alliance and substantial funding commitments exceeding €400 billion through 2030.

A critical market driver is the growing emphasis on safety standards and risk quantification for hydrogen infrastructure. End-users are increasingly demanding advanced materials and components that minimize hydrogen embrittlement risks, with willingness to pay premium prices for solutions that offer superior safety profiles and longer operational lifespans.

Market research indicates that 78% of hydrogen infrastructure operators cite safety concerns—particularly hydrogen embrittlement—as a primary consideration in procurement decisions. This has created a specialized market segment for advanced testing equipment, monitoring systems, and predictive maintenance solutions specifically designed to quantify and mitigate hydrogen embrittlement risks in storage and transport systems.

Current Challenges in Hydrogen Embrittlement Quantification

Despite significant advancements in hydrogen technology, quantifying hydrogen embrittlement (HE) risk for pressure-bearing components remains challenging. Current methodologies often lack standardization across different industries and applications, creating inconsistencies in risk assessment approaches. The absence of universally accepted quantification metrics makes it difficult to establish reliable safety thresholds for hydrogen infrastructure components.

Material variability presents a major obstacle in quantification efforts. Different alloys and manufacturing processes result in varying susceptibility to hydrogen embrittlement, complicating the development of comprehensive risk models. Even within the same material specification, microstructural differences can significantly alter hydrogen diffusion rates and trapping mechanisms, leading to unpredictable embrittlement behavior.

Environmental factors further complicate quantification. Temperature fluctuations, pressure cycling, and exposure to contaminants can dramatically influence hydrogen absorption and material degradation rates. Current models struggle to account for these dynamic variables, particularly in real-world operating conditions where multiple factors interact simultaneously.

Testing limitations represent another significant challenge. Accelerated laboratory tests often fail to accurately replicate long-term field conditions, creating a disconnect between experimental data and actual service performance. The time-dependent nature of hydrogen embrittlement means that short-duration tests may not capture delayed cracking phenomena that emerge after years of service.

Non-destructive evaluation (NDE) techniques for in-service components remain inadequate. Current methods cannot reliably detect hydrogen-induced damage before it reaches critical levels, forcing operators to rely on conservative design approaches rather than condition-based assessments. This limitation is particularly problematic for aging infrastructure where hydrogen damage may have accumulated over time.

Data integration challenges persist across the hydrogen value chain. Information from material suppliers, component manufacturers, and end-users often exists in isolation, preventing holistic risk assessment. The lack of comprehensive databases correlating material properties, operating conditions, and failure incidents hampers the development of predictive models.

Computational modeling faces limitations in accurately simulating hydrogen-material interactions at multiple scales. While atomistic simulations provide insights into fundamental mechanisms, translating these findings to component-level risk predictions remains problematic. Current models struggle to bridge the gap between microscopic hydrogen diffusion processes and macroscopic mechanical behavior of complex components.

Material variability presents a major obstacle in quantification efforts. Different alloys and manufacturing processes result in varying susceptibility to hydrogen embrittlement, complicating the development of comprehensive risk models. Even within the same material specification, microstructural differences can significantly alter hydrogen diffusion rates and trapping mechanisms, leading to unpredictable embrittlement behavior.

Environmental factors further complicate quantification. Temperature fluctuations, pressure cycling, and exposure to contaminants can dramatically influence hydrogen absorption and material degradation rates. Current models struggle to account for these dynamic variables, particularly in real-world operating conditions where multiple factors interact simultaneously.

Testing limitations represent another significant challenge. Accelerated laboratory tests often fail to accurately replicate long-term field conditions, creating a disconnect between experimental data and actual service performance. The time-dependent nature of hydrogen embrittlement means that short-duration tests may not capture delayed cracking phenomena that emerge after years of service.

Non-destructive evaluation (NDE) techniques for in-service components remain inadequate. Current methods cannot reliably detect hydrogen-induced damage before it reaches critical levels, forcing operators to rely on conservative design approaches rather than condition-based assessments. This limitation is particularly problematic for aging infrastructure where hydrogen damage may have accumulated over time.

Data integration challenges persist across the hydrogen value chain. Information from material suppliers, component manufacturers, and end-users often exists in isolation, preventing holistic risk assessment. The lack of comprehensive databases correlating material properties, operating conditions, and failure incidents hampers the development of predictive models.

Computational modeling faces limitations in accurately simulating hydrogen-material interactions at multiple scales. While atomistic simulations provide insights into fundamental mechanisms, translating these findings to component-level risk predictions remains problematic. Current models struggle to bridge the gap between microscopic hydrogen diffusion processes and macroscopic mechanical behavior of complex components.

Established Quantification Methods for Hydrogen Embrittlement Risk

01 Measurement and testing methods for hydrogen embrittlement

Various testing methods are employed to quantify hydrogen embrittlement risk in materials. These include electrochemical techniques, mechanical testing under hydrogen environments, and specialized equipment for measuring hydrogen concentration and diffusion rates. These methods help in establishing threshold values for safe operation and predicting material behavior under hydrogen exposure conditions.- Measurement and testing methods for hydrogen embrittlement: Various testing methods are used to quantify hydrogen embrittlement risk in materials. These include electrochemical techniques, mechanical testing under hydrogen environments, and specialized apparatus designed to measure hydrogen diffusion and trapping. These methods allow for the determination of critical hydrogen concentrations and the assessment of material susceptibility to hydrogen-induced damage under different conditions.

- Computational models and simulation techniques: Advanced computational models and simulation techniques are employed to predict hydrogen embrittlement behavior in materials. These include finite element analysis, molecular dynamics simulations, and machine learning algorithms that can quantify risk factors based on material composition, microstructure, and environmental conditions. These predictive models help in assessing the probability of hydrogen-induced failure without extensive physical testing.

- Material composition and microstructure optimization: The risk of hydrogen embrittlement can be quantified and mitigated through optimization of material composition and microstructure. This includes controlling alloying elements, grain size, and phase distribution to reduce hydrogen trapping sites. Techniques such as heat treatment, surface modification, and the addition of specific elements can enhance resistance to hydrogen embrittlement and allow for more precise risk assessment.

- Environmental factors and service condition assessment: Quantification of hydrogen embrittlement risk involves assessment of environmental factors and service conditions. This includes analyzing the effects of temperature, pressure, pH levels, and exposure time on hydrogen uptake and material degradation. Standardized protocols have been developed to evaluate these factors and establish threshold values for safe operation in hydrogen-containing environments.

- In-situ monitoring and real-time risk assessment: Advanced sensor technologies and monitoring systems enable real-time assessment of hydrogen embrittlement risk in operational components. These systems can detect hydrogen concentration, material property changes, and early signs of crack initiation. Integration with digital platforms allows for continuous risk quantification and predictive maintenance strategies to prevent catastrophic failures due to hydrogen embrittlement.

02 Material composition and microstructure effects on hydrogen embrittlement

The chemical composition and microstructural features of materials significantly influence their susceptibility to hydrogen embrittlement. Factors such as grain size, phase distribution, inclusion content, and alloying elements can either enhance or mitigate hydrogen-induced damage. Understanding these relationships enables the development of materials with improved resistance to hydrogen embrittlement.Expand Specific Solutions03 Computational models and simulation techniques

Advanced computational models and simulation techniques are utilized to predict hydrogen embrittlement behavior in materials. These include finite element analysis, molecular dynamics simulations, and machine learning algorithms that can quantify risk factors based on material properties, environmental conditions, and loading scenarios. Such models help in risk assessment without extensive experimental testing.Expand Specific Solutions04 Environmental factors and operating conditions assessment

The evaluation of environmental factors and operating conditions is crucial for hydrogen embrittlement risk quantification. Parameters such as hydrogen partial pressure, temperature, pH levels, applied stress, and exposure time significantly influence embrittlement susceptibility. Standardized methodologies have been developed to assess these factors and establish safe operating windows for various applications.Expand Specific Solutions05 Protective measures and mitigation strategies

Various protective measures and mitigation strategies have been developed to reduce hydrogen embrittlement risk. These include surface coatings, heat treatments, controlled manufacturing processes, and hydrogen trapping techniques. Quantitative assessment of these protective measures allows for optimization of their application and effectiveness in reducing hydrogen-induced failures.Expand Specific Solutions

Key Industry Players in Hydrogen Infrastructure Components

Hydrogen embrittlement risk quantification for cylinders, valves, and piping is currently in a growth phase, with the market expanding due to increasing hydrogen applications in energy transition. The global market size is projected to reach significant value as industries adopt hydrogen technologies. Technologically, the field is advancing rapidly with varying maturity levels across companies. Saudi Aramco and China Petroleum lead in oil and gas sector applications, while specialized firms like Rotarex SA and Haldor Topsøe offer advanced testing methodologies. Research institutions including EPRI and China University of Petroleum contribute fundamental knowledge. Boeing and Japan Steel Works represent aerospace and manufacturing perspectives, developing standardized quantification methods as hydrogen infrastructure expands globally.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed a comprehensive Hydrogen Embrittlement Risk Assessment Framework (HERAF) specifically for high-pressure vessels, valves, and pipeline systems. Their approach combines microstructural analysis with advanced finite element modeling to predict hydrogen diffusion and trapping mechanisms in steel components. The company employs hydrogen permeation tests coupled with thermal desorption spectroscopy to quantify hydrogen concentration thresholds that initiate embrittlement. For critical pipeline infrastructure, they've implemented continuous monitoring systems using acoustic emission sensors that detect microcrack formation - an early indicator of hydrogen damage. Their proprietary software integrates operational parameters (pressure cycles, temperature fluctuations) with material-specific hydrogen susceptibility data to generate risk matrices for different components, allowing for targeted inspection and maintenance schedules based on quantified failure probabilities[1][3].

Strengths: Comprehensive integration of material science and operational parameters; real-time monitoring capabilities; extensive field validation across diverse operating environments. Weaknesses: System requires significant computational resources; calibration needed for each specific material composition; limited effectiveness in predicting embrittlement in newer high-strength alloys.

The Japan Steel Works Ltd.

Technical Solution: The Japan Steel Works (JSW) has established a proprietary Hydrogen Embrittlement Quantification System (HEQS) specifically designed for high-pressure hydrogen storage vessels and transmission components. Their methodology integrates microstructural characterization with hydrogen charging experiments to determine material-specific thresholds for embrittlement initiation. JSW employs constant load testing under hydrogen environments at varying pressures to establish stress thresholds below which embrittlement does not occur - a critical parameter for safety factor calculations in pressure vessel design. For pipeline materials, they've developed specialized small punch testing techniques that correlate with full-scale component behavior, allowing for efficient material screening. Their risk assessment framework incorporates hydrogen trapping site density measurements through thermal desorption spectroscopy, correlating these with mechanical property degradation to establish quantitative embrittlement susceptibility indices. JSW has pioneered the use of acoustic emission monitoring during hydrogen charging to detect the onset of internal crack formation before visible damage occurs[6][8].

Strengths: Extensive metallurgical expertise specifically focused on hydrogen-resistant steel development; well-established correlation between laboratory tests and field performance; comprehensive material database spanning decades of research. Weaknesses: Assessment methodology heavily focused on steel alloys with less coverage of non-ferrous materials; testing protocols require specialized facilities; limited public disclosure of proprietary techniques.

Critical Technical Standards and Testing Protocols

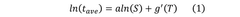

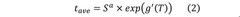

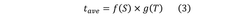

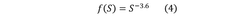

Hydrogen embrittlement risk assessment method and device therefor

PatentWO2023058086A1

Innovation

- A method and device that use a first function representing the average rupture time of steel materials under varying tensile stress and a second function representing the impact of temperature to calculate the hydrogen embrittlement risk, allowing for the evaluation of how the risk changes with changes in these factors.

Apparatus and method for the non-destructive measurement of hydrogen diffusivity

PatentWO2018200626A1

Innovation

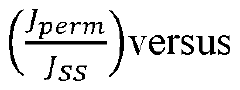

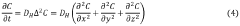

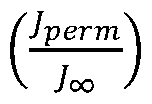

- A non-destructive method and apparatus that utilize a hydrogen charging surface and an oxidation surface on the external surface of the metal structure to generate and measure hydrogen flux, allowing for the determination of hydrogen diffusivity using a Fickian diffusion model or simulated master graphs, independent of geometric dimensions and experimental parameters.

Material Selection Strategies for Hydrogen Service

Material selection is a critical factor in mitigating hydrogen embrittlement risks in industrial applications. When designing systems for hydrogen service, engineers must carefully evaluate material properties to ensure long-term integrity and safety. The selection process begins with understanding the susceptibility of different material classes to hydrogen damage mechanisms.

Ferritic steels, while economical, generally exhibit higher susceptibility to hydrogen embrittlement compared to austenitic stainless steels. This is primarily due to their body-centered cubic (BCC) crystal structure, which allows faster hydrogen diffusion. Austenitic stainless steels, with their face-centered cubic (FCC) structure, typically demonstrate superior resistance to hydrogen effects, making them preferred choices for critical hydrogen applications despite higher costs.

Nickel alloys and aluminum-based materials represent premium options for severe hydrogen service conditions. These materials offer excellent resistance to hydrogen embrittlement but require careful economic justification due to their significantly higher cost profiles. The selection decision often involves balancing technical requirements against budgetary constraints.

Material selection strategies must incorporate comprehensive testing protocols specific to hydrogen service. Slow strain rate testing (SSRT), fracture mechanics assessments, and hydrogen charging experiments provide valuable data on material performance under hydrogen exposure. These tests help quantify the threshold stress intensity factors below which crack propagation is unlikely to occur.

Surface treatments and coatings represent another strategic approach to material selection. Techniques such as nitriding, carburizing, or applying specialized barrier coatings can enhance the hydrogen resistance of base materials. These treatments modify surface properties to reduce hydrogen ingress while maintaining the mechanical properties of the underlying material.

Standardization bodies have developed specific guidelines for material selection in hydrogen service. ASME B31.12, API 941, and NACE MR0175 provide industry-accepted frameworks for evaluating material suitability. These standards typically categorize materials based on their hydrogen compatibility and prescribe maximum allowable stress values for different operating conditions.

The operating environment significantly influences material selection decisions. Parameters such as pressure, temperature, hydrogen concentration, and the presence of contaminants must be carefully evaluated. Materials that perform adequately at ambient conditions may exhibit dramatically different behavior under elevated temperatures or pressures, necessitating a comprehensive assessment of the entire operating envelope.

Ferritic steels, while economical, generally exhibit higher susceptibility to hydrogen embrittlement compared to austenitic stainless steels. This is primarily due to their body-centered cubic (BCC) crystal structure, which allows faster hydrogen diffusion. Austenitic stainless steels, with their face-centered cubic (FCC) structure, typically demonstrate superior resistance to hydrogen effects, making them preferred choices for critical hydrogen applications despite higher costs.

Nickel alloys and aluminum-based materials represent premium options for severe hydrogen service conditions. These materials offer excellent resistance to hydrogen embrittlement but require careful economic justification due to their significantly higher cost profiles. The selection decision often involves balancing technical requirements against budgetary constraints.

Material selection strategies must incorporate comprehensive testing protocols specific to hydrogen service. Slow strain rate testing (SSRT), fracture mechanics assessments, and hydrogen charging experiments provide valuable data on material performance under hydrogen exposure. These tests help quantify the threshold stress intensity factors below which crack propagation is unlikely to occur.

Surface treatments and coatings represent another strategic approach to material selection. Techniques such as nitriding, carburizing, or applying specialized barrier coatings can enhance the hydrogen resistance of base materials. These treatments modify surface properties to reduce hydrogen ingress while maintaining the mechanical properties of the underlying material.

Standardization bodies have developed specific guidelines for material selection in hydrogen service. ASME B31.12, API 941, and NACE MR0175 provide industry-accepted frameworks for evaluating material suitability. These standards typically categorize materials based on their hydrogen compatibility and prescribe maximum allowable stress values for different operating conditions.

The operating environment significantly influences material selection decisions. Parameters such as pressure, temperature, hydrogen concentration, and the presence of contaminants must be carefully evaluated. Materials that perform adequately at ambient conditions may exhibit dramatically different behavior under elevated temperatures or pressures, necessitating a comprehensive assessment of the entire operating envelope.

Regulatory Framework for Hydrogen Pressure Systems

The regulatory landscape governing hydrogen pressure systems has evolved significantly in response to the growing adoption of hydrogen technologies across various industries. International standards such as ISO 19880 specifically address hydrogen refueling stations, while ISO 16111 covers portable hydrogen storage systems. These standards establish critical parameters for material selection, design considerations, and testing protocols to mitigate hydrogen embrittlement risks.

In the United States, the ASME Boiler and Pressure Vessel Code Section VIII provides comprehensive guidelines for pressure vessels, with specific provisions addressing hydrogen service. The code mandates stringent material selection criteria and design factors to account for hydrogen's unique properties and potential embrittlement effects. Additionally, NFPA 2 (Hydrogen Technologies Code) establishes safety standards for hydrogen infrastructure, including storage and handling requirements.

The European framework centers around the Pressure Equipment Directive (PED) 2014/68/EU, which has been supplemented with hydrogen-specific technical standards. The EN 13445 standard for unfired pressure vessels includes dedicated sections addressing hydrogen service conditions and material compatibility requirements. These regulations incorporate quantitative risk assessment methodologies that must be applied during the design and certification process.

For cylinders specifically, ISO 11114-4 outlines test methods for selecting metallic materials resistant to hydrogen embrittlement, providing a standardized approach to quantifying susceptibility. This standard establishes threshold values for acceptable hydrogen-induced degradation and prescribes specific testing protocols based on application parameters.

Regulatory compliance for hydrogen piping systems typically follows ASME B31.12 (Hydrogen Piping and Pipelines), which contains detailed requirements for material selection, design factors, and inspection protocols specifically tailored to hydrogen service. The code incorporates quantitative risk assessment methodologies that account for operating pressure, temperature cycles, and environmental factors.

Certification processes for hydrogen pressure systems generally require documented evidence of compliance with these standards, including material certification, design validation, and testing results that quantitatively demonstrate resistance to hydrogen embrittlement. Many jurisdictions mandate periodic inspection and recertification based on risk-based assessment methodologies that consider service history, operating conditions, and detected anomalies.

Recent regulatory developments have focused on harmonizing international standards to facilitate global hydrogen market development while maintaining rigorous safety requirements. These efforts aim to establish consistent quantitative metrics for hydrogen embrittlement risk assessment across different regulatory frameworks.

In the United States, the ASME Boiler and Pressure Vessel Code Section VIII provides comprehensive guidelines for pressure vessels, with specific provisions addressing hydrogen service. The code mandates stringent material selection criteria and design factors to account for hydrogen's unique properties and potential embrittlement effects. Additionally, NFPA 2 (Hydrogen Technologies Code) establishes safety standards for hydrogen infrastructure, including storage and handling requirements.

The European framework centers around the Pressure Equipment Directive (PED) 2014/68/EU, which has been supplemented with hydrogen-specific technical standards. The EN 13445 standard for unfired pressure vessels includes dedicated sections addressing hydrogen service conditions and material compatibility requirements. These regulations incorporate quantitative risk assessment methodologies that must be applied during the design and certification process.

For cylinders specifically, ISO 11114-4 outlines test methods for selecting metallic materials resistant to hydrogen embrittlement, providing a standardized approach to quantifying susceptibility. This standard establishes threshold values for acceptable hydrogen-induced degradation and prescribes specific testing protocols based on application parameters.

Regulatory compliance for hydrogen piping systems typically follows ASME B31.12 (Hydrogen Piping and Pipelines), which contains detailed requirements for material selection, design factors, and inspection protocols specifically tailored to hydrogen service. The code incorporates quantitative risk assessment methodologies that account for operating pressure, temperature cycles, and environmental factors.

Certification processes for hydrogen pressure systems generally require documented evidence of compliance with these standards, including material certification, design validation, and testing results that quantitatively demonstrate resistance to hydrogen embrittlement. Many jurisdictions mandate periodic inspection and recertification based on risk-based assessment methodologies that consider service history, operating conditions, and detected anomalies.

Recent regulatory developments have focused on harmonizing international standards to facilitate global hydrogen market development while maintaining rigorous safety requirements. These efforts aim to establish consistent quantitative metrics for hydrogen embrittlement risk assessment across different regulatory frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!