Hydrogen Embrittlement Prevention: Baking Protocols, Coating Choices And Cathodic Control

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement Background and Prevention Goals

Hydrogen embrittlement (HE) represents one of the most significant challenges in metallurgical engineering, particularly affecting high-strength steels and other susceptible alloys. This phenomenon occurs when hydrogen atoms penetrate into the metal lattice, causing a reduction in ductility and load-bearing capacity, ultimately leading to catastrophic failure under stresses well below the material's design specifications. The history of hydrogen embrittlement dates back to the 19th century, with significant research acceleration following major industrial failures in the mid-20th century.

The evolution of this technical field has been marked by progressive understanding of the underlying mechanisms. Initially viewed as a simple diffusion process, research has revealed complex interactions between hydrogen and various microstructural features including grain boundaries, dislocations, and precipitates. Recent advances in analytical techniques such as thermal desorption spectroscopy and atom probe tomography have significantly enhanced our ability to characterize hydrogen behavior within metals.

Current technological trends focus on three primary prevention strategies: post-processing thermal treatments (baking protocols), protective coatings, and electrochemical control methods. Baking protocols have evolved from simple uniform heating to sophisticated time-temperature profiles optimized for specific alloy systems. Coating technologies have progressed from traditional metallic layers to advanced composite and nano-engineered barriers with enhanced hydrogen impermeability.

The prevention goals in this technical domain are multifaceted and increasingly demanding. Primary objectives include developing universal prevention protocols applicable across diverse industrial sectors, establishing standardized testing methodologies for hydrogen embrittlement susceptibility, and creating predictive models that accurately forecast embrittlement risk under varied service conditions.

Additional goals involve the creation of cost-effective prevention strategies suitable for mass production environments, particularly in automotive and aerospace applications where high-strength materials are increasingly utilized. There is also growing emphasis on developing environmentally sustainable prevention methods that reduce or eliminate hazardous chemicals traditionally used in anti-embrittlement treatments.

The intersection of hydrogen embrittlement prevention with emerging manufacturing technologies, particularly additive manufacturing, presents new challenges and opportunities. As these advanced production methods gain industrial acceptance, tailored prevention strategies must be developed to address their unique microstructural characteristics and processing conditions.

Looking forward, the technical trajectory points toward integrated prevention systems that combine multiple protection mechanisms, real-time monitoring capabilities, and self-healing properties to provide comprehensive safeguards against hydrogen-induced damage throughout a component's service life.

The evolution of this technical field has been marked by progressive understanding of the underlying mechanisms. Initially viewed as a simple diffusion process, research has revealed complex interactions between hydrogen and various microstructural features including grain boundaries, dislocations, and precipitates. Recent advances in analytical techniques such as thermal desorption spectroscopy and atom probe tomography have significantly enhanced our ability to characterize hydrogen behavior within metals.

Current technological trends focus on three primary prevention strategies: post-processing thermal treatments (baking protocols), protective coatings, and electrochemical control methods. Baking protocols have evolved from simple uniform heating to sophisticated time-temperature profiles optimized for specific alloy systems. Coating technologies have progressed from traditional metallic layers to advanced composite and nano-engineered barriers with enhanced hydrogen impermeability.

The prevention goals in this technical domain are multifaceted and increasingly demanding. Primary objectives include developing universal prevention protocols applicable across diverse industrial sectors, establishing standardized testing methodologies for hydrogen embrittlement susceptibility, and creating predictive models that accurately forecast embrittlement risk under varied service conditions.

Additional goals involve the creation of cost-effective prevention strategies suitable for mass production environments, particularly in automotive and aerospace applications where high-strength materials are increasingly utilized. There is also growing emphasis on developing environmentally sustainable prevention methods that reduce or eliminate hazardous chemicals traditionally used in anti-embrittlement treatments.

The intersection of hydrogen embrittlement prevention with emerging manufacturing technologies, particularly additive manufacturing, presents new challenges and opportunities. As these advanced production methods gain industrial acceptance, tailored prevention strategies must be developed to address their unique microstructural characteristics and processing conditions.

Looking forward, the technical trajectory points toward integrated prevention systems that combine multiple protection mechanisms, real-time monitoring capabilities, and self-healing properties to provide comprehensive safeguards against hydrogen-induced damage throughout a component's service life.

Market Demand for Hydrogen Embrittlement Solutions

The global market for hydrogen embrittlement prevention solutions has experienced significant growth in recent years, driven primarily by expanding industrial applications in sectors where high-strength metals are critical. The oil and gas industry represents the largest market segment, with an estimated demand growth of 6.2% annually, as deep-sea exploration and extraction operations require increasingly sophisticated materials resistant to hydrogen-induced damage.

Aerospace and automotive industries follow closely, collectively accounting for approximately 40% of the total market share. The transition toward lightweight, high-strength materials in these sectors has intensified concerns about hydrogen embrittlement, particularly as electric vehicles with specialized metal components gain market traction. Defense contractors have similarly increased their demand for embrittlement prevention technologies, especially for naval and submarine applications where exposure to hydrogen-rich environments is unavoidable.

Regional analysis reveals that North America and Europe currently dominate the market for advanced hydrogen embrittlement solutions, though Asia-Pacific regions—particularly China, Japan, and South Korea—are showing the fastest growth rates. This geographic shift correlates with the expansion of high-tech manufacturing and infrastructure development in these regions.

The market for specialized coatings designed to prevent hydrogen penetration has seen particularly robust growth, with zinc-nickel and specialized polymer coatings leading the segment. Demand for advanced baking protocols has similarly increased as manufacturers seek cost-effective solutions that can be integrated into existing production lines without significant capital investment.

Industry surveys indicate that end-users are increasingly prioritizing preventive solutions over remedial treatments, reflecting a shift toward lifecycle cost management rather than focusing solely on initial implementation expenses. This trend has created market opportunities for integrated service providers offering comprehensive hydrogen embrittlement management systems that combine multiple prevention strategies.

Regulatory factors are also driving market demand, particularly in sectors where safety standards are becoming more stringent. The implementation of new industrial safety codes in Europe and North America has created immediate demand for certified hydrogen embrittlement prevention solutions, especially in critical infrastructure applications.

Market forecasts suggest that demand for specialized cathodic protection systems will grow at the fastest rate among all solution categories, driven by infrastructure renewal projects and expanding offshore energy installations. This segment is expected to benefit from technological innovations that allow for more precise control and monitoring of cathodic protection parameters.

Aerospace and automotive industries follow closely, collectively accounting for approximately 40% of the total market share. The transition toward lightweight, high-strength materials in these sectors has intensified concerns about hydrogen embrittlement, particularly as electric vehicles with specialized metal components gain market traction. Defense contractors have similarly increased their demand for embrittlement prevention technologies, especially for naval and submarine applications where exposure to hydrogen-rich environments is unavoidable.

Regional analysis reveals that North America and Europe currently dominate the market for advanced hydrogen embrittlement solutions, though Asia-Pacific regions—particularly China, Japan, and South Korea—are showing the fastest growth rates. This geographic shift correlates with the expansion of high-tech manufacturing and infrastructure development in these regions.

The market for specialized coatings designed to prevent hydrogen penetration has seen particularly robust growth, with zinc-nickel and specialized polymer coatings leading the segment. Demand for advanced baking protocols has similarly increased as manufacturers seek cost-effective solutions that can be integrated into existing production lines without significant capital investment.

Industry surveys indicate that end-users are increasingly prioritizing preventive solutions over remedial treatments, reflecting a shift toward lifecycle cost management rather than focusing solely on initial implementation expenses. This trend has created market opportunities for integrated service providers offering comprehensive hydrogen embrittlement management systems that combine multiple prevention strategies.

Regulatory factors are also driving market demand, particularly in sectors where safety standards are becoming more stringent. The implementation of new industrial safety codes in Europe and North America has created immediate demand for certified hydrogen embrittlement prevention solutions, especially in critical infrastructure applications.

Market forecasts suggest that demand for specialized cathodic protection systems will grow at the fastest rate among all solution categories, driven by infrastructure renewal projects and expanding offshore energy installations. This segment is expected to benefit from technological innovations that allow for more precise control and monitoring of cathodic protection parameters.

Current Challenges in Hydrogen Embrittlement Prevention

Despite significant advancements in hydrogen embrittlement (HE) prevention technologies, several critical challenges persist in industrial applications. The multifaceted nature of hydrogen-metal interactions continues to complicate prevention strategies, as hydrogen diffusion mechanisms vary significantly across different metal alloys and environmental conditions. This fundamental knowledge gap hinders the development of universally effective prevention protocols.

Current baking protocols face significant standardization challenges. While post-plating baking at 190-220°C for 2-24 hours remains common practice, optimal parameters vary widely depending on material composition, component geometry, and hydrogen concentration. The industry lacks consensus on precise time-temperature relationships for complete hydrogen removal, particularly for high-strength steels above 1000 MPa where embrittlement sensitivity increases exponentially.

Coating technologies present another area of ongoing difficulty. Traditional cadmium coatings, while effective hydrogen barriers, face phase-out due to environmental regulations. Alternative coatings such as zinc-nickel and various ceramic composites demonstrate promising barrier properties but often introduce new complications including adhesion issues, thermal expansion mismatches, and inconsistent performance across varying service environments.

Cathodic protection systems, though theoretically sound, encounter practical implementation challenges in complex structures. Achieving uniform current distribution remains problematic, with overprotection in some areas potentially generating hydrogen while other sections receive insufficient protection. Modern systems incorporating reference electrodes and feedback control improve precision but increase complexity and maintenance requirements.

Testing methodologies represent a significant bottleneck in prevention strategy development. Accelerated testing often fails to accurately predict real-world performance, while field testing requires prohibitively long timeframes. The industry lacks standardized, reliable methods to quantify hydrogen concentration and diffusion rates in components under actual service conditions.

Economic considerations further complicate implementation of optimal prevention strategies. Cost-benefit analyses frequently favor less effective but more economical solutions, particularly in price-sensitive industries. The true lifecycle costs of hydrogen damage often remain underestimated, skewing decision-making toward short-term savings rather than long-term reliability.

Emerging high-performance materials, particularly ultra-high-strength steels, advanced titanium alloys, and novel composites, demonstrate heightened susceptibility to hydrogen damage, requiring entirely new prevention approaches. These materials' increasing adoption in critical applications like aerospace, automotive lightweighting, and renewable energy infrastructure amplifies the urgency of addressing these technical challenges.

Current baking protocols face significant standardization challenges. While post-plating baking at 190-220°C for 2-24 hours remains common practice, optimal parameters vary widely depending on material composition, component geometry, and hydrogen concentration. The industry lacks consensus on precise time-temperature relationships for complete hydrogen removal, particularly for high-strength steels above 1000 MPa where embrittlement sensitivity increases exponentially.

Coating technologies present another area of ongoing difficulty. Traditional cadmium coatings, while effective hydrogen barriers, face phase-out due to environmental regulations. Alternative coatings such as zinc-nickel and various ceramic composites demonstrate promising barrier properties but often introduce new complications including adhesion issues, thermal expansion mismatches, and inconsistent performance across varying service environments.

Cathodic protection systems, though theoretically sound, encounter practical implementation challenges in complex structures. Achieving uniform current distribution remains problematic, with overprotection in some areas potentially generating hydrogen while other sections receive insufficient protection. Modern systems incorporating reference electrodes and feedback control improve precision but increase complexity and maintenance requirements.

Testing methodologies represent a significant bottleneck in prevention strategy development. Accelerated testing often fails to accurately predict real-world performance, while field testing requires prohibitively long timeframes. The industry lacks standardized, reliable methods to quantify hydrogen concentration and diffusion rates in components under actual service conditions.

Economic considerations further complicate implementation of optimal prevention strategies. Cost-benefit analyses frequently favor less effective but more economical solutions, particularly in price-sensitive industries. The true lifecycle costs of hydrogen damage often remain underestimated, skewing decision-making toward short-term savings rather than long-term reliability.

Emerging high-performance materials, particularly ultra-high-strength steels, advanced titanium alloys, and novel composites, demonstrate heightened susceptibility to hydrogen damage, requiring entirely new prevention approaches. These materials' increasing adoption in critical applications like aerospace, automotive lightweighting, and renewable energy infrastructure amplifies the urgency of addressing these technical challenges.

Analysis of Current Baking Protocols and Coating Systems

01 Surface coating and treatment methods

Various surface coating and treatment methods can be applied to prevent hydrogen embrittlement in metal components. These include applying protective layers such as zinc, nickel, or chromium coatings that act as barriers against hydrogen penetration. Surface treatments like shot peening, nitriding, and carburizing can also create compressive stresses on the surface that inhibit hydrogen diffusion into the metal substrate, thereby reducing susceptibility to embrittlement.- Surface coating and treatment methods: Various surface coating and treatment methods can be applied to prevent hydrogen embrittlement in metal components. These include specialized plating techniques, surface passivation treatments, and protective coatings that create barriers against hydrogen penetration. These methods typically involve creating a physical barrier on the metal surface that prevents hydrogen atoms from diffusing into the material structure, thereby maintaining the mechanical integrity of the components under hydrogen-rich environments.

- Alloy composition modifications: Modifying the composition of metal alloys can significantly improve resistance to hydrogen embrittlement. By incorporating specific elements or adjusting the proportions of existing components in the alloy, materials can be engineered to have reduced susceptibility to hydrogen-induced damage. These modifications often target grain boundary strengthening, trap site creation for hydrogen atoms, or overall microstructural improvements that limit hydrogen mobility within the material.

- Heat treatment and thermal processing: Specialized heat treatment processes can be employed to mitigate hydrogen embrittlement risks. These thermal processes include baking treatments after plating, controlled cooling regimes, and specific annealing procedures that help release trapped hydrogen from the metal structure. By carefully managing temperature profiles and exposure times, these treatments can effectively reduce hydrogen concentration in susceptible materials before they enter service conditions.

- Hydrogen trapping mechanisms: Implementing hydrogen trapping mechanisms within materials can prevent embrittlement by capturing and immobilizing hydrogen atoms. These mechanisms involve introducing specific microstructural features or compounds that act as hydrogen traps, preventing the hydrogen from accumulating at critical locations such as grain boundaries or crack tips. By controlling the distribution and mobility of hydrogen within the material, these trapping approaches can significantly enhance resistance to hydrogen-induced damage.

- Environmental and operational controls: Controlling the operational environment and service conditions can effectively prevent hydrogen embrittlement. This includes managing exposure to hydrogen sources, controlling pH levels in corrosive environments, implementing cathodic protection systems, and establishing proper handling procedures for hydrogen-containing materials. By limiting the initial ingress of hydrogen into susceptible materials through careful environmental management, the risk of embrittlement can be significantly reduced without requiring modifications to the materials themselves.

02 Alloy composition modifications

Modifying the composition of metal alloys can significantly improve resistance to hydrogen embrittlement. Adding specific alloying elements such as chromium, molybdenum, or vanadium can trap hydrogen atoms at harmless sites within the microstructure. Some alloys are specifically designed with fine precipitates that act as hydrogen traps, preventing hydrogen from accumulating at grain boundaries and other critical locations where it could cause cracking.Expand Specific Solutions03 Heat treatment and microstructure control

Specialized heat treatment processes can be employed to develop microstructures resistant to hydrogen embrittlement. These include baking treatments after plating or welding to allow hydrogen to diffuse out of the material, controlled cooling rates to optimize grain structure, and tempering treatments that create beneficial precipitates. Controlling the microstructure by reducing the density of potential hydrogen trapping sites such as dislocations and grain boundaries can significantly improve resistance to embrittlement.Expand Specific Solutions04 Hydrogen barrier technologies

Innovative barrier technologies can prevent hydrogen from entering metal components. These include specialized polymer coatings, ceramic layers, and composite materials designed to block hydrogen permeation. Some barriers incorporate hydrogen scavengers or getters that chemically bind with hydrogen molecules before they can reach the metal surface. These technologies are particularly important in high-pressure hydrogen environments such as fuel cells and hydrogen storage systems.Expand Specific Solutions05 Process control and environmental management

Controlling manufacturing processes and operating environments is crucial for preventing hydrogen embrittlement. This includes careful regulation of electroplating parameters, welding procedures, and acid cleaning processes to minimize hydrogen introduction. Environmental management strategies involve controlling humidity, pH levels, and exposure to hydrogen-containing compounds. Implementing proper storage conditions and handling procedures for susceptible materials can significantly reduce the risk of hydrogen-induced failures in service.Expand Specific Solutions

Key Industry Players in Hydrogen Embrittlement Solutions

The hydrogen embrittlement prevention market is currently in a growth phase, with increasing awareness of its critical importance across automotive, aerospace, and manufacturing sectors. The global market for hydrogen embrittlement solutions is estimated at approximately $2.5-3 billion annually, driven by stringent safety standards in high-stakes industries. Technologically, the field shows varying maturity levels across different prevention approaches. Leading companies like Boeing, Toyota, and NIPPON STEEL have established advanced baking protocols and proprietary coating technologies, while research institutions such as MIT and A*STAR are pioneering next-generation cathodic protection systems. Companies including BASF, Kansai Paint, and Luna Labs USA are developing specialized coatings with enhanced hydrogen barrier properties, representing the most rapidly evolving segment of this technical domain.

The Boeing Co.

Technical Solution: Boeing has developed comprehensive hydrogen embrittlement prevention protocols specifically engineered for aerospace applications. Their multi-layered approach begins with proprietary surface preparation techniques that remove hydrogen-promoting contaminants while creating optimal surface profiles for coating adhesion. Boeing's specialized cadmium replacement coating systems incorporate aluminum-zinc alloys with carefully controlled microstructures that provide excellent barrier properties against hydrogen permeation. Their baking protocols employ precision-controlled vacuum furnaces with temperature uniformity of ±2°C across complex geometries, utilizing multi-stage heating profiles with specific temperature plateaus at 190°C, 210°C, and 230°C to target different hydrogen trapping mechanisms. For critical high-strength steel components, Boeing has developed specialized titanium-based conversion coatings that create nanoscale barrier layers while maintaining dimensional tolerances within ±0.0005 inches. Their cathodic protection systems for aircraft structures utilize distributed sacrificial anodes with precisely engineered dissolution rates to maintain protective potentials within the narrow -820mV to -920mV range, preventing both corrosion and hydrogen evolution.

Strengths: Unparalleled expertise in aerospace-grade materials and processes with solutions validated under extreme operating conditions. Their technologies meet stringent safety and reliability requirements for flight-critical components. Weaknesses: Solutions are highly specialized for aerospace applications and often involve proprietary processes with limited transferability to other industries. Implementation typically requires extensive qualification testing and regulatory approval.

Robert Bosch GmbH

Technical Solution: Bosch has developed sophisticated hydrogen embrittlement prevention technologies for automotive and industrial components. Their multi-stage approach begins with proprietary pre-treatment processes that remove surface contaminants known to catalyze hydrogen absorption. Bosch's electroplating systems incorporate pulse-reverse current modulation that reduces hydrogen evolution by up to 60% compared to conventional DC plating. Their baking protocols utilize precision-controlled vacuum furnaces with temperature uniformity of ±3°C and programmable multi-stage heating profiles optimized for different component geometries. For critical high-strength fasteners and fuel system components, Bosch employs specialized zinc-nickel alloy coatings with chromium-free passivation layers that provide excellent hydrogen barriers while meeting stringent environmental regulations. Their cathodic protection systems integrate with vehicle electrical architectures to provide dynamic protection that adjusts based on environmental conditions, maintaining optimal protection potentials between -800mV and -1000mV while minimizing hydrogen generation.

Strengths: Exceptional systems integration capability allows for holistic solutions across complex manufacturing processes. Their technologies are extensively validated in demanding automotive applications. Weaknesses: Solutions often require significant capital investment and are primarily optimized for automotive-specific applications rather than broader industrial use.

Core Innovations in Cathodic Protection Technologies

Method of preventing hydrogen embrittlement

PatentInactiveJP2013087336A

Innovation

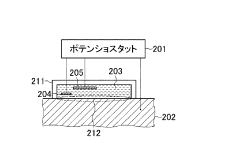

- A method involving contacting steel with an alkaline aqueous solution and applying a potential to oxidize hydrogen to hydrogen ions, forming a non-conductive film on the steel surface, using a potentiostat to control the electrode potential.

Prevention of hydrogen embrittlement of high-strength steel by hydrazine compositions

PatentInactiveUS3919014A

Innovation

- Adding potassium hydroxide to hydrazine-containing fuel compositions controls the dissociation constant of hydrazine, reducing acidity without forming a precipitate, allowing for long-term storage in austenitic steel tanks by neutralizing acidic impurities and preventing hydrogen embrittlement.

Material Selection Strategies for Embrittlement Resistance

Material selection represents a critical first line of defense against hydrogen embrittlement in engineering applications. The susceptibility of metals to hydrogen-induced damage varies significantly across different alloy systems. High-strength steels with tensile strengths exceeding 1000 MPa demonstrate particular vulnerability, while austenitic stainless steels generally exhibit superior resistance due to their face-centered cubic (FCC) crystal structure, which provides lower hydrogen diffusivity compared to body-centered cubic (BCC) structures.

Nickel-based alloys and certain aluminum alloys present viable alternatives in hydrogen-rich environments, offering inherently lower hydrogen solubility and diffusion rates. The microstructural characteristics of materials play a decisive role in embrittlement resistance, with fine-grained microstructures generally outperforming coarse-grained variants by providing more numerous hydrogen trapping sites that reduce hydrogen mobility to critical stress zones.

Precipitation-hardened alloys require particular attention, as coherent precipitates can serve as hydrogen traps but may also become initiation sites for hydrogen-assisted cracking under certain conditions. The introduction of specific alloying elements can significantly enhance resistance to hydrogen embrittlement. For instance, additions of chromium, molybdenum, and vanadium have demonstrated effectiveness in forming stable carbides that function as beneficial hydrogen traps.

Recent metallurgical innovations have focused on developing advanced high-entropy alloys (HEAs) with multiple principal elements in near-equiatomic proportions. These materials show promising resistance to hydrogen embrittlement due to their complex lattice distortion and numerous atomic interfaces that impede hydrogen diffusion pathways.

For applications involving electroplating processes, which inherently introduce hydrogen, selecting substrate materials with lower susceptibility becomes particularly important. Medium-carbon steels with carefully controlled heat treatments offer a practical compromise between mechanical properties and embrittlement resistance in many industrial applications.

The implementation of composite or laminate structures represents another strategic approach, where layers with different hydrogen permeation characteristics can be combined to create effective hydrogen barriers while maintaining required mechanical properties. This multi-material approach has shown particular promise in pressure vessel applications for hydrogen storage.

When selecting materials for hydrogen service, consideration must also be given to operational parameters including temperature cycling, pressure fluctuations, and mechanical loading profiles, as these factors significantly influence hydrogen uptake and mobility within the material microstructure.

Nickel-based alloys and certain aluminum alloys present viable alternatives in hydrogen-rich environments, offering inherently lower hydrogen solubility and diffusion rates. The microstructural characteristics of materials play a decisive role in embrittlement resistance, with fine-grained microstructures generally outperforming coarse-grained variants by providing more numerous hydrogen trapping sites that reduce hydrogen mobility to critical stress zones.

Precipitation-hardened alloys require particular attention, as coherent precipitates can serve as hydrogen traps but may also become initiation sites for hydrogen-assisted cracking under certain conditions. The introduction of specific alloying elements can significantly enhance resistance to hydrogen embrittlement. For instance, additions of chromium, molybdenum, and vanadium have demonstrated effectiveness in forming stable carbides that function as beneficial hydrogen traps.

Recent metallurgical innovations have focused on developing advanced high-entropy alloys (HEAs) with multiple principal elements in near-equiatomic proportions. These materials show promising resistance to hydrogen embrittlement due to their complex lattice distortion and numerous atomic interfaces that impede hydrogen diffusion pathways.

For applications involving electroplating processes, which inherently introduce hydrogen, selecting substrate materials with lower susceptibility becomes particularly important. Medium-carbon steels with carefully controlled heat treatments offer a practical compromise between mechanical properties and embrittlement resistance in many industrial applications.

The implementation of composite or laminate structures represents another strategic approach, where layers with different hydrogen permeation characteristics can be combined to create effective hydrogen barriers while maintaining required mechanical properties. This multi-material approach has shown particular promise in pressure vessel applications for hydrogen storage.

When selecting materials for hydrogen service, consideration must also be given to operational parameters including temperature cycling, pressure fluctuations, and mechanical loading profiles, as these factors significantly influence hydrogen uptake and mobility within the material microstructure.

Testing Standards and Quality Control Protocols

Effective testing standards and quality control protocols are essential components of any comprehensive hydrogen embrittlement prevention strategy. The industry has developed several standardized testing methods to evaluate materials' susceptibility to hydrogen embrittlement and verify the effectiveness of preventive measures. ASTM F519 stands as one of the most widely recognized standards, providing detailed procedures for mechanical hydrogen embrittlement testing of plated or coated materials. This test involves subjecting notched specimens to sustained loads while monitoring for delayed failures, offering quantitative data on embrittlement susceptibility.

ISO 15330 complements these efforts by focusing specifically on fasteners, establishing protocols for testing hydrogen embrittlement through pre-loading methods. For electroplated components, ASTM F1940 provides guidelines for detecting hydrogen embrittlement through thermal desorption analysis, enabling precise measurement of hydrogen concentration within materials.

Quality control in manufacturing environments typically follows a multi-tiered approach. First-article inspection protocols require thorough testing of initial production batches to establish baseline performance before full-scale manufacturing begins. Statistical process control (SPC) methods are then implemented to monitor key variables during production, including plating bath chemistry, current density, and baking parameters. These variables must remain within established control limits to ensure consistent quality.

Documentation requirements form another critical aspect of quality control, with manufacturers maintaining detailed records of process parameters, test results, and any deviations from standard procedures. Traceability systems enable the tracking of components throughout the production process, facilitating rapid identification and isolation of potentially affected batches should issues arise.

Non-destructive testing techniques have also been integrated into quality control protocols, with methods such as ultrasonic testing and electromagnetic techniques allowing for the detection of hydrogen-induced defects without compromising component integrity. These techniques are particularly valuable for high-value or critical components where destructive testing of samples is impractical.

Certification programs offered by organizations like NADCAP (National Aerospace and Defense Contractors Accreditation Program) provide standardized frameworks for quality assurance in hydrogen embrittlement prevention, particularly in aerospace and defense applications. These programs establish rigorous requirements for process control, personnel training, and documentation, ensuring consistent implementation of preventive measures across the supply chain.

ISO 15330 complements these efforts by focusing specifically on fasteners, establishing protocols for testing hydrogen embrittlement through pre-loading methods. For electroplated components, ASTM F1940 provides guidelines for detecting hydrogen embrittlement through thermal desorption analysis, enabling precise measurement of hydrogen concentration within materials.

Quality control in manufacturing environments typically follows a multi-tiered approach. First-article inspection protocols require thorough testing of initial production batches to establish baseline performance before full-scale manufacturing begins. Statistical process control (SPC) methods are then implemented to monitor key variables during production, including plating bath chemistry, current density, and baking parameters. These variables must remain within established control limits to ensure consistent quality.

Documentation requirements form another critical aspect of quality control, with manufacturers maintaining detailed records of process parameters, test results, and any deviations from standard procedures. Traceability systems enable the tracking of components throughout the production process, facilitating rapid identification and isolation of potentially affected batches should issues arise.

Non-destructive testing techniques have also been integrated into quality control protocols, with methods such as ultrasonic testing and electromagnetic techniques allowing for the detection of hydrogen-induced defects without compromising component integrity. These techniques are particularly valuable for high-value or critical components where destructive testing of samples is impractical.

Certification programs offered by organizations like NADCAP (National Aerospace and Defense Contractors Accreditation Program) provide standardized frameworks for quality assurance in hydrogen embrittlement prevention, particularly in aerospace and defense applications. These programs establish rigorous requirements for process control, personnel training, and documentation, ensuring consistent implementation of preventive measures across the supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!