Hydrogen Embrittlement In Fasteners: Preload Loss, Delayed Failure And Field Diagnostics

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement Background and Objectives

Hydrogen embrittlement (HE) represents one of the most significant metallurgical challenges in fastener technology, with documented cases dating back to the early 20th century. This phenomenon occurs when hydrogen atoms penetrate metal structures, causing a reduction in ductility and load-bearing capacity, ultimately leading to catastrophic failure. The evolution of this technical challenge has paralleled industrial development, becoming increasingly critical as high-strength fasteners have been deployed in more demanding applications across aerospace, automotive, and structural engineering sectors.

The historical trajectory of hydrogen embrittlement research shows distinct phases of understanding. Initial observations in the 1940s focused primarily on phenomenological descriptions, while the 1960s-1980s saw significant advances in mechanistic understanding through electron microscopy and fracture mechanics. Recent decades have witnessed the integration of computational modeling with experimental approaches, enabling more sophisticated prediction of embrittlement behavior.

Current technical trends indicate a shift toward preventive methodologies rather than reactive solutions. This includes advanced coating technologies, innovative heat treatment processes, and real-time monitoring systems that can detect early signs of hydrogen-induced degradation. The industry is moving toward a more holistic approach that considers the entire fastener lifecycle from manufacturing to service conditions.

The primary objectives of this technical investigation are threefold. First, to comprehensively analyze the mechanisms of preload loss in hydrogen-embrittled fasteners, particularly focusing on the time-dependent nature of this phenomenon. Second, to develop predictive models for delayed failure that account for variable environmental conditions and loading scenarios. Third, to evaluate emerging field diagnostic technologies that enable non-destructive assessment of hydrogen concentration and material degradation in installed fasteners.

These objectives align with the broader industry need for reliable fastening systems in critical applications where failure could result in significant economic losses or safety hazards. The increasing use of high-strength steels (>1000 MPa tensile strength) in lightweight structures has exacerbated the hydrogen embrittlement risk, making this research particularly timely.

The expected technical outcomes include improved testing protocols that better simulate real-world conditions, enhanced predictive capabilities for estimating fastener service life under hydrogen exposure, and practical field implementation strategies for monitoring technologies. These advancements would significantly contribute to industry standards and best practices for hydrogen management in fastener applications.

The historical trajectory of hydrogen embrittlement research shows distinct phases of understanding. Initial observations in the 1940s focused primarily on phenomenological descriptions, while the 1960s-1980s saw significant advances in mechanistic understanding through electron microscopy and fracture mechanics. Recent decades have witnessed the integration of computational modeling with experimental approaches, enabling more sophisticated prediction of embrittlement behavior.

Current technical trends indicate a shift toward preventive methodologies rather than reactive solutions. This includes advanced coating technologies, innovative heat treatment processes, and real-time monitoring systems that can detect early signs of hydrogen-induced degradation. The industry is moving toward a more holistic approach that considers the entire fastener lifecycle from manufacturing to service conditions.

The primary objectives of this technical investigation are threefold. First, to comprehensively analyze the mechanisms of preload loss in hydrogen-embrittled fasteners, particularly focusing on the time-dependent nature of this phenomenon. Second, to develop predictive models for delayed failure that account for variable environmental conditions and loading scenarios. Third, to evaluate emerging field diagnostic technologies that enable non-destructive assessment of hydrogen concentration and material degradation in installed fasteners.

These objectives align with the broader industry need for reliable fastening systems in critical applications where failure could result in significant economic losses or safety hazards. The increasing use of high-strength steels (>1000 MPa tensile strength) in lightweight structures has exacerbated the hydrogen embrittlement risk, making this research particularly timely.

The expected technical outcomes include improved testing protocols that better simulate real-world conditions, enhanced predictive capabilities for estimating fastener service life under hydrogen exposure, and practical field implementation strategies for monitoring technologies. These advancements would significantly contribute to industry standards and best practices for hydrogen management in fastener applications.

Market Demand for Hydrogen-Resistant Fasteners

The global market for hydrogen-resistant fasteners has been experiencing significant growth, driven primarily by industries where hydrogen embrittlement poses critical safety and performance risks. The aerospace sector represents one of the largest demand segments, with an estimated annual growth rate exceeding the industry average due to stringent safety requirements and the catastrophic consequences of fastener failure in aircraft structures.

The automotive industry, particularly with the rise of hydrogen fuel cell vehicles, has emerged as another major consumer of hydrogen-resistant fasteners. As hydrogen infrastructure expands globally, the demand for specialized fasteners capable of withstanding hydrogen exposure without degradation has increased substantially across the transportation sector.

Oil and gas operations, especially in deep-sea drilling and high-pressure hydrogen environments, constitute a premium market segment willing to pay significantly higher prices for fasteners with proven resistance to hydrogen embrittlement. This sector prioritizes long-term reliability over initial cost considerations, creating a stable demand for high-performance solutions.

The renewable energy sector, particularly wind energy, has become an unexpected growth driver for hydrogen-resistant fasteners. Wind turbines operating in marine environments face unique challenges from hydrogen generated through galvanic corrosion processes, creating specialized requirements for fastener performance under combined stress conditions.

Market research indicates that industries are increasingly moving away from traditional post-plating baking treatments toward inherently resistant fastener materials and designs. This shift reflects growing awareness of hydrogen embrittlement risks and the limitations of conventional mitigation approaches in preventing delayed failures.

The construction industry, particularly for critical infrastructure projects in corrosive environments, has begun specifying hydrogen-resistant fasteners in their material requirements. This trend has expanded the market beyond traditional industrial applications into broader commercial construction segments.

Geographically, demand is highest in regions with established industrial bases and stringent safety regulations, with North America, Europe, and Japan leading consumption. However, emerging economies in Asia, particularly China and India, are showing the fastest growth rates as their manufacturing capabilities advance and safety standards evolve.

Market forecasts suggest that the specialized segment for fasteners with integrated diagnostic capabilities for hydrogen detection represents the highest growth potential, reflecting industry's increasing focus on predictive maintenance and real-time monitoring of critical components.

The automotive industry, particularly with the rise of hydrogen fuel cell vehicles, has emerged as another major consumer of hydrogen-resistant fasteners. As hydrogen infrastructure expands globally, the demand for specialized fasteners capable of withstanding hydrogen exposure without degradation has increased substantially across the transportation sector.

Oil and gas operations, especially in deep-sea drilling and high-pressure hydrogen environments, constitute a premium market segment willing to pay significantly higher prices for fasteners with proven resistance to hydrogen embrittlement. This sector prioritizes long-term reliability over initial cost considerations, creating a stable demand for high-performance solutions.

The renewable energy sector, particularly wind energy, has become an unexpected growth driver for hydrogen-resistant fasteners. Wind turbines operating in marine environments face unique challenges from hydrogen generated through galvanic corrosion processes, creating specialized requirements for fastener performance under combined stress conditions.

Market research indicates that industries are increasingly moving away from traditional post-plating baking treatments toward inherently resistant fastener materials and designs. This shift reflects growing awareness of hydrogen embrittlement risks and the limitations of conventional mitigation approaches in preventing delayed failures.

The construction industry, particularly for critical infrastructure projects in corrosive environments, has begun specifying hydrogen-resistant fasteners in their material requirements. This trend has expanded the market beyond traditional industrial applications into broader commercial construction segments.

Geographically, demand is highest in regions with established industrial bases and stringent safety regulations, with North America, Europe, and Japan leading consumption. However, emerging economies in Asia, particularly China and India, are showing the fastest growth rates as their manufacturing capabilities advance and safety standards evolve.

Market forecasts suggest that the specialized segment for fasteners with integrated diagnostic capabilities for hydrogen detection represents the highest growth potential, reflecting industry's increasing focus on predictive maintenance and real-time monitoring of critical components.

Current Challenges in Hydrogen Embrittlement Prevention

Despite significant advancements in understanding hydrogen embrittlement (HE) mechanisms, the prevention of this phenomenon in fasteners remains challenging across multiple fronts. Current prevention strategies face limitations in their effectiveness, particularly in high-strength fasteners where the risk of embrittlement increases exponentially with tensile strength.

Material selection presents a significant challenge as traditional high-strength steels remain vulnerable to hydrogen damage. While alternative materials like certain stainless steels and titanium alloys offer improved resistance, they introduce trade-offs in mechanical properties, cost considerations, and manufacturing complexities that limit their widespread adoption in critical applications.

Coating technologies, though widely implemented, struggle to provide complete protection. Conventional zinc plating processes, even with supplementary chromate treatments, cannot guarantee total hydrogen exclusion. The industry's transition away from hexavalent chromium due to environmental regulations has further complicated this landscape, as alternative passivation systems often demonstrate reduced effectiveness in hydrogen barrier properties.

Baking procedures for hydrogen degassing face significant practical limitations. The time-temperature relationships required for effective hydrogen removal often conflict with production schedules and economic constraints. Moreover, the effectiveness of baking diminishes with increasing material hardness and fastener diameter, creating a technical ceiling that current thermal processes cannot overcome.

Quality control methodologies represent another critical challenge. Non-destructive testing techniques capable of reliably detecting hydrogen concentration or predicting embrittlement susceptibility in production environments remain elusive. Current methods either lack sensitivity, require destructive sampling, or prove impractical for high-volume manufacturing settings.

The industry also grapples with standardization issues. Existing standards for hydrogen embrittlement testing exhibit inconsistencies in methodologies and acceptance criteria across different sectors and regions. This fragmentation complicates the development of universally effective prevention strategies and creates regulatory compliance challenges for global manufacturers.

Perhaps most concerning is the knowledge gap regarding environmental factors that trigger hydrogen embrittlement in field applications. The synergistic effects of mechanical stress, environmental exposure, and time-dependent hydrogen diffusion remain inadequately characterized, making it difficult to predict failure risks in diverse service environments accurately.

These multifaceted challenges necessitate a comprehensive approach to hydrogen embrittlement prevention that addresses material science innovations, process engineering improvements, advanced testing methodologies, and enhanced predictive modeling capabilities to ensure fastener reliability in critical applications.

Material selection presents a significant challenge as traditional high-strength steels remain vulnerable to hydrogen damage. While alternative materials like certain stainless steels and titanium alloys offer improved resistance, they introduce trade-offs in mechanical properties, cost considerations, and manufacturing complexities that limit their widespread adoption in critical applications.

Coating technologies, though widely implemented, struggle to provide complete protection. Conventional zinc plating processes, even with supplementary chromate treatments, cannot guarantee total hydrogen exclusion. The industry's transition away from hexavalent chromium due to environmental regulations has further complicated this landscape, as alternative passivation systems often demonstrate reduced effectiveness in hydrogen barrier properties.

Baking procedures for hydrogen degassing face significant practical limitations. The time-temperature relationships required for effective hydrogen removal often conflict with production schedules and economic constraints. Moreover, the effectiveness of baking diminishes with increasing material hardness and fastener diameter, creating a technical ceiling that current thermal processes cannot overcome.

Quality control methodologies represent another critical challenge. Non-destructive testing techniques capable of reliably detecting hydrogen concentration or predicting embrittlement susceptibility in production environments remain elusive. Current methods either lack sensitivity, require destructive sampling, or prove impractical for high-volume manufacturing settings.

The industry also grapples with standardization issues. Existing standards for hydrogen embrittlement testing exhibit inconsistencies in methodologies and acceptance criteria across different sectors and regions. This fragmentation complicates the development of universally effective prevention strategies and creates regulatory compliance challenges for global manufacturers.

Perhaps most concerning is the knowledge gap regarding environmental factors that trigger hydrogen embrittlement in field applications. The synergistic effects of mechanical stress, environmental exposure, and time-dependent hydrogen diffusion remain inadequately characterized, making it difficult to predict failure risks in diverse service environments accurately.

These multifaceted challenges necessitate a comprehensive approach to hydrogen embrittlement prevention that addresses material science innovations, process engineering improvements, advanced testing methodologies, and enhanced predictive modeling capabilities to ensure fastener reliability in critical applications.

Existing Solutions for Hydrogen Embrittlement Mitigation

01 Mechanisms of hydrogen embrittlement in fasteners

Hydrogen embrittlement occurs when hydrogen atoms penetrate into the metal structure of fasteners, causing a reduction in ductility and tensile strength. This leads to delayed failure under stress, even at stress levels below the yield strength. The hydrogen can originate from various sources including manufacturing processes, environmental exposure, or corrosion reactions. The embrittlement mechanism involves hydrogen diffusion to high-stress regions, leading to microcrack formation and eventual catastrophic failure without warning signs.- Mechanisms of hydrogen embrittlement in fasteners: Hydrogen embrittlement occurs when hydrogen atoms penetrate into the metal structure of fasteners, causing reduced ductility and tensile strength. This leads to delayed failure under sustained loads, even below the yield strength of the material. The hydrogen can be introduced during manufacturing processes like electroplating or from environmental exposure. The embrittlement mechanism involves hydrogen accumulation at stress points, promoting crack initiation and propagation, ultimately resulting in catastrophic failure without warning signs.

- Preload loss in hydrogen-affected fasteners: Hydrogen-affected fasteners experience significant preload loss over time, compromising joint integrity. When hydrogen diffuses into the fastener material, it causes internal stress relaxation and dimensional changes that reduce the clamping force. This preload loss occurs gradually and can lead to loosening of bolted connections, vibration-induced failures, and eventual joint separation. The rate of preload loss depends on factors such as initial tightening torque, material composition, and environmental exposure conditions.

- Material selection and treatments to mitigate hydrogen embrittlement: Selecting appropriate materials and applying specialized treatments can significantly reduce hydrogen embrittlement susceptibility in fasteners. Lower-strength steels (below 1000 MPa) generally show better resistance to hydrogen effects. Post-plating baking processes at controlled temperatures help diffuse hydrogen out of the material. Alternative materials like certain stainless steel grades, titanium alloys, or aluminum can be used in hydrogen-rich environments. Surface treatments such as specialized coatings create barriers against hydrogen penetration while maintaining corrosion resistance.

- Testing and detection methods for hydrogen embrittlement: Various testing methodologies have been developed to evaluate fasteners' susceptibility to hydrogen embrittlement and detect early signs of failure. These include sustained load testing where fasteners are subjected to constant loads below yield strength for extended periods to identify delayed failure tendencies. Nondestructive evaluation techniques using ultrasonic or acoustic emission can detect internal crack formation. Specialized hydrogen content measurement methods quantify hydrogen concentration in fastener materials. Accelerated testing protocols simulate long-term hydrogen exposure effects in shorter timeframes.

- Design considerations for hydrogen-resistant fastener systems: Proper design of fastener systems can minimize hydrogen embrittlement risks and preload loss. This includes specifying appropriate torque values that balance joint security against excessive stress that might accelerate hydrogen-induced failures. Implementing controlled tightening sequences and methods ensures uniform load distribution. Using specialized washers or locking mechanisms helps maintain preload despite hydrogen effects. Designing for accessibility allows periodic inspection and retightening. Incorporating redundancy in critical connections provides fail-safe protection against individual fastener failures due to hydrogen embrittlement.

02 Preload loss in hydrogen-affected fasteners

Fasteners subjected to hydrogen embrittlement often experience significant preload loss over time. This reduction in clamping force can occur due to hydrogen-induced relaxation of the fastener material, dimensional changes in the fastener, or microcrack formation that affects the stress distribution. Preload loss compromises joint integrity and can lead to loosening, vibration-induced failures, or complete joint separation. The rate of preload loss is influenced by factors such as initial preload level, environmental conditions, and material properties.Expand Specific Solutions03 Material selection and treatments to mitigate hydrogen embrittlement

Selecting appropriate materials and applying specialized treatments can significantly reduce hydrogen embrittlement susceptibility in fasteners. Lower-strength steels generally show better resistance than high-strength variants. Protective coatings such as zinc-nickel alloys or specialized plating processes can create barriers against hydrogen penetration. Heat treatments like baking after plating help remove trapped hydrogen. Alternative materials such as certain stainless steel grades, titanium alloys, or precipitation-hardened alloys can offer improved resistance to hydrogen-induced damage while maintaining necessary mechanical properties.Expand Specific Solutions04 Testing and detection methods for hydrogen embrittlement

Various testing methodologies have been developed to evaluate fasteners' susceptibility to hydrogen embrittlement and detect early signs of damage. These include sustained load testing, where fasteners are subjected to constant loads below yield strength to identify delayed failure tendencies. Electrochemical techniques can measure hydrogen permeation rates and concentration. Non-destructive testing methods such as acoustic emission monitoring can detect microcrack formation before catastrophic failure. Specialized inspection protocols help identify affected fasteners before critical failure occurs in service.Expand Specific Solutions05 Design considerations and installation practices for hydrogen environments

Proper design and installation practices can minimize hydrogen embrittlement risks in fastener applications. These include specifying appropriate torque values that balance joint security against excessive stress, implementing controlled tightening sequences, and designing for stress distribution that avoids localized high-stress regions. Environmental protection measures such as sealants or protective barriers can reduce hydrogen exposure. Regular inspection schedules and maintenance protocols help identify at-risk fasteners before failure. For critical applications, redundant fastening systems or alternative joining methods may be considered to prevent catastrophic failures.Expand Specific Solutions

Key Industry Players in Fastener Technology

Hydrogen embrittlement in fasteners represents a critical challenge in the advanced materials sector, currently in a growth phase with increasing market demand driven by safety concerns across aerospace, automotive, and energy industries. The global market for hydrogen embrittlement prevention solutions is expanding rapidly, estimated at several billion dollars annually. Technologically, the field remains in development with varying maturity levels across different solutions. Leading companies like Boeing, NIPPON STEEL, and Hilti AG have made significant advancements in preload monitoring technologies, while POSCO Holdings and JFE Steel focus on material innovations. Research institutions including Tohoku University and IIT Madras collaborate with industry players like Valley Forge & Bolts to develop field diagnostic tools, though comprehensive solutions for delayed failure prediction remain elusive.

The Boeing Co.

Technical Solution: Boeing has developed an advanced multi-layered approach to hydrogen embrittlement management in aerospace fasteners. Their proprietary Hydrogen Mitigation System (HMS) combines specialized material selection, controlled manufacturing processes, and innovative coating technologies. Boeing's fasteners undergo a rigorous hydrogen degassing treatment at precisely controlled temperatures (150-200°C) for extended periods to reduce hydrogen content below critical thresholds. Their fastener designs incorporate graduated hardness zones to minimize stress concentration while maintaining required mechanical properties. For field diagnostics, Boeing employs a combination of ultrasonic testing and electrochemical impedance spectroscopy to detect early signs of hydrogen damage in installed fasteners. Their Smart Fastener Technology incorporates embedded sensors that can monitor preload conditions and alert maintenance crews to potential issues before catastrophic failure occurs. Boeing's approach includes comprehensive material traceability and batch testing to ensure consistent performance across all critical fastener applications.

Strengths: Exceptional quality control throughout manufacturing process; advanced non-destructive testing capabilities for in-service inspection; comprehensive material science approach addressing multiple failure mechanisms simultaneously. Weaknesses: Significantly higher cost compared to standard industrial fasteners; complex implementation requiring specialized training; primarily optimized for aerospace applications with limited transferability to other industries.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed an integrated approach to hydrogen embrittlement management in high-strength fasteners through their Advanced Hydrogen Control Technology (AHCT). Their solution combines metallurgical innovations with specialized surface treatments to minimize hydrogen absorption and diffusion. Nippon Steel's proprietary steel compositions incorporate fine-dispersed vanadium carbide precipitates that act as hydrogen trapping sites, effectively reducing the concentration of diffusible hydrogen that causes embrittlement. Their manufacturing process includes a precisely controlled dehydrogenation heat treatment at 200-250°C for 8-24 hours depending on fastener dimensions. For critical applications, they've developed a multi-layer coating system that combines zinc-nickel base layers with specialized topcoats containing hydrogen scavengers. Their field diagnostic approach includes portable hydrogen analyzers capable of detecting hydrogen content in installed fasteners through non-destructive electrochemical methods. Nippon Steel's research has established correlations between specific microstructural features and hydrogen embrittlement resistance, allowing for tailored solutions based on application requirements.

Strengths: Superior metallurgical understanding of hydrogen-material interactions; comprehensive material design approach from composition to final coating; extensive research database correlating microstructure to hydrogen embrittlement resistance. Weaknesses: Solutions often require specialized manufacturing capabilities; higher production costs compared to conventional fasteners; some diagnostic techniques require specialized training and equipment.

Critical Patents and Research on Fastener Embrittlement

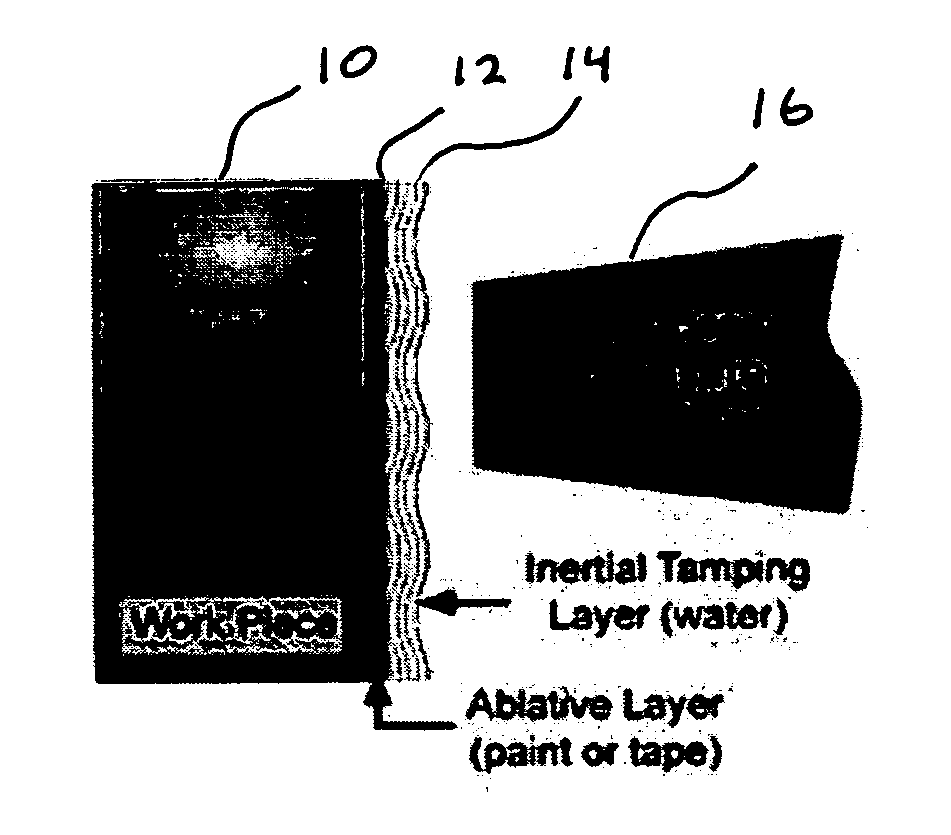

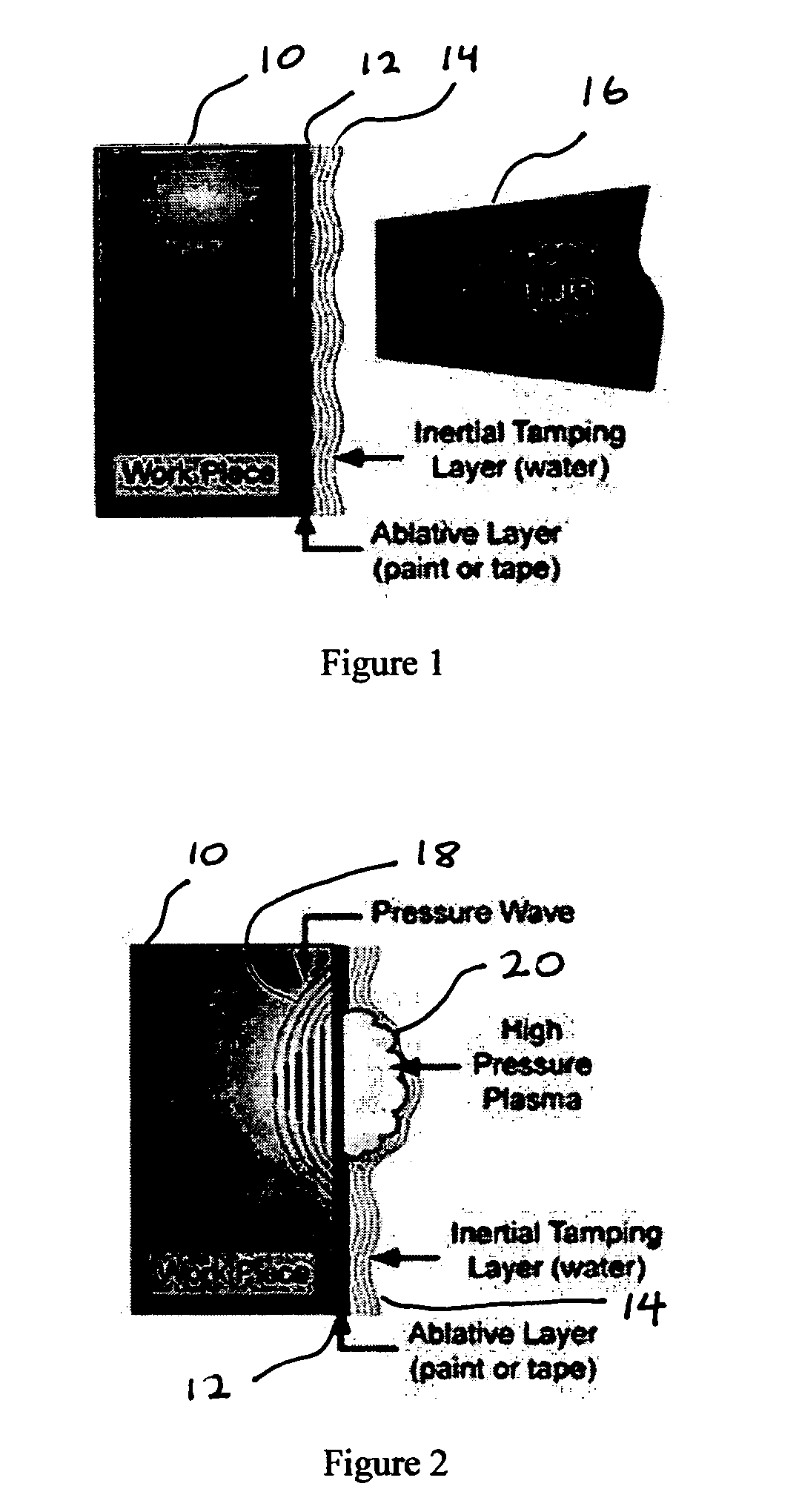

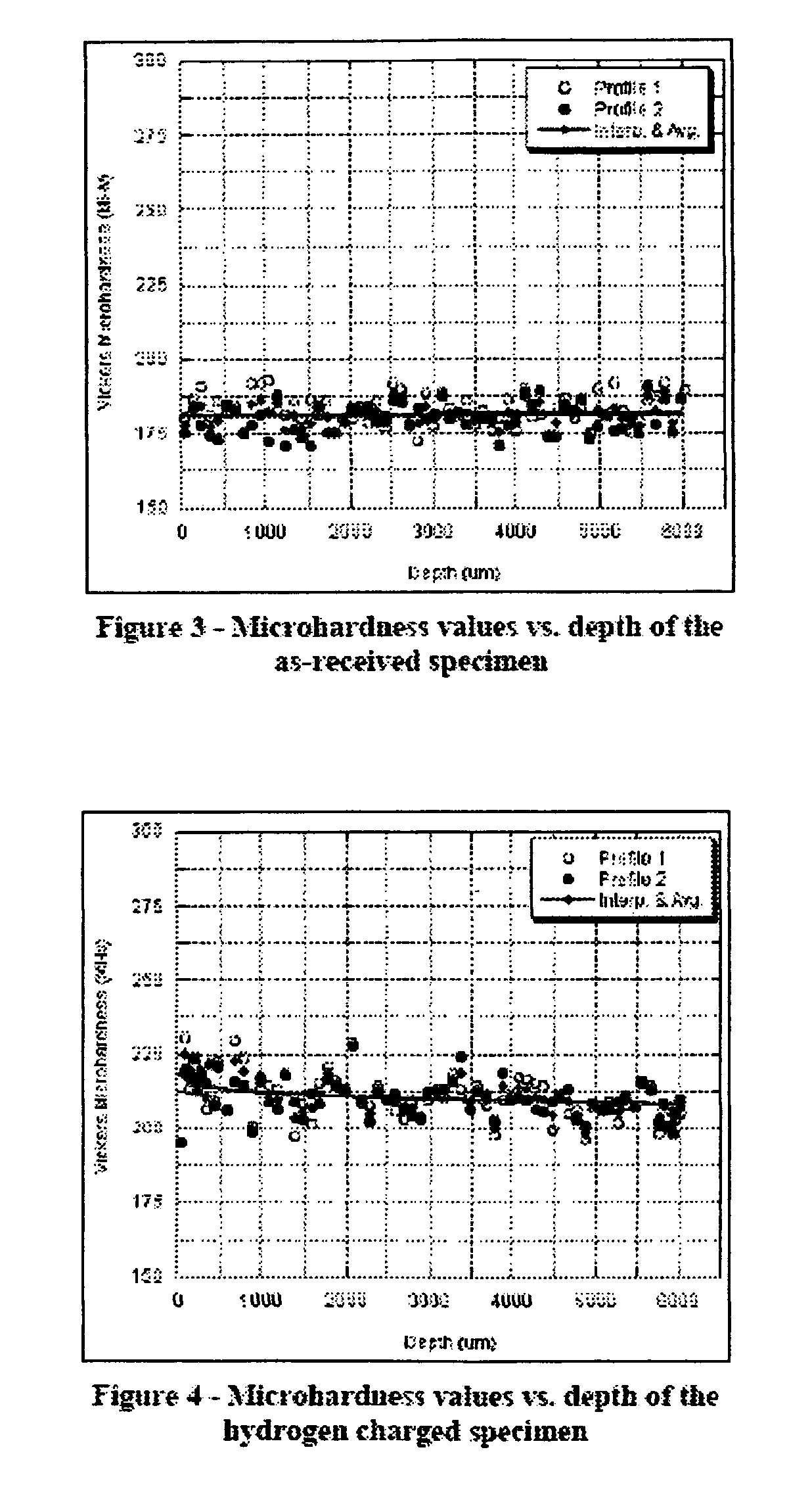

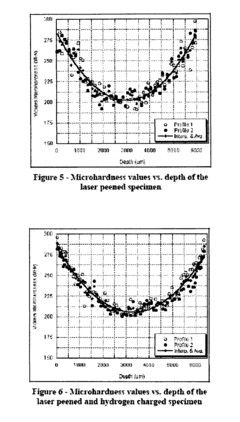

Laser peening for reducing hydrogen embrittlement

PatentActiveUS20070221641A1

Innovation

- A laser peening process that densifies the metal surface and sub-layer, altering its chemical activity to reduce hydrogen penetration, using parameters such as long pulses, large footprints, and multiple layers to induce compressive stress and resistance to hydrogen uptake.

Fastening element

PatentInactiveUS7824142B2

Innovation

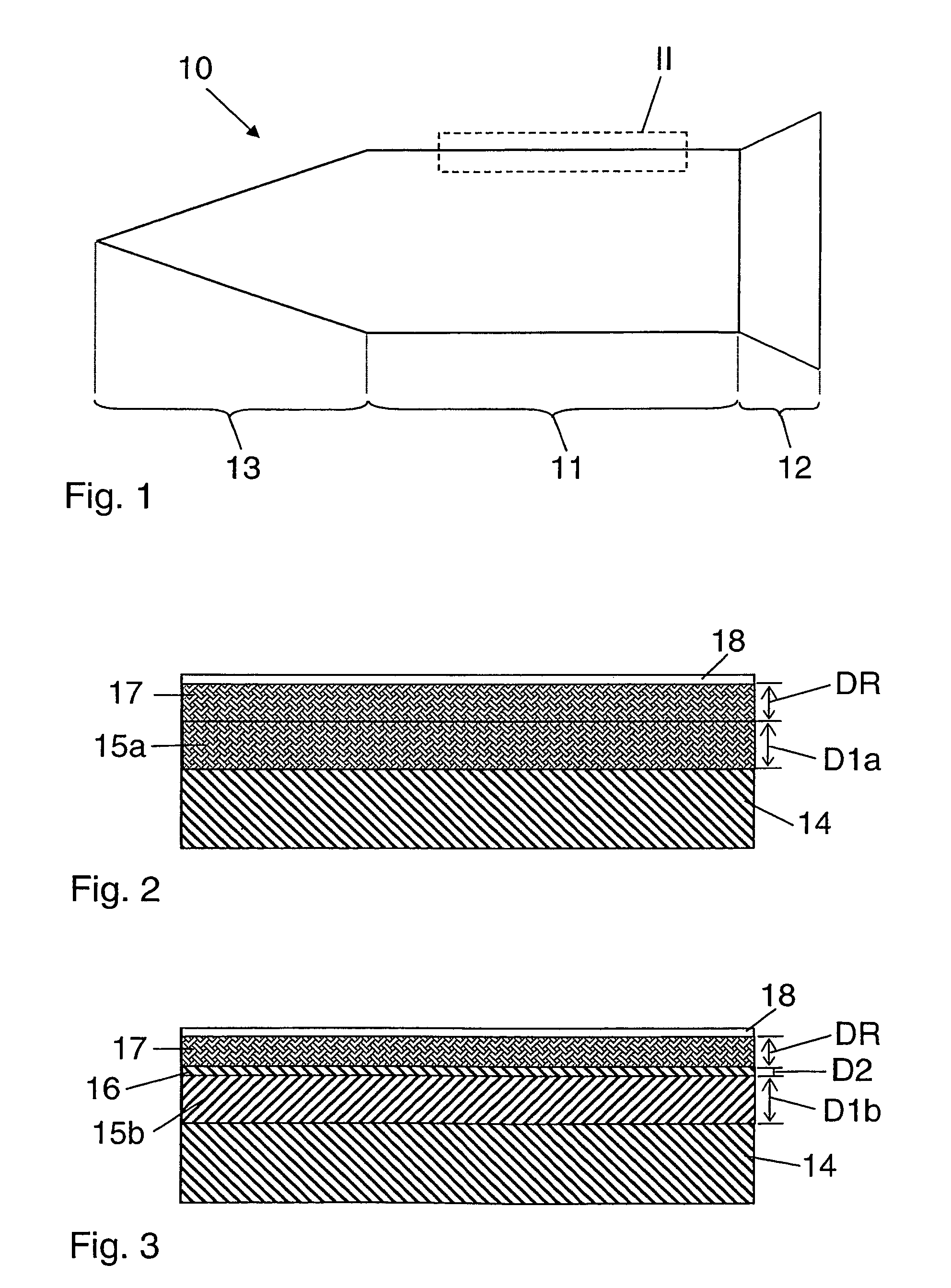

- A fastening element with a core zone of martensitic or bainitic carbon steel and a skin zone of low-carbon austenitic steel, incorporating an intermediate zone of ferritic or austenitic steel with varying alloy metal concentrations, which provides a double filtration effect against hydrogen embrittlement and increased toughness, while allowing for cost-effective production and corrosion resistance.

Non-Destructive Testing Methods for Field Diagnostics

Non-destructive testing (NDT) methods represent a critical approach for field diagnostics of hydrogen embrittlement in fasteners without compromising structural integrity. These techniques enable real-time assessment of fastener conditions while maintaining operational functionality of assembled structures.

Ultrasonic testing stands as a primary NDT method, utilizing high-frequency sound waves to detect internal defects. When applied to hydrogen-embrittled fasteners, ultrasonic velocity measurements can identify microstructural changes and crack initiation sites. Advanced techniques such as Time-of-Flight Diffraction (TOFD) provide enhanced sensitivity for detecting hydrogen-induced microcracks before catastrophic failure occurs.

Acoustic emission testing offers complementary capabilities by monitoring stress waves generated during crack propagation. This method proves particularly valuable for detecting active hydrogen embrittlement processes in fasteners under load. The distinctive acoustic signature of hydrogen-assisted cracking allows for early identification of compromised fasteners in field conditions.

Electromagnetic methods, including eddy current testing and magnetic flux leakage, enable surface and near-surface defect detection. These techniques can identify hydrogen-induced surface cracks and material property changes. Recent advancements in electromagnetic array technology have improved detection sensitivity for hydrogen damage in various fastener materials and geometries.

Radiographic testing provides visualization of internal structures through X-ray or gamma-ray imaging. Digital radiography and computed tomography offer three-dimensional insights into hydrogen damage progression within fasteners. These methods can detect hydrogen-induced void formation and crack networks that might remain undetected by other techniques.

Electrochemical testing methods measure hydrogen concentration and diffusion characteristics in fastener materials. Techniques such as hydrogen permeation testing and potentiodynamic polarization can quantify hydrogen content and assess embrittlement susceptibility in field environments. Portable electrochemical sensors have emerged as promising tools for on-site hydrogen detection.

Infrared thermography detects thermal anomalies associated with stress concentration and crack formation. When applied to fasteners under cyclic loading, this technique can identify areas experiencing hydrogen-enhanced localized plasticity before visible damage occurs. Advanced signal processing algorithms improve detection sensitivity in variable field conditions.

Recent developments in portable NDT equipment have significantly enhanced field diagnostic capabilities. Miniaturized ultrasonic arrays, handheld eddy current devices, and smartphone-integrated thermal cameras now enable comprehensive on-site assessment of hydrogen embrittlement in fasteners across diverse industrial applications.

Ultrasonic testing stands as a primary NDT method, utilizing high-frequency sound waves to detect internal defects. When applied to hydrogen-embrittled fasteners, ultrasonic velocity measurements can identify microstructural changes and crack initiation sites. Advanced techniques such as Time-of-Flight Diffraction (TOFD) provide enhanced sensitivity for detecting hydrogen-induced microcracks before catastrophic failure occurs.

Acoustic emission testing offers complementary capabilities by monitoring stress waves generated during crack propagation. This method proves particularly valuable for detecting active hydrogen embrittlement processes in fasteners under load. The distinctive acoustic signature of hydrogen-assisted cracking allows for early identification of compromised fasteners in field conditions.

Electromagnetic methods, including eddy current testing and magnetic flux leakage, enable surface and near-surface defect detection. These techniques can identify hydrogen-induced surface cracks and material property changes. Recent advancements in electromagnetic array technology have improved detection sensitivity for hydrogen damage in various fastener materials and geometries.

Radiographic testing provides visualization of internal structures through X-ray or gamma-ray imaging. Digital radiography and computed tomography offer three-dimensional insights into hydrogen damage progression within fasteners. These methods can detect hydrogen-induced void formation and crack networks that might remain undetected by other techniques.

Electrochemical testing methods measure hydrogen concentration and diffusion characteristics in fastener materials. Techniques such as hydrogen permeation testing and potentiodynamic polarization can quantify hydrogen content and assess embrittlement susceptibility in field environments. Portable electrochemical sensors have emerged as promising tools for on-site hydrogen detection.

Infrared thermography detects thermal anomalies associated with stress concentration and crack formation. When applied to fasteners under cyclic loading, this technique can identify areas experiencing hydrogen-enhanced localized plasticity before visible damage occurs. Advanced signal processing algorithms improve detection sensitivity in variable field conditions.

Recent developments in portable NDT equipment have significantly enhanced field diagnostic capabilities. Miniaturized ultrasonic arrays, handheld eddy current devices, and smartphone-integrated thermal cameras now enable comprehensive on-site assessment of hydrogen embrittlement in fasteners across diverse industrial applications.

Standards and Compliance Requirements for Critical Applications

Compliance with industry standards is paramount in sectors where hydrogen embrittlement poses significant risks. The aerospace industry adheres to stringent standards such as AMS2759/9 and ASTM F519, which outline specific requirements for hydrogen embrittlement testing and prevention in high-strength fasteners. These standards mandate precise testing protocols, including sustained load testing and environmental exposure assessments to evaluate susceptibility to hydrogen-induced failure.

In the automotive sector, standards like SAE J1237 and ISO 15330 govern fastener specifications with particular attention to hydrogen embrittlement prevention. These standards specify acceptable hydrogen concentration thresholds and establish protocols for baking procedures to mitigate hydrogen absorption during manufacturing processes. Compliance with these standards is increasingly critical as automotive designs incorporate higher-strength materials to meet lightweighting objectives.

The oil and gas industry follows NACE MR0175/ISO 15156 standards, which provide comprehensive guidelines for materials selection and treatment in hydrogen sulfide environments. These standards establish specific requirements for fastener materials, coatings, and installation procedures to minimize hydrogen embrittlement risks in corrosive environments. Regular inspection protocols are also mandated to detect early signs of hydrogen-induced damage.

For nuclear applications, standards such as ASME BPVC Section III impose rigorous requirements on fastener materials and manufacturing processes. These include detailed specifications for material composition, heat treatment procedures, and non-destructive testing methods to ensure fastener integrity throughout the operational lifecycle. Compliance documentation must be maintained for the entire service life of nuclear components.

Regulatory bodies like the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) enforce these standards through certification processes that require extensive documentation of compliance. This includes material certifications, process validation records, and test results demonstrating resistance to hydrogen embrittlement under specified conditions.

Recent updates to international standards have incorporated advanced testing methodologies, including electrochemical hydrogen permeation techniques and acoustic emission monitoring, to provide more accurate assessment of hydrogen embrittlement susceptibility. These evolving standards reflect growing understanding of hydrogen-material interactions and aim to establish more predictive measures of long-term fastener performance.

Compliance with these standards requires comprehensive quality management systems that ensure traceability throughout the supply chain, from raw material sourcing to final installation. This includes documentation of material composition, manufacturing processes, surface treatments, and testing results for each batch of fasteners used in critical applications.

In the automotive sector, standards like SAE J1237 and ISO 15330 govern fastener specifications with particular attention to hydrogen embrittlement prevention. These standards specify acceptable hydrogen concentration thresholds and establish protocols for baking procedures to mitigate hydrogen absorption during manufacturing processes. Compliance with these standards is increasingly critical as automotive designs incorporate higher-strength materials to meet lightweighting objectives.

The oil and gas industry follows NACE MR0175/ISO 15156 standards, which provide comprehensive guidelines for materials selection and treatment in hydrogen sulfide environments. These standards establish specific requirements for fastener materials, coatings, and installation procedures to minimize hydrogen embrittlement risks in corrosive environments. Regular inspection protocols are also mandated to detect early signs of hydrogen-induced damage.

For nuclear applications, standards such as ASME BPVC Section III impose rigorous requirements on fastener materials and manufacturing processes. These include detailed specifications for material composition, heat treatment procedures, and non-destructive testing methods to ensure fastener integrity throughout the operational lifecycle. Compliance documentation must be maintained for the entire service life of nuclear components.

Regulatory bodies like the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) enforce these standards through certification processes that require extensive documentation of compliance. This includes material certifications, process validation records, and test results demonstrating resistance to hydrogen embrittlement under specified conditions.

Recent updates to international standards have incorporated advanced testing methodologies, including electrochemical hydrogen permeation techniques and acoustic emission monitoring, to provide more accurate assessment of hydrogen embrittlement susceptibility. These evolving standards reflect growing understanding of hydrogen-material interactions and aim to establish more predictive measures of long-term fastener performance.

Compliance with these standards requires comprehensive quality management systems that ensure traceability throughout the supply chain, from raw material sourcing to final installation. This includes documentation of material composition, manufacturing processes, surface treatments, and testing results for each batch of fasteners used in critical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!