How Hydrogen Embrittlement Management Aligns With ISO/API Acceptance Criteria?

SEP 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Embrittlement Background and Objectives

Hydrogen embrittlement (HE) represents one of the most significant challenges in materials science and engineering, particularly in industries where high-strength metals are exposed to hydrogen-rich environments. The phenomenon was first documented in the late 19th century, but comprehensive understanding has evolved significantly over the past several decades with advances in microscopy, computational modeling, and materials testing methodologies.

The evolution of hydrogen embrittlement research has progressed through distinct phases: initial observation and documentation, mechanistic understanding, predictive modeling, and now toward integrated management systems aligned with international standards. This progression reflects the increasing sophistication of both our understanding of the underlying physics and our approach to industrial risk management.

Current technological trends in hydrogen embrittlement research focus on in-situ monitoring techniques, development of hydrogen-resistant alloys, and implementation of comprehensive management protocols that address the entire lifecycle of components susceptible to HE. The emergence of hydrogen as a clean energy carrier has further accelerated research in this field, as infrastructure for hydrogen storage and transport must be designed with embrittlement resistance as a primary consideration.

The primary objective of hydrogen embrittlement management is to ensure structural integrity and operational safety while optimizing component performance and service life. This requires balancing sometimes competing priorities: material strength, cost-effectiveness, and resistance to environmental degradation. Modern management approaches increasingly emphasize predictive rather than reactive methodologies.

ISO and API standards have evolved to provide structured frameworks for hydrogen embrittlement management, establishing acceptance criteria that define the boundaries of safe operation. These standards incorporate both empirical knowledge gained from field experience and theoretical understanding derived from laboratory research. Key standards include ISO 15156/NACE MR0175 for materials in H2S-containing environments and API RP 941 for hydrogen pressure vessel steels.

The alignment of hydrogen embrittlement management practices with these international standards represents a critical intersection of scientific understanding and practical implementation. This alignment ensures that theoretical knowledge translates into effective risk mitigation strategies across diverse industrial applications, from oil and gas production to automotive manufacturing and renewable energy systems.

The technological goal of current research is to develop more precise, quantitative relationships between material properties, environmental conditions, and embrittlement susceptibility that can be directly incorporated into standards-based acceptance criteria, thereby reducing reliance on overly conservative safety factors while maintaining or improving system reliability.

The evolution of hydrogen embrittlement research has progressed through distinct phases: initial observation and documentation, mechanistic understanding, predictive modeling, and now toward integrated management systems aligned with international standards. This progression reflects the increasing sophistication of both our understanding of the underlying physics and our approach to industrial risk management.

Current technological trends in hydrogen embrittlement research focus on in-situ monitoring techniques, development of hydrogen-resistant alloys, and implementation of comprehensive management protocols that address the entire lifecycle of components susceptible to HE. The emergence of hydrogen as a clean energy carrier has further accelerated research in this field, as infrastructure for hydrogen storage and transport must be designed with embrittlement resistance as a primary consideration.

The primary objective of hydrogen embrittlement management is to ensure structural integrity and operational safety while optimizing component performance and service life. This requires balancing sometimes competing priorities: material strength, cost-effectiveness, and resistance to environmental degradation. Modern management approaches increasingly emphasize predictive rather than reactive methodologies.

ISO and API standards have evolved to provide structured frameworks for hydrogen embrittlement management, establishing acceptance criteria that define the boundaries of safe operation. These standards incorporate both empirical knowledge gained from field experience and theoretical understanding derived from laboratory research. Key standards include ISO 15156/NACE MR0175 for materials in H2S-containing environments and API RP 941 for hydrogen pressure vessel steels.

The alignment of hydrogen embrittlement management practices with these international standards represents a critical intersection of scientific understanding and practical implementation. This alignment ensures that theoretical knowledge translates into effective risk mitigation strategies across diverse industrial applications, from oil and gas production to automotive manufacturing and renewable energy systems.

The technological goal of current research is to develop more precise, quantitative relationships between material properties, environmental conditions, and embrittlement susceptibility that can be directly incorporated into standards-based acceptance criteria, thereby reducing reliance on overly conservative safety factors while maintaining or improving system reliability.

Industry Demand for Hydrogen Embrittlement Solutions

The global demand for effective hydrogen embrittlement (HE) solutions has surged significantly across multiple industrial sectors, particularly in oil and gas, aerospace, automotive, and renewable energy. This growth is primarily driven by the increasing use of high-strength steels and other susceptible materials in critical applications where failure could lead to catastrophic consequences.

In the oil and gas sector, the transition toward sour service environments with higher H2S content has intensified the need for materials and components resistant to hydrogen-induced damage. Industry reports indicate that approximately 25% of failures in oil and gas pipelines and equipment can be attributed to hydrogen embrittlement, creating an urgent market need for reliable prevention strategies that align with ISO 15156 and API 5CT standards.

The aerospace industry faces similar challenges, with hydrogen embrittlement being a critical concern in landing gear components, fasteners, and structural elements. The market for specialized treatments and materials that meet aerospace standards has expanded by nearly 15% annually over the past five years, reflecting the industry's commitment to addressing this issue.

Automotive manufacturers, particularly those involved in electric vehicle production, are increasingly concerned about hydrogen embrittlement in high-strength fasteners and structural components. The market for hydrogen embrittlement prevention solutions in this sector is projected to grow substantially as vehicle designs incorporate more advanced high-strength materials to reduce weight while maintaining structural integrity.

The renewable energy sector, especially hydrogen production and storage facilities, represents an emerging market for hydrogen embrittlement solutions. As green hydrogen initiatives expand globally, the demand for materials and components that can safely contain and transport hydrogen without degradation has created a specialized market segment with significant growth potential.

Industry stakeholders consistently express demand for solutions that not only prevent hydrogen embrittlement but also align with established acceptance criteria in international standards. Companies seek cost-effective testing protocols that accurately predict material performance under service conditions while complying with ISO 11114, API 579, and NACE MR0175 requirements.

The market increasingly values integrated approaches that combine material selection, coating technologies, and monitoring systems to manage hydrogen embrittlement risks throughout asset lifecycles. This holistic demand reflects the industry's recognition that hydrogen embrittlement management requires comprehensive strategies rather than isolated interventions.

Economic analyses suggest that the global market for hydrogen embrittlement prevention technologies exceeds $3.5 billion annually, with projected growth rates of 8-10% through 2030 as industries continue to adopt higher-strength materials and expand into hydrogen-rich environments.

In the oil and gas sector, the transition toward sour service environments with higher H2S content has intensified the need for materials and components resistant to hydrogen-induced damage. Industry reports indicate that approximately 25% of failures in oil and gas pipelines and equipment can be attributed to hydrogen embrittlement, creating an urgent market need for reliable prevention strategies that align with ISO 15156 and API 5CT standards.

The aerospace industry faces similar challenges, with hydrogen embrittlement being a critical concern in landing gear components, fasteners, and structural elements. The market for specialized treatments and materials that meet aerospace standards has expanded by nearly 15% annually over the past five years, reflecting the industry's commitment to addressing this issue.

Automotive manufacturers, particularly those involved in electric vehicle production, are increasingly concerned about hydrogen embrittlement in high-strength fasteners and structural components. The market for hydrogen embrittlement prevention solutions in this sector is projected to grow substantially as vehicle designs incorporate more advanced high-strength materials to reduce weight while maintaining structural integrity.

The renewable energy sector, especially hydrogen production and storage facilities, represents an emerging market for hydrogen embrittlement solutions. As green hydrogen initiatives expand globally, the demand for materials and components that can safely contain and transport hydrogen without degradation has created a specialized market segment with significant growth potential.

Industry stakeholders consistently express demand for solutions that not only prevent hydrogen embrittlement but also align with established acceptance criteria in international standards. Companies seek cost-effective testing protocols that accurately predict material performance under service conditions while complying with ISO 11114, API 579, and NACE MR0175 requirements.

The market increasingly values integrated approaches that combine material selection, coating technologies, and monitoring systems to manage hydrogen embrittlement risks throughout asset lifecycles. This holistic demand reflects the industry's recognition that hydrogen embrittlement management requires comprehensive strategies rather than isolated interventions.

Economic analyses suggest that the global market for hydrogen embrittlement prevention technologies exceeds $3.5 billion annually, with projected growth rates of 8-10% through 2030 as industries continue to adopt higher-strength materials and expand into hydrogen-rich environments.

Current Challenges in Hydrogen Embrittlement Management

Despite significant advancements in hydrogen embrittlement (HE) management, the industry continues to face substantial challenges in aligning practices with ISO and API acceptance criteria. One primary challenge is the inconsistency in testing methodologies across different standards. While ISO 15156/NACE MR0175 provides guidelines for materials selection in H2S environments, and API 579-1/ASME FFS-1 addresses fitness-for-service assessments, these standards often employ different testing protocols and acceptance thresholds.

Material qualification represents another significant hurdle. Current standards require extensive testing under specific environmental conditions, but real-world operating environments frequently involve complex combinations of temperature, pressure, and chemical exposure that are difficult to replicate in standardized tests. This creates uncertainty in translating laboratory results to field performance predictions.

The detection and monitoring of hydrogen-induced damage present ongoing technical difficulties. Non-destructive testing (NDT) methods such as ultrasonic testing and acoustic emission have limitations in detecting early-stage hydrogen damage before it progresses to critical levels. This gap between detection capabilities and the requirements specified in acceptance criteria creates significant risk management challenges.

Risk assessment frameworks within current standards often lack sufficient guidance for quantitative evaluation of hydrogen embrittlement susceptibility. While API RP 941 provides Nelson curves for hydrogen pressure-temperature limits, these tools do not adequately address the complex interplay of metallurgical, environmental, and mechanical factors that influence hydrogen embrittlement.

Data interpretation and threshold setting remain problematic areas. The transition from laboratory data to field acceptance criteria involves significant engineering judgment, with limited standardized approaches for establishing safety factors that account for statistical variations in material properties and service conditions.

Implementation challenges also exist at the operational level. Many facilities struggle to integrate hydrogen embrittlement management into broader asset integrity programs as required by ISO 55000 and API 580. This integration is essential for comprehensive risk-based inspection approaches but requires specialized expertise that is often in short supply.

Emerging materials and technologies present additional complications. As the industry adopts advanced high-strength steels, nickel alloys, and composite materials to meet performance demands, existing acceptance criteria may not adequately address their unique susceptibility to hydrogen damage mechanisms, necessitating continuous updates to standards and testing protocols.

Material qualification represents another significant hurdle. Current standards require extensive testing under specific environmental conditions, but real-world operating environments frequently involve complex combinations of temperature, pressure, and chemical exposure that are difficult to replicate in standardized tests. This creates uncertainty in translating laboratory results to field performance predictions.

The detection and monitoring of hydrogen-induced damage present ongoing technical difficulties. Non-destructive testing (NDT) methods such as ultrasonic testing and acoustic emission have limitations in detecting early-stage hydrogen damage before it progresses to critical levels. This gap between detection capabilities and the requirements specified in acceptance criteria creates significant risk management challenges.

Risk assessment frameworks within current standards often lack sufficient guidance for quantitative evaluation of hydrogen embrittlement susceptibility. While API RP 941 provides Nelson curves for hydrogen pressure-temperature limits, these tools do not adequately address the complex interplay of metallurgical, environmental, and mechanical factors that influence hydrogen embrittlement.

Data interpretation and threshold setting remain problematic areas. The transition from laboratory data to field acceptance criteria involves significant engineering judgment, with limited standardized approaches for establishing safety factors that account for statistical variations in material properties and service conditions.

Implementation challenges also exist at the operational level. Many facilities struggle to integrate hydrogen embrittlement management into broader asset integrity programs as required by ISO 55000 and API 580. This integration is essential for comprehensive risk-based inspection approaches but requires specialized expertise that is often in short supply.

Emerging materials and technologies present additional complications. As the industry adopts advanced high-strength steels, nickel alloys, and composite materials to meet performance demands, existing acceptance criteria may not adequately address their unique susceptibility to hydrogen damage mechanisms, necessitating continuous updates to standards and testing protocols.

ISO/API Compliance Strategies for Hydrogen Service

01 Testing and evaluation methods for hydrogen embrittlement

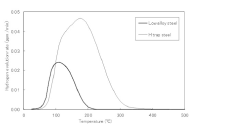

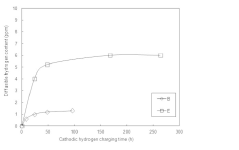

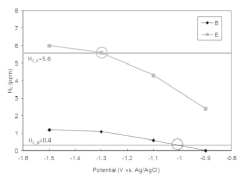

Various testing methodologies are employed to evaluate hydrogen embrittlement susceptibility in materials. These include standardized tests that measure mechanical properties before and after hydrogen exposure, electrochemical testing to assess hydrogen uptake rates, and specialized techniques to determine threshold stress levels for embrittlement. These methods help establish acceptance criteria by quantifying a material's resistance to hydrogen-induced damage under specific conditions, enabling engineers to set appropriate safety margins for components in hydrogen-rich environments.- Testing and detection methods for hydrogen embrittlement: Various testing methodologies and detection techniques are employed to assess hydrogen embrittlement in materials. These include specialized testing protocols to evaluate material susceptibility to hydrogen damage, non-destructive testing methods for detecting hydrogen-induced defects, and monitoring systems that can track hydrogen concentration in real-time. These testing approaches help establish acceptance criteria by providing quantifiable data on material performance under hydrogen exposure conditions.

- Material selection and treatment processes: Proper material selection and treatment processes are critical for managing hydrogen embrittlement. This includes selecting hydrogen-resistant alloys, applying protective coatings, and implementing heat treatment processes that reduce susceptibility to hydrogen damage. Surface treatments such as shot peening and specialized coating applications can create barriers against hydrogen penetration. These material considerations form the basis for acceptance criteria in hydrogen-rich environments.

- Manufacturing controls and quality assurance: Manufacturing controls and quality assurance protocols are essential for hydrogen embrittlement management. This includes implementing strict process controls during manufacturing, establishing quality checkpoints, and developing standardized procedures for handling hydrogen-sensitive components. Proper documentation and traceability systems ensure that all components meet established acceptance criteria before entering service in hydrogen environments.

- Risk assessment and acceptance criteria development: Developing appropriate acceptance criteria requires comprehensive risk assessment methodologies specific to hydrogen embrittlement. This involves analyzing failure modes, establishing safety factors, and determining threshold values for hydrogen concentration and exposure time. Risk-based inspection approaches help prioritize monitoring efforts based on component criticality and susceptibility to hydrogen damage. These assessments inform the development of acceptance criteria tailored to specific applications and operating conditions.

- In-service monitoring and maintenance strategies: Effective hydrogen embrittlement management requires ongoing monitoring and maintenance strategies throughout component service life. This includes implementing periodic inspection schedules, condition monitoring techniques, and predictive maintenance approaches to detect early signs of hydrogen damage. Establishing clear remediation protocols when components approach or exceed acceptance criteria limits helps prevent catastrophic failures and extends asset life in hydrogen service environments.

02 Material selection and treatment for hydrogen embrittlement resistance

Selecting appropriate materials and applying specific treatments can significantly reduce hydrogen embrittlement risks. This includes using alloys with optimized microstructures, applying protective coatings or surface treatments, and implementing heat treatment processes that enhance resistance to hydrogen penetration. Material specifications often include acceptance criteria related to chemical composition, microstructure characteristics, and mechanical properties that must be met to ensure adequate performance in hydrogen-containing environments.Expand Specific Solutions03 Monitoring and inspection techniques for hydrogen embrittlement

Continuous monitoring and periodic inspection are essential components of hydrogen embrittlement management. Non-destructive testing methods, including ultrasonic testing, acoustic emission monitoring, and advanced imaging techniques, can detect early signs of hydrogen damage before catastrophic failure occurs. These techniques are aligned with acceptance criteria that define permissible defect sizes, crack growth rates, and material property changes, allowing for timely intervention when measurements exceed established thresholds.Expand Specific Solutions04 Environmental control strategies to mitigate hydrogen embrittlement

Managing the environmental conditions that promote hydrogen embrittlement is crucial for preventing material degradation. This includes controlling pH levels, temperature, and hydrogen partial pressure in process environments, as well as implementing cathodic protection systems with carefully calibrated parameters. Acceptance criteria for environmental control typically specify allowable ranges for these parameters, with monitoring systems designed to alert operators when conditions approach critical thresholds that could accelerate hydrogen uptake and embrittlement.Expand Specific Solutions05 Regulatory compliance and standardization for hydrogen embrittlement management

Hydrogen embrittlement management must align with industry standards and regulatory requirements that establish minimum acceptance criteria for materials, components, and systems exposed to hydrogen. These standards often specify qualification testing procedures, documentation requirements, and inspection protocols that must be followed to demonstrate compliance. Organizations implement management systems that integrate these requirements into their operations, ensuring that all hydrogen-related activities meet or exceed the established acceptance criteria through systematic risk assessment and quality control processes.Expand Specific Solutions

Leading Organizations in Hydrogen Embrittlement Research

Hydrogen embrittlement management is currently in a transitional phase, moving from emerging to established technology as industries recognize its critical importance in material integrity. The global market for hydrogen embrittlement solutions is expanding rapidly, driven by growing hydrogen economy initiatives and stringent safety standards in oil and gas, automotive, and aerospace sectors. Technical maturity varies significantly across key players, with companies like NIPPON STEEL, Shell Oil, and Air Liquide demonstrating advanced capabilities through established protocols aligned with ISO/API criteria. Research institutions including Massachusetts Institute of Technology and Zhejiang University are advancing fundamental understanding, while industrial leaders such as Boeing, Kawasaki Heavy Industries, and Toshiba are developing application-specific solutions. The competitive landscape features both specialized materials science companies and diversified industrial conglomerates implementing comprehensive hydrogen management strategies.

NIPPON STEEL CORP.

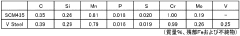

Technical Solution: NIPPON STEEL has developed a comprehensive hydrogen embrittlement management system that aligns with ISO 15156/NACE MR0175 standards for sour service environments. Their approach includes specialized heat treatment processes to control microstructure and reduce hydrogen trapping sites. The company employs Hydrogen Induced Cracking (HIC) testing protocols that exceed the minimum requirements of NACE TM0284 standard, with extended exposure times of 96+ hours compared to the standard 96 hours. Their proprietary steel compositions feature carefully controlled sulfur levels (<0.002%) and inclusion shape control technology to minimize susceptibility to hydrogen damage. NIPPON STEEL has also implemented in-line monitoring systems during production that utilize ultrasonic testing combined with advanced algorithms to detect potential hydrogen flaws before products reach service conditions.

Strengths: Industry-leading expertise in metallurgical solutions for hydrogen service; extensive R&D capabilities; proprietary steel compositions with superior resistance to hydrogen embrittlement. Weaknesses: Higher production costs compared to standard steel grades; longer lead times for specialized hydrogen-resistant products; limited flexibility in customization for certain applications.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed an integrated hydrogen embrittlement management framework that exceeds API RP 941 and ISO 15156 requirements for high-pressure hydrogen service in refinery operations. Their approach combines materials selection, fitness-for-service assessment, and risk-based inspection methodologies. Shell employs a proprietary Hydrogen Damage Assessment Tool (HDAT) that incorporates operating parameters, material properties, and inspection data to predict remaining component life with greater accuracy than standard Nelson curves. Their management system includes specialized inspection protocols using phased array ultrasonic testing with customized scan patterns that can detect hydrogen-induced cracking at earlier stages than conventional methods. Shell has established material qualification procedures that include accelerated hydrogen charging tests at elevated temperatures and pressures to simulate worst-case operating scenarios. Their risk assessment matrix incorporates hydrogen partial pressure, temperature, material composition, and process upsets to determine inspection intervals that are typically 20-30% more conservative than API 510/570 minimum requirements.

Strengths: Comprehensive risk-based approach that integrates operational data with materials science; extensive field experience across global operations; sophisticated predictive modeling capabilities. Weaknesses: Proprietary systems may require significant training for implementation; conservative approach may lead to higher maintenance costs; solutions optimized primarily for oil and gas applications rather than emerging hydrogen economy needs.

Critical Technologies for Hydrogen Damage Mitigation

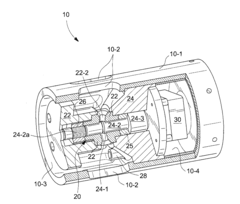

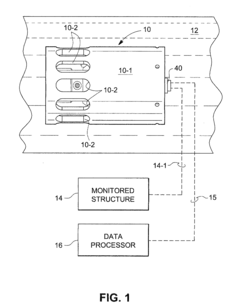

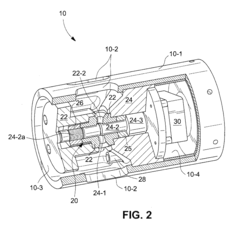

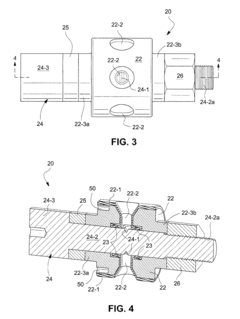

In-situ sensors and methods for monitoring environment assisted cracking of structural components

PatentActiveUS20110100131A1

Innovation

- A compact sensor system utilizing a circumferentially notched tensile (CNT) specimen with high-resolution strain gage instrumentation and a stiff sensor construction to measure crack depth in real-time, mimicking the loading conditions of the monitored structure, allowing for early detection of cracking and correlation with structural damage.

Evaluation method of hydrogen embrittlement resistance

PatentActiveJP2017122633A

Innovation

- A method involving electrolysis of the specimen as a cathode, determining cathodic hydrogen charge conditions, measuring critical diffusible hydrogen amount and intruding hydrogen amount, and performing a delayed fracture test to evaluate hydrogen embrittlement resistance, using potential difference as a key criterion.

Material Selection Guidelines for Hydrogen Environments

Material selection for hydrogen service environments requires careful consideration of multiple factors to mitigate hydrogen embrittlement risks. The selection process must align with established industry standards, particularly those outlined in ISO 11114, ASME B31.12, and API RP 941, which provide comprehensive guidelines for material compatibility in hydrogen environments.

Primary consideration should be given to materials with proven resistance to hydrogen embrittlement. Austenitic stainless steels (304L, 316L) demonstrate superior performance due to their face-centered cubic (FCC) crystal structure, which inherently limits hydrogen diffusion. For high-pressure applications exceeding 7,000 psi, precipitation-hardened nickel alloys such as Inconel 718 and Monel K-500 offer enhanced resistance while maintaining mechanical integrity.

Carbon and low-alloy steels require particular attention when used in hydrogen service. These materials should be limited to applications below 450°F (232°C) and moderate pressures, with careful control of hardness levels. NACE MR0175/ISO 15156 recommends maximum hardness values of 22 HRC for carbon steels in hydrogen-containing environments to minimize susceptibility to hydrogen-induced cracking.

Aluminum alloys present a viable alternative for specific hydrogen applications due to their inherent resistance to hydrogen embrittlement. Series 6061 and 6063 aluminum alloys have demonstrated satisfactory performance in hydrogen storage systems operating at moderate pressures and ambient temperatures.

Material selection must also account for environmental factors including temperature, pressure, and hydrogen concentration. The Nelson Curves, referenced in API RP 941, provide essential guidance for material selection based on hydrogen partial pressure and temperature conditions, helping engineers identify safe operating windows for various alloys.

Surface treatments and coatings can significantly enhance material performance in hydrogen environments. Techniques such as nitriding, carburizing, and application of barrier coatings (e.g., aluminum-based or ceramic coatings) have proven effective in reducing hydrogen permeation and subsequent embrittlement.

Quality assurance protocols must be integrated into the material selection process, including verification of material composition, microstructure evaluation, and mechanical property testing according to ASTM standards. Fracture toughness testing per ASTM E1820 is particularly valuable for assessing material resistance to hydrogen-assisted cracking under service conditions.

Primary consideration should be given to materials with proven resistance to hydrogen embrittlement. Austenitic stainless steels (304L, 316L) demonstrate superior performance due to their face-centered cubic (FCC) crystal structure, which inherently limits hydrogen diffusion. For high-pressure applications exceeding 7,000 psi, precipitation-hardened nickel alloys such as Inconel 718 and Monel K-500 offer enhanced resistance while maintaining mechanical integrity.

Carbon and low-alloy steels require particular attention when used in hydrogen service. These materials should be limited to applications below 450°F (232°C) and moderate pressures, with careful control of hardness levels. NACE MR0175/ISO 15156 recommends maximum hardness values of 22 HRC for carbon steels in hydrogen-containing environments to minimize susceptibility to hydrogen-induced cracking.

Aluminum alloys present a viable alternative for specific hydrogen applications due to their inherent resistance to hydrogen embrittlement. Series 6061 and 6063 aluminum alloys have demonstrated satisfactory performance in hydrogen storage systems operating at moderate pressures and ambient temperatures.

Material selection must also account for environmental factors including temperature, pressure, and hydrogen concentration. The Nelson Curves, referenced in API RP 941, provide essential guidance for material selection based on hydrogen partial pressure and temperature conditions, helping engineers identify safe operating windows for various alloys.

Surface treatments and coatings can significantly enhance material performance in hydrogen environments. Techniques such as nitriding, carburizing, and application of barrier coatings (e.g., aluminum-based or ceramic coatings) have proven effective in reducing hydrogen permeation and subsequent embrittlement.

Quality assurance protocols must be integrated into the material selection process, including verification of material composition, microstructure evaluation, and mechanical property testing according to ASTM standards. Fracture toughness testing per ASTM E1820 is particularly valuable for assessing material resistance to hydrogen-assisted cracking under service conditions.

Risk Assessment Frameworks for Hydrogen Service Equipment

Risk assessment frameworks for hydrogen service equipment have evolved significantly to address the unique challenges posed by hydrogen embrittlement. These frameworks integrate both qualitative and quantitative methodologies to systematically evaluate potential failure modes and their consequences in hydrogen environments. The primary frameworks currently employed include Failure Mode and Effects Analysis (FMEA), Hazard and Operability Study (HAZOP), and Quantitative Risk Assessment (QRA), each offering distinct approaches to risk identification and mitigation.

Industry standards such as API RP 941 and ISO 11114 provide structured guidelines for risk assessment specifically tailored to hydrogen service. These frameworks emphasize the importance of material selection considerations, operating condition boundaries, and inspection protocols that align with hydrogen embrittlement management principles. The Nelson curves incorporated in API RP 941, for instance, establish temperature-pressure thresholds for various steel compositions, serving as fundamental decision-making tools in risk assessment processes.

Recent advancements have introduced probabilistic risk assessment methodologies that account for the stochastic nature of hydrogen embrittlement phenomena. These approaches utilize statistical models to predict failure probabilities based on material properties, environmental conditions, and service history. Fitness-for-Service (FFS) assessments, as outlined in API 579-1/ASME FFS-1, have been adapted to incorporate hydrogen damage mechanisms, providing a comprehensive framework for evaluating equipment integrity in hydrogen service.

Digital risk assessment tools have emerged as valuable resources for implementing these frameworks efficiently. These tools leverage computational models to simulate hydrogen diffusion, trapping, and material degradation processes, enabling more accurate prediction of equipment behavior under various operating scenarios. Machine learning algorithms are increasingly being integrated to enhance predictive capabilities by analyzing historical failure data and identifying patterns that may not be apparent through conventional analysis methods.

Cross-industry collaboration has led to the development of harmonized risk assessment approaches that bridge the gap between different sectors utilizing hydrogen technologies. The energy, transportation, and manufacturing industries have established joint working groups to share best practices and standardize risk evaluation methodologies. This collaborative effort has resulted in more robust frameworks that incorporate lessons learned across diverse applications of hydrogen equipment.

The implementation of these frameworks requires multidisciplinary expertise, combining materials science, mechanical engineering, and reliability analysis. Organizations typically establish dedicated risk assessment teams that follow structured processes for identifying, analyzing, and mitigating hydrogen embrittlement risks throughout the equipment lifecycle, from design and material selection to operation and maintenance strategies.

Industry standards such as API RP 941 and ISO 11114 provide structured guidelines for risk assessment specifically tailored to hydrogen service. These frameworks emphasize the importance of material selection considerations, operating condition boundaries, and inspection protocols that align with hydrogen embrittlement management principles. The Nelson curves incorporated in API RP 941, for instance, establish temperature-pressure thresholds for various steel compositions, serving as fundamental decision-making tools in risk assessment processes.

Recent advancements have introduced probabilistic risk assessment methodologies that account for the stochastic nature of hydrogen embrittlement phenomena. These approaches utilize statistical models to predict failure probabilities based on material properties, environmental conditions, and service history. Fitness-for-Service (FFS) assessments, as outlined in API 579-1/ASME FFS-1, have been adapted to incorporate hydrogen damage mechanisms, providing a comprehensive framework for evaluating equipment integrity in hydrogen service.

Digital risk assessment tools have emerged as valuable resources for implementing these frameworks efficiently. These tools leverage computational models to simulate hydrogen diffusion, trapping, and material degradation processes, enabling more accurate prediction of equipment behavior under various operating scenarios. Machine learning algorithms are increasingly being integrated to enhance predictive capabilities by analyzing historical failure data and identifying patterns that may not be apparent through conventional analysis methods.

Cross-industry collaboration has led to the development of harmonized risk assessment approaches that bridge the gap between different sectors utilizing hydrogen technologies. The energy, transportation, and manufacturing industries have established joint working groups to share best practices and standardize risk evaluation methodologies. This collaborative effort has resulted in more robust frameworks that incorporate lessons learned across diverse applications of hydrogen equipment.

The implementation of these frameworks requires multidisciplinary expertise, combining materials science, mechanical engineering, and reliability analysis. Organizations typically establish dedicated risk assessment teams that follow structured processes for identifying, analyzing, and mitigating hydrogen embrittlement risks throughout the equipment lifecycle, from design and material selection to operation and maintenance strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!