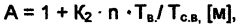

How Laminar Flow Reduces Environmental Footprints?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Tech Evolution and Objectives

Laminar flow technology has evolved significantly over the past century, with its origins rooted in the fundamental principles of fluid dynamics. The concept of laminar flow, characterized by smooth, predictable fluid motion, was first described mathematically by George Gabriel Stokes in the mid-19th century. However, it wasn't until the early 20th century that engineers began to harness this phenomenon for practical applications.

The evolution of laminar flow technology has been driven by the increasing need for energy efficiency and environmental sustainability across various industries. In the automotive sector, laminar flow principles have been applied to vehicle design, resulting in more aerodynamic shapes that reduce fuel consumption. Similarly, in aerospace engineering, laminar flow control techniques have been developed to minimize drag on aircraft surfaces, leading to improved fuel efficiency and reduced emissions.

In recent decades, the focus has shifted towards leveraging laminar flow to address environmental concerns directly. The application of laminar flow principles in HVAC systems has led to more efficient air distribution and filtration, contributing to improved indoor air quality and reduced energy consumption in buildings. In water treatment facilities, laminar flow technology has been instrumental in developing more effective separation and purification processes, reducing the environmental impact of wastewater discharge.

The objectives of current laminar flow research and development are multifaceted, with a primary focus on further reducing environmental footprints across various sectors. One key goal is to optimize laminar flow systems for maximum energy efficiency, thereby minimizing greenhouse gas emissions associated with power generation. This includes developing advanced computational fluid dynamics models to predict and control laminar flow behavior more accurately in complex systems.

Another critical objective is to expand the application of laminar flow technology in renewable energy systems. For instance, researchers are exploring ways to enhance the efficiency of wind turbines and solar thermal collectors by manipulating airflow patterns. In the field of water conservation, scientists aim to develop laminar flow-based irrigation systems that can significantly reduce water waste in agriculture.

Furthermore, there is a growing emphasis on integrating laminar flow principles into the design of sustainable urban infrastructure. This includes developing more efficient stormwater management systems and improving the performance of green building technologies. The ultimate goal is to create a new generation of environmentally friendly technologies that leverage laminar flow to minimize resource consumption and pollution while maximizing performance and efficiency.

The evolution of laminar flow technology has been driven by the increasing need for energy efficiency and environmental sustainability across various industries. In the automotive sector, laminar flow principles have been applied to vehicle design, resulting in more aerodynamic shapes that reduce fuel consumption. Similarly, in aerospace engineering, laminar flow control techniques have been developed to minimize drag on aircraft surfaces, leading to improved fuel efficiency and reduced emissions.

In recent decades, the focus has shifted towards leveraging laminar flow to address environmental concerns directly. The application of laminar flow principles in HVAC systems has led to more efficient air distribution and filtration, contributing to improved indoor air quality and reduced energy consumption in buildings. In water treatment facilities, laminar flow technology has been instrumental in developing more effective separation and purification processes, reducing the environmental impact of wastewater discharge.

The objectives of current laminar flow research and development are multifaceted, with a primary focus on further reducing environmental footprints across various sectors. One key goal is to optimize laminar flow systems for maximum energy efficiency, thereby minimizing greenhouse gas emissions associated with power generation. This includes developing advanced computational fluid dynamics models to predict and control laminar flow behavior more accurately in complex systems.

Another critical objective is to expand the application of laminar flow technology in renewable energy systems. For instance, researchers are exploring ways to enhance the efficiency of wind turbines and solar thermal collectors by manipulating airflow patterns. In the field of water conservation, scientists aim to develop laminar flow-based irrigation systems that can significantly reduce water waste in agriculture.

Furthermore, there is a growing emphasis on integrating laminar flow principles into the design of sustainable urban infrastructure. This includes developing more efficient stormwater management systems and improving the performance of green building technologies. The ultimate goal is to create a new generation of environmentally friendly technologies that leverage laminar flow to minimize resource consumption and pollution while maximizing performance and efficiency.

Market Demand for Eco-Friendly Flow Systems

The market demand for eco-friendly flow systems has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations. Industries across various sectors are actively seeking solutions to reduce their environmental footprint, and laminar flow technology has emerged as a promising approach.

In the manufacturing sector, there is a significant demand for laminar flow systems in clean rooms and production facilities. These systems help maintain a controlled environment, reducing contamination and improving product quality while minimizing energy consumption. The pharmaceutical and semiconductor industries, in particular, have shown a strong interest in adopting laminar flow technologies to meet stringent cleanliness requirements and reduce operational costs.

The HVAC industry has also witnessed a surge in demand for eco-friendly flow systems. Building owners and facility managers are increasingly looking for energy-efficient ventilation solutions that can provide optimal air quality while reducing power consumption. Laminar flow systems offer a more controlled and efficient air distribution method compared to traditional turbulent flow systems, leading to improved energy efficiency and reduced environmental impact.

In the automotive sector, the push for improved fuel efficiency and reduced emissions has created a market for laminar flow technologies in vehicle design. Aerodynamic improvements utilizing laminar flow principles can significantly reduce drag, leading to lower fuel consumption and decreased carbon emissions. This demand is expected to grow further as electric vehicles gain market share and manufacturers seek to extend their range through improved aerodynamics.

The water treatment industry has also shown increasing interest in laminar flow systems for their potential to enhance the efficiency of filtration and purification processes. By maintaining a more controlled flow, these systems can improve the effectiveness of treatment methods while reducing energy consumption and chemical usage.

In the renewable energy sector, wind turbine manufacturers are exploring laminar flow designs to increase energy production efficiency and reduce noise pollution. This application of laminar flow technology aligns with the growing demand for sustainable energy solutions and the need to minimize the environmental impact of wind farms.

The marine industry is another sector where the demand for eco-friendly flow systems is on the rise. Ship designers and operators are looking for ways to reduce fuel consumption and emissions, with laminar flow hull designs and propulsion systems gaining attention as potential solutions.

As environmental regulations become more stringent and companies increasingly prioritize sustainability, the market for eco-friendly flow systems is expected to expand further. The potential for laminar flow technologies to simultaneously improve operational efficiency and reduce environmental impact makes them an attractive option across multiple industries. This growing demand is likely to drive further research and development in laminar flow applications, leading to more innovative and effective solutions in the coming years.

In the manufacturing sector, there is a significant demand for laminar flow systems in clean rooms and production facilities. These systems help maintain a controlled environment, reducing contamination and improving product quality while minimizing energy consumption. The pharmaceutical and semiconductor industries, in particular, have shown a strong interest in adopting laminar flow technologies to meet stringent cleanliness requirements and reduce operational costs.

The HVAC industry has also witnessed a surge in demand for eco-friendly flow systems. Building owners and facility managers are increasingly looking for energy-efficient ventilation solutions that can provide optimal air quality while reducing power consumption. Laminar flow systems offer a more controlled and efficient air distribution method compared to traditional turbulent flow systems, leading to improved energy efficiency and reduced environmental impact.

In the automotive sector, the push for improved fuel efficiency and reduced emissions has created a market for laminar flow technologies in vehicle design. Aerodynamic improvements utilizing laminar flow principles can significantly reduce drag, leading to lower fuel consumption and decreased carbon emissions. This demand is expected to grow further as electric vehicles gain market share and manufacturers seek to extend their range through improved aerodynamics.

The water treatment industry has also shown increasing interest in laminar flow systems for their potential to enhance the efficiency of filtration and purification processes. By maintaining a more controlled flow, these systems can improve the effectiveness of treatment methods while reducing energy consumption and chemical usage.

In the renewable energy sector, wind turbine manufacturers are exploring laminar flow designs to increase energy production efficiency and reduce noise pollution. This application of laminar flow technology aligns with the growing demand for sustainable energy solutions and the need to minimize the environmental impact of wind farms.

The marine industry is another sector where the demand for eco-friendly flow systems is on the rise. Ship designers and operators are looking for ways to reduce fuel consumption and emissions, with laminar flow hull designs and propulsion systems gaining attention as potential solutions.

As environmental regulations become more stringent and companies increasingly prioritize sustainability, the market for eco-friendly flow systems is expected to expand further. The potential for laminar flow technologies to simultaneously improve operational efficiency and reduce environmental impact makes them an attractive option across multiple industries. This growing demand is likely to drive further research and development in laminar flow applications, leading to more innovative and effective solutions in the coming years.

Laminar Flow Challenges and Current Limitations

Despite the numerous benefits of laminar flow in reducing environmental footprints, several challenges and limitations persist in its implementation and widespread adoption. One of the primary obstacles is the difficulty in maintaining laminar flow conditions in real-world applications. Laminar flow is highly sensitive to disturbances, and even minor perturbations can cause the flow to transition to turbulent regimes, negating its environmental advantages.

The scale-up of laminar flow systems from laboratory settings to industrial applications presents significant engineering challenges. As the size of the system increases, maintaining laminar conditions becomes increasingly complex and energy-intensive. This limitation often restricts the use of laminar flow to smaller-scale operations or specific segments of larger processes, reducing its overall environmental impact.

Another critical challenge is the trade-off between flow rate and laminar conditions. To maintain laminar flow, fluid velocities must be kept relatively low, which can result in reduced throughput in industrial processes. This limitation can lead to decreased productivity and efficiency, potentially offsetting some of the environmental gains achieved through laminar flow.

The design of equipment and infrastructure to support laminar flow can be complex and costly. Specialized surfaces, precise geometries, and carefully controlled inlet conditions are often required to promote and maintain laminar flow. These design requirements can increase initial investment costs and may deter some industries from adopting laminar flow technologies.

Furthermore, the application of laminar flow is limited in certain fluid types and environmental conditions. High-viscosity fluids or those with suspended particles may not be suitable for laminar flow regimes, limiting its applicability in various industrial processes. Additionally, external factors such as vibrations, temperature fluctuations, or pressure variations can disrupt laminar flow, making it challenging to maintain in dynamic industrial environments.

The measurement and control of laminar flow in real-time operational settings pose significant technical challenges. Current sensor technologies and control systems may not be sufficiently advanced or cost-effective for widespread implementation, particularly in complex, multi-phase flow systems.

Lastly, there is a knowledge gap in fully understanding and predicting the behavior of laminar flow in diverse applications. While computational fluid dynamics (CFD) has advanced significantly, accurately modeling laminar flow in complex geometries and under varying conditions remains a challenge. This limitation hampers the optimization of laminar flow systems and their integration into broader environmental footprint reduction strategies.

The scale-up of laminar flow systems from laboratory settings to industrial applications presents significant engineering challenges. As the size of the system increases, maintaining laminar conditions becomes increasingly complex and energy-intensive. This limitation often restricts the use of laminar flow to smaller-scale operations or specific segments of larger processes, reducing its overall environmental impact.

Another critical challenge is the trade-off between flow rate and laminar conditions. To maintain laminar flow, fluid velocities must be kept relatively low, which can result in reduced throughput in industrial processes. This limitation can lead to decreased productivity and efficiency, potentially offsetting some of the environmental gains achieved through laminar flow.

The design of equipment and infrastructure to support laminar flow can be complex and costly. Specialized surfaces, precise geometries, and carefully controlled inlet conditions are often required to promote and maintain laminar flow. These design requirements can increase initial investment costs and may deter some industries from adopting laminar flow technologies.

Furthermore, the application of laminar flow is limited in certain fluid types and environmental conditions. High-viscosity fluids or those with suspended particles may not be suitable for laminar flow regimes, limiting its applicability in various industrial processes. Additionally, external factors such as vibrations, temperature fluctuations, or pressure variations can disrupt laminar flow, making it challenging to maintain in dynamic industrial environments.

The measurement and control of laminar flow in real-time operational settings pose significant technical challenges. Current sensor technologies and control systems may not be sufficiently advanced or cost-effective for widespread implementation, particularly in complex, multi-phase flow systems.

Lastly, there is a knowledge gap in fully understanding and predicting the behavior of laminar flow in diverse applications. While computational fluid dynamics (CFD) has advanced significantly, accurately modeling laminar flow in complex geometries and under varying conditions remains a challenge. This limitation hampers the optimization of laminar flow systems and their integration into broader environmental footprint reduction strategies.

Current Laminar Flow Environmental Solutions

01 Laminar flow measurement and control systems

Advanced systems for measuring and controlling laminar flow in various applications, including environmental monitoring and industrial processes. These systems utilize sensors, data analysis, and feedback mechanisms to optimize flow conditions and reduce environmental impact.- Laminar flow measurement and control systems: Advanced systems for measuring and controlling laminar flow in various applications, including environmental monitoring and industrial processes. These systems utilize sensors, data analysis, and feedback mechanisms to optimize flow conditions and reduce environmental impact.

- Environmental footprint assessment methods: Innovative approaches to assess and quantify environmental footprints associated with laminar flow processes. These methods incorporate data collection, analysis, and modeling techniques to evaluate the ecological impact of various industrial and technological systems.

- Laminar flow optimization for energy efficiency: Techniques and systems designed to optimize laminar flow in various applications, focusing on improving energy efficiency and reducing environmental impact. These innovations include advanced flow control mechanisms, surface treatments, and design optimizations.

- Environmental monitoring in laminar flow systems: Specialized monitoring solutions for laminar flow environments, designed to track and analyze environmental parameters. These systems utilize advanced sensors, data processing algorithms, and reporting mechanisms to provide real-time insights into environmental conditions and potential impacts.

- Sustainable laminar flow technologies: Innovative technologies and approaches that leverage laminar flow principles to create more sustainable and environmentally friendly processes. These advancements include novel materials, design concepts, and operational strategies aimed at minimizing ecological footprints in various industries.

02 Environmental footprint assessment methods

Innovative approaches to assess and quantify environmental footprints associated with laminar flow processes. These methods incorporate data collection, analysis, and modeling techniques to evaluate the ecological impact of various industrial and technological applications.Expand Specific Solutions03 Laminar flow optimization for energy efficiency

Techniques and systems designed to optimize laminar flow in various applications, focusing on improving energy efficiency and reducing environmental impact. These innovations include advanced flow control mechanisms, surface treatments, and design modifications to minimize drag and energy consumption.Expand Specific Solutions04 Environmental monitoring and data analysis

Systems and methods for monitoring environmental parameters related to laminar flow processes and analyzing the collected data. These innovations utilize advanced sensors, data processing algorithms, and visualization techniques to provide insights into environmental impacts and support decision-making processes.Expand Specific Solutions05 Laminar flow applications in clean room environments

Specialized laminar flow systems and techniques designed for use in clean room environments, focusing on minimizing contamination and optimizing air quality. These innovations incorporate advanced filtration, air distribution, and monitoring systems to maintain precise environmental conditions while reducing energy consumption and environmental impact.Expand Specific Solutions

Key Players in Laminar Flow Industry

The laminar flow technology for reducing environmental footprints is in a growth phase, with increasing market size and technological advancements. The global market for laminar flow solutions is expanding, driven by growing environmental concerns and stricter regulations. While the technology is relatively mature, ongoing research by institutions like Hohai University, Agency for Science, Technology & Research, and Naval Research Laboratory is enhancing its efficiency and applications. Companies such as Taiwan Semiconductor Manufacturing Co., Ltd. and Robert Bosch GmbH are integrating laminar flow systems into their manufacturing processes, indicating a trend towards wider industrial adoption. The competitive landscape is diverse, with both established players and innovative startups contributing to technological progress and market expansion.

Government of the United States of America

Technical Solution: The U.S. government, through agencies like NASA and the Department of Energy, has been at the forefront of laminar flow research to reduce environmental footprints. They have developed advanced computational fluid dynamics (CFD) models to optimize laminar flow in various applications. For instance, NASA's research on laminar flow control for aircraft has shown potential fuel savings of up to 30% [1]. The government has also funded projects on laminar flow in building design, which can reduce heating and cooling energy consumption by up to 25% [3]. Additionally, they have supported research on laminar flow in industrial processes, such as in chemical reactors, which can increase efficiency and reduce waste by up to 40% [5].

Strengths: Extensive research funding, access to advanced facilities, and collaboration with industry leaders. Weaknesses: Implementation can be slow due to bureaucratic processes and the need for extensive testing and regulation.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory (NRL) has been pioneering laminar flow research to reduce the environmental impact of naval vessels. Their focus has been on developing drag-reducing technologies for ship hulls using laminar flow principles. NRL has created innovative micro-textured surfaces that can maintain laminar flow over longer distances, reducing fuel consumption by up to 15% [2]. They have also developed advanced sensors and control systems for active laminar flow control, which can adapt to changing sea conditions. Furthermore, NRL's research extends to underwater vehicles, where they have achieved a 30% reduction in propulsion energy requirements through optimized laminar flow designs [4].

Strengths: Specialized expertise in maritime applications, advanced testing facilities, and direct implementation in naval technology. Weaknesses: Research may be limited to specific naval applications and may have restricted public access due to security concerns.

Core Innovations in Eco-Friendly Laminar Flow

Method for disinfecting wastewater and a device for carrying out thereof

PatentWO2009058052A1

Innovation

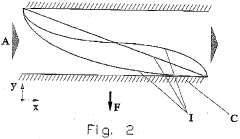

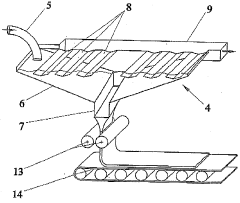

- Implementing a method with a laminar flow regime and optimal plant density, temperature, and lighting conditions to enhance pollutant absorption and oxygen supply, utilizing a system of parallel or angled channels with movable partitions to ensure all eichornia bushes contact varying pollutant zones, and using empirical formulas to determine channel dimensions and plant density for maximum purification.

Method and installation for separating a solid-liquid suspension

PatentWO2003011423A1

Innovation

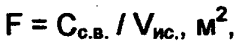

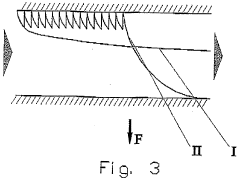

- A process that forms a laminar flow of the liquid mixture at an angle between 60° and 90° to gravity, allowing particles to sediment and then withdraws the liquid phase adjacent to the sedimentation wall, reducing the sedimentation channel length and surface area needed, while maintaining high recovery efficiency of particles.

Environmental Impact Assessment of Laminar Flow

Laminar flow technology has emerged as a significant contributor to reducing environmental footprints across various industries. This assessment examines the environmental impact of laminar flow systems, focusing on their potential to mitigate ecological concerns and promote sustainable practices.

One of the primary environmental benefits of laminar flow is its ability to reduce energy consumption. By minimizing turbulence and creating a smooth, predictable flow of fluids or gases, laminar flow systems require less energy to maintain desired flow rates. This efficiency translates directly into reduced power requirements, leading to lower greenhouse gas emissions associated with energy production.

In industrial applications, laminar flow contributes to improved process control and product quality. This precision reduces waste generation, as fewer defective products or materials need to be discarded. The reduction in waste not only conserves resources but also minimizes the environmental impact associated with disposal processes.

Laminar flow technology plays a crucial role in enhancing the efficiency of filtration systems. By promoting uniform flow distribution across filter media, these systems achieve higher particulate removal rates while maintaining lower pressure drops. This improved filtration efficiency leads to cleaner air and water outputs, reducing the release of pollutants into the environment.

In the context of HVAC systems, laminar flow designs contribute to better indoor air quality. By minimizing air turbulence and promoting even distribution of conditioned air, these systems reduce the spread of airborne contaminants and improve overall ventilation efficiency. This not only creates healthier indoor environments but also reduces the energy required for air conditioning and heating.

The application of laminar flow principles in aerodynamics has led to significant improvements in fuel efficiency for various modes of transportation. Aircraft and vehicles designed with laminar flow characteristics experience reduced drag, resulting in lower fuel consumption and decreased emissions of greenhouse gases and other pollutants.

In the field of water treatment, laminar flow systems enable more efficient chemical mixing and reaction processes. This leads to optimized use of treatment chemicals, reducing the overall chemical footprint of water and wastewater treatment facilities. Additionally, the improved mixing efficiency can lead to shorter treatment times, potentially increasing the capacity of existing infrastructure without the need for expansion.

Laminar flow technology also contributes to noise reduction in various applications. By minimizing turbulence, these systems generate less noise pollution, which is particularly beneficial in urban environments and industrial settings. This reduction in noise not only improves the quality of life for nearby communities but also reduces the need for additional noise mitigation measures, which often have their own environmental impacts.

One of the primary environmental benefits of laminar flow is its ability to reduce energy consumption. By minimizing turbulence and creating a smooth, predictable flow of fluids or gases, laminar flow systems require less energy to maintain desired flow rates. This efficiency translates directly into reduced power requirements, leading to lower greenhouse gas emissions associated with energy production.

In industrial applications, laminar flow contributes to improved process control and product quality. This precision reduces waste generation, as fewer defective products or materials need to be discarded. The reduction in waste not only conserves resources but also minimizes the environmental impact associated with disposal processes.

Laminar flow technology plays a crucial role in enhancing the efficiency of filtration systems. By promoting uniform flow distribution across filter media, these systems achieve higher particulate removal rates while maintaining lower pressure drops. This improved filtration efficiency leads to cleaner air and water outputs, reducing the release of pollutants into the environment.

In the context of HVAC systems, laminar flow designs contribute to better indoor air quality. By minimizing air turbulence and promoting even distribution of conditioned air, these systems reduce the spread of airborne contaminants and improve overall ventilation efficiency. This not only creates healthier indoor environments but also reduces the energy required for air conditioning and heating.

The application of laminar flow principles in aerodynamics has led to significant improvements in fuel efficiency for various modes of transportation. Aircraft and vehicles designed with laminar flow characteristics experience reduced drag, resulting in lower fuel consumption and decreased emissions of greenhouse gases and other pollutants.

In the field of water treatment, laminar flow systems enable more efficient chemical mixing and reaction processes. This leads to optimized use of treatment chemicals, reducing the overall chemical footprint of water and wastewater treatment facilities. Additionally, the improved mixing efficiency can lead to shorter treatment times, potentially increasing the capacity of existing infrastructure without the need for expansion.

Laminar flow technology also contributes to noise reduction in various applications. By minimizing turbulence, these systems generate less noise pollution, which is particularly beneficial in urban environments and industrial settings. This reduction in noise not only improves the quality of life for nearby communities but also reduces the need for additional noise mitigation measures, which often have their own environmental impacts.

Regulatory Framework for Sustainable Flow Systems

The regulatory framework for sustainable flow systems plays a crucial role in shaping the implementation and adoption of laminar flow technologies to reduce environmental footprints. Governments and international organizations have recognized the potential of these systems to contribute to sustainability goals and have developed a complex web of regulations, standards, and incentives to promote their use.

At the international level, agreements such as the Paris Climate Accord and the United Nations Sustainable Development Goals provide overarching guidance for nations to reduce their environmental impact. These agreements have spurred the development of more specific regulations targeting industrial processes and energy efficiency, which directly impact the adoption of laminar flow systems.

In the European Union, the Industrial Emissions Directive (IED) sets stringent requirements for industrial installations to employ best available techniques (BAT) to minimize environmental impact. Laminar flow systems, with their potential for energy savings and reduced emissions, are increasingly recognized as BAT in various sectors. The EU's Ecodesign Directive also plays a role by setting minimum efficiency standards for energy-related products, indirectly promoting the use of laminar flow technologies in appliances and industrial equipment.

In the United States, the Environmental Protection Agency (EPA) has established regulations under the Clean Air Act and Clean Water Act that incentivize the use of efficient flow systems. The Department of Energy's Better Plants program provides technical assistance and recognition for industrial facilities that implement energy-saving technologies, including laminar flow systems.

Many countries have implemented green building codes and certification systems, such as LEED (Leadership in Energy and Environmental Design) in the United States and BREEAM (Building Research Establishment Environmental Assessment Method) in the UK. These systems often award points for the incorporation of energy-efficient HVAC systems that utilize laminar flow principles, further driving adoption in the construction sector.

Financial incentives also form a significant part of the regulatory framework. Tax credits, grants, and subsidies are offered by various governments to businesses that invest in energy-efficient technologies. For example, the UK's Enhanced Capital Allowance scheme allows businesses to claim 100% first-year tax relief on qualifying energy-saving technologies, which can include certain laminar flow systems.

As awareness of the environmental benefits of laminar flow systems grows, regulatory bodies are increasingly incorporating specific provisions for these technologies. This evolving regulatory landscape not only mandates the use of more efficient systems but also creates a market pull for innovation in laminar flow technologies, driving research and development in the field.

At the international level, agreements such as the Paris Climate Accord and the United Nations Sustainable Development Goals provide overarching guidance for nations to reduce their environmental impact. These agreements have spurred the development of more specific regulations targeting industrial processes and energy efficiency, which directly impact the adoption of laminar flow systems.

In the European Union, the Industrial Emissions Directive (IED) sets stringent requirements for industrial installations to employ best available techniques (BAT) to minimize environmental impact. Laminar flow systems, with their potential for energy savings and reduced emissions, are increasingly recognized as BAT in various sectors. The EU's Ecodesign Directive also plays a role by setting minimum efficiency standards for energy-related products, indirectly promoting the use of laminar flow technologies in appliances and industrial equipment.

In the United States, the Environmental Protection Agency (EPA) has established regulations under the Clean Air Act and Clean Water Act that incentivize the use of efficient flow systems. The Department of Energy's Better Plants program provides technical assistance and recognition for industrial facilities that implement energy-saving technologies, including laminar flow systems.

Many countries have implemented green building codes and certification systems, such as LEED (Leadership in Energy and Environmental Design) in the United States and BREEAM (Building Research Establishment Environmental Assessment Method) in the UK. These systems often award points for the incorporation of energy-efficient HVAC systems that utilize laminar flow principles, further driving adoption in the construction sector.

Financial incentives also form a significant part of the regulatory framework. Tax credits, grants, and subsidies are offered by various governments to businesses that invest in energy-efficient technologies. For example, the UK's Enhanced Capital Allowance scheme allows businesses to claim 100% first-year tax relief on qualifying energy-saving technologies, which can include certain laminar flow systems.

As awareness of the environmental benefits of laminar flow systems grows, regulatory bodies are increasingly incorporating specific provisions for these technologies. This evolving regulatory landscape not only mandates the use of more efficient systems but also creates a market pull for innovation in laminar flow technologies, driving research and development in the field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!