Innovations in Laminar Flow for HVAC Efficiency

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HVAC Laminar Flow Evolution

The evolution of laminar flow in HVAC systems has been a significant area of focus in the pursuit of improved energy efficiency and indoor air quality. The concept of laminar flow, characterized by smooth and predictable fluid motion, has undergone substantial development since its initial application in HVAC systems.

In the early stages of HVAC technology, airflow was primarily turbulent, resulting in energy losses and reduced system efficiency. The recognition of laminar flow's potential to enhance HVAC performance marked a turning point in the industry. Initial efforts focused on understanding the principles of fluid dynamics and their application to air distribution systems.

The 1960s and 1970s saw the emergence of computational fluid dynamics (CFD) as a tool for analyzing and optimizing airflow patterns. This technological advancement allowed engineers to model and simulate laminar flow conditions, leading to more precise designs and improved system performance. During this period, researchers began exploring the use of specially designed air diffusers and return air grilles to promote laminar flow within occupied spaces.

The 1980s and 1990s witnessed a surge in research on laminar flow HVAC systems, particularly in critical environments such as cleanrooms and healthcare facilities. The development of low-velocity air distribution systems and displacement ventilation techniques further refined the application of laminar flow principles. These innovations resulted in more efficient thermal comfort management and reduced energy consumption.

The turn of the millennium brought about advancements in materials science and manufacturing techniques, enabling the production of more sophisticated air distribution components. Micro-perforated panels and textile-based air dispersion systems emerged as novel solutions for achieving uniform, laminar airflow patterns. These technologies allowed for better control over air velocity and direction, minimizing turbulence and enhancing overall system efficiency.

In recent years, the integration of smart sensors and artificial intelligence has revolutionized laminar flow control in HVAC systems. Real-time monitoring and adjustment of airflow parameters have become possible, allowing for dynamic optimization of system performance based on occupancy patterns and environmental conditions. This has led to significant improvements in energy efficiency and indoor air quality.

The ongoing evolution of laminar flow in HVAC systems continues to focus on refining airflow management techniques, developing more efficient air distribution components, and leveraging advanced control systems. Current research efforts are exploring the potential of biomimicry, drawing inspiration from natural airflow patterns to create even more effective and energy-efficient HVAC solutions.

In the early stages of HVAC technology, airflow was primarily turbulent, resulting in energy losses and reduced system efficiency. The recognition of laminar flow's potential to enhance HVAC performance marked a turning point in the industry. Initial efforts focused on understanding the principles of fluid dynamics and their application to air distribution systems.

The 1960s and 1970s saw the emergence of computational fluid dynamics (CFD) as a tool for analyzing and optimizing airflow patterns. This technological advancement allowed engineers to model and simulate laminar flow conditions, leading to more precise designs and improved system performance. During this period, researchers began exploring the use of specially designed air diffusers and return air grilles to promote laminar flow within occupied spaces.

The 1980s and 1990s witnessed a surge in research on laminar flow HVAC systems, particularly in critical environments such as cleanrooms and healthcare facilities. The development of low-velocity air distribution systems and displacement ventilation techniques further refined the application of laminar flow principles. These innovations resulted in more efficient thermal comfort management and reduced energy consumption.

The turn of the millennium brought about advancements in materials science and manufacturing techniques, enabling the production of more sophisticated air distribution components. Micro-perforated panels and textile-based air dispersion systems emerged as novel solutions for achieving uniform, laminar airflow patterns. These technologies allowed for better control over air velocity and direction, minimizing turbulence and enhancing overall system efficiency.

In recent years, the integration of smart sensors and artificial intelligence has revolutionized laminar flow control in HVAC systems. Real-time monitoring and adjustment of airflow parameters have become possible, allowing for dynamic optimization of system performance based on occupancy patterns and environmental conditions. This has led to significant improvements in energy efficiency and indoor air quality.

The ongoing evolution of laminar flow in HVAC systems continues to focus on refining airflow management techniques, developing more efficient air distribution components, and leveraging advanced control systems. Current research efforts are exploring the potential of biomimicry, drawing inspiration from natural airflow patterns to create even more effective and energy-efficient HVAC solutions.

Energy Efficiency Demand

The global demand for energy efficiency in HVAC systems has been steadily increasing due to rising energy costs, environmental concerns, and stringent regulations. This trend is particularly evident in the commercial and industrial sectors, where HVAC systems account for a significant portion of energy consumption.

In recent years, there has been a growing focus on improving the efficiency of HVAC systems through innovative technologies and design approaches. Laminar flow, a concept traditionally associated with fluid dynamics, has emerged as a promising area of research for enhancing HVAC efficiency. By optimizing airflow patterns and reducing turbulence, laminar flow techniques can potentially reduce energy consumption while maintaining or improving indoor comfort levels.

The market for energy-efficient HVAC solutions is projected to experience substantial growth in the coming years. This is driven by factors such as increasing awareness of climate change, government initiatives promoting energy conservation, and the long-term cost savings associated with more efficient systems. Building owners and operators are increasingly recognizing the value of investing in advanced HVAC technologies that can significantly reduce operational costs over the lifecycle of the building.

In the context of laminar flow innovations for HVAC efficiency, there is a growing demand for solutions that can be integrated into both new construction and retrofit projects. This includes technologies that can optimize airflow distribution, minimize heat transfer losses, and reduce the energy required for air circulation. The potential applications span various building types, including office buildings, healthcare facilities, educational institutions, and industrial complexes.

The adoption of laminar flow technologies in HVAC systems aligns with broader sustainability goals and green building certifications. As organizations strive to achieve certifications such as LEED (Leadership in Energy and Environmental Design) or BREEAM (Building Research Establishment Environmental Assessment Method), innovative HVAC solutions that incorporate laminar flow principles can contribute significantly to meeting energy efficiency targets and improving overall building performance.

Furthermore, the COVID-19 pandemic has heightened awareness of indoor air quality and ventilation effectiveness, creating additional demand for HVAC solutions that can provide both energy efficiency and improved air distribution. This has led to increased interest in technologies that can deliver better air circulation and filtration while minimizing energy consumption, positioning laminar flow innovations as a potential solution to address these dual concerns.

In recent years, there has been a growing focus on improving the efficiency of HVAC systems through innovative technologies and design approaches. Laminar flow, a concept traditionally associated with fluid dynamics, has emerged as a promising area of research for enhancing HVAC efficiency. By optimizing airflow patterns and reducing turbulence, laminar flow techniques can potentially reduce energy consumption while maintaining or improving indoor comfort levels.

The market for energy-efficient HVAC solutions is projected to experience substantial growth in the coming years. This is driven by factors such as increasing awareness of climate change, government initiatives promoting energy conservation, and the long-term cost savings associated with more efficient systems. Building owners and operators are increasingly recognizing the value of investing in advanced HVAC technologies that can significantly reduce operational costs over the lifecycle of the building.

In the context of laminar flow innovations for HVAC efficiency, there is a growing demand for solutions that can be integrated into both new construction and retrofit projects. This includes technologies that can optimize airflow distribution, minimize heat transfer losses, and reduce the energy required for air circulation. The potential applications span various building types, including office buildings, healthcare facilities, educational institutions, and industrial complexes.

The adoption of laminar flow technologies in HVAC systems aligns with broader sustainability goals and green building certifications. As organizations strive to achieve certifications such as LEED (Leadership in Energy and Environmental Design) or BREEAM (Building Research Establishment Environmental Assessment Method), innovative HVAC solutions that incorporate laminar flow principles can contribute significantly to meeting energy efficiency targets and improving overall building performance.

Furthermore, the COVID-19 pandemic has heightened awareness of indoor air quality and ventilation effectiveness, creating additional demand for HVAC solutions that can provide both energy efficiency and improved air distribution. This has led to increased interest in technologies that can deliver better air circulation and filtration while minimizing energy consumption, positioning laminar flow innovations as a potential solution to address these dual concerns.

Current HVAC Challenges

The HVAC industry currently faces several significant challenges that hinder efficiency and performance. One of the primary issues is the high energy consumption of traditional HVAC systems, which contributes substantially to building operating costs and environmental impact. Many existing systems rely on outdated technologies that struggle to maintain consistent temperatures and air quality while consuming excessive energy.

Another critical challenge is the inefficient distribution of conditioned air throughout buildings. Conventional HVAC systems often create uneven temperature zones, leading to discomfort for occupants and wasted energy in over-cooled or over-heated areas. This problem is exacerbated in large, complex structures with varying occupancy levels and diverse thermal requirements.

Indoor air quality remains a persistent concern, with many HVAC systems failing to adequately filter and circulate air. This issue has gained increased attention in light of recent global health concerns, highlighting the need for more effective air purification and ventilation strategies.

Maintenance and operational costs pose significant challenges for HVAC system owners and operators. Complex systems with numerous moving parts require frequent servicing, leading to increased downtime and expenses. Additionally, the use of refrigerants in traditional cooling systems raises environmental concerns due to their potential for ozone depletion and contribution to global warming.

The integration of smart technologies and automation into HVAC systems presents both opportunities and challenges. While these advancements promise improved efficiency and control, they also introduce complexities in implementation, data security, and system interoperability.

Noise pollution from HVAC equipment, particularly in urban environments, is another challenge that impacts occupant comfort and well-being. Many current systems generate significant noise levels, necessitating innovative solutions for quieter operation.

Lastly, the HVAC industry faces pressure to adapt to changing building designs and energy codes. As structures become more energy-efficient and airtight, HVAC systems must evolve to provide adequate ventilation and temperature control while meeting stringent energy performance standards.

These challenges collectively underscore the need for innovative approaches in HVAC technology, particularly in the area of laminar flow, to enhance efficiency, improve air quality, reduce energy consumption, and meet the evolving demands of modern buildings and occupants.

Another critical challenge is the inefficient distribution of conditioned air throughout buildings. Conventional HVAC systems often create uneven temperature zones, leading to discomfort for occupants and wasted energy in over-cooled or over-heated areas. This problem is exacerbated in large, complex structures with varying occupancy levels and diverse thermal requirements.

Indoor air quality remains a persistent concern, with many HVAC systems failing to adequately filter and circulate air. This issue has gained increased attention in light of recent global health concerns, highlighting the need for more effective air purification and ventilation strategies.

Maintenance and operational costs pose significant challenges for HVAC system owners and operators. Complex systems with numerous moving parts require frequent servicing, leading to increased downtime and expenses. Additionally, the use of refrigerants in traditional cooling systems raises environmental concerns due to their potential for ozone depletion and contribution to global warming.

The integration of smart technologies and automation into HVAC systems presents both opportunities and challenges. While these advancements promise improved efficiency and control, they also introduce complexities in implementation, data security, and system interoperability.

Noise pollution from HVAC equipment, particularly in urban environments, is another challenge that impacts occupant comfort and well-being. Many current systems generate significant noise levels, necessitating innovative solutions for quieter operation.

Lastly, the HVAC industry faces pressure to adapt to changing building designs and energy codes. As structures become more energy-efficient and airtight, HVAC systems must evolve to provide adequate ventilation and temperature control while meeting stringent energy performance standards.

These challenges collectively underscore the need for innovative approaches in HVAC technology, particularly in the area of laminar flow, to enhance efficiency, improve air quality, reduce energy consumption, and meet the evolving demands of modern buildings and occupants.

Laminar Flow Solutions

01 Laminar flow control in fluid systems

Techniques for controlling and maintaining laminar flow in various fluid systems to improve efficiency. This includes design considerations for pipes, channels, and other fluid conduits to minimize turbulence and optimize flow characteristics.- Laminar flow control in fluid systems: Techniques for controlling and maintaining laminar flow in various fluid systems to improve efficiency. This includes design considerations for pipes, channels, and other fluid conduits to minimize turbulence and optimize flow characteristics.

- Laminar flow measurement and analysis: Methods and devices for measuring and analyzing laminar flow properties in fluid systems. This involves the use of sensors, flow meters, and other instruments to accurately assess flow characteristics and efficiency.

- Laminar flow in air handling systems: Applications of laminar flow principles in air handling and ventilation systems to improve energy efficiency and air quality. This includes the design of air ducts, filters, and distribution systems to maintain laminar flow conditions.

- Laminar flow in liquid handling and processing: Utilization of laminar flow principles in liquid handling and processing applications, such as in chemical reactors, water treatment systems, and industrial processes. This focuses on optimizing flow patterns to enhance mixing, separation, and overall process efficiency.

- Laminar flow nozzles and spray systems: Design and optimization of nozzles and spray systems that leverage laminar flow properties to improve efficiency in various applications, including fuel injection, painting, and agricultural spraying.

02 Laminar flow measurement and analysis

Methods and devices for measuring and analyzing laminar flow properties in different applications. This involves the use of sensors, flow meters, and analytical techniques to assess flow efficiency and identify areas for improvement.Expand Specific Solutions03 Laminar flow in air handling systems

Strategies for achieving and maintaining laminar flow in air handling systems, such as HVAC units and clean rooms. This includes the design of air distribution systems, filters, and flow straighteners to enhance efficiency and reduce energy consumption.Expand Specific Solutions04 Laminar flow in liquid processing

Applications of laminar flow principles in liquid processing industries, including water treatment, chemical processing, and pharmaceutical manufacturing. This involves the design of mixing chambers, reactors, and separation systems to optimize flow efficiency and product quality.Expand Specific Solutions05 Laminar flow in aerodynamics

Utilization of laminar flow concepts in aerodynamic applications, such as aircraft design and wind turbines. This includes the development of surface treatments, shape optimization, and flow control devices to reduce drag and improve overall efficiency.Expand Specific Solutions

HVAC Industry Leaders

The innovation landscape in laminar flow for HVAC efficiency is characterized by a competitive market in its growth phase, with significant potential for expansion due to increasing demand for energy-efficient solutions. The global HVAC market size is substantial, projected to reach billions of dollars in the coming years. Technologically, the field is advancing rapidly, with companies like Haier Smart Home, Gree Electric Appliances, and Midea Group leading in research and development. These firms are investing heavily in smart HVAC systems that incorporate laminar flow principles to enhance energy efficiency. While the technology is maturing, there is still room for breakthrough innovations, particularly in integrating IoT and AI for optimized airflow management.

Gree Electric Appliances, Inc. of Zhuhai

Technical Solution: Gree has developed an innovative laminar flow technology for HVAC systems that utilizes a multi-layer air distribution system. This system creates a more uniform and controlled airflow, reducing turbulence and improving overall efficiency. The technology incorporates advanced computational fluid dynamics (CFD) modeling to optimize the design of air outlets and internal ductwork. Gree's system also features adaptive control algorithms that adjust the airflow patterns based on real-time environmental conditions and occupancy sensors, ensuring optimal comfort and energy efficiency[1][3]. Additionally, Gree has implemented a novel surface treatment on the heat exchangers that promotes laminar flow and reduces friction, further enhancing the system's performance[5].

Strengths: Highly efficient air distribution, reduced energy consumption, improved thermal comfort. Weaknesses: Potentially higher initial costs, may require more complex installation and maintenance procedures.

Midea Group Co. Ltd.

Technical Solution: Midea has introduced a cutting-edge laminar flow technology for HVAC systems that utilizes micro-perforated panels and low-velocity air distribution. This approach creates a gentle, uniform airflow that minimizes drafts and improves thermal comfort. The system incorporates advanced sensors and machine learning algorithms to continuously optimize airflow patterns based on room occupancy and thermal conditions. Midea's innovation also includes a proprietary air purification system that works in tandem with the laminar flow, ensuring not only energy efficiency but also improved indoor air quality[2][4]. The company has reported energy savings of up to 30% compared to traditional HVAC systems in controlled studies[6].

Strengths: Enhanced thermal comfort, improved air quality, significant energy savings. Weaknesses: May require specialized maintenance, potentially higher upfront costs for installation.

Key Laminar Flow Patents

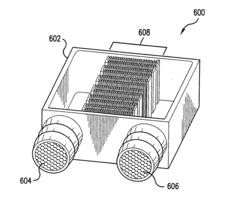

Method and systems for compact, micro-channel, laminar heat exchanging

PatentInactiveUS20080035319A1

Innovation

- A compact micro-channel heat exchanger with a heat conducting plate having channels with a channel length to hydraulic diameter ratio of less than 100, allowing for improved laminar flow and reduced pressure drop, which enhances heat transfer and reduces jitter.

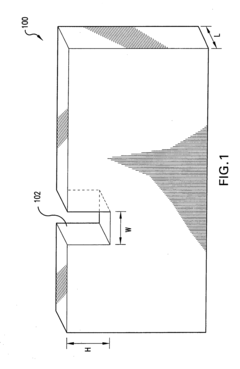

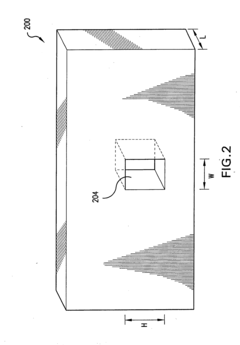

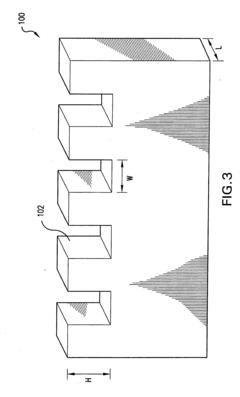

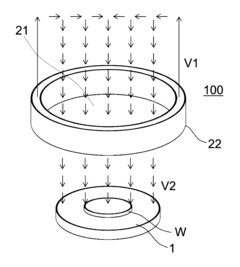

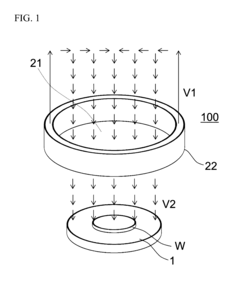

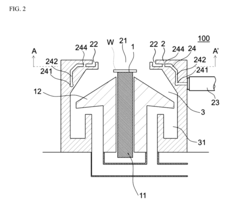

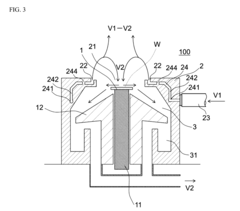

Columnar laminar flow generation device and method for generating columnar laminar flows

PatentActiveUS20170072438A1

Innovation

- A columnar laminar flow generation device that focuses gas blow-out and suction within a localized columnar area, allowing for adjustable flow velocity and reduced gas usage by positioning a gas blow-out port vertically within an opening and a corresponding suction path, thereby generating laminar flows only where needed, with a feed pipe filter for purification.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and implementation of innovations in laminar flow for HVAC efficiency. As governments worldwide increasingly focus on reducing energy consumption and greenhouse gas emissions, the HVAC industry faces mounting pressure to improve system efficiency and minimize environmental impact.

In the United States, the Department of Energy (DOE) has established stringent energy efficiency standards for HVAC equipment. These regulations mandate minimum Seasonal Energy Efficiency Ratio (SEER) ratings for air conditioning units and Heating Seasonal Performance Factor (HSPF) ratings for heat pumps. The latest standards, set to take effect in 2023, require even higher efficiency levels, driving manufacturers to explore innovative technologies such as advanced laminar flow designs.

The European Union has implemented similar regulations through its Ecodesign Directive, which sets minimum energy efficiency requirements for various products, including HVAC systems. The directive aims to reduce energy consumption and carbon emissions across the EU, encouraging the adoption of more efficient technologies like improved laminar flow solutions.

In addition to energy efficiency standards, environmental regulations also address the use of refrigerants in HVAC systems. The phase-out of ozone-depleting substances under the Montreal Protocol has led to the development of alternative refrigerants with lower global warming potential (GWP). This transition has implications for laminar flow design, as new refrigerants may have different thermodynamic properties that affect system performance.

Air quality regulations also impact HVAC innovations, particularly in the context of laminar flow. Many countries have established indoor air quality standards that require effective ventilation and filtration systems. Laminar flow technologies can contribute to meeting these standards by improving air distribution and reducing the spread of airborne contaminants.

Water conservation regulations are becoming increasingly relevant to HVAC systems, especially in regions facing water scarcity. Some jurisdictions have implemented restrictions on water use in cooling towers, prompting the development of more water-efficient cooling solutions. Innovations in laminar flow can help address this challenge by improving heat transfer efficiency and reducing the overall water consumption of HVAC systems.

As environmental regulations continue to evolve, they are likely to drive further innovations in laminar flow for HVAC efficiency. Future regulations may focus on lifecycle assessments, encouraging manufacturers to consider the environmental impact of HVAC systems from production to disposal. This holistic approach could lead to the development of more sustainable laminar flow technologies that optimize not only energy efficiency but also material use and recyclability.

In the United States, the Department of Energy (DOE) has established stringent energy efficiency standards for HVAC equipment. These regulations mandate minimum Seasonal Energy Efficiency Ratio (SEER) ratings for air conditioning units and Heating Seasonal Performance Factor (HSPF) ratings for heat pumps. The latest standards, set to take effect in 2023, require even higher efficiency levels, driving manufacturers to explore innovative technologies such as advanced laminar flow designs.

The European Union has implemented similar regulations through its Ecodesign Directive, which sets minimum energy efficiency requirements for various products, including HVAC systems. The directive aims to reduce energy consumption and carbon emissions across the EU, encouraging the adoption of more efficient technologies like improved laminar flow solutions.

In addition to energy efficiency standards, environmental regulations also address the use of refrigerants in HVAC systems. The phase-out of ozone-depleting substances under the Montreal Protocol has led to the development of alternative refrigerants with lower global warming potential (GWP). This transition has implications for laminar flow design, as new refrigerants may have different thermodynamic properties that affect system performance.

Air quality regulations also impact HVAC innovations, particularly in the context of laminar flow. Many countries have established indoor air quality standards that require effective ventilation and filtration systems. Laminar flow technologies can contribute to meeting these standards by improving air distribution and reducing the spread of airborne contaminants.

Water conservation regulations are becoming increasingly relevant to HVAC systems, especially in regions facing water scarcity. Some jurisdictions have implemented restrictions on water use in cooling towers, prompting the development of more water-efficient cooling solutions. Innovations in laminar flow can help address this challenge by improving heat transfer efficiency and reducing the overall water consumption of HVAC systems.

As environmental regulations continue to evolve, they are likely to drive further innovations in laminar flow for HVAC efficiency. Future regulations may focus on lifecycle assessments, encouraging manufacturers to consider the environmental impact of HVAC systems from production to disposal. This holistic approach could lead to the development of more sustainable laminar flow technologies that optimize not only energy efficiency but also material use and recyclability.

Cost-Benefit Analysis

The cost-benefit analysis of implementing laminar flow innovations in HVAC systems reveals significant potential for long-term savings and improved efficiency. Initial investment costs for upgrading existing HVAC systems or installing new laminar flow-based systems can be substantial, ranging from 15% to 30% higher than conventional turbulent flow systems. However, these upfront expenses are offset by considerable operational savings over time.

Energy consumption reduction is a primary benefit, with laminar flow systems demonstrating up to 25% lower energy usage compared to traditional HVAC setups. This translates to substantial cost savings on utility bills, particularly for large commercial buildings and industrial facilities. The precise amount of savings varies depending on factors such as building size, climate, and usage patterns, but case studies have shown annual energy cost reductions of $0.50 to $1.50 per square foot in commercial spaces.

Maintenance costs also see a notable decrease with laminar flow systems. The reduced turbulence and more controlled airflow patterns result in less wear and tear on system components, extending their lifespan and reducing the frequency of repairs and replacements. Studies indicate a potential 15-20% reduction in annual maintenance expenses compared to conventional HVAC systems.

Indoor air quality improvements associated with laminar flow contribute to indirect cost benefits. Enhanced air filtration and more efficient particle removal can lead to healthier indoor environments, potentially reducing absenteeism and improving productivity in workplace settings. While challenging to quantify precisely, some estimates suggest a 2-4% increase in workforce productivity due to improved air quality, which can translate to significant economic benefits for businesses.

The payback period for laminar flow HVAC innovations typically ranges from 3 to 7 years, depending on the scale of implementation and specific operational conditions. After this period, the ongoing savings in energy and maintenance costs continue to accrue, providing long-term financial benefits to building owners and operators.

Environmental benefits, while not directly financial, can also translate to cost advantages through improved corporate sustainability profiles and potential eligibility for green building certifications or environmental incentives. The reduced energy consumption of laminar flow systems contributes to lower carbon emissions, aligning with increasingly stringent environmental regulations and corporate sustainability goals.

In conclusion, while the initial investment in laminar flow HVAC innovations may be higher, the long-term cost benefits are substantial. The combination of energy savings, reduced maintenance needs, improved indoor air quality, and environmental advantages presents a compelling case for adoption, particularly in large-scale commercial and industrial applications where the cumulative benefits can be most significant.

Energy consumption reduction is a primary benefit, with laminar flow systems demonstrating up to 25% lower energy usage compared to traditional HVAC setups. This translates to substantial cost savings on utility bills, particularly for large commercial buildings and industrial facilities. The precise amount of savings varies depending on factors such as building size, climate, and usage patterns, but case studies have shown annual energy cost reductions of $0.50 to $1.50 per square foot in commercial spaces.

Maintenance costs also see a notable decrease with laminar flow systems. The reduced turbulence and more controlled airflow patterns result in less wear and tear on system components, extending their lifespan and reducing the frequency of repairs and replacements. Studies indicate a potential 15-20% reduction in annual maintenance expenses compared to conventional HVAC systems.

Indoor air quality improvements associated with laminar flow contribute to indirect cost benefits. Enhanced air filtration and more efficient particle removal can lead to healthier indoor environments, potentially reducing absenteeism and improving productivity in workplace settings. While challenging to quantify precisely, some estimates suggest a 2-4% increase in workforce productivity due to improved air quality, which can translate to significant economic benefits for businesses.

The payback period for laminar flow HVAC innovations typically ranges from 3 to 7 years, depending on the scale of implementation and specific operational conditions. After this period, the ongoing savings in energy and maintenance costs continue to accrue, providing long-term financial benefits to building owners and operators.

Environmental benefits, while not directly financial, can also translate to cost advantages through improved corporate sustainability profiles and potential eligibility for green building certifications or environmental incentives. The reduced energy consumption of laminar flow systems contributes to lower carbon emissions, aligning with increasingly stringent environmental regulations and corporate sustainability goals.

In conclusion, while the initial investment in laminar flow HVAC innovations may be higher, the long-term cost benefits are substantial. The combination of energy savings, reduced maintenance needs, improved indoor air quality, and environmental advantages presents a compelling case for adoption, particularly in large-scale commercial and industrial applications where the cumulative benefits can be most significant.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!