Navigating Environmental Policy Reforms with Laminar Flow Innovation

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Environmental Policy Context and Laminar Flow Goals

Environmental policy reforms have become increasingly crucial in addressing global climate change and sustainability challenges. In this context, laminar flow innovation emerges as a promising technological solution to navigate these reforms effectively. The development of laminar flow technology has progressed significantly over the past decades, driven by the need for more efficient and environmentally friendly fluid dynamics applications across various industries.

The primary goal of integrating laminar flow innovation into environmental policy reforms is to achieve substantial reductions in energy consumption and emissions while maintaining or improving process efficiency. This aligns with broader policy objectives of transitioning towards a low-carbon economy and meeting international climate commitments. Laminar flow technology offers the potential to revolutionize fluid handling systems in industries such as aerospace, automotive, and HVAC, where energy efficiency and environmental impact are critical concerns.

As environmental regulations become more stringent, industries are under increasing pressure to adopt cleaner technologies. Laminar flow innovation presents a viable pathway to compliance by minimizing turbulence and optimizing fluid flow, resulting in reduced friction losses and improved overall system performance. This technology aims to address key environmental challenges, including greenhouse gas emissions, air quality, and resource conservation.

The evolution of laminar flow research has been closely tied to advancements in computational fluid dynamics (CFD) and materials science. These interdisciplinary developments have enabled more accurate modeling and implementation of laminar flow principles in real-world applications. The goal is to push the boundaries of what is possible in fluid dynamics, seeking to create near-perfect laminar flow conditions in scenarios where turbulence has traditionally been the norm.

In the context of environmental policy, laminar flow goals extend beyond mere technological advancement. They encompass the creation of scalable and adaptable solutions that can be widely implemented across different sectors. This includes developing standardized design principles, establishing best practices for implementation, and creating frameworks for measuring and verifying the environmental benefits of laminar flow systems.

Furthermore, the integration of laminar flow innovation into environmental policy reforms aims to foster collaboration between policymakers, industry leaders, and research institutions. This collaborative approach is essential for aligning technological development with regulatory requirements and market demands. The ultimate objective is to create a synergy between environmental protection and economic growth, demonstrating that sustainable technologies can drive innovation and competitiveness.

The primary goal of integrating laminar flow innovation into environmental policy reforms is to achieve substantial reductions in energy consumption and emissions while maintaining or improving process efficiency. This aligns with broader policy objectives of transitioning towards a low-carbon economy and meeting international climate commitments. Laminar flow technology offers the potential to revolutionize fluid handling systems in industries such as aerospace, automotive, and HVAC, where energy efficiency and environmental impact are critical concerns.

As environmental regulations become more stringent, industries are under increasing pressure to adopt cleaner technologies. Laminar flow innovation presents a viable pathway to compliance by minimizing turbulence and optimizing fluid flow, resulting in reduced friction losses and improved overall system performance. This technology aims to address key environmental challenges, including greenhouse gas emissions, air quality, and resource conservation.

The evolution of laminar flow research has been closely tied to advancements in computational fluid dynamics (CFD) and materials science. These interdisciplinary developments have enabled more accurate modeling and implementation of laminar flow principles in real-world applications. The goal is to push the boundaries of what is possible in fluid dynamics, seeking to create near-perfect laminar flow conditions in scenarios where turbulence has traditionally been the norm.

In the context of environmental policy, laminar flow goals extend beyond mere technological advancement. They encompass the creation of scalable and adaptable solutions that can be widely implemented across different sectors. This includes developing standardized design principles, establishing best practices for implementation, and creating frameworks for measuring and verifying the environmental benefits of laminar flow systems.

Furthermore, the integration of laminar flow innovation into environmental policy reforms aims to foster collaboration between policymakers, industry leaders, and research institutions. This collaborative approach is essential for aligning technological development with regulatory requirements and market demands. The ultimate objective is to create a synergy between environmental protection and economic growth, demonstrating that sustainable technologies can drive innovation and competitiveness.

Market Demand for Sustainable Fluid Dynamics Solutions

The market demand for sustainable fluid dynamics solutions has been steadily increasing in recent years, driven by a combination of environmental concerns, regulatory pressures, and economic incentives. As industries face stricter environmental policies and sustainability targets, there is a growing need for innovative technologies that can optimize fluid flow processes while reducing energy consumption and environmental impact.

In the industrial sector, manufacturers are seeking advanced laminar flow solutions to improve production efficiency and reduce waste. The automotive industry, for instance, is exploring laminar flow technologies to enhance aerodynamics and fuel efficiency in vehicle design. This demand is further amplified by the shift towards electric vehicles, where optimizing fluid dynamics plays a crucial role in battery cooling and overall performance.

The energy sector, particularly in renewable energy production, has shown significant interest in sustainable fluid dynamics solutions. Wind turbine manufacturers are investing in research to improve blade designs using laminar flow principles, aiming to increase energy output and reduce noise pollution. Similarly, the solar industry is exploring fluid dynamics innovations to enhance heat transfer in concentrated solar power systems.

Water management and treatment facilities are another key market for sustainable fluid dynamics solutions. With growing water scarcity concerns, there is an increasing demand for technologies that can improve water distribution efficiency and reduce energy consumption in treatment processes. Laminar flow innovations are being sought to optimize pipe networks, reduce friction losses, and enhance filtration systems.

The aerospace industry continues to be a significant driver of demand for advanced fluid dynamics solutions. Airlines and aircraft manufacturers are actively seeking ways to reduce fuel consumption and emissions, with a focus on improving aerodynamics through laminar flow control technologies. This demand is expected to grow as the industry faces increasing pressure to meet stringent environmental regulations.

In the building and construction sector, there is a rising interest in sustainable HVAC systems that leverage laminar flow principles to improve energy efficiency and indoor air quality. As green building standards become more prevalent, architects and engineers are looking for innovative fluid dynamics solutions to optimize ventilation and thermal management in buildings.

The healthcare industry has also emerged as a potential growth market for sustainable fluid dynamics solutions. From improving drug delivery systems to enhancing medical imaging techniques, there is a growing recognition of the role that advanced fluid dynamics can play in developing more effective and efficient healthcare technologies.

In the industrial sector, manufacturers are seeking advanced laminar flow solutions to improve production efficiency and reduce waste. The automotive industry, for instance, is exploring laminar flow technologies to enhance aerodynamics and fuel efficiency in vehicle design. This demand is further amplified by the shift towards electric vehicles, where optimizing fluid dynamics plays a crucial role in battery cooling and overall performance.

The energy sector, particularly in renewable energy production, has shown significant interest in sustainable fluid dynamics solutions. Wind turbine manufacturers are investing in research to improve blade designs using laminar flow principles, aiming to increase energy output and reduce noise pollution. Similarly, the solar industry is exploring fluid dynamics innovations to enhance heat transfer in concentrated solar power systems.

Water management and treatment facilities are another key market for sustainable fluid dynamics solutions. With growing water scarcity concerns, there is an increasing demand for technologies that can improve water distribution efficiency and reduce energy consumption in treatment processes. Laminar flow innovations are being sought to optimize pipe networks, reduce friction losses, and enhance filtration systems.

The aerospace industry continues to be a significant driver of demand for advanced fluid dynamics solutions. Airlines and aircraft manufacturers are actively seeking ways to reduce fuel consumption and emissions, with a focus on improving aerodynamics through laminar flow control technologies. This demand is expected to grow as the industry faces increasing pressure to meet stringent environmental regulations.

In the building and construction sector, there is a rising interest in sustainable HVAC systems that leverage laminar flow principles to improve energy efficiency and indoor air quality. As green building standards become more prevalent, architects and engineers are looking for innovative fluid dynamics solutions to optimize ventilation and thermal management in buildings.

The healthcare industry has also emerged as a potential growth market for sustainable fluid dynamics solutions. From improving drug delivery systems to enhancing medical imaging techniques, there is a growing recognition of the role that advanced fluid dynamics can play in developing more effective and efficient healthcare technologies.

Current Challenges in Laminar Flow Technology

Laminar flow technology, while offering significant potential for environmental policy reforms, faces several critical challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the complexity of maintaining laminar flow conditions in real-world applications. Unlike controlled laboratory environments, industrial and environmental settings often present unpredictable variables that can disrupt the delicate balance required for laminar flow.

The scale-up of laminar flow systems from laboratory prototypes to industrial-scale implementations poses another significant challenge. As the size of the system increases, maintaining uniform flow characteristics becomes increasingly difficult, often leading to unexpected turbulence or flow irregularities. This scaling issue not only affects the efficiency of the technology but also impacts its economic viability in large-scale environmental applications.

Energy efficiency remains a concern in laminar flow systems, particularly when applied to environmental policy reforms. While laminar flow can reduce friction and improve overall system performance, achieving and maintaining these conditions often requires additional energy input. This energy requirement can potentially offset some of the environmental benefits gained from the technology, creating a delicate balance that policymakers and engineers must carefully consider.

Material limitations present another hurdle in advancing laminar flow technology. The surfaces and components used in these systems must meet exacting specifications to promote and maintain laminar flow conditions. Finding materials that are both suitable for laminar flow and resistant to the often harsh conditions encountered in environmental applications (such as corrosive pollutants or extreme temperatures) remains an ongoing challenge.

The integration of laminar flow technology with existing infrastructure and processes is also proving to be a significant challenge. Many environmental systems and industrial processes were not originally designed with laminar flow principles in mind, making retrofitting difficult and sometimes cost-prohibitive. This integration challenge often requires innovative engineering solutions and may necessitate substantial modifications to existing systems.

Measurement and control systems for laminar flow applications in environmental contexts present their own set of challenges. Accurately monitoring and maintaining laminar flow conditions in dynamic environmental settings requires sophisticated sensors and control algorithms. Developing robust, reliable, and cost-effective monitoring systems that can operate in diverse environmental conditions is crucial for the successful implementation of laminar flow technology in policy-driven applications.

Lastly, the regulatory landscape surrounding the use of laminar flow technology in environmental applications is still evolving. The lack of standardized guidelines and performance metrics specific to laminar flow systems in environmental contexts can create uncertainty for both technology developers and potential adopters. This regulatory ambiguity may slow down the implementation of laminar flow solutions in addressing environmental policy objectives.

The scale-up of laminar flow systems from laboratory prototypes to industrial-scale implementations poses another significant challenge. As the size of the system increases, maintaining uniform flow characteristics becomes increasingly difficult, often leading to unexpected turbulence or flow irregularities. This scaling issue not only affects the efficiency of the technology but also impacts its economic viability in large-scale environmental applications.

Energy efficiency remains a concern in laminar flow systems, particularly when applied to environmental policy reforms. While laminar flow can reduce friction and improve overall system performance, achieving and maintaining these conditions often requires additional energy input. This energy requirement can potentially offset some of the environmental benefits gained from the technology, creating a delicate balance that policymakers and engineers must carefully consider.

Material limitations present another hurdle in advancing laminar flow technology. The surfaces and components used in these systems must meet exacting specifications to promote and maintain laminar flow conditions. Finding materials that are both suitable for laminar flow and resistant to the often harsh conditions encountered in environmental applications (such as corrosive pollutants or extreme temperatures) remains an ongoing challenge.

The integration of laminar flow technology with existing infrastructure and processes is also proving to be a significant challenge. Many environmental systems and industrial processes were not originally designed with laminar flow principles in mind, making retrofitting difficult and sometimes cost-prohibitive. This integration challenge often requires innovative engineering solutions and may necessitate substantial modifications to existing systems.

Measurement and control systems for laminar flow applications in environmental contexts present their own set of challenges. Accurately monitoring and maintaining laminar flow conditions in dynamic environmental settings requires sophisticated sensors and control algorithms. Developing robust, reliable, and cost-effective monitoring systems that can operate in diverse environmental conditions is crucial for the successful implementation of laminar flow technology in policy-driven applications.

Lastly, the regulatory landscape surrounding the use of laminar flow technology in environmental applications is still evolving. The lack of standardized guidelines and performance metrics specific to laminar flow systems in environmental contexts can create uncertainty for both technology developers and potential adopters. This regulatory ambiguity may slow down the implementation of laminar flow solutions in addressing environmental policy objectives.

Existing Laminar Flow Solutions for Policy Compliance

01 Flow measurement and control innovations

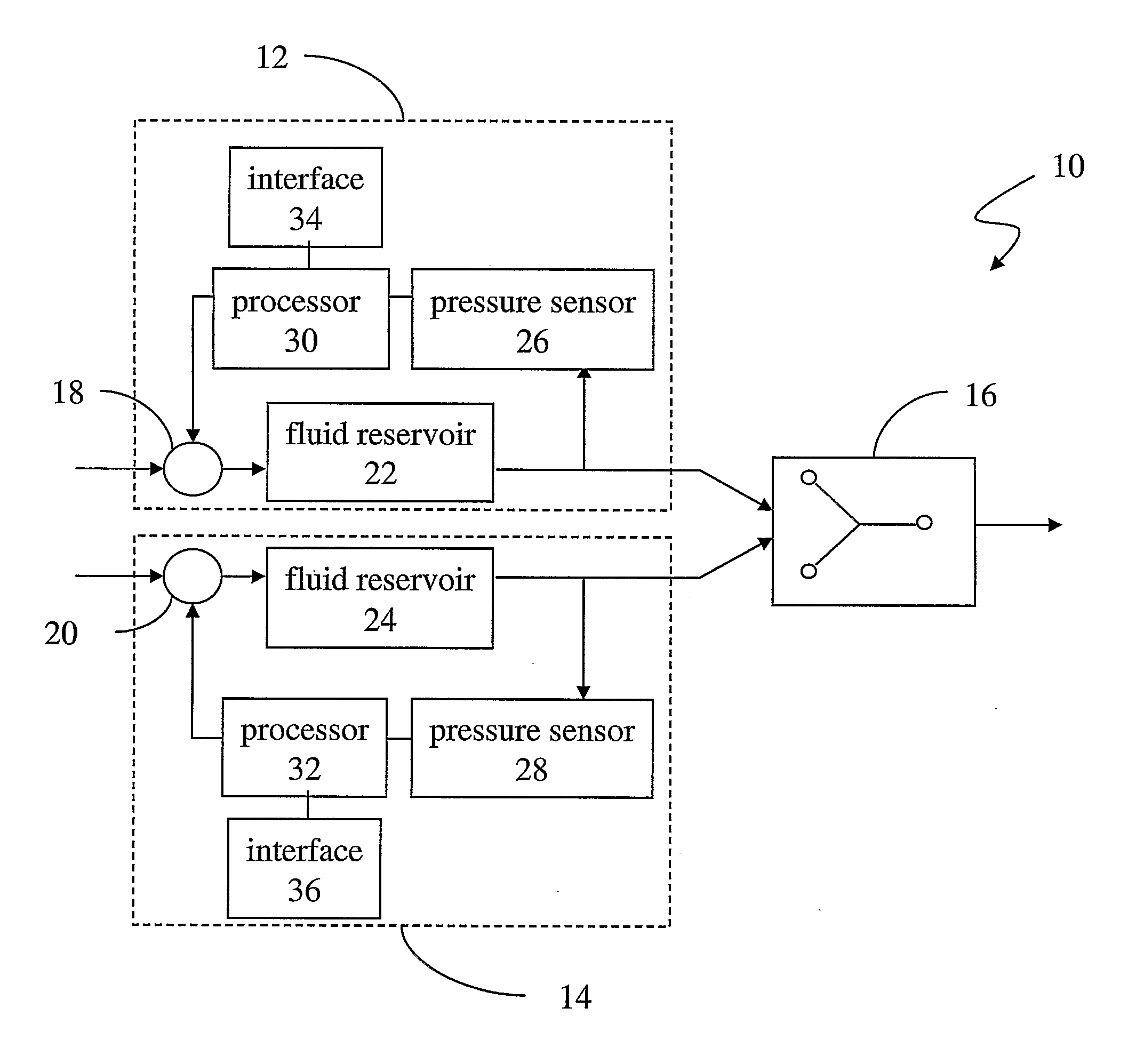

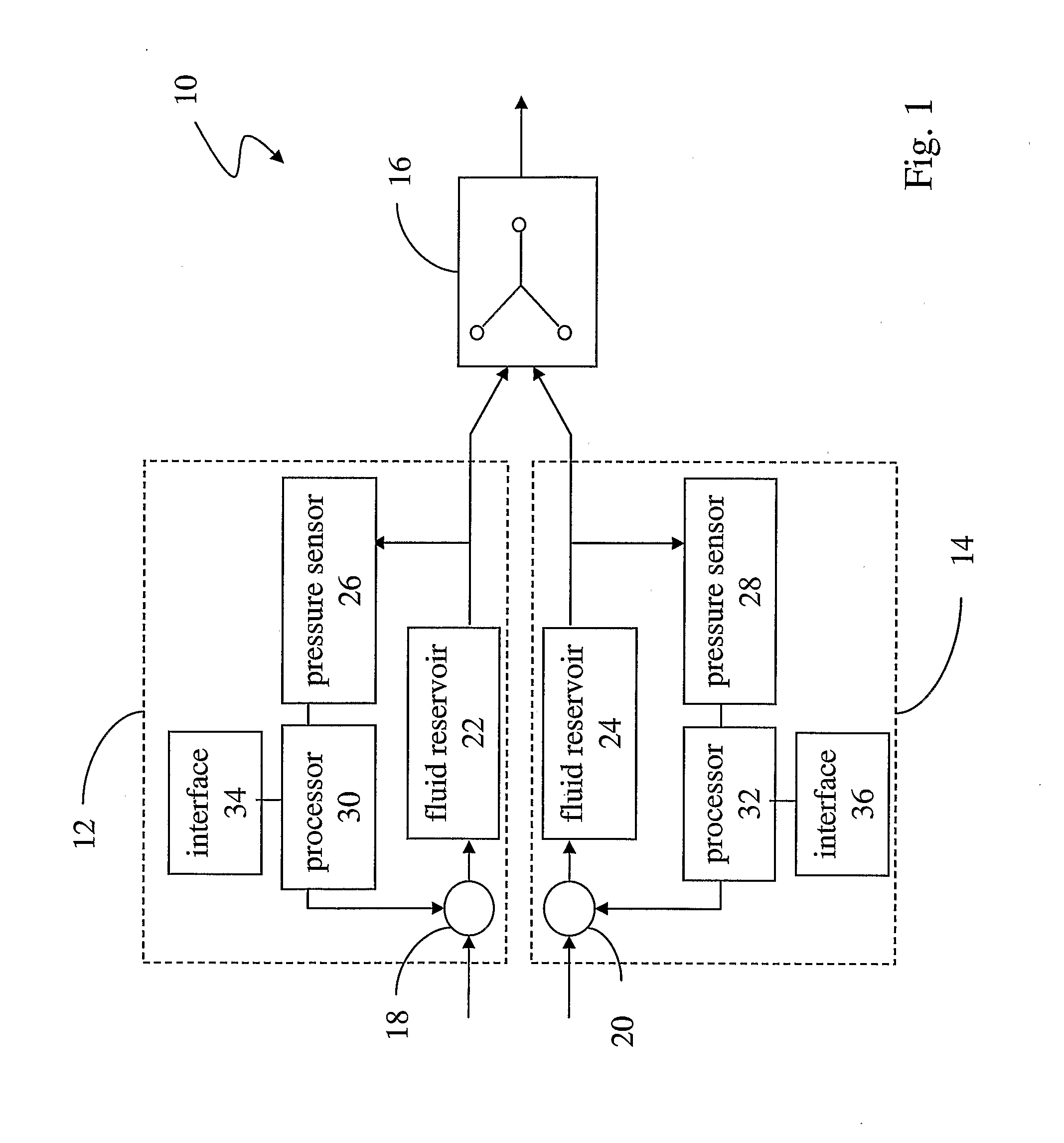

Advancements in laminar flow measurement and control systems, including improved sensors, flow meters, and control mechanisms for precise monitoring and regulation of fluid flow in various applications.- Flow measurement and control innovations: Advancements in laminar flow measurement and control systems, including improved sensors, flow meters, and control mechanisms. These innovations enhance accuracy and precision in monitoring and regulating laminar flow in various applications, such as fluid dynamics research and industrial processes.

- Laminar flow airfoil designs: Novel airfoil designs that promote and maintain laminar flow over larger portions of the surface. These innovations aim to reduce drag and improve aerodynamic efficiency in aircraft, wind turbines, and other applications where airflow management is critical.

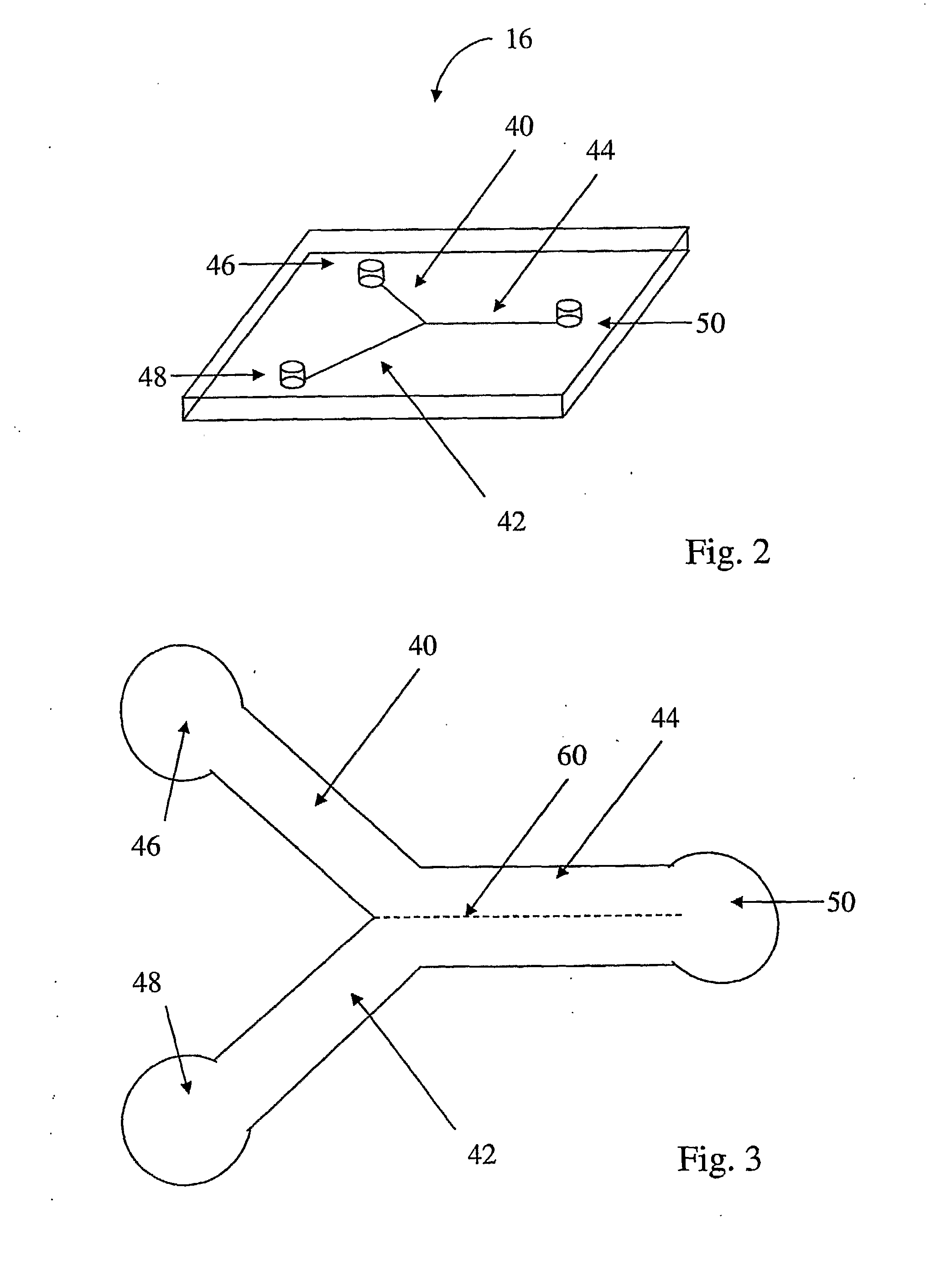

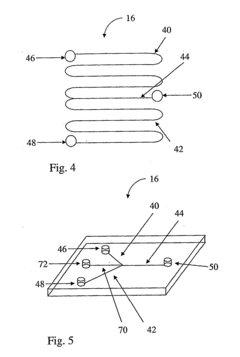

- Microfluidic laminar flow devices: Development of microfluidic devices that utilize laminar flow properties for various applications, including particle separation, chemical analysis, and biological assays. These innovations leverage the predictable behavior of laminar flow at small scales to achieve precise control over fluid manipulation.

- Laminar flow in HVAC and cleanroom systems: Innovations in heating, ventilation, air conditioning (HVAC), and cleanroom systems that utilize laminar flow principles to improve air quality, reduce contamination, and enhance energy efficiency. These advancements include novel air distribution methods and filtration techniques.

- Laminar flow water features and irrigation: Innovative designs for water features, fountains, and irrigation systems that create and maintain laminar flow. These advancements result in visually appealing water displays, improved water conservation, and more efficient irrigation methods for agriculture and landscaping.

02 Laminar flow nozzle designs

Novel nozzle designs that promote and maintain laminar flow, enhancing efficiency and reducing turbulence in fluid delivery systems for applications such as spray coating, fuel injection, and water distribution.Expand Specific Solutions03 Laminar flow in microfluidic devices

Innovations in microfluidic devices that utilize laminar flow principles for improved performance in applications such as lab-on-a-chip technologies, medical diagnostics, and chemical analysis systems.Expand Specific Solutions04 Laminar flow air purification systems

Development of air purification and ventilation systems that leverage laminar flow principles to enhance air quality, reduce contamination, and improve overall efficiency in clean rooms, hospitals, and industrial environments.Expand Specific Solutions05 Laminar flow in fluid separation technologies

Advancements in fluid separation technologies that utilize laminar flow principles to improve efficiency and effectiveness in processes such as filtration, chromatography, and particle separation in various industrial and scientific applications.Expand Specific Solutions

Key Players in Environmental Policy and Fluid Dynamics

The environmental policy reform landscape, driven by laminar flow innovation, is in a dynamic growth phase. The market is expanding rapidly as governments and industries seek sustainable solutions, with a projected global market size reaching billions. Technologically, the field is advancing swiftly, with varying maturity levels across different applications. Key players like Carnegie Mellon University, Wuhan University, and Taiwan Semiconductor Manufacturing Co. are at the forefront, developing cutting-edge laminar flow technologies. Companies such as China City Environment Protection Engineering Ltd. and Hayward Industries are applying these innovations in practical environmental solutions, while research institutions like Queen's University Belfast and Chongqing University are contributing to fundamental advancements in the field.

Carnegie Mellon University

Technical Solution: Carnegie Mellon University has developed innovative laminar flow technologies to address environmental policy reforms. Their approach focuses on computational fluid dynamics (CFD) simulations to optimize air and water flow patterns in urban environments[1]. By integrating machine learning algorithms, they've created predictive models that can anticipate the impact of policy changes on air quality and water management systems[3]. The university has also pioneered the use of smart sensors and IoT devices to monitor real-time environmental conditions, allowing for adaptive control of laminar flow systems in response to changing policy requirements[5].

Strengths: Strong research capabilities, interdisciplinary approach combining environmental science and computer science. Weaknesses: May face challenges in scaling solutions from academic research to large-scale implementation.

China City Environment Protection Engineering Ltd. Co.

Technical Solution: China City Environment Protection Engineering Ltd. Co. has developed a comprehensive laminar flow-based solution for urban environmental management. Their system incorporates advanced air purification technologies that utilize laminar flow principles to efficiently remove pollutants from city air[2]. The company has also implemented innovative water treatment facilities that leverage laminar flow dynamics to enhance the separation of contaminants and improve overall water quality[4]. Additionally, they have integrated these technologies with smart city infrastructure, allowing for real-time monitoring and adjustment of environmental parameters in response to policy changes[6].

Strengths: Practical experience in implementing large-scale environmental solutions, strong government connections. Weaknesses: May face challenges in adapting to rapidly changing international environmental standards.

Core Innovations in Policy-Driven Laminar Flow Research

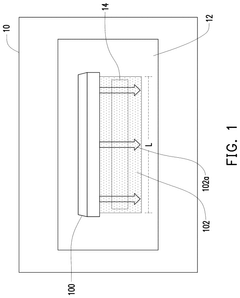

Apparatuses, Systems, and Methods Utilizing Laminar Flow Interface Control and for Controlling Laminar Flow Interface

PatentInactiveUS20080131323A1

Innovation

- A microfluidic system that controls laminar flow interfaces allows for precise manipulation of the chemical environment of cells and simultaneous measurement of cellular responses, enabling the generation of quantitative time series data through controlled pressure systems and microfluidic devices with narrow channels that ensure laminar flow, preventing turbulent mixing.

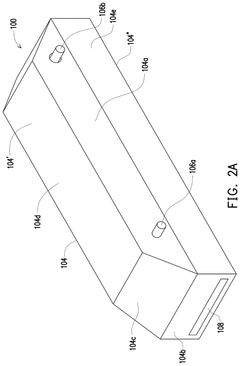

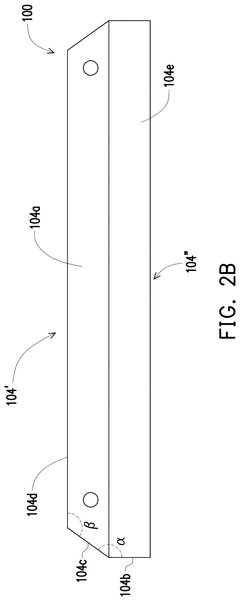

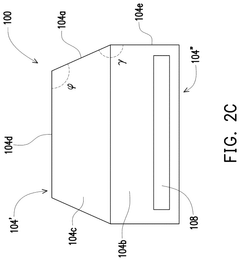

Laminar Gas Flow Filter

PatentPendingUS20250065254A1

Innovation

- A laminar gas flow filter and apparatus are designed to produce a laminar flow of gas, or air curtain, that covers the opening to a semiconductor FAB space or equipment chamber. This is achieved through a pair of diffuser tubes with gas inlets at opposite ends, which create a uniform gas flow velocity across the length of the filter, and an air filter module that can be selectively replaced.

Economic Impact of Environmental Policy on Fluid Dynamics

Environmental policies have a profound impact on the field of fluid dynamics, particularly in industries that rely heavily on fluid systems. The implementation of stricter environmental regulations has necessitated significant changes in how companies approach fluid dynamics research and applications. These policy reforms have led to increased investment in laminar flow technologies, which offer improved efficiency and reduced environmental impact compared to turbulent flow systems.

The economic implications of these policy changes are far-reaching. Industries such as aerospace, automotive, and energy production have had to allocate substantial resources to redesign their fluid systems to comply with new environmental standards. This has resulted in short-term increases in production costs and research and development expenditures. However, the long-term economic benefits of adopting laminar flow innovations are becoming increasingly apparent.

Companies that have successfully implemented laminar flow technologies have reported significant reductions in energy consumption and operational costs. For instance, in the automotive industry, the use of laminar flow principles in vehicle design has led to improved fuel efficiency, directly translating to cost savings for consumers and reduced environmental impact. Similarly, in the energy sector, laminar flow innovations in pipeline design have resulted in more efficient oil and gas transportation, reducing both operational costs and the risk of environmental accidents.

The economic impact extends beyond individual companies to entire industries and regions. Regions with strong environmental policies have seen the emergence of new industries focused on developing and manufacturing laminar flow technologies. This has created new job opportunities and stimulated economic growth in these areas. Additionally, the export of these technologies to regions with emerging environmental regulations represents a growing market opportunity for companies at the forefront of laminar flow innovation.

However, the transition to laminar flow systems is not without challenges. Smaller companies may struggle with the initial investment required to overhaul their existing systems, potentially leading to market consolidation as larger firms with more resources gain a competitive advantage. This has raised concerns about potential job losses in traditional industries and the need for workforce retraining programs.

Despite these challenges, the overall economic trajectory appears positive. As laminar flow technologies mature and become more cost-effective, their adoption is expected to accelerate across various industries. This trend is likely to drive further innovation, create new market opportunities, and ultimately contribute to sustainable economic growth while meeting environmental policy objectives.

The economic implications of these policy changes are far-reaching. Industries such as aerospace, automotive, and energy production have had to allocate substantial resources to redesign their fluid systems to comply with new environmental standards. This has resulted in short-term increases in production costs and research and development expenditures. However, the long-term economic benefits of adopting laminar flow innovations are becoming increasingly apparent.

Companies that have successfully implemented laminar flow technologies have reported significant reductions in energy consumption and operational costs. For instance, in the automotive industry, the use of laminar flow principles in vehicle design has led to improved fuel efficiency, directly translating to cost savings for consumers and reduced environmental impact. Similarly, in the energy sector, laminar flow innovations in pipeline design have resulted in more efficient oil and gas transportation, reducing both operational costs and the risk of environmental accidents.

The economic impact extends beyond individual companies to entire industries and regions. Regions with strong environmental policies have seen the emergence of new industries focused on developing and manufacturing laminar flow technologies. This has created new job opportunities and stimulated economic growth in these areas. Additionally, the export of these technologies to regions with emerging environmental regulations represents a growing market opportunity for companies at the forefront of laminar flow innovation.

However, the transition to laminar flow systems is not without challenges. Smaller companies may struggle with the initial investment required to overhaul their existing systems, potentially leading to market consolidation as larger firms with more resources gain a competitive advantage. This has raised concerns about potential job losses in traditional industries and the need for workforce retraining programs.

Despite these challenges, the overall economic trajectory appears positive. As laminar flow technologies mature and become more cost-effective, their adoption is expected to accelerate across various industries. This trend is likely to drive further innovation, create new market opportunities, and ultimately contribute to sustainable economic growth while meeting environmental policy objectives.

Cross-Sector Applications of Policy-Driven Laminar Flow

Laminar flow innovation, driven by environmental policy reforms, has demonstrated remarkable versatility across various sectors. This cross-sector applicability has led to significant advancements in energy efficiency, resource conservation, and pollution reduction across industries.

In the automotive sector, policy-driven laminar flow technologies have revolutionized vehicle design. Manufacturers have implemented streamlined body shapes and advanced aerodynamic features, resulting in reduced fuel consumption and lower emissions. These innovations have not only improved the environmental performance of vehicles but also enhanced their overall efficiency and performance.

The aerospace industry has also benefited greatly from laminar flow advancements. Aircraft manufacturers have incorporated laminar flow control systems into wing and fuselage designs, significantly reducing drag and improving fuel efficiency. This has led to substantial reductions in carbon emissions from commercial aviation, aligning with global environmental goals.

In the renewable energy sector, laminar flow principles have been applied to wind turbine design. Policy-driven research has led to the development of more efficient blade shapes and turbine configurations, maximizing energy capture from wind resources. These innovations have contributed to the increased viability and competitiveness of wind energy as a sustainable power source.

The building and construction industry has embraced laminar flow concepts in HVAC systems and building envelope design. Policy incentives have encouraged the adoption of energy-efficient ventilation systems that utilize laminar flow principles to optimize air distribution and temperature control. This has resulted in significant energy savings and improved indoor air quality in both residential and commercial buildings.

Water management has seen notable improvements through the application of laminar flow technologies. Wastewater treatment plants have implemented laminar flow reactors, enhancing the efficiency of biological treatment processes. Additionally, laminar flow principles have been applied to the design of water distribution systems, reducing energy consumption in pumping and improving overall system performance.

In the manufacturing sector, laminar flow innovations have transformed production processes. Policy-driven initiatives have led to the development of more efficient fluid handling systems, optimizing material flow in various industrial applications. This has resulted in reduced energy consumption, improved product quality, and minimized waste generation across manufacturing operations.

The cross-sector applications of policy-driven laminar flow innovations demonstrate the far-reaching impact of environmental policies on technological advancements. By incentivizing research and development in this field, policymakers have catalyzed improvements across multiple industries, contributing to broader sustainability goals and economic efficiency.

In the automotive sector, policy-driven laminar flow technologies have revolutionized vehicle design. Manufacturers have implemented streamlined body shapes and advanced aerodynamic features, resulting in reduced fuel consumption and lower emissions. These innovations have not only improved the environmental performance of vehicles but also enhanced their overall efficiency and performance.

The aerospace industry has also benefited greatly from laminar flow advancements. Aircraft manufacturers have incorporated laminar flow control systems into wing and fuselage designs, significantly reducing drag and improving fuel efficiency. This has led to substantial reductions in carbon emissions from commercial aviation, aligning with global environmental goals.

In the renewable energy sector, laminar flow principles have been applied to wind turbine design. Policy-driven research has led to the development of more efficient blade shapes and turbine configurations, maximizing energy capture from wind resources. These innovations have contributed to the increased viability and competitiveness of wind energy as a sustainable power source.

The building and construction industry has embraced laminar flow concepts in HVAC systems and building envelope design. Policy incentives have encouraged the adoption of energy-efficient ventilation systems that utilize laminar flow principles to optimize air distribution and temperature control. This has resulted in significant energy savings and improved indoor air quality in both residential and commercial buildings.

Water management has seen notable improvements through the application of laminar flow technologies. Wastewater treatment plants have implemented laminar flow reactors, enhancing the efficiency of biological treatment processes. Additionally, laminar flow principles have been applied to the design of water distribution systems, reducing energy consumption in pumping and improving overall system performance.

In the manufacturing sector, laminar flow innovations have transformed production processes. Policy-driven initiatives have led to the development of more efficient fluid handling systems, optimizing material flow in various industrial applications. This has resulted in reduced energy consumption, improved product quality, and minimized waste generation across manufacturing operations.

The cross-sector applications of policy-driven laminar flow innovations demonstrate the far-reaching impact of environmental policies on technological advancements. By incentivizing research and development in this field, policymakers have catalyzed improvements across multiple industries, contributing to broader sustainability goals and economic efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!