How to Utilize Laminar Flow for Noise Reduction?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Noise Reduction Background and Objectives

Laminar flow noise reduction has emerged as a critical area of research in aerodynamics and acoustics, with significant implications for various industries, including aerospace, automotive, and wind energy. The concept of utilizing laminar flow for noise reduction stems from the fundamental principles of fluid dynamics, where smooth, layered fluid motion can potentially minimize turbulence and associated noise generation.

The historical development of laminar flow technology can be traced back to the early 20th century, with pioneering work by Ludwig Prandtl on boundary layer theory. However, it wasn't until the latter half of the century that researchers began to explore its potential for noise reduction specifically. The 1960s and 1970s saw increased interest in laminar flow control for drag reduction in aircraft, which inadvertently led to observations of reduced noise levels.

As environmental concerns and stringent noise regulations have come to the forefront in recent decades, the focus on laminar flow for noise reduction has intensified. The aviation industry, in particular, has been a driving force behind this research, seeking ways to mitigate aircraft noise during takeoff, landing, and cruise phases. Similarly, the automotive sector has shown growing interest in laminar flow applications for reducing wind noise and improving vehicle aerodynamics.

The primary objective of laminar flow noise reduction research is to develop practical, efficient, and cost-effective methods to maintain laminar flow over surfaces where turbulent flow would typically occur. This involves understanding the complex interactions between fluid dynamics, surface properties, and acoustic phenomena. Researchers aim to create innovative designs and materials that can promote and sustain laminar flow under various operating conditions.

Key technical goals include extending the range of Reynolds numbers over which laminar flow can be maintained, developing active and passive flow control mechanisms, and integrating laminar flow technologies with existing noise reduction strategies. Additionally, there is a focus on creating computational models and simulation tools that can accurately predict the acoustic benefits of laminar flow in different applications.

The potential benefits of successful laminar flow noise reduction are substantial. In aviation, it could lead to quieter aircraft, reduced fuel consumption, and improved overall efficiency. For wind turbines, laminar flow control could result in increased energy output while minimizing noise pollution. In automotive applications, it could enhance vehicle performance and passenger comfort.

As research in this field progresses, interdisciplinary collaboration between aerodynamicists, acousticians, materials scientists, and engineers is becoming increasingly important. The ultimate aim is to translate theoretical understanding and laboratory experiments into practical, real-world applications that can significantly impact noise reduction across multiple industries.

The historical development of laminar flow technology can be traced back to the early 20th century, with pioneering work by Ludwig Prandtl on boundary layer theory. However, it wasn't until the latter half of the century that researchers began to explore its potential for noise reduction specifically. The 1960s and 1970s saw increased interest in laminar flow control for drag reduction in aircraft, which inadvertently led to observations of reduced noise levels.

As environmental concerns and stringent noise regulations have come to the forefront in recent decades, the focus on laminar flow for noise reduction has intensified. The aviation industry, in particular, has been a driving force behind this research, seeking ways to mitigate aircraft noise during takeoff, landing, and cruise phases. Similarly, the automotive sector has shown growing interest in laminar flow applications for reducing wind noise and improving vehicle aerodynamics.

The primary objective of laminar flow noise reduction research is to develop practical, efficient, and cost-effective methods to maintain laminar flow over surfaces where turbulent flow would typically occur. This involves understanding the complex interactions between fluid dynamics, surface properties, and acoustic phenomena. Researchers aim to create innovative designs and materials that can promote and sustain laminar flow under various operating conditions.

Key technical goals include extending the range of Reynolds numbers over which laminar flow can be maintained, developing active and passive flow control mechanisms, and integrating laminar flow technologies with existing noise reduction strategies. Additionally, there is a focus on creating computational models and simulation tools that can accurately predict the acoustic benefits of laminar flow in different applications.

The potential benefits of successful laminar flow noise reduction are substantial. In aviation, it could lead to quieter aircraft, reduced fuel consumption, and improved overall efficiency. For wind turbines, laminar flow control could result in increased energy output while minimizing noise pollution. In automotive applications, it could enhance vehicle performance and passenger comfort.

As research in this field progresses, interdisciplinary collaboration between aerodynamicists, acousticians, materials scientists, and engineers is becoming increasingly important. The ultimate aim is to translate theoretical understanding and laboratory experiments into practical, real-world applications that can significantly impact noise reduction across multiple industries.

Market Demand for Noise Reduction Technologies

The market demand for noise reduction technologies has been steadily increasing across various industries, driven by growing awareness of the negative impacts of noise pollution on human health and well-being. In urban environments, the need for effective noise reduction solutions has become particularly acute, with cities worldwide implementing stricter noise regulations to improve quality of life for residents.

The transportation sector represents a significant market for noise reduction technologies. As air travel continues to expand, airports face mounting pressure to mitigate aircraft noise, creating opportunities for innovative solutions that utilize laminar flow principles. Similarly, the automotive industry is investing heavily in noise reduction technologies to enhance passenger comfort and comply with increasingly stringent noise emission standards.

In the industrial sector, demand for noise reduction solutions is rising due to occupational health and safety regulations. Manufacturing facilities, power plants, and construction sites are seeking advanced technologies to protect workers from harmful noise levels while maintaining operational efficiency. This has led to increased interest in laminar flow-based noise reduction systems that can be integrated into existing industrial processes.

The consumer electronics market has also emerged as a key driver for noise reduction technologies. With the proliferation of personal audio devices and the growing popularity of noise-cancelling headphones, there is a strong demand for miniaturized, energy-efficient noise reduction solutions that can be incorporated into portable devices.

In the building and construction industry, architects and developers are increasingly prioritizing acoustic comfort in both residential and commercial spaces. This trend has spurred demand for innovative noise reduction materials and systems that can be seamlessly integrated into building designs, including those that leverage laminar flow principles for enhanced sound insulation.

The healthcare sector presents another significant market opportunity for noise reduction technologies. Hospitals and medical facilities are recognizing the importance of quiet environments for patient recovery and staff well-being, leading to increased adoption of advanced noise control solutions in healthcare settings.

As environmental concerns continue to gain prominence, there is growing interest in eco-friendly noise reduction technologies. This has created a niche market for sustainable solutions that utilize natural principles, such as laminar flow, to achieve effective noise reduction without relying on energy-intensive or chemically-based methods.

The global market for noise reduction technologies is projected to experience substantial growth in the coming years, with some estimates suggesting a compound annual growth rate of over 5% through 2025. This growth is expected to be driven by a combination of regulatory pressures, technological advancements, and increasing consumer demand for quieter, more comfortable environments across various sectors.

The transportation sector represents a significant market for noise reduction technologies. As air travel continues to expand, airports face mounting pressure to mitigate aircraft noise, creating opportunities for innovative solutions that utilize laminar flow principles. Similarly, the automotive industry is investing heavily in noise reduction technologies to enhance passenger comfort and comply with increasingly stringent noise emission standards.

In the industrial sector, demand for noise reduction solutions is rising due to occupational health and safety regulations. Manufacturing facilities, power plants, and construction sites are seeking advanced technologies to protect workers from harmful noise levels while maintaining operational efficiency. This has led to increased interest in laminar flow-based noise reduction systems that can be integrated into existing industrial processes.

The consumer electronics market has also emerged as a key driver for noise reduction technologies. With the proliferation of personal audio devices and the growing popularity of noise-cancelling headphones, there is a strong demand for miniaturized, energy-efficient noise reduction solutions that can be incorporated into portable devices.

In the building and construction industry, architects and developers are increasingly prioritizing acoustic comfort in both residential and commercial spaces. This trend has spurred demand for innovative noise reduction materials and systems that can be seamlessly integrated into building designs, including those that leverage laminar flow principles for enhanced sound insulation.

The healthcare sector presents another significant market opportunity for noise reduction technologies. Hospitals and medical facilities are recognizing the importance of quiet environments for patient recovery and staff well-being, leading to increased adoption of advanced noise control solutions in healthcare settings.

As environmental concerns continue to gain prominence, there is growing interest in eco-friendly noise reduction technologies. This has created a niche market for sustainable solutions that utilize natural principles, such as laminar flow, to achieve effective noise reduction without relying on energy-intensive or chemically-based methods.

The global market for noise reduction technologies is projected to experience substantial growth in the coming years, with some estimates suggesting a compound annual growth rate of over 5% through 2025. This growth is expected to be driven by a combination of regulatory pressures, technological advancements, and increasing consumer demand for quieter, more comfortable environments across various sectors.

Current State and Challenges in Laminar Flow Noise Control

The current state of laminar flow noise control technology is characterized by significant advancements, yet it still faces numerous challenges. Researchers and engineers have made substantial progress in understanding the fundamental principles of laminar flow and its potential for noise reduction. The technology has been successfully implemented in various applications, particularly in aerospace and automotive industries, where noise reduction is crucial for passenger comfort and environmental considerations.

One of the primary achievements in this field is the development of advanced computational fluid dynamics (CFD) models that can accurately simulate laminar flow behavior and predict noise generation mechanisms. These models have greatly enhanced our ability to design and optimize laminar flow control systems for noise reduction. Additionally, experimental techniques, such as particle image velocimetry (PIV) and acoustic holography, have been refined to provide more precise measurements of flow characteristics and noise sources.

Despite these advancements, several significant challenges persist in the field of laminar flow noise control. One of the most pressing issues is maintaining laminar flow over extended surfaces and under varying environmental conditions. Factors such as surface roughness, pressure gradients, and atmospheric turbulence can disrupt laminar flow, leading to increased noise generation. Researchers are actively working on developing more robust laminar flow control techniques that can adapt to these dynamic conditions.

Another major challenge is the integration of laminar flow control systems into existing structures without compromising their aerodynamic or structural integrity. This is particularly crucial in aircraft design, where weight and space constraints are critical factors. Engineers are exploring innovative materials and manufacturing techniques to create seamless, lightweight laminar flow control surfaces that can be effectively incorporated into aircraft wings and fuselages.

The energy efficiency of laminar flow control systems also remains a concern. While these systems can significantly reduce noise, they often require additional power input, which can offset some of the environmental benefits. Researchers are investigating passive laminar flow control methods and more energy-efficient active systems to address this challenge.

Furthermore, the cost-effectiveness of implementing laminar flow noise control technology on a large scale is still a barrier to widespread adoption. The complexity of manufacturing and maintaining laminar flow surfaces, especially for commercial applications, poses economic challenges that need to be overcome.

Lastly, there is a need for more comprehensive understanding of the interaction between laminar flow control systems and other noise reduction technologies. Integrating laminar flow control with acoustic liners, active noise control systems, and other noise mitigation strategies requires further research to maximize overall noise reduction effectiveness.

One of the primary achievements in this field is the development of advanced computational fluid dynamics (CFD) models that can accurately simulate laminar flow behavior and predict noise generation mechanisms. These models have greatly enhanced our ability to design and optimize laminar flow control systems for noise reduction. Additionally, experimental techniques, such as particle image velocimetry (PIV) and acoustic holography, have been refined to provide more precise measurements of flow characteristics and noise sources.

Despite these advancements, several significant challenges persist in the field of laminar flow noise control. One of the most pressing issues is maintaining laminar flow over extended surfaces and under varying environmental conditions. Factors such as surface roughness, pressure gradients, and atmospheric turbulence can disrupt laminar flow, leading to increased noise generation. Researchers are actively working on developing more robust laminar flow control techniques that can adapt to these dynamic conditions.

Another major challenge is the integration of laminar flow control systems into existing structures without compromising their aerodynamic or structural integrity. This is particularly crucial in aircraft design, where weight and space constraints are critical factors. Engineers are exploring innovative materials and manufacturing techniques to create seamless, lightweight laminar flow control surfaces that can be effectively incorporated into aircraft wings and fuselages.

The energy efficiency of laminar flow control systems also remains a concern. While these systems can significantly reduce noise, they often require additional power input, which can offset some of the environmental benefits. Researchers are investigating passive laminar flow control methods and more energy-efficient active systems to address this challenge.

Furthermore, the cost-effectiveness of implementing laminar flow noise control technology on a large scale is still a barrier to widespread adoption. The complexity of manufacturing and maintaining laminar flow surfaces, especially for commercial applications, poses economic challenges that need to be overcome.

Lastly, there is a need for more comprehensive understanding of the interaction between laminar flow control systems and other noise reduction technologies. Integrating laminar flow control with acoustic liners, active noise control systems, and other noise mitigation strategies requires further research to maximize overall noise reduction effectiveness.

Existing Laminar Flow Noise Reduction Solutions

01 Noise reduction in laminar flow systems

Various techniques are employed to reduce noise in laminar flow systems, including the use of specialized nozzles, flow straighteners, and acoustic dampening materials. These methods aim to minimize turbulence and maintain smooth, quiet flow in applications such as air conditioning systems, clean rooms, and laboratory equipment.- Noise reduction in laminar flow systems: Various techniques are employed to reduce noise in laminar flow systems. These include optimizing flow path design, using sound-absorbing materials, and implementing flow control devices. Such methods help minimize turbulence and acoustic disturbances, resulting in quieter operation of laminar flow equipment.

- Laminar flow nozzles and aerators: Specialized nozzles and aerators are designed to maintain laminar flow while reducing noise. These devices often incorporate features such as flow straighteners, pressure regulators, and carefully engineered outlet geometries to ensure smooth, quiet water flow in applications like faucets and showerheads.

- Measurement and analysis of laminar flow noise: Advanced measurement techniques and analysis methods are used to characterize and quantify noise in laminar flow systems. These may include acoustic sensors, flow visualization tools, and computational fluid dynamics simulations to identify noise sources and optimize system performance.

- Laminar flow in HVAC and cleanroom applications: Laminar flow is crucial in HVAC systems and cleanroom environments to maintain air quality and reduce contamination. Noise reduction strategies in these applications focus on optimizing air handling units, ductwork design, and filtration systems to minimize turbulence and acoustic emissions.

- Fluid handling and control in laminar flow systems: Effective fluid handling and control mechanisms are essential for maintaining laminar flow and reducing noise. This includes the use of specialized valves, flow regulators, and pressure control devices to ensure smooth, consistent fluid movement and minimize disturbances that could lead to noise generation.

02 Laminar flow control in aircraft

Laminar flow control techniques are applied to aircraft surfaces to reduce drag and improve aerodynamic efficiency. This involves careful design of wing surfaces, suction systems, and boundary layer control mechanisms to maintain laminar flow and reduce turbulence-induced noise.Expand Specific Solutions03 Measurement and analysis of laminar flow noise

Advanced measurement techniques and analysis methods are used to characterize and quantify noise in laminar flow systems. This includes the use of specialized sensors, flow visualization techniques, and computational fluid dynamics simulations to understand and mitigate noise sources.Expand Specific Solutions04 Laminar flow in fluid handling systems

Laminar flow principles are applied in various fluid handling systems to minimize noise and improve efficiency. This includes the design of valves, pipes, and flow control devices that maintain laminar flow characteristics and reduce turbulence-induced noise in industrial and domestic applications.Expand Specific Solutions05 Noise reduction in HVAC systems using laminar flow

Heating, ventilation, and air conditioning (HVAC) systems incorporate laminar flow principles to reduce noise and improve air distribution. This involves the design of air diffusers, ductwork, and fan systems that promote smooth, quiet airflow throughout buildings and vehicles.Expand Specific Solutions

Key Players in Laminar Flow and Noise Reduction Industry

The utilization of laminar flow for noise reduction is an emerging field in acoustic engineering, currently in its early development stage. The market size is growing steadily as industries seek more efficient noise control solutions. Technologically, it's still evolving, with varying levels of maturity across different applications. Companies like BSH Hausgeräte GmbH and Airbus Operations GmbH are at the forefront, leveraging their expertise in appliance and aerospace engineering respectively. ASML Netherlands BV and Infineon Technologies AG are contributing advanced semiconductor technologies, potentially enhancing the precision of laminar flow control systems. The Boeing Co. and LG Electronics, Inc. are also exploring this technology, indicating its potential across diverse sectors from aviation to consumer electronics.

Airbus Operations GmbH

Technical Solution: Airbus has invested heavily in laminar flow technology for noise reduction and improved aerodynamics. Their BLADE (Breakthrough Laminar Aircraft Demonstrator in Europe) project focuses on natural laminar flow (NLF) wing design. The company has developed specialized wing sections with smooth surfaces and specific contours to maintain laminar flow over larger portions of the wing[4]. Airbus has also explored hybrid laminar flow control (HLFC) systems, combining passive shaping with active suction systems on the leading edges of wings and tail surfaces[5]. Their research indicates potential for up to 5% fuel savings and corresponding noise reduction through these technologies[6].

Strengths: Innovative wing design, comprehensive flight testing experience. Weaknesses: Complexity in manufacturing specialized surfaces, sensitivity to environmental factors.

The Boeing Co.

Technical Solution: Boeing has developed advanced laminar flow control (LFC) technologies for noise reduction in aircraft. Their approach involves designing wing surfaces and engine nacelles to maintain laminar airflow, reducing turbulence and associated noise. Boeing's method includes suction systems integrated into the wing structure to remove the boundary layer and promote laminar flow[1]. They have also implemented hybrid laminar flow control (HLFC) on the vertical tail and engine nacelles of some aircraft models, combining passive and active flow control techniques[2]. Boeing's research has shown that maintaining laminar flow over 50% of the wing surface can reduce overall aircraft drag by up to 15%, indirectly contributing to noise reduction[3].

Strengths: Extensive experience in aerospace applications, proven results in drag reduction. Weaknesses: High implementation costs, potential maintenance challenges for active systems.

Core Innovations in Laminar Flow Acoustics

Ultrasound probe arrangement

PatentActiveEP1882183A1

Innovation

- The introduction of flow or filter chambers with increasing flow channels and decreasing diameters perpendicular to the flow direction within the jet nozzle, combined with a central liquid inlet and a flat jet nozzle design, ensures a laminar flow and reduces turbulence, allowing for undisturbed sound coupling and improved signal-to-noise ratios.

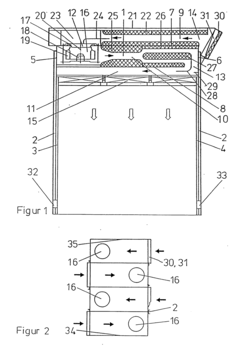

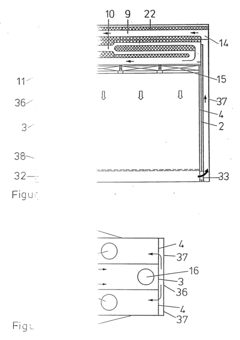

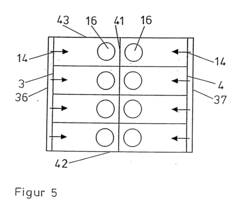

Tunnel module for creating a clean space by the laminar flow technique

PatentInactiveEP0340433A2

Innovation

- The tunnel module design features a fan placement in the middle chamber opposite the return air opening, combined with backward-curved blades and an external rotor motor, along with sound-damping baffles and a spoiler, to reduce energy consumption and turbulence, ensuring efficient conversion of dynamic to static pressure while minimizing noise and flow obstacles.

Environmental Impact of Laminar Flow Noise Control

The implementation of laminar flow technology for noise reduction presents significant environmental implications that warrant careful consideration. This approach to noise control offers potential benefits in terms of reduced energy consumption and improved air quality, particularly in urban environments where noise pollution is a pressing concern.

Laminar flow systems, when properly designed and implemented, can lead to a decrease in overall energy usage. By streamlining airflow and reducing turbulence, these systems can enhance the efficiency of heating, ventilation, and air conditioning (HVAC) systems in buildings. This improved efficiency translates to lower power consumption, which in turn reduces the carbon footprint associated with energy production.

Furthermore, the application of laminar flow principles in vehicle design, particularly in the automotive and aerospace industries, can contribute to improved fuel efficiency. Vehicles with optimized aerodynamics require less energy to overcome air resistance, resulting in reduced fuel consumption and lower emissions of greenhouse gases and other pollutants.

In urban settings, the adoption of laminar flow noise control techniques can lead to a significant reduction in ambient noise levels. This decrease in noise pollution can have far-reaching positive effects on public health and well-being. Lower noise levels are associated with reduced stress, improved sleep quality, and enhanced cognitive performance among urban residents.

The environmental benefits extend to wildlife as well. Noise pollution has been shown to disrupt natural ecosystems, affecting animal communication, breeding patterns, and overall biodiversity. By implementing laminar flow noise control measures, particularly near sensitive habitats, we can mitigate these negative impacts and support the preservation of local ecosystems.

However, it is crucial to consider potential drawbacks. The production and installation of laminar flow systems may require specialized materials and manufacturing processes, which could have their own environmental impacts. A comprehensive life cycle assessment would be necessary to fully understand the net environmental effect of widespread adoption of this technology.

Additionally, the implementation of laminar flow noise control measures may necessitate modifications to existing infrastructure or the development of new designs in various sectors. This could lead to increased resource consumption in the short term, although long-term benefits may outweigh these initial costs.

In conclusion, while laminar flow noise control technology offers promising environmental benefits, particularly in terms of energy efficiency and noise reduction, a holistic approach is required to ensure that its implementation aligns with broader sustainability goals. Ongoing research and development should focus on optimizing the environmental performance of these systems throughout their entire life cycle.

Laminar flow systems, when properly designed and implemented, can lead to a decrease in overall energy usage. By streamlining airflow and reducing turbulence, these systems can enhance the efficiency of heating, ventilation, and air conditioning (HVAC) systems in buildings. This improved efficiency translates to lower power consumption, which in turn reduces the carbon footprint associated with energy production.

Furthermore, the application of laminar flow principles in vehicle design, particularly in the automotive and aerospace industries, can contribute to improved fuel efficiency. Vehicles with optimized aerodynamics require less energy to overcome air resistance, resulting in reduced fuel consumption and lower emissions of greenhouse gases and other pollutants.

In urban settings, the adoption of laminar flow noise control techniques can lead to a significant reduction in ambient noise levels. This decrease in noise pollution can have far-reaching positive effects on public health and well-being. Lower noise levels are associated with reduced stress, improved sleep quality, and enhanced cognitive performance among urban residents.

The environmental benefits extend to wildlife as well. Noise pollution has been shown to disrupt natural ecosystems, affecting animal communication, breeding patterns, and overall biodiversity. By implementing laminar flow noise control measures, particularly near sensitive habitats, we can mitigate these negative impacts and support the preservation of local ecosystems.

However, it is crucial to consider potential drawbacks. The production and installation of laminar flow systems may require specialized materials and manufacturing processes, which could have their own environmental impacts. A comprehensive life cycle assessment would be necessary to fully understand the net environmental effect of widespread adoption of this technology.

Additionally, the implementation of laminar flow noise control measures may necessitate modifications to existing infrastructure or the development of new designs in various sectors. This could lead to increased resource consumption in the short term, although long-term benefits may outweigh these initial costs.

In conclusion, while laminar flow noise control technology offers promising environmental benefits, particularly in terms of energy efficiency and noise reduction, a holistic approach is required to ensure that its implementation aligns with broader sustainability goals. Ongoing research and development should focus on optimizing the environmental performance of these systems throughout their entire life cycle.

Standardization and Testing of Laminar Flow Noise Reduction

Standardization and testing of laminar flow noise reduction techniques are crucial for ensuring consistent and reliable performance across various applications. The development of standardized testing procedures allows for accurate comparison of different laminar flow designs and their effectiveness in noise reduction.

One key aspect of standardization is the establishment of uniform measurement protocols. These protocols define the specific conditions under which noise measurements should be taken, including factors such as flow velocity, ambient temperature, and humidity. By controlling these variables, researchers and engineers can obtain consistent and reproducible results, enabling meaningful comparisons between different laminar flow systems.

Testing methodologies for laminar flow noise reduction typically involve a combination of experimental and computational approaches. Wind tunnel testing remains a primary method for evaluating the acoustic performance of laminar flow designs. Advanced wind tunnels equipped with acoustic measurement capabilities allow for precise quantification of noise levels under controlled conditions. These facilities often incorporate anechoic chambers to minimize external noise interference and isolate the sound generated by the laminar flow system.

Computational fluid dynamics (CFD) simulations play an increasingly important role in the testing process. CFD models can predict the flow characteristics and acoustic properties of laminar flow designs before physical prototypes are built. This approach allows for rapid iteration and optimization of designs, reducing the time and cost associated with experimental testing.

Standardized metrics for quantifying noise reduction performance are essential for comparing different laminar flow solutions. Common metrics include overall sound pressure level (SPL) reduction, frequency-specific noise attenuation, and psychoacoustic parameters such as loudness and sharpness. These metrics provide a comprehensive assessment of the acoustic benefits offered by laminar flow designs.

The development of industry-wide standards for laminar flow noise reduction testing is an ongoing process. Organizations such as the International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE) are working to establish guidelines and best practices for acoustic testing of laminar flow systems. These standards aim to ensure consistency and reliability in noise reduction measurements across different laboratories and testing facilities.

As laminar flow noise reduction techniques continue to evolve, standardization efforts must keep pace with technological advancements. This includes adapting testing procedures to accommodate new materials, innovative flow control mechanisms, and emerging applications of laminar flow technology. Regular review and updating of standards ensure that they remain relevant and effective in assessing the latest noise reduction solutions.

One key aspect of standardization is the establishment of uniform measurement protocols. These protocols define the specific conditions under which noise measurements should be taken, including factors such as flow velocity, ambient temperature, and humidity. By controlling these variables, researchers and engineers can obtain consistent and reproducible results, enabling meaningful comparisons between different laminar flow systems.

Testing methodologies for laminar flow noise reduction typically involve a combination of experimental and computational approaches. Wind tunnel testing remains a primary method for evaluating the acoustic performance of laminar flow designs. Advanced wind tunnels equipped with acoustic measurement capabilities allow for precise quantification of noise levels under controlled conditions. These facilities often incorporate anechoic chambers to minimize external noise interference and isolate the sound generated by the laminar flow system.

Computational fluid dynamics (CFD) simulations play an increasingly important role in the testing process. CFD models can predict the flow characteristics and acoustic properties of laminar flow designs before physical prototypes are built. This approach allows for rapid iteration and optimization of designs, reducing the time and cost associated with experimental testing.

Standardized metrics for quantifying noise reduction performance are essential for comparing different laminar flow solutions. Common metrics include overall sound pressure level (SPL) reduction, frequency-specific noise attenuation, and psychoacoustic parameters such as loudness and sharpness. These metrics provide a comprehensive assessment of the acoustic benefits offered by laminar flow designs.

The development of industry-wide standards for laminar flow noise reduction testing is an ongoing process. Organizations such as the International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE) are working to establish guidelines and best practices for acoustic testing of laminar flow systems. These standards aim to ensure consistency and reliability in noise reduction measurements across different laboratories and testing facilities.

As laminar flow noise reduction techniques continue to evolve, standardization efforts must keep pace with technological advancements. This includes adapting testing procedures to accommodate new materials, innovative flow control mechanisms, and emerging applications of laminar flow technology. Regular review and updating of standards ensure that they remain relevant and effective in assessing the latest noise reduction solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!