The Science Behind Laminar Flow in Oil and Gas

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Fundamentals and Objectives

Laminar flow, a fundamental concept in fluid dynamics, plays a crucial role in the oil and gas industry. This flow regime is characterized by smooth, predictable fluid motion where layers of fluid slide past one another with minimal mixing. In the context of oil and gas operations, understanding laminar flow is essential for optimizing production, designing efficient pipeline systems, and enhancing overall process performance.

The historical development of laminar flow theory can be traced back to the 19th century, with significant contributions from scientists like George Gabriel Stokes and Osborne Reynolds. Their work laid the foundation for modern fluid dynamics and its applications in various industries, including oil and gas. As the energy sector evolved, the importance of laminar flow in hydrocarbon extraction and transportation became increasingly apparent.

In recent years, the oil and gas industry has witnessed a surge in technological advancements, leading to more sophisticated applications of laminar flow principles. These developments aim to address the growing challenges in extracting and transporting hydrocarbons from increasingly complex reservoirs. The industry now focuses on leveraging laminar flow characteristics to improve well productivity, enhance recovery rates, and optimize pipeline operations.

The primary objective of studying laminar flow in the oil and gas sector is to maximize efficiency and minimize energy losses throughout the production and transportation processes. By understanding the behavior of fluids under laminar conditions, engineers can design more effective wellbore completions, optimize production rates, and develop advanced enhanced oil recovery (EOR) techniques. Additionally, laminar flow analysis helps in the accurate prediction of pressure drops in pipelines, leading to more efficient and cost-effective transportation systems.

Another critical goal is to improve the accuracy of reservoir modeling and simulation. Laminar flow principles are essential in developing realistic models of fluid behavior within porous media, which is crucial for predicting reservoir performance and planning production strategies. These models help in making informed decisions regarding well placement, production rates, and reservoir management techniques.

Furthermore, the industry aims to extend the application of laminar flow principles to new frontiers, such as unconventional reservoirs and deep-water operations. This involves adapting existing theories and developing new models to account for the unique challenges presented by these environments. By doing so, the industry seeks to unlock previously inaccessible resources and improve the overall efficiency of hydrocarbon extraction.

The historical development of laminar flow theory can be traced back to the 19th century, with significant contributions from scientists like George Gabriel Stokes and Osborne Reynolds. Their work laid the foundation for modern fluid dynamics and its applications in various industries, including oil and gas. As the energy sector evolved, the importance of laminar flow in hydrocarbon extraction and transportation became increasingly apparent.

In recent years, the oil and gas industry has witnessed a surge in technological advancements, leading to more sophisticated applications of laminar flow principles. These developments aim to address the growing challenges in extracting and transporting hydrocarbons from increasingly complex reservoirs. The industry now focuses on leveraging laminar flow characteristics to improve well productivity, enhance recovery rates, and optimize pipeline operations.

The primary objective of studying laminar flow in the oil and gas sector is to maximize efficiency and minimize energy losses throughout the production and transportation processes. By understanding the behavior of fluids under laminar conditions, engineers can design more effective wellbore completions, optimize production rates, and develop advanced enhanced oil recovery (EOR) techniques. Additionally, laminar flow analysis helps in the accurate prediction of pressure drops in pipelines, leading to more efficient and cost-effective transportation systems.

Another critical goal is to improve the accuracy of reservoir modeling and simulation. Laminar flow principles are essential in developing realistic models of fluid behavior within porous media, which is crucial for predicting reservoir performance and planning production strategies. These models help in making informed decisions regarding well placement, production rates, and reservoir management techniques.

Furthermore, the industry aims to extend the application of laminar flow principles to new frontiers, such as unconventional reservoirs and deep-water operations. This involves adapting existing theories and developing new models to account for the unique challenges presented by these environments. By doing so, the industry seeks to unlock previously inaccessible resources and improve the overall efficiency of hydrocarbon extraction.

Oil and Gas Industry Demand for Laminar Flow

The oil and gas industry's demand for laminar flow technology has been steadily increasing due to its critical role in enhancing operational efficiency and safety. Laminar flow, characterized by smooth and predictable fluid movement, is essential in various stages of oil and gas production, from extraction to transportation and processing.

In upstream operations, laminar flow is crucial for optimizing well performance and maximizing recovery rates. As oil and gas reservoirs become more complex and challenging to access, the industry requires advanced laminar flow technologies to improve production rates and reduce formation damage. This demand is particularly evident in unconventional resources such as shale oil and tight gas, where maintaining laminar flow conditions is vital for effective hydraulic fracturing and enhanced oil recovery techniques.

Midstream operations heavily rely on laminar flow principles for efficient and safe transportation of oil and gas through pipelines. The industry seeks laminar flow solutions to minimize pressure drops, reduce pumping costs, and prevent flow instabilities that can lead to pipeline damage or leaks. As pipeline networks expand and transport increasingly diverse fluid compositions, the demand for sophisticated laminar flow management systems continues to grow.

In downstream processes, refineries and petrochemical plants require precise control of laminar flow conditions to optimize heat transfer, separation processes, and chemical reactions. The industry's push towards more energy-efficient and environmentally friendly operations has further intensified the need for advanced laminar flow technologies in refining and processing equipment.

The demand for laminar flow expertise extends beyond operational aspects to safety and environmental considerations. Accurate prediction and control of laminar flow behavior are essential for preventing accidents, minimizing spills, and reducing emissions. As regulatory requirements become more stringent, oil and gas companies are investing in laminar flow research and technologies to ensure compliance and improve their environmental performance.

Furthermore, the industry's digital transformation has created new opportunities and challenges related to laminar flow. The integration of sensors, data analytics, and artificial intelligence in flow management systems has led to increased demand for sophisticated laminar flow modeling and real-time monitoring solutions. These technologies enable operators to optimize flow conditions, predict maintenance needs, and make data-driven decisions to improve overall system performance.

As the oil and gas sector continues to evolve, the demand for laminar flow expertise and technologies is expected to grow. This trend is driven by the need to extract resources from increasingly challenging environments, improve operational efficiency, enhance safety measures, and meet stringent environmental standards. Consequently, investment in laminar flow research, development of innovative flow control technologies, and training of specialized personnel remain high priorities for the industry.

In upstream operations, laminar flow is crucial for optimizing well performance and maximizing recovery rates. As oil and gas reservoirs become more complex and challenging to access, the industry requires advanced laminar flow technologies to improve production rates and reduce formation damage. This demand is particularly evident in unconventional resources such as shale oil and tight gas, where maintaining laminar flow conditions is vital for effective hydraulic fracturing and enhanced oil recovery techniques.

Midstream operations heavily rely on laminar flow principles for efficient and safe transportation of oil and gas through pipelines. The industry seeks laminar flow solutions to minimize pressure drops, reduce pumping costs, and prevent flow instabilities that can lead to pipeline damage or leaks. As pipeline networks expand and transport increasingly diverse fluid compositions, the demand for sophisticated laminar flow management systems continues to grow.

In downstream processes, refineries and petrochemical plants require precise control of laminar flow conditions to optimize heat transfer, separation processes, and chemical reactions. The industry's push towards more energy-efficient and environmentally friendly operations has further intensified the need for advanced laminar flow technologies in refining and processing equipment.

The demand for laminar flow expertise extends beyond operational aspects to safety and environmental considerations. Accurate prediction and control of laminar flow behavior are essential for preventing accidents, minimizing spills, and reducing emissions. As regulatory requirements become more stringent, oil and gas companies are investing in laminar flow research and technologies to ensure compliance and improve their environmental performance.

Furthermore, the industry's digital transformation has created new opportunities and challenges related to laminar flow. The integration of sensors, data analytics, and artificial intelligence in flow management systems has led to increased demand for sophisticated laminar flow modeling and real-time monitoring solutions. These technologies enable operators to optimize flow conditions, predict maintenance needs, and make data-driven decisions to improve overall system performance.

As the oil and gas sector continues to evolve, the demand for laminar flow expertise and technologies is expected to grow. This trend is driven by the need to extract resources from increasingly challenging environments, improve operational efficiency, enhance safety measures, and meet stringent environmental standards. Consequently, investment in laminar flow research, development of innovative flow control technologies, and training of specialized personnel remain high priorities for the industry.

Current Challenges in Laminar Flow Control

Laminar flow control in oil and gas operations faces several significant challenges that hinder its widespread implementation and effectiveness. One of the primary obstacles is the complexity of fluid dynamics in real-world scenarios. While laminar flow can be easily achieved and studied in controlled laboratory environments, the unpredictable nature of oil and gas reservoirs introduces numerous variables that complicate flow control.

The heterogeneity of reservoir formations presents a major challenge. Variations in porosity, permeability, and rock composition across different layers and regions of a reservoir can disrupt laminar flow patterns. These inconsistencies make it difficult to maintain uniform flow conditions throughout the entire production zone, leading to potential inefficiencies and reduced recovery rates.

Another significant challenge is the presence of multiphase flow in oil and gas production. The simultaneous flow of oil, gas, and water through porous media introduces complex interactions between different fluid phases. These interactions can lead to flow instabilities, such as fingering or channeling, which deviate from ideal laminar flow conditions and reduce overall production efficiency.

The high pressures and temperatures encountered in deep reservoirs further complicate laminar flow control. Extreme conditions can alter fluid properties, such as viscosity and density, which directly impact flow behavior. Additionally, these harsh environments can cause equipment degradation, affecting the performance of flow control devices and sensors crucial for maintaining laminar flow.

Scale formation and deposition pose another challenge to laminar flow control. The accumulation of mineral scales on wellbore surfaces and within the reservoir can alter flow paths and create turbulence, disrupting laminar flow patterns. This not only reduces production efficiency but also increases the risk of equipment failure and costly interventions.

The dynamic nature of reservoir conditions over time presents ongoing challenges for laminar flow control. As reservoirs deplete, changes in pressure, fluid composition, and flow rates occur, requiring continuous adjustment of flow control strategies. This necessitates sophisticated monitoring and control systems capable of real-time adaptation to evolving reservoir conditions.

Furthermore, the limitations of current sensing and measurement technologies hinder precise laminar flow control. Accurate, real-time data on flow conditions deep within reservoirs is crucial for effective control, but existing technologies often fall short in providing the required level of detail and reliability in harsh downhole environments.

Lastly, the economic feasibility of implementing advanced laminar flow control technologies remains a challenge. The high costs associated with developing, installing, and maintaining sophisticated flow control systems must be balanced against potential production gains. This economic consideration often limits the adoption of cutting-edge laminar flow control solutions, particularly in mature or marginal fields.

The heterogeneity of reservoir formations presents a major challenge. Variations in porosity, permeability, and rock composition across different layers and regions of a reservoir can disrupt laminar flow patterns. These inconsistencies make it difficult to maintain uniform flow conditions throughout the entire production zone, leading to potential inefficiencies and reduced recovery rates.

Another significant challenge is the presence of multiphase flow in oil and gas production. The simultaneous flow of oil, gas, and water through porous media introduces complex interactions between different fluid phases. These interactions can lead to flow instabilities, such as fingering or channeling, which deviate from ideal laminar flow conditions and reduce overall production efficiency.

The high pressures and temperatures encountered in deep reservoirs further complicate laminar flow control. Extreme conditions can alter fluid properties, such as viscosity and density, which directly impact flow behavior. Additionally, these harsh environments can cause equipment degradation, affecting the performance of flow control devices and sensors crucial for maintaining laminar flow.

Scale formation and deposition pose another challenge to laminar flow control. The accumulation of mineral scales on wellbore surfaces and within the reservoir can alter flow paths and create turbulence, disrupting laminar flow patterns. This not only reduces production efficiency but also increases the risk of equipment failure and costly interventions.

The dynamic nature of reservoir conditions over time presents ongoing challenges for laminar flow control. As reservoirs deplete, changes in pressure, fluid composition, and flow rates occur, requiring continuous adjustment of flow control strategies. This necessitates sophisticated monitoring and control systems capable of real-time adaptation to evolving reservoir conditions.

Furthermore, the limitations of current sensing and measurement technologies hinder precise laminar flow control. Accurate, real-time data on flow conditions deep within reservoirs is crucial for effective control, but existing technologies often fall short in providing the required level of detail and reliability in harsh downhole environments.

Lastly, the economic feasibility of implementing advanced laminar flow control technologies remains a challenge. The high costs associated with developing, installing, and maintaining sophisticated flow control systems must be balanced against potential production gains. This economic consideration often limits the adoption of cutting-edge laminar flow control solutions, particularly in mature or marginal fields.

Existing Laminar Flow Solutions

01 Measurement and analysis of laminar flow characteristics

Various methods and devices are used to measure and analyze laminar flow characteristics. These include optical systems, sensors, and flow meters that can detect and quantify parameters such as velocity profiles, pressure distributions, and boundary layer behavior in laminar flow conditions.- Measurement and analysis of laminar flow characteristics: Various methods and devices are used to measure and analyze laminar flow characteristics. These include optical systems, sensors, and flow meters that can detect and quantify flow patterns, velocities, and other properties of laminar flow. Such measurements are crucial for understanding and optimizing fluid dynamics in various applications.

- Control and manipulation of laminar flow: Techniques and systems for controlling and manipulating laminar flow are developed to achieve desired flow characteristics. This includes the use of specialized nozzles, flow conditioners, and other devices that can modify flow patterns, reduce turbulence, and maintain laminar conditions in various fluid systems.

- Applications of laminar flow in aerodynamics: Laminar flow principles are applied in aerodynamic design to reduce drag and improve efficiency. This includes the development of laminar flow airfoils, wing designs, and surface treatments that promote laminar flow conditions on aircraft and other vehicles.

- Laminar flow in microfluidic devices: The characteristics of laminar flow are utilized in microfluidic devices for various applications. These include lab-on-a-chip systems, micro-mixers, and other miniaturized fluid handling devices where precise control of fluid behavior is critical.

- Laminar flow in industrial processes: Laminar flow characteristics are important in various industrial processes, including filtration, separation, and chemical reactions. Understanding and controlling laminar flow in these contexts can lead to improved efficiency, product quality, and process control.

02 Control and manipulation of laminar flow

Techniques and systems are developed to control and manipulate laminar flow characteristics. This includes the use of flow control devices, surface modifications, and active flow control methods to maintain, enhance, or disrupt laminar flow conditions for various applications in aerodynamics, fluid dynamics, and process engineering.Expand Specific Solutions03 Laminar flow in microfluidic devices

The study and application of laminar flow characteristics in microfluidic devices are crucial for various fields such as biomedical research, chemical analysis, and lab-on-a-chip technologies. This involves designing channels and structures that maintain laminar flow at microscale levels for precise fluid handling and analysis.Expand Specific Solutions04 Laminar flow in heat exchange and cooling systems

Laminar flow characteristics are utilized in heat exchange and cooling systems to optimize thermal management. This includes the design of heat sinks, cooling channels, and fluid circulation systems that leverage laminar flow properties for efficient heat transfer in various industrial and electronic applications.Expand Specific Solutions05 Laminar flow in aerodynamics and vehicle design

The principles of laminar flow are applied in aerodynamics and vehicle design to reduce drag and improve efficiency. This involves shaping surfaces, optimizing airfoils, and developing flow control mechanisms to maintain laminar flow over wings, fuselages, and other vehicle components for enhanced performance.Expand Specific Solutions

Key Players in Laminar Flow Research

The science behind laminar flow in oil and gas is a critical area of study in the energy sector, currently in a mature stage of development but with ongoing research for optimization. The market size is substantial, given the global importance of oil and gas industries. Technologically, major players like PetroChina, China Petroleum & Chemical Corp., and ExxonMobil Upstream Research Co. have made significant advancements in understanding and applying laminar flow principles. Research institutions such as Southwest Petroleum University and the Massachusetts Institute of Technology continue to contribute to the field's development, focusing on improving efficiency and reducing environmental impact in oil and gas operations.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has invested heavily in laminar flow research for enhanced oil recovery (EOR) techniques. Their approach focuses on developing smart fluids with adaptive viscosity properties that can maintain laminar flow under varying reservoir conditions. Sinopec has pioneered the use of nanoparticle-based additives to modify fluid rheology, enabling better control of flow regimes in porous media[3]. The company has also developed advanced monitoring systems using distributed fiber optic sensing to detect and respond to flow pattern changes in real-time, ensuring optimal laminar flow conditions are maintained throughout the production process[4].

Strengths: Cutting-edge smart fluid technology, advanced real-time monitoring capabilities. Weaknesses: Potential environmental concerns with nanoparticle additives, high development and implementation costs.

Exxonmobil Upstream Research Co.

Technical Solution: Exxonmobil has developed advanced computational fluid dynamics (CFD) models to simulate and optimize laminar flow in oil and gas pipelines. Their approach combines high-fidelity numerical simulations with experimental validation to accurately predict flow behavior under various conditions. The company has implemented machine learning algorithms to enhance real-time flow prediction and control, allowing for adaptive optimization of pipeline operations[1]. Exxonmobil's research also focuses on developing novel surface coatings and pipeline geometries to promote laminar flow and reduce turbulence, potentially increasing throughput and reducing energy consumption in oil and gas transportation[2].

Strengths: Industry-leading CFD capabilities, integration of machine learning for real-time optimization, and innovative surface technologies. Weaknesses: High implementation costs and potential challenges in retrofitting existing infrastructure.

Core Innovations in Laminar Flow Science

Single-Piece Extended Laminar Flow Inlet Lipskin

PatentActiveUS20180339783A1

Innovation

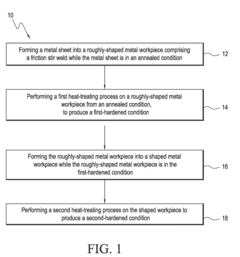

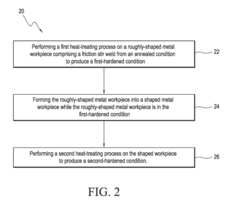

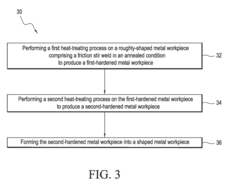

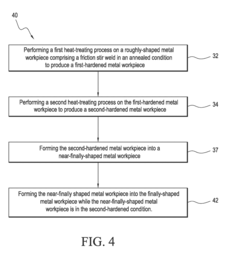

- A method involving heat-treating metal workpieces with friction stir welds in specified conditions to maintain the welds within the finished lipskin, using processes like super-plastic forming, diffusion bonding, and explosive forming to create unitary, lightweight structures that retain 'fly-away' welds without the need for additional reinforcing components.

Method for processing of liquid hydrocarbon raw materials

PatentInactiveIN5433DELNP2014A

Innovation

- The method involves pretreating crude oil by creating a straight tubular laminar flow that is then directed into a spiral trajectory, maintaining laminarity and achieving critical Reynolds numbers, which allows for phase transition into a fifth state, reducing energy consumption and enhancing hydrocarbon separation without depending on chemical or physical properties.

Environmental Impact of Laminar Flow

Laminar flow in oil and gas operations has significant environmental implications that warrant careful consideration. The controlled, predictable nature of laminar flow can contribute to reduced environmental impact when properly managed. In pipeline transportation, laminar flow regimes help minimize friction losses, leading to lower energy consumption and reduced carbon emissions associated with pumping operations. This efficiency gain translates to a smaller environmental footprint for oil and gas transportation systems.

Moreover, laminar flow characteristics play a crucial role in preventing leaks and spills. The smooth, parallel flow lines typical of laminar regimes reduce the risk of erosion and corrosion in pipelines and processing equipment. This enhanced structural integrity contributes to longer operational lifespans and fewer incidents of environmental contamination due to equipment failure.

In offshore drilling operations, understanding and maintaining laminar flow conditions in drilling fluids is essential for well control and preventing blowouts. By ensuring stable pressure profiles and efficient cuttings removal, laminar flow helps mitigate the risk of catastrophic environmental events associated with uncontrolled well releases.

The application of laminar flow principles in separation processes within oil and gas facilities also has positive environmental implications. Improved separation efficiency reduces the volume of waste products and enhances the quality of treated water for disposal or reuse. This leads to decreased environmental stress on local ecosystems and water resources.

However, it is important to note that while laminar flow can contribute to environmental protection, it is not without challenges. Maintaining laminar flow conditions often requires careful control of fluid properties and flow rates, which may necessitate the use of chemical additives or energy-intensive processes. The environmental impact of these interventions must be weighed against the benefits of laminar flow.

Furthermore, in some scenarios, the transition from laminar to turbulent flow can be beneficial for certain environmental processes, such as the natural dispersion of pollutants in water bodies. Therefore, a nuanced understanding of flow regimes and their environmental consequences is crucial for optimizing oil and gas operations while minimizing ecological impact.

As the industry moves towards more sustainable practices, the role of laminar flow in reducing environmental footprint will likely gain increased attention. Future research and technological developments may focus on enhancing the environmental benefits of laminar flow while addressing its limitations, potentially leading to more eco-friendly oil and gas operations.

Moreover, laminar flow characteristics play a crucial role in preventing leaks and spills. The smooth, parallel flow lines typical of laminar regimes reduce the risk of erosion and corrosion in pipelines and processing equipment. This enhanced structural integrity contributes to longer operational lifespans and fewer incidents of environmental contamination due to equipment failure.

In offshore drilling operations, understanding and maintaining laminar flow conditions in drilling fluids is essential for well control and preventing blowouts. By ensuring stable pressure profiles and efficient cuttings removal, laminar flow helps mitigate the risk of catastrophic environmental events associated with uncontrolled well releases.

The application of laminar flow principles in separation processes within oil and gas facilities also has positive environmental implications. Improved separation efficiency reduces the volume of waste products and enhances the quality of treated water for disposal or reuse. This leads to decreased environmental stress on local ecosystems and water resources.

However, it is important to note that while laminar flow can contribute to environmental protection, it is not without challenges. Maintaining laminar flow conditions often requires careful control of fluid properties and flow rates, which may necessitate the use of chemical additives or energy-intensive processes. The environmental impact of these interventions must be weighed against the benefits of laminar flow.

Furthermore, in some scenarios, the transition from laminar to turbulent flow can be beneficial for certain environmental processes, such as the natural dispersion of pollutants in water bodies. Therefore, a nuanced understanding of flow regimes and their environmental consequences is crucial for optimizing oil and gas operations while minimizing ecological impact.

As the industry moves towards more sustainable practices, the role of laminar flow in reducing environmental footprint will likely gain increased attention. Future research and technological developments may focus on enhancing the environmental benefits of laminar flow while addressing its limitations, potentially leading to more eco-friendly oil and gas operations.

Economic Implications of Laminar Flow

The economic implications of laminar flow in the oil and gas industry are far-reaching and multifaceted. At its core, laminar flow contributes to enhanced operational efficiency and cost-effectiveness in various processes, particularly in pipeline transportation and well production.

In pipeline systems, achieving laminar flow conditions can significantly reduce energy consumption. The smooth, predictable movement of fluids under laminar flow requires less pumping power compared to turbulent flow regimes. This translates to lower operational costs for companies, as they can maintain the same throughput with reduced energy input. Over time, these savings can amount to substantial financial benefits, especially for large-scale operations with extensive pipeline networks.

Laminar flow also plays a crucial role in well production optimization. By maintaining laminar flow conditions in wellbores and near-wellbore regions, operators can maximize production rates while minimizing pressure drops. This optimization leads to increased recovery rates and extended well life, ultimately improving the economic viability of oil and gas fields. The ability to extract more resources from existing wells reduces the need for additional drilling, thereby lowering capital expenditures and environmental impact.

Furthermore, the predictability of laminar flow allows for more accurate flow modeling and forecasting. This enhanced predictability enables better resource management and production planning, reducing uncertainties in operational decision-making. Improved forecasting capabilities can lead to more efficient inventory management, optimized scheduling of maintenance activities, and better-informed investment decisions.

In the realm of enhanced oil recovery (EOR) techniques, understanding and controlling laminar flow is essential for maximizing sweep efficiency and displacement of oil. Techniques such as polymer flooding rely on maintaining laminar flow conditions to ensure uniform displacement of oil and prevent fingering effects. The successful implementation of these EOR methods can significantly increase recovery factors, thereby enhancing the economic value of reservoirs that would otherwise be considered depleted.

The impact of laminar flow extends to equipment design and maintenance as well. Pumps, valves, and other flow control devices can be optimized for laminar flow conditions, potentially reducing wear and tear and extending equipment lifespan. This optimization can lead to lower maintenance costs and reduced downtime, further contributing to operational efficiency and cost savings.

In conclusion, the economic implications of laminar flow in the oil and gas industry are substantial, affecting various aspects of operations from production to transportation. By leveraging the benefits of laminar flow, companies can achieve significant cost reductions, improved resource recovery, and enhanced operational efficiency, ultimately leading to improved profitability and competitiveness in the global energy market.

In pipeline systems, achieving laminar flow conditions can significantly reduce energy consumption. The smooth, predictable movement of fluids under laminar flow requires less pumping power compared to turbulent flow regimes. This translates to lower operational costs for companies, as they can maintain the same throughput with reduced energy input. Over time, these savings can amount to substantial financial benefits, especially for large-scale operations with extensive pipeline networks.

Laminar flow also plays a crucial role in well production optimization. By maintaining laminar flow conditions in wellbores and near-wellbore regions, operators can maximize production rates while minimizing pressure drops. This optimization leads to increased recovery rates and extended well life, ultimately improving the economic viability of oil and gas fields. The ability to extract more resources from existing wells reduces the need for additional drilling, thereby lowering capital expenditures and environmental impact.

Furthermore, the predictability of laminar flow allows for more accurate flow modeling and forecasting. This enhanced predictability enables better resource management and production planning, reducing uncertainties in operational decision-making. Improved forecasting capabilities can lead to more efficient inventory management, optimized scheduling of maintenance activities, and better-informed investment decisions.

In the realm of enhanced oil recovery (EOR) techniques, understanding and controlling laminar flow is essential for maximizing sweep efficiency and displacement of oil. Techniques such as polymer flooding rely on maintaining laminar flow conditions to ensure uniform displacement of oil and prevent fingering effects. The successful implementation of these EOR methods can significantly increase recovery factors, thereby enhancing the economic value of reservoirs that would otherwise be considered depleted.

The impact of laminar flow extends to equipment design and maintenance as well. Pumps, valves, and other flow control devices can be optimized for laminar flow conditions, potentially reducing wear and tear and extending equipment lifespan. This optimization can lead to lower maintenance costs and reduced downtime, further contributing to operational efficiency and cost savings.

In conclusion, the economic implications of laminar flow in the oil and gas industry are substantial, affecting various aspects of operations from production to transportation. By leveraging the benefits of laminar flow, companies can achieve significant cost reductions, improved resource recovery, and enhanced operational efficiency, ultimately leading to improved profitability and competitiveness in the global energy market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!