How to Enhance Heat Transfer with Laminar Flow?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Transfer Enhancement Background and Objectives

Heat transfer enhancement has been a critical area of research in thermal engineering for decades, driven by the increasing demand for more efficient and compact heat exchange systems across various industries. The concept of enhancing heat transfer in laminar flow conditions has gained particular attention due to its relevance in microfluidic devices, biomedical applications, and energy systems where low Reynolds number flows are prevalent.

The historical development of heat transfer enhancement techniques can be traced back to the early 20th century, with significant advancements occurring in the latter half of the century. Initially, focus was primarily on turbulent flow regimes, but as technology progressed, the importance of laminar flow heat transfer became increasingly apparent, especially in miniaturized systems and precision applications.

The evolution of heat transfer enhancement in laminar flow has been marked by several key milestones. Early passive techniques involved the use of extended surfaces and roughened channels. This was followed by the introduction of more sophisticated geometries, such as twisted tapes, coiled tubes, and corrugated channels. In recent years, the field has seen a surge in research on nanofluids and micro/nanostructured surfaces, leveraging advancements in materials science and nanotechnology.

The primary objective of enhancing heat transfer in laminar flow is to overcome the inherent limitations of low Reynolds number flows, which typically exhibit poor mixing and thermal transport characteristics. Researchers aim to develop innovative methods that can significantly increase heat transfer rates without incurring excessive pressure drops or compromising the laminar flow regime.

Current technological trends in this field are focused on several key areas. These include the development of novel surface modifications at the micro and nanoscale, the exploration of complex flow geometries enabled by advanced manufacturing techniques, and the investigation of smart materials that can dynamically respond to flow conditions. Additionally, there is growing interest in hybrid systems that combine multiple enhancement techniques to achieve synergistic effects.

The potential applications of enhanced laminar flow heat transfer are vast and diverse. In the biomedical field, it could lead to more efficient cooling systems for medical devices and improved thermal management in targeted drug delivery. In electronics cooling, it offers the promise of handling ever-increasing heat fluxes in compact devices. For renewable energy systems, enhanced laminar flow heat transfer could improve the efficiency of solar thermal collectors and geothermal heat exchangers.

As we look towards the future, the goals for heat transfer enhancement in laminar flow are becoming increasingly ambitious. Researchers are striving to develop techniques that can approach or even exceed the heat transfer rates typically associated with turbulent flows, while maintaining the benefits of laminar flow conditions. This includes minimal pressure drop, predictable flow patterns, and reduced wear on system components.

The historical development of heat transfer enhancement techniques can be traced back to the early 20th century, with significant advancements occurring in the latter half of the century. Initially, focus was primarily on turbulent flow regimes, but as technology progressed, the importance of laminar flow heat transfer became increasingly apparent, especially in miniaturized systems and precision applications.

The evolution of heat transfer enhancement in laminar flow has been marked by several key milestones. Early passive techniques involved the use of extended surfaces and roughened channels. This was followed by the introduction of more sophisticated geometries, such as twisted tapes, coiled tubes, and corrugated channels. In recent years, the field has seen a surge in research on nanofluids and micro/nanostructured surfaces, leveraging advancements in materials science and nanotechnology.

The primary objective of enhancing heat transfer in laminar flow is to overcome the inherent limitations of low Reynolds number flows, which typically exhibit poor mixing and thermal transport characteristics. Researchers aim to develop innovative methods that can significantly increase heat transfer rates without incurring excessive pressure drops or compromising the laminar flow regime.

Current technological trends in this field are focused on several key areas. These include the development of novel surface modifications at the micro and nanoscale, the exploration of complex flow geometries enabled by advanced manufacturing techniques, and the investigation of smart materials that can dynamically respond to flow conditions. Additionally, there is growing interest in hybrid systems that combine multiple enhancement techniques to achieve synergistic effects.

The potential applications of enhanced laminar flow heat transfer are vast and diverse. In the biomedical field, it could lead to more efficient cooling systems for medical devices and improved thermal management in targeted drug delivery. In electronics cooling, it offers the promise of handling ever-increasing heat fluxes in compact devices. For renewable energy systems, enhanced laminar flow heat transfer could improve the efficiency of solar thermal collectors and geothermal heat exchangers.

As we look towards the future, the goals for heat transfer enhancement in laminar flow are becoming increasingly ambitious. Researchers are striving to develop techniques that can approach or even exceed the heat transfer rates typically associated with turbulent flows, while maintaining the benefits of laminar flow conditions. This includes minimal pressure drop, predictable flow patterns, and reduced wear on system components.

Market Analysis for Improved Heat Transfer Solutions

The market for improved heat transfer solutions in laminar flow systems is experiencing significant growth, driven by increasing demand for energy-efficient and high-performance thermal management across various industries. This market segment is particularly relevant in applications where maintaining laminar flow is crucial, such as in microfluidic devices, heat exchangers, and certain industrial processes.

The global heat transfer market, which encompasses solutions for both laminar and turbulent flow regimes, is projected to expand steadily over the coming years. Within this broader market, the demand for specialized solutions that enhance heat transfer in laminar flow conditions is gaining traction. This growth is fueled by the need for more efficient cooling systems in electronics, advancements in medical devices, and the push for energy conservation in industrial processes.

Key industries driving the demand for improved laminar flow heat transfer solutions include electronics cooling, biomedical engineering, chemical processing, and renewable energy systems. In the electronics sector, the miniaturization of components and increasing power densities necessitate more effective cooling solutions that can operate within the constraints of laminar flow. The biomedical field requires precise temperature control in microfluidic devices for applications such as lab-on-a-chip technologies and point-of-care diagnostics.

The chemical processing industry is another significant market for enhanced laminar flow heat transfer, particularly in applications involving viscous fluids or where maintaining laminar flow is critical for product quality. In the renewable energy sector, improved heat transfer in laminar flow conditions can enhance the efficiency of solar thermal systems and certain types of fuel cells.

Market trends indicate a growing preference for compact, high-efficiency heat transfer solutions that can operate effectively under laminar flow conditions. This trend is driving innovation in surface modification techniques, novel materials, and advanced geometries for heat exchangers and cooling systems. Additionally, there is an increasing focus on developing passive enhancement techniques that do not require external power input, aligning with the global push for energy conservation.

The competitive landscape in this market segment is characterized by a mix of established thermal management companies and innovative startups. Key players are investing in research and development to create proprietary technologies that can significantly enhance heat transfer rates in laminar flow regimes. Collaborations between industry and academic institutions are also becoming more common, fostering the development of cutting-edge solutions.

As environmental regulations become more stringent and energy efficiency gains paramount importance, the market for improved heat transfer solutions in laminar flow systems is expected to continue its upward trajectory. The ability to enhance heat transfer without transitioning to turbulent flow offers significant advantages in terms of energy efficiency and system control, making it an attractive area for ongoing research and development efforts.

The global heat transfer market, which encompasses solutions for both laminar and turbulent flow regimes, is projected to expand steadily over the coming years. Within this broader market, the demand for specialized solutions that enhance heat transfer in laminar flow conditions is gaining traction. This growth is fueled by the need for more efficient cooling systems in electronics, advancements in medical devices, and the push for energy conservation in industrial processes.

Key industries driving the demand for improved laminar flow heat transfer solutions include electronics cooling, biomedical engineering, chemical processing, and renewable energy systems. In the electronics sector, the miniaturization of components and increasing power densities necessitate more effective cooling solutions that can operate within the constraints of laminar flow. The biomedical field requires precise temperature control in microfluidic devices for applications such as lab-on-a-chip technologies and point-of-care diagnostics.

The chemical processing industry is another significant market for enhanced laminar flow heat transfer, particularly in applications involving viscous fluids or where maintaining laminar flow is critical for product quality. In the renewable energy sector, improved heat transfer in laminar flow conditions can enhance the efficiency of solar thermal systems and certain types of fuel cells.

Market trends indicate a growing preference for compact, high-efficiency heat transfer solutions that can operate effectively under laminar flow conditions. This trend is driving innovation in surface modification techniques, novel materials, and advanced geometries for heat exchangers and cooling systems. Additionally, there is an increasing focus on developing passive enhancement techniques that do not require external power input, aligning with the global push for energy conservation.

The competitive landscape in this market segment is characterized by a mix of established thermal management companies and innovative startups. Key players are investing in research and development to create proprietary technologies that can significantly enhance heat transfer rates in laminar flow regimes. Collaborations between industry and academic institutions are also becoming more common, fostering the development of cutting-edge solutions.

As environmental regulations become more stringent and energy efficiency gains paramount importance, the market for improved heat transfer solutions in laminar flow systems is expected to continue its upward trajectory. The ability to enhance heat transfer without transitioning to turbulent flow offers significant advantages in terms of energy efficiency and system control, making it an attractive area for ongoing research and development efforts.

Current Challenges in Laminar Flow Heat Transfer

Laminar flow heat transfer faces several significant challenges that hinder its widespread application and efficiency in various industrial processes. One of the primary obstacles is the inherently low heat transfer rates associated with laminar flow regimes. The absence of turbulent mixing limits the convective heat transfer, resulting in reduced thermal efficiency compared to turbulent flow systems.

The development of boundary layers in laminar flow presents another major challenge. As fluid flows over a surface, a thin layer of fluid adjacent to the surface experiences reduced velocity due to viscous effects. This boundary layer acts as a thermal resistance, impeding heat transfer between the fluid and the surface. The thickness of this layer increases along the flow direction, further diminishing heat transfer effectiveness in downstream regions.

Another critical issue is the difficulty in maintaining laminar flow conditions over extended distances or in complex geometries. Even minor disturbances or irregularities can trigger a transition to turbulent flow, disrupting the desired laminar regime and altering heat transfer characteristics. This sensitivity to external factors makes it challenging to design and control laminar flow systems in practical applications.

The limited mixing in laminar flow also leads to temperature stratification within the fluid. This phenomenon results in non-uniform heat distribution and can create localized hot spots or cold regions, potentially compromising the overall system performance or product quality in heat-sensitive processes.

Furthermore, the low Reynolds numbers associated with laminar flow often necessitate larger heat transfer areas to achieve the desired thermal performance. This requirement can lead to increased system size and cost, making laminar flow heat transfer less attractive for space-constrained or cost-sensitive applications.

The accurate prediction and modeling of laminar flow heat transfer pose additional challenges. While computational fluid dynamics (CFD) tools have advanced significantly, simulating laminar flow heat transfer in complex geometries or with temperature-dependent fluid properties remains computationally intensive and prone to numerical instabilities.

Lastly, the integration of passive or active heat transfer enhancement techniques in laminar flow systems presents unique difficulties. Many conventional enhancement methods, such as turbulators or vortex generators, are less effective or even counterproductive in laminar flow regimes. Developing innovative approaches that can augment heat transfer without disrupting the laminar flow characteristics remains an ongoing challenge for researchers and engineers in this field.

The development of boundary layers in laminar flow presents another major challenge. As fluid flows over a surface, a thin layer of fluid adjacent to the surface experiences reduced velocity due to viscous effects. This boundary layer acts as a thermal resistance, impeding heat transfer between the fluid and the surface. The thickness of this layer increases along the flow direction, further diminishing heat transfer effectiveness in downstream regions.

Another critical issue is the difficulty in maintaining laminar flow conditions over extended distances or in complex geometries. Even minor disturbances or irregularities can trigger a transition to turbulent flow, disrupting the desired laminar regime and altering heat transfer characteristics. This sensitivity to external factors makes it challenging to design and control laminar flow systems in practical applications.

The limited mixing in laminar flow also leads to temperature stratification within the fluid. This phenomenon results in non-uniform heat distribution and can create localized hot spots or cold regions, potentially compromising the overall system performance or product quality in heat-sensitive processes.

Furthermore, the low Reynolds numbers associated with laminar flow often necessitate larger heat transfer areas to achieve the desired thermal performance. This requirement can lead to increased system size and cost, making laminar flow heat transfer less attractive for space-constrained or cost-sensitive applications.

The accurate prediction and modeling of laminar flow heat transfer pose additional challenges. While computational fluid dynamics (CFD) tools have advanced significantly, simulating laminar flow heat transfer in complex geometries or with temperature-dependent fluid properties remains computationally intensive and prone to numerical instabilities.

Lastly, the integration of passive or active heat transfer enhancement techniques in laminar flow systems presents unique difficulties. Many conventional enhancement methods, such as turbulators or vortex generators, are less effective or even counterproductive in laminar flow regimes. Developing innovative approaches that can augment heat transfer without disrupting the laminar flow characteristics remains an ongoing challenge for researchers and engineers in this field.

Existing Laminar Flow Heat Transfer Enhancement Methods

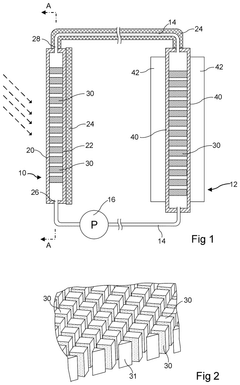

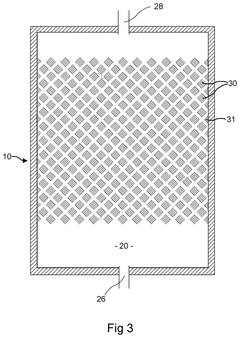

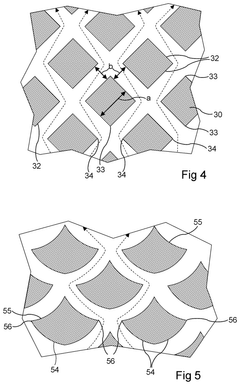

01 Heat exchanger design for laminar flow

Specialized heat exchanger designs are developed to optimize heat transfer in laminar flow conditions. These designs may include specific geometries, surface modifications, or flow arrangements to enhance heat transfer efficiency while maintaining laminar flow characteristics.- Heat exchanger design for laminar flow: Specialized heat exchanger designs are developed to optimize heat transfer in laminar flow conditions. These designs may include specific geometries, surface modifications, or flow arrangements to enhance heat transfer efficiency while maintaining laminar flow characteristics.

- Laminar flow cooling systems for electronic devices: Cooling systems utilizing laminar flow are implemented in electronic devices to manage heat dissipation. These systems often incorporate heat sinks, fluid channels, or other structures designed to maintain laminar flow while effectively transferring heat away from sensitive components.

- Laminar flow heat transfer in microfluidic devices: Microfluidic devices leverage laminar flow characteristics for precise heat transfer control. These devices are designed to manipulate small volumes of fluids in laminar flow regimes, enabling applications in areas such as lab-on-a-chip technologies and miniaturized heat exchangers.

- Enhanced heat transfer techniques for laminar flow: Various techniques are developed to enhance heat transfer in laminar flow conditions. These may include the use of nanofluids, surface texturing, or the introduction of secondary flows to improve heat transfer rates without transitioning to turbulent flow.

- Laminar flow heat transfer in industrial processes: Industrial applications utilize laminar flow heat transfer principles in processes such as chemical reactions, food processing, and materials manufacturing. Specialized equipment and process designs are developed to maintain laminar flow conditions while achieving desired heat transfer rates.

02 Laminar flow cooling systems for electronic devices

Cooling systems utilizing laminar flow are implemented in electronic devices to manage heat dissipation. These systems often incorporate heat sinks, thermal interfaces, and carefully designed airflow paths to maximize heat transfer while minimizing turbulence and noise.Expand Specific Solutions03 Microfluidic heat transfer applications

Laminar flow heat transfer principles are applied in microfluidic devices for various applications, including lab-on-a-chip systems, miniaturized heat exchangers, and thermal management in compact electronic components. These applications leverage the predictable nature of laminar flow for precise thermal control.Expand Specific Solutions04 Enhanced heat transfer surfaces for laminar flow

Specialized surface treatments and geometries are developed to enhance heat transfer in laminar flow conditions. These may include micro-structured surfaces, coatings, or embedded elements that increase surface area or induce local mixing without disrupting the overall laminar flow regime.Expand Specific Solutions05 Laminar flow heat transfer in industrial processes

Industrial applications of laminar flow heat transfer are explored in various processes, such as chemical reactors, food processing, and materials manufacturing. These applications focus on maintaining precise temperature control and uniform heat distribution while operating within laminar flow parameters.Expand Specific Solutions

Key Players in Heat Transfer Technology Industry

The heat transfer enhancement in laminar flow is a mature field with ongoing research and development. The market is in a growth phase, driven by increasing demand for energy-efficient thermal management solutions across industries. Key players like Tsinghua University, DAIKIN INDUSTRIES, and China Petroleum & Chemical Corp. are actively contributing to technological advancements. The market size is expanding, particularly in sectors such as HVAC, electronics cooling, and process industries. While established companies dominate, innovative startups and research institutions are also making significant contributions, focusing on novel materials, surface modifications, and flow control techniques to improve heat transfer efficiency in laminar flow conditions.

Tsinghua University

Technical Solution: Tsinghua University has developed innovative approaches to enhance heat transfer in laminar flow conditions. They have focused on micro-structured surfaces and nanofluids to improve heat transfer efficiency. Their research includes the development of micro-grooved surfaces that create secondary flows, enhancing mixing and heat transfer even in laminar regimes[1]. Additionally, they have explored the use of nanofluids, which are engineered colloidal suspensions of nanoparticles in a base fluid, to increase thermal conductivity and convective heat transfer coefficients[2]. These nanofluids have shown promising results in enhancing heat transfer rates by up to 40% in some laminar flow applications[3].

Strengths: Cutting-edge research in micro-structured surfaces and nanofluids. Weaknesses: Potential scalability issues and high production costs for practical applications.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has developed advanced heat exchanger designs specifically tailored for laminar flow conditions. Their approach involves the use of corrugated fins and specially designed tube arrangements to create controlled turbulence within the laminar boundary layer[4]. This technique, known as "boundary layer disruption," effectively increases the heat transfer coefficient without significantly increasing pressure drop. DAIKIN has also implemented surface coatings that enhance wettability and promote dropwise condensation, further improving heat transfer in two-phase flow systems[5]. Their latest heat exchangers incorporate these technologies and have demonstrated up to 30% improvement in heat transfer efficiency for laminar flow applications in HVAC systems[6].

Strengths: Practical solutions for HVAC industry, balancing heat transfer enhancement with energy efficiency. Weaknesses: May be limited to specific flow regimes and fluid types.

Innovative Approaches to Laminar Flow Heat Transfer

Heat Transfer System

PatentPendingUS20250093110A1

Innovation

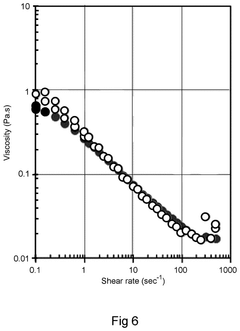

- The implementation of a heat transfer device with a chamber containing an array of obstructions that induces elastic turbulence in the flowing fluid by adjusting the viscosity, flow rate, and gap width, allowing for a Reynolds number range of 1 to 1000, thereby enhancing heat transfer through the phenomenon of elastic turbulence.

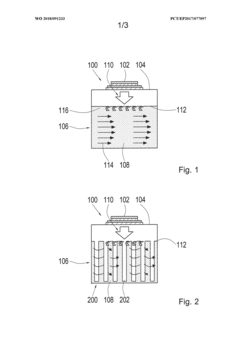

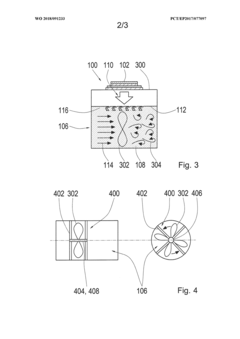

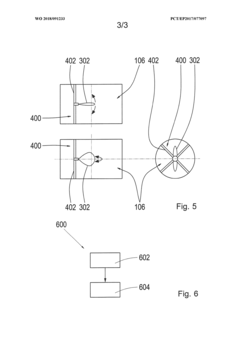

Electronic module and method for the production thereof

PatentWO2018091233A1

Innovation

- An electronic module with a laser-sintered heat sink and integrated turbulator body, which promotes turbulent flow through the cooling channel by using additive manufacturing techniques, enhancing heat transfer and reducing thermal resistance.

Energy Efficiency Implications of Enhanced Heat Transfer

Enhanced heat transfer in laminar flow systems has significant implications for energy efficiency across various industries. By improving heat transfer rates without transitioning to turbulent flow, these advancements can lead to substantial energy savings and increased overall system performance. In the context of heat exchangers, which are ubiquitous in industrial processes, enhanced laminar flow heat transfer can result in more compact designs, reduced pumping power requirements, and lower operational costs.

One of the primary benefits of improved heat transfer in laminar flow is the potential for downsizing equipment while maintaining or even increasing thermal performance. This reduction in size translates directly to material savings in manufacturing and lower space requirements for installation. Moreover, smaller heat exchangers often require less coolant or working fluid, further contributing to resource conservation and cost reduction.

The energy efficiency gains extend beyond the immediate heat transfer process. Enhanced laminar flow heat transfer techniques can lead to lower pressure drops across heat exchange systems, resulting in decreased pumping power needs. This reduction in pumping energy can be substantial, especially in large-scale industrial applications where fluid circulation is a significant contributor to overall energy consumption.

In the realm of electronics cooling, where maintaining laminar flow is often crucial for precise temperature control, enhanced heat transfer techniques can lead to more efficient thermal management. This improvement allows for higher power densities in electronic devices without compromising reliability, potentially enabling advancements in computing power and miniaturization of electronic components.

Furthermore, in renewable energy systems such as solar thermal collectors, enhanced laminar flow heat transfer can increase the efficiency of energy capture and conversion. By improving the heat transfer from the absorber surface to the working fluid, these systems can operate at higher efficiencies, making renewable energy sources more competitive with traditional fossil fuel-based alternatives.

The automotive industry also stands to benefit from these advancements. In electric vehicle battery thermal management systems, enhanced laminar flow heat transfer can lead to more efficient cooling of battery packs, potentially extending battery life and improving overall vehicle performance. This efficiency gain contributes to the broader goal of increasing the range and reliability of electric vehicles, further promoting the transition to sustainable transportation.

One of the primary benefits of improved heat transfer in laminar flow is the potential for downsizing equipment while maintaining or even increasing thermal performance. This reduction in size translates directly to material savings in manufacturing and lower space requirements for installation. Moreover, smaller heat exchangers often require less coolant or working fluid, further contributing to resource conservation and cost reduction.

The energy efficiency gains extend beyond the immediate heat transfer process. Enhanced laminar flow heat transfer techniques can lead to lower pressure drops across heat exchange systems, resulting in decreased pumping power needs. This reduction in pumping energy can be substantial, especially in large-scale industrial applications where fluid circulation is a significant contributor to overall energy consumption.

In the realm of electronics cooling, where maintaining laminar flow is often crucial for precise temperature control, enhanced heat transfer techniques can lead to more efficient thermal management. This improvement allows for higher power densities in electronic devices without compromising reliability, potentially enabling advancements in computing power and miniaturization of electronic components.

Furthermore, in renewable energy systems such as solar thermal collectors, enhanced laminar flow heat transfer can increase the efficiency of energy capture and conversion. By improving the heat transfer from the absorber surface to the working fluid, these systems can operate at higher efficiencies, making renewable energy sources more competitive with traditional fossil fuel-based alternatives.

The automotive industry also stands to benefit from these advancements. In electric vehicle battery thermal management systems, enhanced laminar flow heat transfer can lead to more efficient cooling of battery packs, potentially extending battery life and improving overall vehicle performance. This efficiency gain contributes to the broader goal of increasing the range and reliability of electric vehicles, further promoting the transition to sustainable transportation.

Environmental Impact of Advanced Heat Transfer Technologies

The environmental impact of advanced heat transfer technologies, particularly those aimed at enhancing heat transfer with laminar flow, is a critical consideration in the development and implementation of these systems. As industries strive for more efficient thermal management solutions, the ecological footprint of these technologies becomes increasingly important.

Advanced heat transfer technologies often lead to improved energy efficiency, which can significantly reduce greenhouse gas emissions and overall energy consumption. By enhancing heat transfer in laminar flow conditions, systems can operate at lower temperatures or with reduced pumping power, resulting in decreased energy requirements. This reduction in energy usage translates directly to lower carbon emissions, contributing to global efforts to mitigate climate change.

Water conservation is another key environmental benefit of advanced heat transfer technologies. Improved heat transfer efficiency can lead to reduced water consumption in cooling systems, particularly in industrial processes and power generation. This is especially crucial in regions facing water scarcity, where the implementation of such technologies can help alleviate pressure on local water resources.

However, the production and disposal of advanced heat transfer materials and components may pose environmental challenges. Some high-performance heat transfer surfaces or nanofluids may contain materials that are difficult to recycle or potentially harmful if released into the environment. It is essential to consider the entire lifecycle of these technologies, from manufacturing to end-of-life disposal, to ensure a net positive environmental impact.

The use of advanced heat transfer technologies can also lead to reduced chemical usage in industrial processes. More efficient heat exchange can minimize the need for chemical additives used in traditional cooling systems, thereby reducing the risk of chemical pollution in water bodies and soil.

In the context of urban environments, advanced heat transfer technologies can play a role in mitigating the urban heat island effect. By improving the efficiency of cooling systems in buildings and industrial facilities, these technologies can help reduce waste heat released into the urban atmosphere, contributing to more comfortable and sustainable city environments.

As research in laminar flow heat transfer continues to advance, there is potential for the development of bio-inspired or nature-mimicking technologies. These innovations could lead to heat transfer solutions that are not only highly efficient but also inherently more compatible with natural ecosystems, further reducing environmental impact.

Advanced heat transfer technologies often lead to improved energy efficiency, which can significantly reduce greenhouse gas emissions and overall energy consumption. By enhancing heat transfer in laminar flow conditions, systems can operate at lower temperatures or with reduced pumping power, resulting in decreased energy requirements. This reduction in energy usage translates directly to lower carbon emissions, contributing to global efforts to mitigate climate change.

Water conservation is another key environmental benefit of advanced heat transfer technologies. Improved heat transfer efficiency can lead to reduced water consumption in cooling systems, particularly in industrial processes and power generation. This is especially crucial in regions facing water scarcity, where the implementation of such technologies can help alleviate pressure on local water resources.

However, the production and disposal of advanced heat transfer materials and components may pose environmental challenges. Some high-performance heat transfer surfaces or nanofluids may contain materials that are difficult to recycle or potentially harmful if released into the environment. It is essential to consider the entire lifecycle of these technologies, from manufacturing to end-of-life disposal, to ensure a net positive environmental impact.

The use of advanced heat transfer technologies can also lead to reduced chemical usage in industrial processes. More efficient heat exchange can minimize the need for chemical additives used in traditional cooling systems, thereby reducing the risk of chemical pollution in water bodies and soil.

In the context of urban environments, advanced heat transfer technologies can play a role in mitigating the urban heat island effect. By improving the efficiency of cooling systems in buildings and industrial facilities, these technologies can help reduce waste heat released into the urban atmosphere, contributing to more comfortable and sustainable city environments.

As research in laminar flow heat transfer continues to advance, there is potential for the development of bio-inspired or nature-mimicking technologies. These innovations could lead to heat transfer solutions that are not only highly efficient but also inherently more compatible with natural ecosystems, further reducing environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!