How to Improve Thermal Insulation Using Laminar Flow?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Insulation Background and Objectives

Laminar flow insulation represents a cutting-edge approach to thermal management, leveraging the unique properties of fluid dynamics to enhance insulation performance. This technology has its roots in the fundamental principles of fluid mechanics, particularly the concept of laminar flow, which occurs when a fluid moves in parallel layers without lateral mixing. The evolution of this field has been driven by the increasing demand for more efficient and environmentally friendly insulation solutions across various industries.

The primary objective of laminar flow insulation is to create a highly effective thermal barrier by utilizing the low thermal conductivity of gases or liquids in a controlled, laminar state. This approach aims to surpass the limitations of traditional insulation materials, which often rely on static air pockets or foam structures. By actively managing fluid flow, laminar flow insulation systems can potentially achieve superior insulation performance while also offering advantages in terms of weight reduction and adaptability to different environmental conditions.

The development of laminar flow insulation technology has been influenced by advancements in materials science, fluid dynamics modeling, and manufacturing techniques. Early research in this field focused on understanding the behavior of fluids in confined spaces and the impact of surface properties on flow characteristics. As computational fluid dynamics (CFD) tools became more sophisticated, researchers gained deeper insights into optimizing flow patterns for maximum insulation efficiency.

Recent technological trends in this area include the exploration of smart materials that can dynamically adjust their properties in response to changing thermal conditions, as well as the integration of micro- and nano-scale structures to enhance fluid control. The convergence of these technologies with laminar flow principles opens up new possibilities for creating highly responsive and efficient insulation systems.

The goals of current research and development efforts in laminar flow insulation are multifaceted. Scientists and engineers are working to improve the stability of laminar flow under various operating conditions, enhance the overall thermal resistance of these systems, and develop cost-effective manufacturing processes for large-scale production. Additionally, there is a growing focus on creating sustainable solutions that minimize environmental impact throughout the product lifecycle.

As the world faces increasing challenges related to energy efficiency and climate change, the potential applications for advanced thermal insulation technologies are expanding. Laminar flow insulation holds promise for revolutionizing thermal management in sectors ranging from building construction and automotive design to aerospace and industrial processes. The ongoing pursuit of innovation in this field is driven by the need to meet stringent energy efficiency standards, reduce carbon footprints, and improve overall system performance across diverse applications.

The primary objective of laminar flow insulation is to create a highly effective thermal barrier by utilizing the low thermal conductivity of gases or liquids in a controlled, laminar state. This approach aims to surpass the limitations of traditional insulation materials, which often rely on static air pockets or foam structures. By actively managing fluid flow, laminar flow insulation systems can potentially achieve superior insulation performance while also offering advantages in terms of weight reduction and adaptability to different environmental conditions.

The development of laminar flow insulation technology has been influenced by advancements in materials science, fluid dynamics modeling, and manufacturing techniques. Early research in this field focused on understanding the behavior of fluids in confined spaces and the impact of surface properties on flow characteristics. As computational fluid dynamics (CFD) tools became more sophisticated, researchers gained deeper insights into optimizing flow patterns for maximum insulation efficiency.

Recent technological trends in this area include the exploration of smart materials that can dynamically adjust their properties in response to changing thermal conditions, as well as the integration of micro- and nano-scale structures to enhance fluid control. The convergence of these technologies with laminar flow principles opens up new possibilities for creating highly responsive and efficient insulation systems.

The goals of current research and development efforts in laminar flow insulation are multifaceted. Scientists and engineers are working to improve the stability of laminar flow under various operating conditions, enhance the overall thermal resistance of these systems, and develop cost-effective manufacturing processes for large-scale production. Additionally, there is a growing focus on creating sustainable solutions that minimize environmental impact throughout the product lifecycle.

As the world faces increasing challenges related to energy efficiency and climate change, the potential applications for advanced thermal insulation technologies are expanding. Laminar flow insulation holds promise for revolutionizing thermal management in sectors ranging from building construction and automotive design to aerospace and industrial processes. The ongoing pursuit of innovation in this field is driven by the need to meet stringent energy efficiency standards, reduce carbon footprints, and improve overall system performance across diverse applications.

Market Analysis for Advanced Thermal Insulation Solutions

The market for advanced thermal insulation solutions is experiencing significant growth, driven by increasing energy efficiency requirements and sustainability concerns across various industries. The global thermal insulation market is projected to reach $78.6 billion by 2026, with a compound annual growth rate (CAGR) of 4.3% from 2021 to 2026. This growth is primarily fueled by stringent building energy codes, rising energy costs, and a growing focus on reducing carbon emissions.

In the construction sector, which accounts for the largest share of the thermal insulation market, there is a strong demand for innovative insulation materials that can provide superior performance while minimizing space requirements. This trend is particularly evident in urban areas where space is at a premium. The automotive industry is another key driver of market growth, as manufacturers seek to improve vehicle fuel efficiency and reduce cabin noise through advanced thermal insulation solutions.

The industrial sector, including oil and gas, chemical processing, and power generation, is also contributing to market expansion. These industries require high-performance insulation materials that can withstand extreme temperatures and harsh environments while maintaining energy efficiency. The growing emphasis on industrial energy conservation and process optimization is creating new opportunities for advanced thermal insulation technologies.

Geographically, North America and Europe are the leading markets for advanced thermal insulation solutions, owing to strict energy efficiency regulations and well-established construction industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, urbanization, and increasing awareness of energy conservation in countries like China and India.

The market is characterized by intense competition among key players, with a focus on product innovation and sustainability. There is a growing trend towards the development of eco-friendly insulation materials, such as aerogels, vacuum insulated panels, and bio-based insulation, which offer superior thermal performance with minimal environmental impact.

Laminar flow-based thermal insulation solutions represent a niche but promising segment within the broader market. While still in the early stages of commercialization, these technologies have the potential to disrupt traditional insulation methods, particularly in applications where conventional materials fall short. The ability of laminar flow systems to provide dynamic and adaptive insulation could address the limitations of static insulation materials, especially in scenarios with varying thermal loads or environmental conditions.

In the construction sector, which accounts for the largest share of the thermal insulation market, there is a strong demand for innovative insulation materials that can provide superior performance while minimizing space requirements. This trend is particularly evident in urban areas where space is at a premium. The automotive industry is another key driver of market growth, as manufacturers seek to improve vehicle fuel efficiency and reduce cabin noise through advanced thermal insulation solutions.

The industrial sector, including oil and gas, chemical processing, and power generation, is also contributing to market expansion. These industries require high-performance insulation materials that can withstand extreme temperatures and harsh environments while maintaining energy efficiency. The growing emphasis on industrial energy conservation and process optimization is creating new opportunities for advanced thermal insulation technologies.

Geographically, North America and Europe are the leading markets for advanced thermal insulation solutions, owing to strict energy efficiency regulations and well-established construction industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, urbanization, and increasing awareness of energy conservation in countries like China and India.

The market is characterized by intense competition among key players, with a focus on product innovation and sustainability. There is a growing trend towards the development of eco-friendly insulation materials, such as aerogels, vacuum insulated panels, and bio-based insulation, which offer superior thermal performance with minimal environmental impact.

Laminar flow-based thermal insulation solutions represent a niche but promising segment within the broader market. While still in the early stages of commercialization, these technologies have the potential to disrupt traditional insulation methods, particularly in applications where conventional materials fall short. The ability of laminar flow systems to provide dynamic and adaptive insulation could address the limitations of static insulation materials, especially in scenarios with varying thermal loads or environmental conditions.

Current Challenges in Laminar Flow Thermal Insulation

Despite the promising potential of laminar flow for thermal insulation, several significant challenges currently hinder its widespread adoption and effectiveness. One of the primary obstacles is achieving and maintaining stable laminar flow conditions in practical applications. Turbulence, which can occur due to surface irregularities, temperature gradients, or external disturbances, disrupts the desired laminar flow pattern and reduces insulation efficiency.

Another challenge lies in the design and manufacturing of suitable structures to support laminar flow insulation. Creating precise, uniform channels or layers that promote laminar flow while also providing structural integrity and durability is a complex engineering task. This is particularly challenging when dealing with large-scale applications or irregular geometries.

The thermal conductivity of the fluid used in laminar flow insulation systems also presents a limitation. While gases generally have lower thermal conductivity than liquids, they are more prone to convection, which can compromise insulation performance. Conversely, liquids offer better stability but may conduct heat more readily, necessitating careful fluid selection and system design.

Energy consumption for maintaining laminar flow is another significant concern. In many cases, active systems are required to ensure consistent laminar flow, which can offset the energy savings gained from improved insulation. Developing passive or low-energy solutions for sustaining laminar flow remains a key challenge in the field.

Scalability and cost-effectiveness pose additional hurdles. While laminar flow thermal insulation may be achievable in laboratory settings or small-scale applications, translating these successes to industrial or commercial scales often encounters technical and economic barriers. The complexity of laminar flow systems can lead to high initial costs and maintenance requirements, potentially limiting their adoption in cost-sensitive markets.

Furthermore, the integration of laminar flow insulation with existing building systems and construction methods presents challenges. Retrofitting older structures or incorporating these systems into standard building practices requires innovative approaches and potentially significant modifications to established techniques.

Lastly, there is a need for more comprehensive research and standardization in the field of laminar flow thermal insulation. The lack of widely accepted performance metrics, testing methodologies, and design guidelines hampers the development and comparison of different solutions. This gap in knowledge and standards makes it difficult for engineers and architects to confidently specify and implement laminar flow insulation systems in their projects.

Another challenge lies in the design and manufacturing of suitable structures to support laminar flow insulation. Creating precise, uniform channels or layers that promote laminar flow while also providing structural integrity and durability is a complex engineering task. This is particularly challenging when dealing with large-scale applications or irregular geometries.

The thermal conductivity of the fluid used in laminar flow insulation systems also presents a limitation. While gases generally have lower thermal conductivity than liquids, they are more prone to convection, which can compromise insulation performance. Conversely, liquids offer better stability but may conduct heat more readily, necessitating careful fluid selection and system design.

Energy consumption for maintaining laminar flow is another significant concern. In many cases, active systems are required to ensure consistent laminar flow, which can offset the energy savings gained from improved insulation. Developing passive or low-energy solutions for sustaining laminar flow remains a key challenge in the field.

Scalability and cost-effectiveness pose additional hurdles. While laminar flow thermal insulation may be achievable in laboratory settings or small-scale applications, translating these successes to industrial or commercial scales often encounters technical and economic barriers. The complexity of laminar flow systems can lead to high initial costs and maintenance requirements, potentially limiting their adoption in cost-sensitive markets.

Furthermore, the integration of laminar flow insulation with existing building systems and construction methods presents challenges. Retrofitting older structures or incorporating these systems into standard building practices requires innovative approaches and potentially significant modifications to established techniques.

Lastly, there is a need for more comprehensive research and standardization in the field of laminar flow thermal insulation. The lack of widely accepted performance metrics, testing methodologies, and design guidelines hampers the development and comparison of different solutions. This gap in knowledge and standards makes it difficult for engineers and architects to confidently specify and implement laminar flow insulation systems in their projects.

Existing Laminar Flow Insulation Techniques

01 Laminar flow control for thermal insulation

Utilizing laminar flow principles to enhance thermal insulation in various systems. This approach involves controlling fluid flow to create a stable, layered structure that minimizes heat transfer. The technique can be applied in building materials, industrial processes, and equipment design to improve energy efficiency and temperature regulation.- Laminar flow control for thermal insulation: Utilizing laminar flow principles to enhance thermal insulation in various systems. This approach involves controlling fluid flow to create stable layers that minimize heat transfer, thereby improving overall insulation efficiency.

- Thermal insulation materials with laminar structure: Development of advanced insulation materials with a laminar structure to improve thermal resistance. These materials are designed to create multiple layers that effectively reduce heat conduction and convection.

- Laminar flow in HVAC systems for improved insulation: Application of laminar flow principles in heating, ventilation, and air conditioning (HVAC) systems to enhance thermal insulation. This involves designing air flow patterns that minimize turbulence and maximize insulation effectiveness.

- Laminar flow-based insulation in electronic devices: Implementing laminar flow techniques for thermal management and insulation in electronic devices. This approach helps in maintaining optimal operating temperatures and improving device efficiency.

- Laminar flow insulation in industrial processes: Utilizing laminar flow principles for thermal insulation in various industrial processes. This includes applications in manufacturing, chemical processing, and energy production to improve energy efficiency and process control.

02 Thermal insulation in fluid handling systems

Implementing thermal insulation techniques in fluid handling systems to maintain temperature stability and reduce heat loss. This includes designing pipes, tanks, and other fluid-containing structures with insulating materials or layers that prevent heat transfer between the fluid and the environment, improving overall system efficiency.Expand Specific Solutions03 Advanced materials for laminar flow thermal insulation

Developing and utilizing advanced materials specifically designed to enhance laminar flow thermal insulation properties. These materials may include composites, aerogels, or engineered structures that optimize both fluid dynamics and thermal resistance, leading to improved insulation performance in various applications.Expand Specific Solutions04 Thermal management in electronic devices

Applying laminar flow thermal insulation concepts to electronic device cooling and heat management. This involves designing internal structures and airflow patterns that create laminar flow conditions, effectively dissipating heat while maintaining insulation between components. The approach can enhance device performance and longevity.Expand Specific Solutions05 Energy-efficient building systems using laminar flow insulation

Incorporating laminar flow thermal insulation principles into building design and HVAC systems. This approach focuses on creating controlled air layers within walls, windows, or ventilation systems to enhance insulation properties. The technique can significantly improve energy efficiency in both residential and commercial structures.Expand Specific Solutions

Key Players in Thermal Insulation Industry

The thermal insulation industry using laminar flow technology is in a growth phase, with increasing market size driven by energy efficiency demands. The technology's maturity is advancing, but still evolving. Key players like Delphi Technology, Boston Scientific Scimed, and ZF Friedrichshafen are investing in R&D to improve thermal insulation efficiency. Companies such as W.L. Gore & Associates and ASML Holding are leveraging their expertise in materials and precision engineering to develop innovative solutions. The competitive landscape is characterized by a mix of established industrial giants and specialized technology firms, each bringing unique capabilities to address the challenges of enhancing thermal insulation through laminar flow techniques.

Hitachi Ltd.

Technical Solution: Hitachi Ltd. has made significant advancements in thermal insulation technology by incorporating laminar flow principles into their heat management solutions. The company has developed a novel approach that combines microfluidic cooling with laminar flow-optimized insulation materials. Hitachi's system uses a network of microscale channels to circulate coolant in a laminar flow regime, effectively removing heat from critical components while minimizing turbulence[13]. This technology has been particularly effective in high-performance computing and data center applications, where it has demonstrated cooling efficiency improvements of up to 30% compared to traditional air cooling methods[14]. Additionally, Hitachi has integrated AI-driven control systems that dynamically adjust flow rates and coolant distribution to maintain optimal laminar flow conditions under varying heat loads[15].

Strengths: Highly efficient cooling for high-density electronics, scalable for various applications, and integrates advanced AI control. Weaknesses: Potentially complex implementation and higher initial costs compared to conventional cooling systems.

Oxycom Beheer BV

Technical Solution: Oxycom Beheer BV has pioneered the use of laminar flow principles in their innovative cooling and ventilation systems. Their technology, known as IntrCooll, combines evaporative cooling with heat recovery in a unique two-stage process that maintains laminar airflow throughout the system. By carefully controlling air velocity and using specially designed heat exchangers, Oxycom achieves highly efficient heat transfer while minimizing turbulence[10]. The company's patented design includes a pre-cooling stage that uses exhaust air to cool incoming fresh air indirectly, followed by a direct evaporative cooling stage[11]. This approach has demonstrated energy savings of up to 80% compared to traditional air conditioning systems in various climates[12]. Furthermore, Oxycom has developed advanced control systems that optimize airflow rates to maintain laminar conditions across a wide range of operating parameters.

Strengths: Extremely energy-efficient, suitable for various climates, and provides both cooling and ventilation. Weaknesses: May require regular maintenance of water systems and is most effective in low-humidity environments.

Innovative Approaches in Laminar Flow Insulation

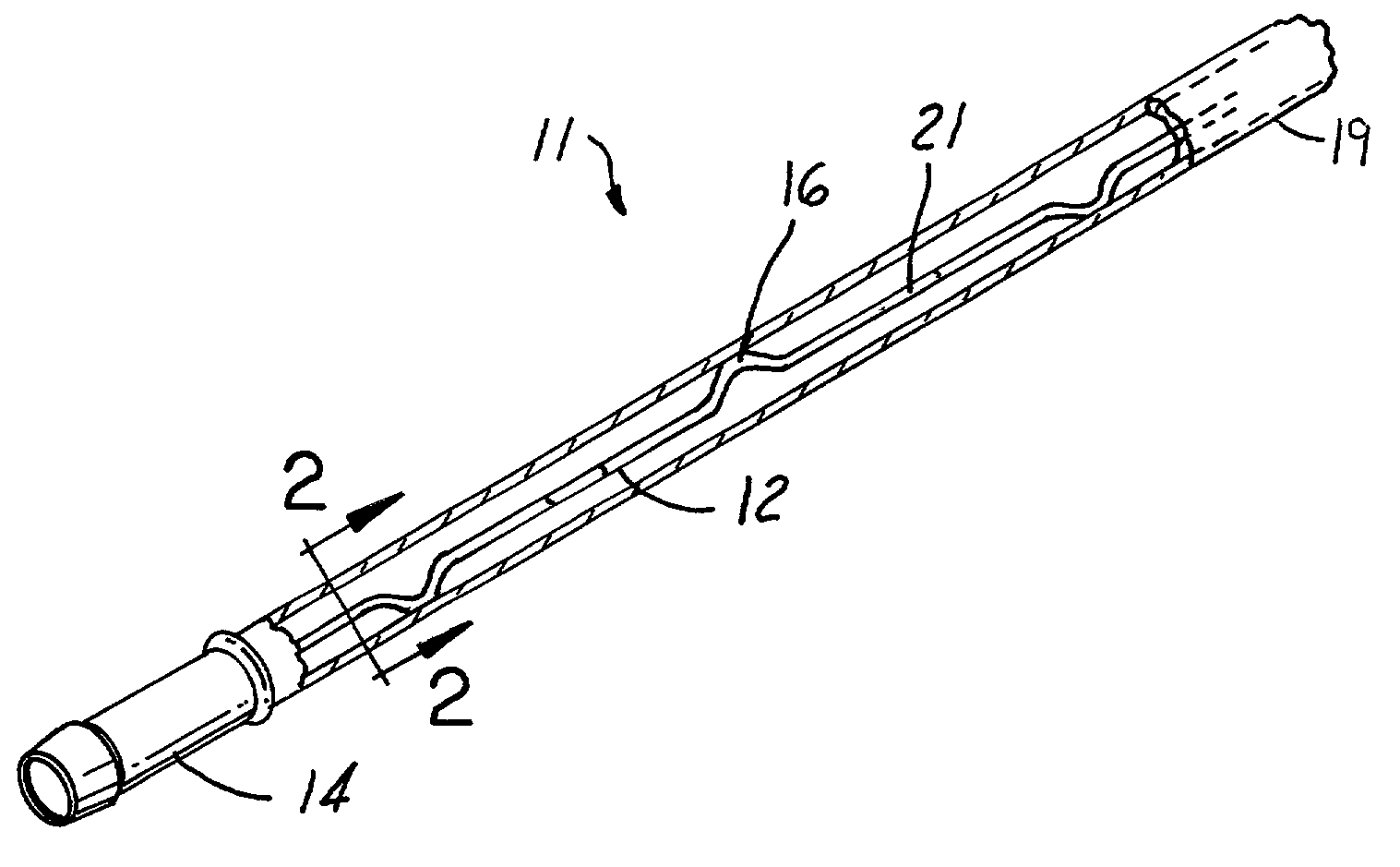

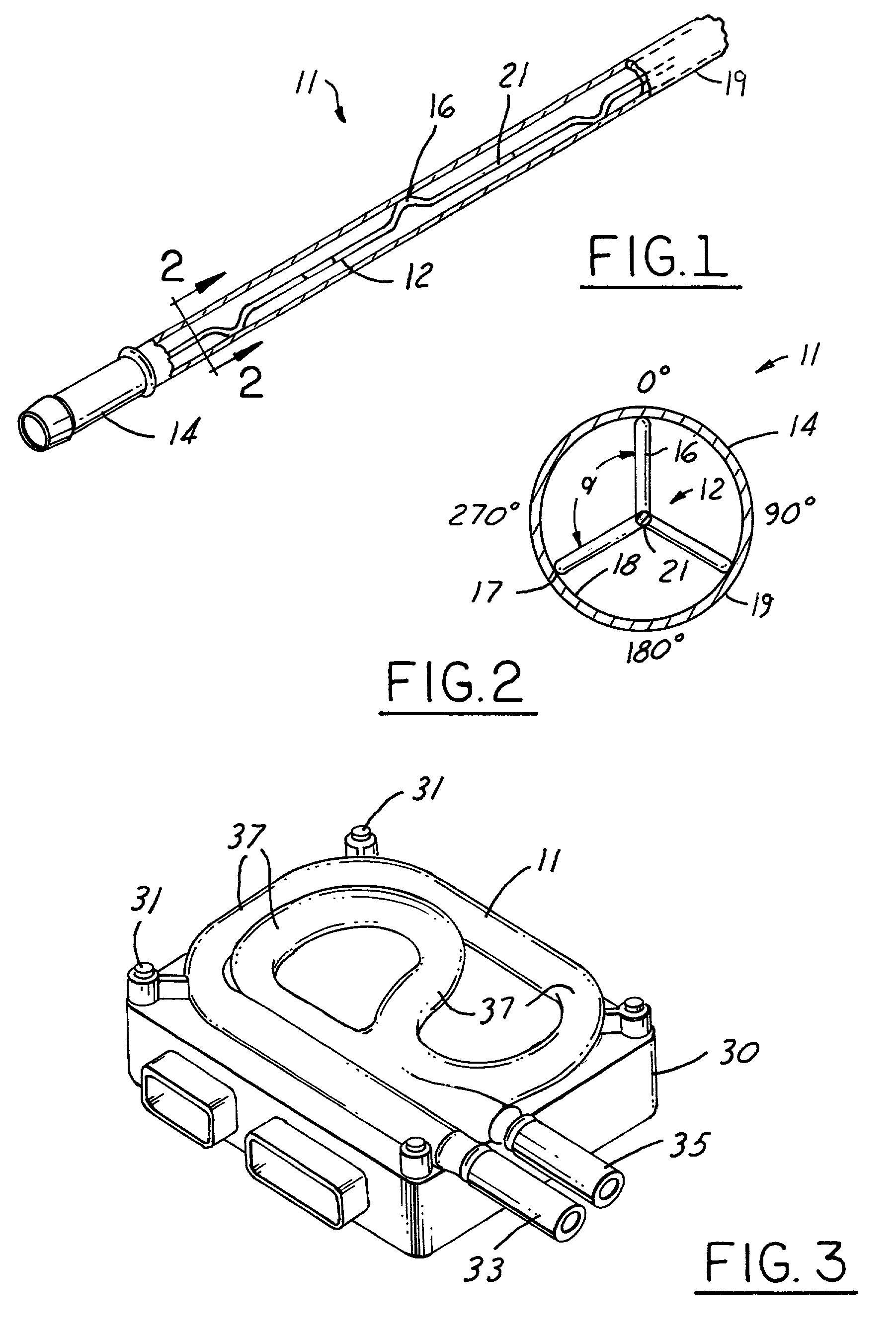

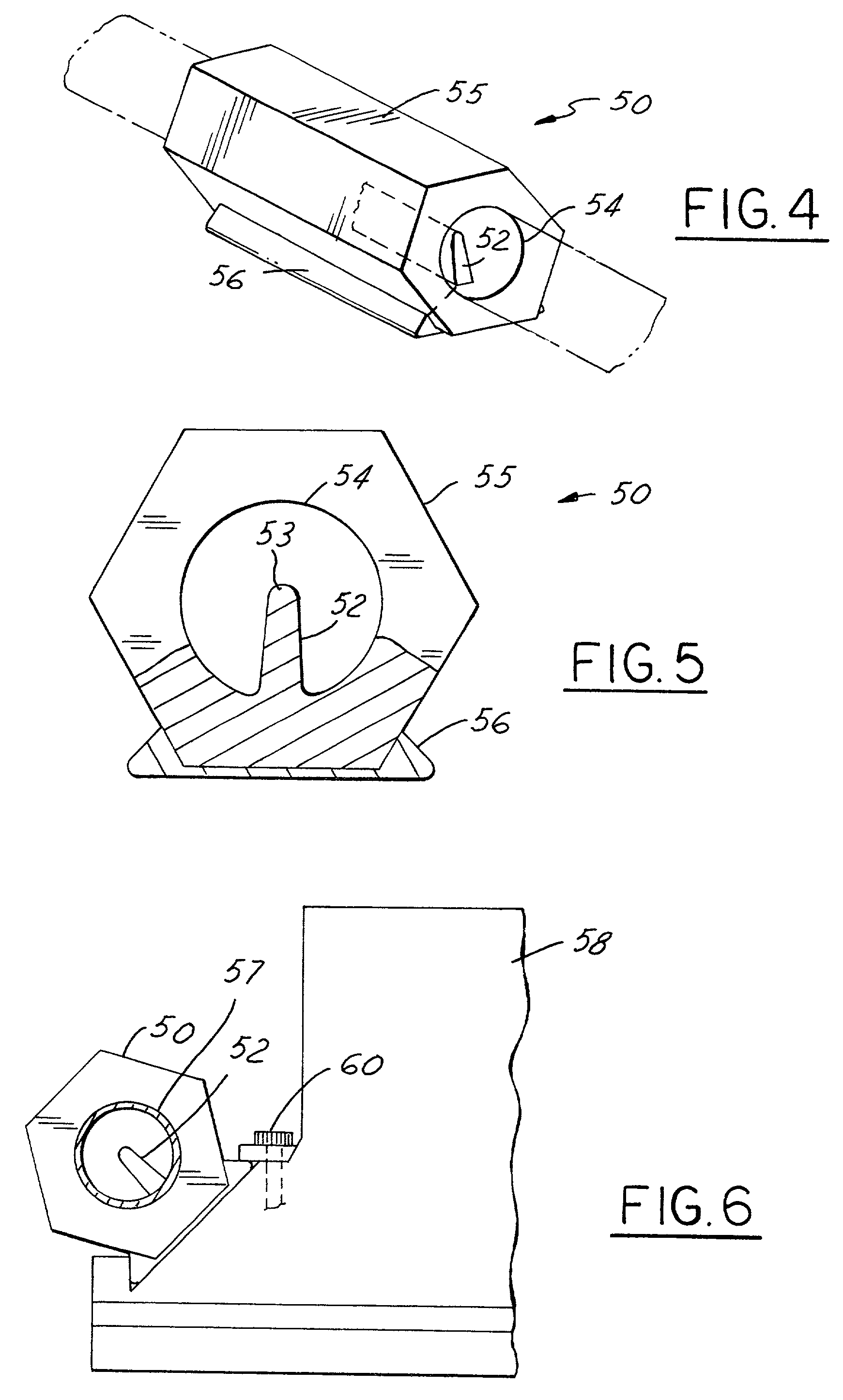

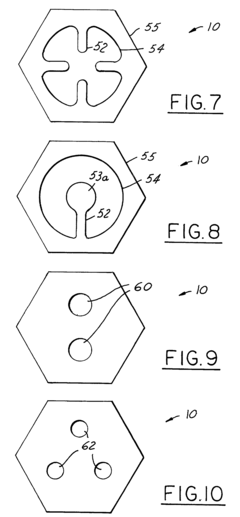

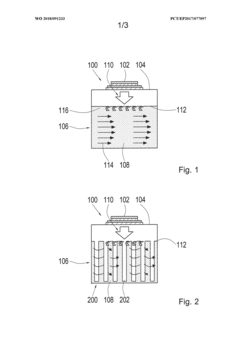

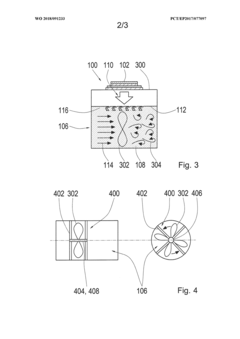

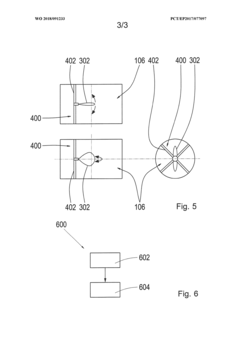

Laminar flow optional liquid cooler

PatentInactiveUS6997246B2

Innovation

- Introducing a wire baffle with kink regions or an elongated ridge member inside the tubing to disrupt laminar flow, reducing heat rise at the inner wall and increasing the surface area, thereby enhancing thermal effectiveness and allowing for smaller, less expensive cooler designs.

Electronic module and method for the production thereof

PatentWO2018091233A1

Innovation

- An electronic module with a laser-sintered heat sink and integrated turbulator body, which promotes turbulent flow through the cooling channel by using additive manufacturing techniques, enhancing heat transfer and reducing thermal resistance.

Energy Efficiency Regulations and Standards

Energy efficiency regulations and standards play a crucial role in shaping the development and implementation of thermal insulation technologies, including those utilizing laminar flow. These regulations and standards are designed to promote energy conservation, reduce greenhouse gas emissions, and improve overall building performance.

In the context of thermal insulation using laminar flow, several key regulations and standards are particularly relevant. The International Energy Conservation Code (IECC) and ASHRAE Standard 90.1 are widely recognized benchmarks for energy efficiency in buildings. These standards set minimum requirements for thermal insulation in various building components, including walls, roofs, and windows. While they do not specifically address laminar flow technologies, they provide a framework for evaluating the performance of innovative insulation solutions.

The European Union's Energy Performance of Buildings Directive (EPBD) is another significant regulatory initiative that impacts thermal insulation technologies. The EPBD requires member states to establish minimum energy performance requirements for new and existing buildings. This directive has led to the development of national building codes that increasingly emphasize the importance of advanced insulation techniques, potentially creating opportunities for laminar flow-based solutions.

In the United States, the Department of Energy's Building Energy Codes Program works with state and local governments to implement energy-efficient building codes. These codes often reference standards such as ASTM C518 for measuring thermal transmission properties, which could be applicable to laminar flow insulation systems. Additionally, the Environmental Protection Agency's ENERGY STAR program provides voluntary guidelines for energy-efficient products and buildings, potentially offering a pathway for recognition of innovative insulation technologies.

As thermal insulation technologies using laminar flow continue to evolve, it is likely that new standards and testing methodologies will be developed to assess their performance. Organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) may play a role in establishing these standards. For example, ISO 9869 for in-situ measurement of thermal resistance and thermal transmittance could be adapted or expanded to include laminar flow insulation systems.

The regulatory landscape also includes incentives and programs that encourage the adoption of energy-efficient technologies. Many countries offer tax credits, rebates, or other financial incentives for implementing advanced insulation solutions in buildings. These incentives could potentially be leveraged to promote the adoption of laminar flow-based thermal insulation technologies, provided they can demonstrate significant energy savings and meet relevant performance criteria.

In the context of thermal insulation using laminar flow, several key regulations and standards are particularly relevant. The International Energy Conservation Code (IECC) and ASHRAE Standard 90.1 are widely recognized benchmarks for energy efficiency in buildings. These standards set minimum requirements for thermal insulation in various building components, including walls, roofs, and windows. While they do not specifically address laminar flow technologies, they provide a framework for evaluating the performance of innovative insulation solutions.

The European Union's Energy Performance of Buildings Directive (EPBD) is another significant regulatory initiative that impacts thermal insulation technologies. The EPBD requires member states to establish minimum energy performance requirements for new and existing buildings. This directive has led to the development of national building codes that increasingly emphasize the importance of advanced insulation techniques, potentially creating opportunities for laminar flow-based solutions.

In the United States, the Department of Energy's Building Energy Codes Program works with state and local governments to implement energy-efficient building codes. These codes often reference standards such as ASTM C518 for measuring thermal transmission properties, which could be applicable to laminar flow insulation systems. Additionally, the Environmental Protection Agency's ENERGY STAR program provides voluntary guidelines for energy-efficient products and buildings, potentially offering a pathway for recognition of innovative insulation technologies.

As thermal insulation technologies using laminar flow continue to evolve, it is likely that new standards and testing methodologies will be developed to assess their performance. Organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) may play a role in establishing these standards. For example, ISO 9869 for in-situ measurement of thermal resistance and thermal transmittance could be adapted or expanded to include laminar flow insulation systems.

The regulatory landscape also includes incentives and programs that encourage the adoption of energy-efficient technologies. Many countries offer tax credits, rebates, or other financial incentives for implementing advanced insulation solutions in buildings. These incentives could potentially be leveraged to promote the adoption of laminar flow-based thermal insulation technologies, provided they can demonstrate significant energy savings and meet relevant performance criteria.

Environmental Impact of Insulation Technologies

The environmental impact of insulation technologies, particularly those utilizing laminar flow for thermal insulation, is a critical consideration in the development and implementation of sustainable building practices. Laminar flow-based insulation systems offer potential advantages in terms of energy efficiency and reduced environmental footprint compared to traditional insulation materials.

One of the primary environmental benefits of laminar flow insulation is its potential to significantly reduce energy consumption in buildings. By effectively minimizing heat transfer, these systems can decrease the need for heating and cooling, leading to lower energy usage and reduced greenhouse gas emissions. This aligns with global efforts to combat climate change and promote energy-efficient construction practices.

The production of laminar flow insulation systems generally requires less raw material compared to conventional insulation methods. This reduction in material usage translates to lower resource extraction and processing, which in turn minimizes the environmental impact associated with manufacturing. Additionally, the lightweight nature of these systems can contribute to reduced transportation emissions during distribution and installation.

Laminar flow insulation technologies often utilize inert gases or vacuum-sealed chambers, which are typically non-toxic and do not contribute to air pollution or ozone depletion. This characteristic makes them environmentally preferable to some traditional insulation materials that may contain harmful chemicals or off-gas volatile organic compounds (VOCs).

The longevity and durability of laminar flow insulation systems can also contribute to their positive environmental impact. With proper design and installation, these systems can maintain their insulating properties for extended periods, reducing the need for frequent replacement and the associated waste generation. This durability factor is particularly important in the context of lifecycle assessment and long-term sustainability of buildings.

However, it is essential to consider the end-of-life implications of laminar flow insulation technologies. The recyclability and disposal methods for these systems must be carefully evaluated to ensure they do not contribute to landfill waste or pose environmental hazards upon decommissioning. Research into eco-friendly disposal or repurposing methods for these materials is crucial for maximizing their overall environmental benefits.

In conclusion, while laminar flow insulation technologies show promise in reducing the environmental impact of building insulation, a comprehensive lifecycle analysis is necessary to fully understand their long-term ecological effects. As the construction industry continues to prioritize sustainability, the development of these innovative insulation methods represents a significant step towards more environmentally responsible building practices.

One of the primary environmental benefits of laminar flow insulation is its potential to significantly reduce energy consumption in buildings. By effectively minimizing heat transfer, these systems can decrease the need for heating and cooling, leading to lower energy usage and reduced greenhouse gas emissions. This aligns with global efforts to combat climate change and promote energy-efficient construction practices.

The production of laminar flow insulation systems generally requires less raw material compared to conventional insulation methods. This reduction in material usage translates to lower resource extraction and processing, which in turn minimizes the environmental impact associated with manufacturing. Additionally, the lightweight nature of these systems can contribute to reduced transportation emissions during distribution and installation.

Laminar flow insulation technologies often utilize inert gases or vacuum-sealed chambers, which are typically non-toxic and do not contribute to air pollution or ozone depletion. This characteristic makes them environmentally preferable to some traditional insulation materials that may contain harmful chemicals or off-gas volatile organic compounds (VOCs).

The longevity and durability of laminar flow insulation systems can also contribute to their positive environmental impact. With proper design and installation, these systems can maintain their insulating properties for extended periods, reducing the need for frequent replacement and the associated waste generation. This durability factor is particularly important in the context of lifecycle assessment and long-term sustainability of buildings.

However, it is essential to consider the end-of-life implications of laminar flow insulation technologies. The recyclability and disposal methods for these systems must be carefully evaluated to ensure they do not contribute to landfill waste or pose environmental hazards upon decommissioning. Research into eco-friendly disposal or repurposing methods for these materials is crucial for maximizing their overall environmental benefits.

In conclusion, while laminar flow insulation technologies show promise in reducing the environmental impact of building insulation, a comprehensive lifecycle analysis is necessary to fully understand their long-term ecological effects. As the construction industry continues to prioritize sustainability, the development of these innovative insulation methods represents a significant step towards more environmentally responsible building practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!