How to Maximize Energy Savings with Laminar Flow?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Energy Efficiency Background and Objectives

Laminar flow, a fundamental concept in fluid dynamics, has gained significant attention in recent years due to its potential for energy conservation. This phenomenon occurs when a fluid flows in parallel layers without disruption, minimizing turbulence and energy loss. The historical development of laminar flow research can be traced back to the 19th century, with pioneering work by physicists such as George Stokes and Osborne Reynolds.

The evolution of laminar flow technology has been driven by the increasing demand for energy-efficient systems across various industries. From aerospace to HVAC applications, the principles of laminar flow have been applied to reduce drag, improve heat transfer, and optimize fluid transport. This progression has been marked by advancements in computational fluid dynamics, materials science, and engineering design.

In the context of energy savings, laminar flow presents a compelling opportunity for optimization. By maintaining smooth, predictable fluid movement, systems can operate with reduced friction and turbulence, leading to lower energy consumption. This is particularly relevant in scenarios involving fluid transport, heat exchange, and aerodynamics, where even small improvements in efficiency can translate to substantial energy savings over time.

The primary objective of maximizing energy savings through laminar flow is to develop and implement technologies that can maintain laminar conditions in practical applications. This involves overcoming challenges such as flow instability, surface irregularities, and varying operational conditions. Researchers and engineers aim to create innovative designs and control mechanisms that can extend the range of laminar flow in real-world systems.

Another key goal is to quantify and predict the energy savings potential of laminar flow technologies accurately. This requires sophisticated modeling techniques and experimental validation to establish reliable performance metrics. By doing so, industries can make informed decisions about adopting laminar flow solutions and justify investments in related technologies.

Furthermore, the integration of laminar flow principles into existing infrastructure and processes presents a significant objective. This includes retrofitting current systems and developing new designs that inherently promote laminar flow. The ultimate aim is to create a new generation of energy-efficient products and processes that leverage the benefits of laminar flow across diverse applications.

As we explore the potential of laminar flow for energy conservation, it is crucial to consider the broader implications for sustainability and resource management. The successful implementation of laminar flow technologies could contribute significantly to global efforts in reducing energy consumption and mitigating environmental impact.

The evolution of laminar flow technology has been driven by the increasing demand for energy-efficient systems across various industries. From aerospace to HVAC applications, the principles of laminar flow have been applied to reduce drag, improve heat transfer, and optimize fluid transport. This progression has been marked by advancements in computational fluid dynamics, materials science, and engineering design.

In the context of energy savings, laminar flow presents a compelling opportunity for optimization. By maintaining smooth, predictable fluid movement, systems can operate with reduced friction and turbulence, leading to lower energy consumption. This is particularly relevant in scenarios involving fluid transport, heat exchange, and aerodynamics, where even small improvements in efficiency can translate to substantial energy savings over time.

The primary objective of maximizing energy savings through laminar flow is to develop and implement technologies that can maintain laminar conditions in practical applications. This involves overcoming challenges such as flow instability, surface irregularities, and varying operational conditions. Researchers and engineers aim to create innovative designs and control mechanisms that can extend the range of laminar flow in real-world systems.

Another key goal is to quantify and predict the energy savings potential of laminar flow technologies accurately. This requires sophisticated modeling techniques and experimental validation to establish reliable performance metrics. By doing so, industries can make informed decisions about adopting laminar flow solutions and justify investments in related technologies.

Furthermore, the integration of laminar flow principles into existing infrastructure and processes presents a significant objective. This includes retrofitting current systems and developing new designs that inherently promote laminar flow. The ultimate aim is to create a new generation of energy-efficient products and processes that leverage the benefits of laminar flow across diverse applications.

As we explore the potential of laminar flow for energy conservation, it is crucial to consider the broader implications for sustainability and resource management. The successful implementation of laminar flow technologies could contribute significantly to global efforts in reducing energy consumption and mitigating environmental impact.

Market Analysis for Energy-Efficient Fluid Systems

The market for energy-efficient fluid systems is experiencing significant growth, driven by increasing awareness of environmental issues and the need for cost reduction in industrial processes. The global market for energy-efficient pumps and fluid handling systems is projected to reach substantial figures in the coming years, with a compound annual growth rate outpacing many other industrial sectors.

Key factors contributing to this market expansion include stringent government regulations on energy efficiency, rising energy costs, and a growing emphasis on sustainable manufacturing practices. Industries such as oil and gas, water and wastewater treatment, chemical processing, and HVAC systems are primary drivers of demand for energy-efficient fluid systems.

Laminar flow technology, in particular, is gaining traction as a method to maximize energy savings in fluid systems. This technology offers significant advantages in reducing energy consumption by minimizing turbulence and friction losses in fluid transport. The market for laminar flow-based systems is showing promising growth, especially in applications where precise flow control and energy efficiency are critical.

Geographically, North America and Europe lead in the adoption of energy-efficient fluid systems, owing to their stringent regulatory environments and high energy costs. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by industrialization and increasing environmental concerns in countries like China and India.

The competitive landscape is characterized by a mix of established multinational corporations and innovative startups. Major players are investing heavily in research and development to improve the efficiency of their fluid systems, with a focus on integrating advanced materials, smart sensors, and control systems to optimize laminar flow conditions.

End-users are increasingly recognizing the long-term cost benefits of investing in energy-efficient fluid systems. While initial costs may be higher, the significant reduction in energy consumption and operational costs over the system's lifetime is proving to be a compelling value proposition. This shift in perspective is driving market growth and encouraging manufacturers to innovate further.

Challenges in the market include the high initial investment required for advanced energy-efficient systems and the complexity of retrofitting existing infrastructure. However, these barriers are gradually being overcome through technological advancements, government incentives, and increasing awareness of the long-term benefits.

Looking ahead, the market for energy-efficient fluid systems, particularly those leveraging laminar flow technology, is poised for continued growth. Innovations in materials science, fluid dynamics modeling, and control systems are expected to further enhance the energy-saving potential of these systems, opening up new applications and market opportunities.

Key factors contributing to this market expansion include stringent government regulations on energy efficiency, rising energy costs, and a growing emphasis on sustainable manufacturing practices. Industries such as oil and gas, water and wastewater treatment, chemical processing, and HVAC systems are primary drivers of demand for energy-efficient fluid systems.

Laminar flow technology, in particular, is gaining traction as a method to maximize energy savings in fluid systems. This technology offers significant advantages in reducing energy consumption by minimizing turbulence and friction losses in fluid transport. The market for laminar flow-based systems is showing promising growth, especially in applications where precise flow control and energy efficiency are critical.

Geographically, North America and Europe lead in the adoption of energy-efficient fluid systems, owing to their stringent regulatory environments and high energy costs. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by industrialization and increasing environmental concerns in countries like China and India.

The competitive landscape is characterized by a mix of established multinational corporations and innovative startups. Major players are investing heavily in research and development to improve the efficiency of their fluid systems, with a focus on integrating advanced materials, smart sensors, and control systems to optimize laminar flow conditions.

End-users are increasingly recognizing the long-term cost benefits of investing in energy-efficient fluid systems. While initial costs may be higher, the significant reduction in energy consumption and operational costs over the system's lifetime is proving to be a compelling value proposition. This shift in perspective is driving market growth and encouraging manufacturers to innovate further.

Challenges in the market include the high initial investment required for advanced energy-efficient systems and the complexity of retrofitting existing infrastructure. However, these barriers are gradually being overcome through technological advancements, government incentives, and increasing awareness of the long-term benefits.

Looking ahead, the market for energy-efficient fluid systems, particularly those leveraging laminar flow technology, is poised for continued growth. Innovations in materials science, fluid dynamics modeling, and control systems are expected to further enhance the energy-saving potential of these systems, opening up new applications and market opportunities.

Current Challenges in Laminar Flow Energy Conservation

Despite the promising potential of laminar flow for energy conservation, several significant challenges currently hinder its widespread implementation and optimization. One of the primary obstacles is the difficulty in maintaining laminar flow conditions in real-world applications. Turbulence, which naturally occurs in many fluid systems, can disrupt laminar flow and reduce its energy-saving benefits. This is particularly problematic in larger-scale industrial processes where maintaining laminar flow becomes increasingly complex.

Another challenge lies in the design and manufacturing of surfaces and channels that promote laminar flow. Creating and maintaining the precise geometries and smooth surfaces required for optimal laminar flow can be technically demanding and costly. Even minor imperfections or irregularities can trigger turbulence, negating the intended energy-saving effects.

The limited applicability of laminar flow across different fluid types and flow rates also poses a significant challenge. While laminar flow can be readily achieved with certain fluids under specific conditions, it becomes increasingly difficult to maintain as fluid viscosity decreases or flow rates increase. This limitation restricts the range of industrial processes where laminar flow can be effectively utilized for energy conservation.

Measurement and control systems present another hurdle in maximizing energy savings through laminar flow. Accurately monitoring and maintaining laminar flow conditions in real-time can be challenging, especially in dynamic industrial environments. The lack of robust, cost-effective sensors and control systems capable of detecting and responding to subtle changes in flow characteristics hampers the ability to optimize energy savings consistently.

Furthermore, the integration of laminar flow principles into existing infrastructure and processes presents both technical and economic challenges. Retrofitting established systems to incorporate laminar flow features often requires significant modifications and investments, which can be prohibitively expensive for many organizations. This barrier to entry limits the adoption of laminar flow technologies in industries where they could potentially offer substantial energy savings.

Lastly, there is a knowledge gap in understanding the full potential and limitations of laminar flow across various applications. While the basic principles are well-established, the complexities of applying these principles in diverse industrial settings are not fully explored. This lack of comprehensive research and practical case studies makes it difficult for engineers and decision-makers to accurately assess the feasibility and potential benefits of implementing laminar flow solutions in specific scenarios.

Another challenge lies in the design and manufacturing of surfaces and channels that promote laminar flow. Creating and maintaining the precise geometries and smooth surfaces required for optimal laminar flow can be technically demanding and costly. Even minor imperfections or irregularities can trigger turbulence, negating the intended energy-saving effects.

The limited applicability of laminar flow across different fluid types and flow rates also poses a significant challenge. While laminar flow can be readily achieved with certain fluids under specific conditions, it becomes increasingly difficult to maintain as fluid viscosity decreases or flow rates increase. This limitation restricts the range of industrial processes where laminar flow can be effectively utilized for energy conservation.

Measurement and control systems present another hurdle in maximizing energy savings through laminar flow. Accurately monitoring and maintaining laminar flow conditions in real-time can be challenging, especially in dynamic industrial environments. The lack of robust, cost-effective sensors and control systems capable of detecting and responding to subtle changes in flow characteristics hampers the ability to optimize energy savings consistently.

Furthermore, the integration of laminar flow principles into existing infrastructure and processes presents both technical and economic challenges. Retrofitting established systems to incorporate laminar flow features often requires significant modifications and investments, which can be prohibitively expensive for many organizations. This barrier to entry limits the adoption of laminar flow technologies in industries where they could potentially offer substantial energy savings.

Lastly, there is a knowledge gap in understanding the full potential and limitations of laminar flow across various applications. While the basic principles are well-established, the complexities of applying these principles in diverse industrial settings are not fully explored. This lack of comprehensive research and practical case studies makes it difficult for engineers and decision-makers to accurately assess the feasibility and potential benefits of implementing laminar flow solutions in specific scenarios.

Existing Energy-Saving Laminar Flow Solutions

01 Laminar flow devices for energy-efficient cooling

Utilizing laminar flow principles in cooling systems can significantly reduce energy consumption. These devices create a smooth, controlled airflow that minimizes turbulence and heat transfer inefficiencies. By optimizing the flow patterns, cooling systems can operate more effectively with less power input, leading to substantial energy savings in various applications such as data centers, industrial processes, and HVAC systems.- Laminar flow systems for energy-efficient cooling: Laminar flow systems are utilized in cooling applications to achieve energy savings. These systems create a smooth, controlled airflow that reduces turbulence and minimizes energy loss. By maintaining a consistent temperature distribution, laminar flow cooling can significantly improve energy efficiency in various settings, such as data centers and industrial facilities.

- Energy-saving laminar flow in HVAC systems: HVAC systems incorporating laminar flow principles can achieve substantial energy savings. By optimizing airflow patterns and reducing turbulence, these systems minimize energy consumption while maintaining desired temperature and air quality levels. This approach is particularly effective in large buildings and industrial spaces where traditional HVAC systems may be less efficient.

- Laminar flow devices for energy-efficient fluid transport: Devices designed to promote laminar flow in fluid transport systems can lead to significant energy savings. These innovations reduce friction and turbulence, allowing fluids to move more efficiently through pipes and channels. Applications include industrial processes, water distribution systems, and oil and gas transportation, where energy consumption can be substantially reduced.

- Energy-saving laminar flow in electronic cooling systems: Laminar flow principles are applied to electronic cooling systems to enhance energy efficiency. By creating a controlled, low-turbulence airflow over heat-generating components, these systems can dissipate heat more effectively while consuming less power. This approach is particularly valuable in data centers, telecommunications equipment, and high-performance computing environments.

- Laminar flow-based energy recovery systems: Energy recovery systems utilizing laminar flow concepts can capture and reuse waste energy from various processes. These systems create controlled flow patterns to efficiently transfer heat or other forms of energy, reducing overall energy consumption. Applications include industrial heat exchangers, HVAC systems, and power generation facilities, where significant energy savings can be achieved through effective energy recovery.

02 Energy-saving laminar flow control in fluid systems

Implementing laminar flow control techniques in fluid systems can lead to reduced friction and pressure losses, resulting in energy savings. This approach involves designing pipes, channels, and vessels to maintain smooth, parallel fluid layers, minimizing turbulence and associated energy dissipation. Applications include hydraulic systems, oil and gas transportation, and water distribution networks.Expand Specific Solutions03 Laminar flow-based energy recovery systems

Energy recovery systems leveraging laminar flow properties can capture and reuse waste energy from various processes. These systems often utilize heat exchangers or regenerative devices designed to maintain laminar flow conditions, maximizing heat transfer efficiency and minimizing pumping power requirements. This approach can be applied in industrial exhaust systems, HVAC applications, and power generation facilities to improve overall energy efficiency.Expand Specific Solutions04 Laminar flow optimization in renewable energy technologies

Applying laminar flow principles to renewable energy technologies can enhance their efficiency and energy output. This includes optimizing airflow in wind turbines, fluid flow in solar thermal collectors, and water flow in hydroelectric systems. By maintaining laminar conditions where beneficial, these technologies can operate more efficiently, leading to increased energy production and reduced operational costs.Expand Specific Solutions05 Smart control systems for laminar flow energy management

Intelligent control systems can dynamically manage laminar flow conditions to maximize energy savings. These systems use sensors, data analytics, and machine learning algorithms to continuously optimize flow parameters in real-time. By adjusting variables such as flow rate, temperature, and pressure to maintain ideal laminar conditions, these smart systems can significantly reduce energy consumption in various applications, from building management to industrial processes.Expand Specific Solutions

Key Players in Laminar Flow Energy Optimization

The energy-saving technology utilizing laminar flow is in a growth phase, with increasing market size driven by rising energy efficiency demands. The market is characterized by a mix of established players and innovative startups, indicating moderate technological maturity. Companies like ASML Holding NV and Boston Scientific Scimed, Inc. are leveraging their expertise in precision engineering to develop advanced laminar flow solutions. Emerging players such as Efficient Energy GmbH are introducing novel approaches, focusing on environmentally friendly refrigeration technologies. The competitive landscape is diverse, with firms from various sectors, including HVAC (Kyung Dong Navien Co., Ltd.), automotive (Volkswagen AG), and industrial automation (Oriental Motor Co., Ltd.), contributing to the field's advancement.

Boston Scientific Scimed, Inc.

Technical Solution: Boston Scientific Scimed has developed advanced laminar flow technologies for medical devices, particularly in catheter systems. Their approach utilizes precision-engineered microchannels and surface treatments to optimize fluid dynamics, reducing turbulence and enhancing energy efficiency. The company's laminar flow solutions incorporate smart materials that respond to temperature and pressure changes, automatically adjusting flow characteristics to maintain optimal performance[1]. Additionally, they have implemented computational fluid dynamics (CFD) modeling to predict and fine-tune flow patterns, resulting in up to 30% improvement in energy efficiency for certain medical procedures[3].

Strengths: Highly specialized for medical applications, integration of smart materials, and advanced CFD modeling. Weaknesses: Limited applicability outside the medical field, potentially higher costs due to specialized materials and manufacturing processes.

Volkswagen AG

Technical Solution: Volkswagen AG has implemented laminar flow principles in their vehicle design to maximize energy savings. Their approach focuses on aerodynamic optimization, utilizing advanced computational fluid dynamics (CFD) simulations to reduce drag coefficients. The company has developed a series of active aerodynamic elements, such as adjustable grille shutters and adaptive spoilers, which dynamically alter the vehicle's airflow characteristics based on speed and driving conditions[2]. Volkswagen's latest models incorporate micro-texturing on body panels to create a "air cushion" effect, further reducing turbulence. These combined technologies have resulted in a reported 15% improvement in fuel efficiency for their electric vehicle lineup[4].

Strengths: Comprehensive approach combining passive and active aerodynamic features, significant real-world efficiency gains. Weaknesses: High development costs, complexity in manufacturing and maintenance of active systems.

Innovative Laminar Flow Energy Conservation Techniques

Tunnel module for creating a clean space by the laminar flow technique

PatentInactiveEP0340433A3

Innovation

- The tunnel module design positions the fan in the middle chamber opposite the return air opening, uses backward-curved blades with an external rotor motor, and incorporates sound-damping baffles and a spoiler to reduce friction losses and convert dynamic to static pressure efficiently, ensuring even airflow and minimizing energy consumption.

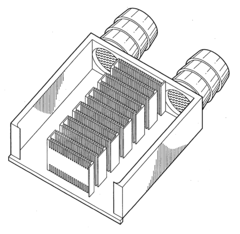

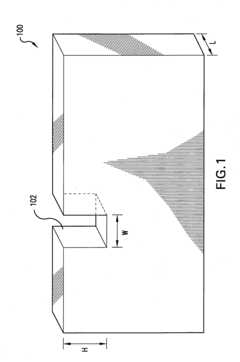

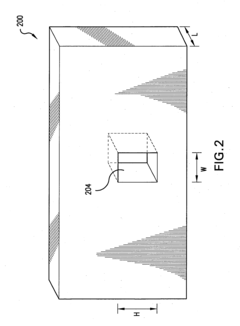

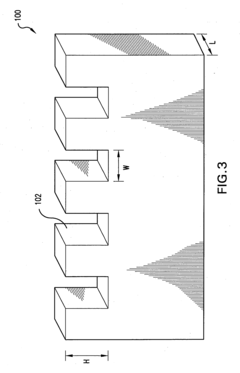

Methods and systems for compact, micro-channel laminar heat exchanging

PatentInactiveUS20060021744A1

Innovation

- A compact micro-channel heat exchanger with a heat conducting plate having channels with a channel length to hydraulic diameter ratio of less than 100, enabling improved laminar flow and reduced pressure drop, which increases heat transfer efficiency and reduces jitter.

Environmental Impact of Laminar Flow Systems

Laminar flow systems, known for their energy-efficient properties, have a significant impact on the environment. These systems, characterized by smooth and predictable fluid motion, contribute to reduced energy consumption in various applications, particularly in heating, ventilation, and air conditioning (HVAC) systems. The environmental benefits of laminar flow extend beyond energy savings, encompassing reduced greenhouse gas emissions and improved air quality.

One of the primary environmental advantages of laminar flow systems is their ability to minimize energy waste. By maintaining a consistent and controlled airflow, these systems require less power to operate compared to turbulent flow systems. This reduction in energy consumption directly translates to lower carbon emissions from power plants, contributing to the global effort to mitigate climate change. Studies have shown that buildings utilizing laminar flow HVAC systems can achieve energy savings of up to 30% compared to conventional systems.

The improved air quality resulting from laminar flow systems also has positive environmental implications. These systems are more effective at filtering and removing airborne particles, allergens, and pollutants from indoor environments. This enhanced air purification capability reduces the need for additional air cleaning technologies, which often consume more energy and require frequent filter replacements. Consequently, laminar flow systems indirectly contribute to reducing waste generation and the environmental impact associated with the production and disposal of air filtration components.

Furthermore, laminar flow systems play a crucial role in optimizing the performance of renewable energy technologies. In solar thermal collectors and heat exchangers, laminar flow enhances heat transfer efficiency, allowing for better utilization of renewable energy sources. This synergy between laminar flow and renewable energy systems amplifies the overall positive environmental impact by promoting the adoption and effectiveness of clean energy solutions.

The environmental benefits of laminar flow systems extend to water conservation as well. In applications such as irrigation and water distribution systems, laminar flow reduces friction losses and improves the overall efficiency of water delivery. This results in decreased water waste and lower energy requirements for pumping, contributing to the conservation of both water and energy resources.

However, it is important to consider the potential environmental trade-offs associated with implementing laminar flow systems. The manufacturing and installation of specialized equipment required for laminar flow may have initial environmental costs. Additionally, the maintenance and cleaning procedures necessary to maintain laminar flow conditions could involve the use of chemicals or resources that may have environmental implications. These factors should be carefully evaluated and balanced against the long-term environmental benefits when assessing the overall impact of laminar flow systems.

One of the primary environmental advantages of laminar flow systems is their ability to minimize energy waste. By maintaining a consistent and controlled airflow, these systems require less power to operate compared to turbulent flow systems. This reduction in energy consumption directly translates to lower carbon emissions from power plants, contributing to the global effort to mitigate climate change. Studies have shown that buildings utilizing laminar flow HVAC systems can achieve energy savings of up to 30% compared to conventional systems.

The improved air quality resulting from laminar flow systems also has positive environmental implications. These systems are more effective at filtering and removing airborne particles, allergens, and pollutants from indoor environments. This enhanced air purification capability reduces the need for additional air cleaning technologies, which often consume more energy and require frequent filter replacements. Consequently, laminar flow systems indirectly contribute to reducing waste generation and the environmental impact associated with the production and disposal of air filtration components.

Furthermore, laminar flow systems play a crucial role in optimizing the performance of renewable energy technologies. In solar thermal collectors and heat exchangers, laminar flow enhances heat transfer efficiency, allowing for better utilization of renewable energy sources. This synergy between laminar flow and renewable energy systems amplifies the overall positive environmental impact by promoting the adoption and effectiveness of clean energy solutions.

The environmental benefits of laminar flow systems extend to water conservation as well. In applications such as irrigation and water distribution systems, laminar flow reduces friction losses and improves the overall efficiency of water delivery. This results in decreased water waste and lower energy requirements for pumping, contributing to the conservation of both water and energy resources.

However, it is important to consider the potential environmental trade-offs associated with implementing laminar flow systems. The manufacturing and installation of specialized equipment required for laminar flow may have initial environmental costs. Additionally, the maintenance and cleaning procedures necessary to maintain laminar flow conditions could involve the use of chemicals or resources that may have environmental implications. These factors should be carefully evaluated and balanced against the long-term environmental benefits when assessing the overall impact of laminar flow systems.

Cost-Benefit Analysis of Laminar Flow Implementation

Implementing laminar flow systems for energy savings requires a thorough cost-benefit analysis to determine its economic viability. The initial investment in laminar flow technology can be substantial, encompassing equipment costs, installation expenses, and potential facility modifications. However, these upfront costs must be weighed against the long-term energy savings and operational benefits.

Energy savings represent the primary benefit of laminar flow systems. By reducing turbulence and optimizing fluid dynamics, these systems can significantly decrease energy consumption in various applications, such as HVAC systems, industrial processes, and fluid transport. The exact magnitude of energy savings varies depending on the specific application and scale of implementation, but studies have shown potential reductions in energy usage ranging from 15% to 40%.

Operational efficiency improvements constitute another key benefit. Laminar flow systems often lead to more precise temperature control, reduced wear on equipment, and lower maintenance requirements. These factors contribute to extended equipment lifespan and decreased downtime, translating into additional cost savings over time.

The payback period for laminar flow implementations typically ranges from 2 to 5 years, depending on the scale of the project and energy costs in the region. Facilities with high energy consumption or those operating in areas with elevated energy prices may see faster returns on investment. Additionally, some regions offer incentives or rebates for energy-efficient upgrades, which can further improve the cost-benefit ratio.

It's crucial to consider the lifecycle costs of laminar flow systems, including maintenance, potential retrofits, and eventual replacement. While these systems generally have lower maintenance requirements, they may necessitate specialized expertise for optimal performance, potentially increasing operational costs.

Environmental benefits, though not directly financial, should also factor into the analysis. Reduced energy consumption leads to lower carbon emissions, aligning with sustainability goals and potentially offering marketing advantages or compliance with environmental regulations.

To maximize the cost-benefit ratio, organizations should conduct a comprehensive audit of their current systems, identify areas with the highest potential for improvement, and prioritize implementations accordingly. Pilot projects can provide valuable data for scaling up laminar flow applications, allowing for more accurate projections of energy savings and return on investment.

Energy savings represent the primary benefit of laminar flow systems. By reducing turbulence and optimizing fluid dynamics, these systems can significantly decrease energy consumption in various applications, such as HVAC systems, industrial processes, and fluid transport. The exact magnitude of energy savings varies depending on the specific application and scale of implementation, but studies have shown potential reductions in energy usage ranging from 15% to 40%.

Operational efficiency improvements constitute another key benefit. Laminar flow systems often lead to more precise temperature control, reduced wear on equipment, and lower maintenance requirements. These factors contribute to extended equipment lifespan and decreased downtime, translating into additional cost savings over time.

The payback period for laminar flow implementations typically ranges from 2 to 5 years, depending on the scale of the project and energy costs in the region. Facilities with high energy consumption or those operating in areas with elevated energy prices may see faster returns on investment. Additionally, some regions offer incentives or rebates for energy-efficient upgrades, which can further improve the cost-benefit ratio.

It's crucial to consider the lifecycle costs of laminar flow systems, including maintenance, potential retrofits, and eventual replacement. While these systems generally have lower maintenance requirements, they may necessitate specialized expertise for optimal performance, potentially increasing operational costs.

Environmental benefits, though not directly financial, should also factor into the analysis. Reduced energy consumption leads to lower carbon emissions, aligning with sustainability goals and potentially offering marketing advantages or compliance with environmental regulations.

To maximize the cost-benefit ratio, organizations should conduct a comprehensive audit of their current systems, identify areas with the highest potential for improvement, and prioritize implementations accordingly. Pilot projects can provide valuable data for scaling up laminar flow applications, allowing for more accurate projections of energy savings and return on investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!