How to Bring Revolutionary Change in Transport with Laminar Flow?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow in Transport: Background and Objectives

Laminar flow, a phenomenon characterized by smooth and predictable fluid motion, has long been a subject of fascination in the field of fluid dynamics. In the context of transport, harnessing laminar flow holds the potential to revolutionize the way we move people and goods across various mediums. The historical development of laminar flow research can be traced back to the 19th century, with pioneering work by physicists such as George Stokes and Osborne Reynolds. Their foundational studies laid the groundwork for our current understanding of fluid behavior and its applications in transport systems.

As technology has advanced, the application of laminar flow principles in transport has gained increasing attention. From aerodynamics in aviation to hydrodynamics in marine vessels, the pursuit of laminar flow has been driven by the promise of enhanced efficiency and performance. The primary objective in this field is to minimize drag and turbulence, thereby reducing energy consumption and improving overall system performance. This goal aligns with the growing global emphasis on sustainable and eco-friendly transportation solutions.

In recent years, the convergence of computational fluid dynamics (CFD), advanced materials science, and innovative design methodologies has accelerated progress in laminar flow research. These technological advancements have enabled more precise modeling and testing of laminar flow concepts, paving the way for practical applications in various transport sectors. The automotive industry, for instance, has been exploring laminar flow techniques to improve fuel efficiency and reduce emissions in vehicle design.

The evolution of laminar flow technology in transport is closely tied to broader trends in the industry, such as the push for electrification and autonomous systems. As these trends reshape the transport landscape, laminar flow principles are being integrated into new vehicle designs and propulsion systems. This integration aims to maximize the benefits of emerging technologies by optimizing energy usage and enhancing overall system performance.

Looking ahead, the future of laminar flow in transport holds exciting possibilities. Researchers and engineers are exploring novel approaches to achieve and maintain laminar flow under diverse operating conditions. These efforts include the development of adaptive surfaces that can dynamically alter their properties to promote laminar flow, as well as the use of active flow control systems to manage boundary layer behavior. The ultimate goal is to create transport solutions that can seamlessly adapt to changing environmental conditions while maintaining optimal efficiency.

As we delve deeper into the potential of laminar flow in transport, it is crucial to consider the multidisciplinary nature of this field. Advancements will require collaboration across various domains, including fluid dynamics, materials science, control systems, and environmental engineering. By leveraging expertise from these diverse areas, we can unlock the full potential of laminar flow to bring about revolutionary changes in transport technology.

As technology has advanced, the application of laminar flow principles in transport has gained increasing attention. From aerodynamics in aviation to hydrodynamics in marine vessels, the pursuit of laminar flow has been driven by the promise of enhanced efficiency and performance. The primary objective in this field is to minimize drag and turbulence, thereby reducing energy consumption and improving overall system performance. This goal aligns with the growing global emphasis on sustainable and eco-friendly transportation solutions.

In recent years, the convergence of computational fluid dynamics (CFD), advanced materials science, and innovative design methodologies has accelerated progress in laminar flow research. These technological advancements have enabled more precise modeling and testing of laminar flow concepts, paving the way for practical applications in various transport sectors. The automotive industry, for instance, has been exploring laminar flow techniques to improve fuel efficiency and reduce emissions in vehicle design.

The evolution of laminar flow technology in transport is closely tied to broader trends in the industry, such as the push for electrification and autonomous systems. As these trends reshape the transport landscape, laminar flow principles are being integrated into new vehicle designs and propulsion systems. This integration aims to maximize the benefits of emerging technologies by optimizing energy usage and enhancing overall system performance.

Looking ahead, the future of laminar flow in transport holds exciting possibilities. Researchers and engineers are exploring novel approaches to achieve and maintain laminar flow under diverse operating conditions. These efforts include the development of adaptive surfaces that can dynamically alter their properties to promote laminar flow, as well as the use of active flow control systems to manage boundary layer behavior. The ultimate goal is to create transport solutions that can seamlessly adapt to changing environmental conditions while maintaining optimal efficiency.

As we delve deeper into the potential of laminar flow in transport, it is crucial to consider the multidisciplinary nature of this field. Advancements will require collaboration across various domains, including fluid dynamics, materials science, control systems, and environmental engineering. By leveraging expertise from these diverse areas, we can unlock the full potential of laminar flow to bring about revolutionary changes in transport technology.

Market Analysis for Laminar Flow Transport Solutions

The market for laminar flow transport solutions is experiencing significant growth, driven by the increasing demand for more efficient and environmentally friendly transportation systems. As global concerns about climate change and energy consumption continue to rise, industries are seeking innovative ways to reduce drag and improve fuel efficiency in various modes of transport.

In the automotive sector, the adoption of laminar flow technologies is gaining traction, particularly in the design of electric vehicles. Major manufacturers are investing heavily in research and development to incorporate laminar flow principles into their vehicle designs, aiming to extend battery range and improve overall performance. This trend is expected to accelerate as governments worldwide implement stricter emissions regulations and push for the transition to electric mobility.

The aerospace industry represents another key market for laminar flow solutions. Airlines and aircraft manufacturers are exploring advanced laminar flow control techniques to reduce fuel consumption and operating costs. The potential for fuel savings of up to 15% has sparked intense interest among industry players, leading to increased investment in laminar flow wing designs and other aerodynamic improvements.

In the maritime sector, the application of laminar flow concepts is emerging as a promising approach to enhance vessel efficiency. Shipbuilders and operators are investigating hull designs and coatings that promote laminar flow, potentially reducing fuel consumption and emissions in commercial shipping. This development is particularly significant given the International Maritime Organization's ambitious targets for reducing greenhouse gas emissions from ships.

The rail industry is also exploring laminar flow technologies to improve the energy efficiency of high-speed trains. By optimizing the aerodynamics of train designs, operators aim to reduce energy consumption and increase speed capabilities, making rail transport more competitive with other modes of long-distance travel.

The market for laminar flow transport solutions extends beyond vehicle design to include supporting technologies and services. This encompasses advanced materials, computational fluid dynamics software, and specialized testing facilities. The growing demand for these ancillary products and services is creating new opportunities for technology providers and engineering firms specializing in fluid dynamics and aerodynamics.

As the market for laminar flow transport solutions continues to expand, collaborations between research institutions, technology companies, and transport operators are becoming more prevalent. These partnerships are driving innovation and accelerating the development of practical applications for laminar flow technologies across various transport modes.

In the automotive sector, the adoption of laminar flow technologies is gaining traction, particularly in the design of electric vehicles. Major manufacturers are investing heavily in research and development to incorporate laminar flow principles into their vehicle designs, aiming to extend battery range and improve overall performance. This trend is expected to accelerate as governments worldwide implement stricter emissions regulations and push for the transition to electric mobility.

The aerospace industry represents another key market for laminar flow solutions. Airlines and aircraft manufacturers are exploring advanced laminar flow control techniques to reduce fuel consumption and operating costs. The potential for fuel savings of up to 15% has sparked intense interest among industry players, leading to increased investment in laminar flow wing designs and other aerodynamic improvements.

In the maritime sector, the application of laminar flow concepts is emerging as a promising approach to enhance vessel efficiency. Shipbuilders and operators are investigating hull designs and coatings that promote laminar flow, potentially reducing fuel consumption and emissions in commercial shipping. This development is particularly significant given the International Maritime Organization's ambitious targets for reducing greenhouse gas emissions from ships.

The rail industry is also exploring laminar flow technologies to improve the energy efficiency of high-speed trains. By optimizing the aerodynamics of train designs, operators aim to reduce energy consumption and increase speed capabilities, making rail transport more competitive with other modes of long-distance travel.

The market for laminar flow transport solutions extends beyond vehicle design to include supporting technologies and services. This encompasses advanced materials, computational fluid dynamics software, and specialized testing facilities. The growing demand for these ancillary products and services is creating new opportunities for technology providers and engineering firms specializing in fluid dynamics and aerodynamics.

As the market for laminar flow transport solutions continues to expand, collaborations between research institutions, technology companies, and transport operators are becoming more prevalent. These partnerships are driving innovation and accelerating the development of practical applications for laminar flow technologies across various transport modes.

Current Challenges in Implementing Laminar Flow Technology

Despite the promising potential of laminar flow technology in revolutionizing transport, several significant challenges hinder its widespread implementation. One of the primary obstacles is the difficulty in maintaining laminar flow conditions in real-world environments. Atmospheric turbulence, surface imperfections, and varying weather conditions can disrupt the delicate balance required for laminar flow, reducing its effectiveness and efficiency.

The high cost associated with implementing laminar flow technology presents another major hurdle. Developing and manufacturing vehicles or aircraft with laminar flow surfaces requires substantial investment in research, materials, and production processes. This financial barrier often deters companies from adopting the technology, particularly in sectors with tight profit margins.

Technical complexity also poses a significant challenge. Achieving and sustaining laminar flow requires precise engineering and manufacturing tolerances. Even minor deviations in surface smoothness or contour can lead to premature transition to turbulent flow, negating the benefits of the technology. This level of precision is difficult to maintain consistently in mass production scenarios.

Maintenance and durability issues further complicate the implementation of laminar flow technology. Surfaces designed for laminar flow are often more susceptible to damage from environmental factors such as dust, insects, and debris. Regular cleaning and maintenance are crucial to preserve the laminar flow properties, which can be costly and time-consuming for operators.

The integration of laminar flow technology with existing vehicle and aircraft designs presents another challenge. Retrofitting current models with laminar flow surfaces often requires significant redesign, which can be impractical or economically unfeasible. This limitation means that the technology is more likely to be implemented in new designs, slowing its adoption across the transport industry.

Regulatory hurdles and certification processes also impede the rapid implementation of laminar flow technology. New transport technologies must undergo rigorous testing and approval procedures to ensure safety and compliance with existing standards. These processes can be lengthy and expensive, further delaying the widespread adoption of laminar flow solutions.

Lastly, there is a knowledge gap in the industry regarding the practical application and benefits of laminar flow technology. Many engineers and decision-makers in the transport sector may not fully understand the potential advantages or have the expertise to implement these advanced aerodynamic concepts effectively. This lack of awareness and technical know-how can lead to hesitation in adopting the technology, even when its benefits are clear.

The high cost associated with implementing laminar flow technology presents another major hurdle. Developing and manufacturing vehicles or aircraft with laminar flow surfaces requires substantial investment in research, materials, and production processes. This financial barrier often deters companies from adopting the technology, particularly in sectors with tight profit margins.

Technical complexity also poses a significant challenge. Achieving and sustaining laminar flow requires precise engineering and manufacturing tolerances. Even minor deviations in surface smoothness or contour can lead to premature transition to turbulent flow, negating the benefits of the technology. This level of precision is difficult to maintain consistently in mass production scenarios.

Maintenance and durability issues further complicate the implementation of laminar flow technology. Surfaces designed for laminar flow are often more susceptible to damage from environmental factors such as dust, insects, and debris. Regular cleaning and maintenance are crucial to preserve the laminar flow properties, which can be costly and time-consuming for operators.

The integration of laminar flow technology with existing vehicle and aircraft designs presents another challenge. Retrofitting current models with laminar flow surfaces often requires significant redesign, which can be impractical or economically unfeasible. This limitation means that the technology is more likely to be implemented in new designs, slowing its adoption across the transport industry.

Regulatory hurdles and certification processes also impede the rapid implementation of laminar flow technology. New transport technologies must undergo rigorous testing and approval procedures to ensure safety and compliance with existing standards. These processes can be lengthy and expensive, further delaying the widespread adoption of laminar flow solutions.

Lastly, there is a knowledge gap in the industry regarding the practical application and benefits of laminar flow technology. Many engineers and decision-makers in the transport sector may not fully understand the potential advantages or have the expertise to implement these advanced aerodynamic concepts effectively. This lack of awareness and technical know-how can lead to hesitation in adopting the technology, even when its benefits are clear.

Existing Laminar Flow Solutions in Transport Sector

01 Laminar flow control in aerodynamics

Revolutionary changes in laminar flow control for aerodynamic applications, including aircraft wings and surfaces. This involves techniques to maintain smooth airflow, reduce drag, and improve fuel efficiency. Innovations include surface modifications, suction systems, and active flow control mechanisms.- Laminar flow control in aerodynamics: Revolutionary changes in laminar flow control for aerodynamic applications, including aircraft wings and surfaces. This involves techniques to maintain smooth airflow, reduce drag, and improve fuel efficiency. Innovations include surface modifications, active flow control systems, and advanced materials to enhance laminar flow characteristics.

- Laminar flow in fluid handling systems: Advancements in creating and maintaining laminar flow in various fluid handling systems, such as pipes, channels, and industrial processes. These innovations focus on improving flow efficiency, reducing turbulence, and enhancing heat transfer or mixing properties in controlled environments.

- Laminar flow in medical and pharmaceutical applications: Revolutionary changes in utilizing laminar flow principles for medical and pharmaceutical purposes. This includes the development of laminar flow cabinets, clean room technologies, and drug delivery systems that rely on controlled, laminar flow conditions to maintain sterility or precise dosing.

- Laminar flow in energy and power generation: Innovative applications of laminar flow principles in energy and power generation systems. This encompasses improvements in turbine designs, solar thermal collectors, and other energy conversion devices that benefit from controlled, laminar flow conditions to enhance efficiency and performance.

- Laminar flow in manufacturing and material processing: Revolutionary changes in manufacturing processes and material treatments utilizing laminar flow principles. This includes advancements in coating technologies, 3D printing, and material extrusion processes that rely on precise control of laminar flow conditions to achieve desired product characteristics and quality.

02 Laminar flow in fluid handling systems

Advancements in creating and maintaining laminar flow in various fluid handling systems, such as pipelines, mixing devices, and reactors. These innovations aim to improve efficiency, reduce turbulence, and enhance process control in industrial applications.Expand Specific Solutions03 Laminar flow in medical devices

Revolutionary changes in the application of laminar flow principles to medical devices and procedures. This includes improvements in drug delivery systems, diagnostic tools, and surgical instruments that utilize controlled laminar flow for enhanced precision and effectiveness.Expand Specific Solutions04 Laminar flow in environmental control

Innovative applications of laminar flow in environmental control systems, including air purification, ventilation, and climate control. These advancements aim to improve air quality, energy efficiency, and overall comfort in various settings such as clean rooms, hospitals, and residential spaces.Expand Specific Solutions05 Laminar flow in manufacturing processes

Revolutionary changes in the use of laminar flow principles in manufacturing processes, particularly in areas such as coating, printing, and material deposition. These innovations aim to improve product quality, increase production efficiency, and enable the creation of novel materials and structures.Expand Specific Solutions

Key Players in Laminar Flow Transport Research

The laminar flow technology in transport is in its early development stage, with a growing market potential due to its promise of revolutionary efficiency improvements. The market size is expanding as major players invest in research and development. Companies like Hyperloop Technologies, Inc. and CRRC Yangtze Co. Ltd. are at the forefront, developing innovative applications for high-speed rail and tube transport. Aerospace giants such as Airbus Operations Ltd. and The Boeing Co. are exploring laminar flow for aircraft design, while NASA continues to push boundaries in aerodynamics research. The technology's maturity varies across sectors, with more advanced applications in aerospace and emerging potential in ground transportation.

Hyperloop Technologies, Inc.

Technical Solution: Hyperloop Technologies, Inc. is pioneering revolutionary transport using laminar flow principles. Their system employs a near-vacuum tube environment to minimize air resistance, allowing capsules to travel at near-supersonic speeds[1]. The company utilizes magnetic levitation technology to eliminate friction between the vehicle and track[2]. Advanced aerodynamic designs incorporate laminar flow concepts to further reduce drag, enabling energy-efficient high-speed travel. Hyperloop's proprietary control systems maintain optimal laminar flow conditions throughout the journey, adjusting for variations in tube pressure and vehicle speed[3].

Strengths: Extremely high speeds, energy efficiency, and reduced travel times. Weaknesses: High infrastructure costs and technical challenges in maintaining vacuum conditions over long distances.

Airbus Operations Ltd.

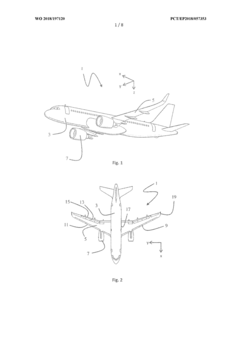

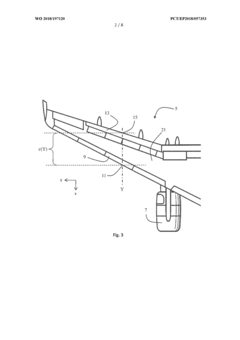

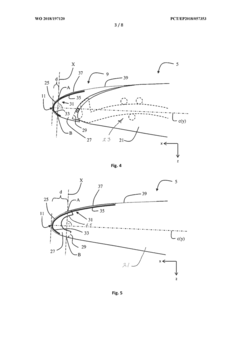

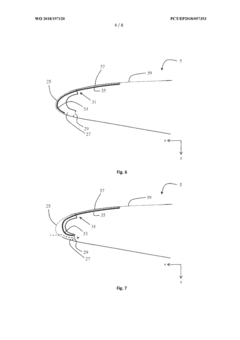

Technical Solution: Airbus Operations Ltd. is applying laminar flow technology to aircraft design, focusing on Natural Laminar Flow (NLF) and Hybrid Laminar Flow Control (HLFC) systems[4]. Their NLF designs optimize wing shapes to maintain laminar flow over larger portions of the wing surface, reducing drag by up to 10%[5]. HLFC technology combines passive shaping with active suction systems to extend laminar flow regions. Airbus has conducted flight tests with these technologies on A340 aircraft, demonstrating significant fuel efficiency improvements[6]. The company is also exploring adaptive wing designs that can dynamically adjust to maintain optimal laminar flow conditions across various flight phases.

Strengths: Significant fuel efficiency gains and reduced emissions for commercial aviation. Weaknesses: Complexity of implementation and potential maintenance challenges for active systems.

Breakthrough Innovations in Laminar Flow Technology

Aerodynamic body

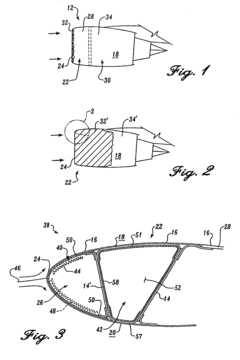

PatentWO2018197120A1

Innovation

- An aerodynamic body with a perforated surface and an integrated ice-protection system featuring an actuatable element that moves between thermal contact and non-contact positions, allowing for efficient heat transfer and laminar flow creation, using micro-perforations and optional electrical heating, to delay boundary layer transition and reduce drag.

Method and apparatus using localized heating for laminar flow

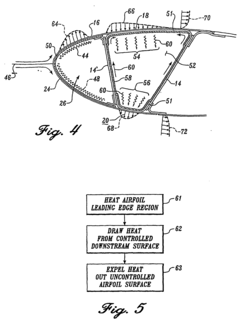

PatentInactiveEP0939028B1

Innovation

- A nacelle with a localized heating system using an electro-thermal heat source and heat pipe to transfer heat from the controlled surface to an uncontrolled inlet surface, maintaining a temperature difference that encourages laminar flow along the nacelle surface without the need for suction or complex configurations.

Environmental Impact of Laminar Flow Transport Systems

The implementation of laminar flow technology in transport systems has the potential to significantly reduce the environmental impact of transportation. By minimizing turbulence and drag, vehicles utilizing laminar flow principles can achieve substantial improvements in fuel efficiency, leading to a marked decrease in greenhouse gas emissions. This reduction in carbon footprint aligns with global efforts to combat climate change and meets increasingly stringent environmental regulations.

Laminar flow transport systems also contribute to noise pollution reduction. The smoother airflow around vehicles results in less aerodynamic noise, creating quieter transportation options for both urban and rural environments. This decrease in noise pollution can have positive effects on human health and wildlife, particularly in areas near transportation corridors.

Furthermore, the enhanced efficiency of laminar flow vehicles may lead to a reduction in the overall number of vehicles required to meet transportation needs. This could result in less congestion on roads and in the air, potentially decreasing the need for extensive infrastructure expansion and its associated environmental impacts.

The materials and manufacturing processes required for laminar flow transport systems may also have environmental implications. While the production of specialized surfaces or coatings might initially have a higher environmental cost, the long-term benefits in operational efficiency could offset these impacts. Additionally, the development of new, environmentally friendly materials for laminar flow applications could drive innovation in sustainable manufacturing practices.

Water-based transport utilizing laminar flow principles could see significant improvements in energy efficiency and reduced wake formation. This would be particularly beneficial for marine ecosystems, minimizing disturbance to aquatic life and reducing erosion in coastal and riverine environments.

However, it is important to consider potential negative environmental impacts. For instance, the disposal or recycling of specialized materials used in laminar flow transport systems at the end of their lifecycle must be carefully managed to prevent environmental contamination.

In conclusion, while laminar flow transport systems offer promising environmental benefits, particularly in terms of energy efficiency and emissions reduction, a comprehensive lifecycle assessment is necessary to fully understand and optimize their environmental impact. This holistic approach will ensure that the implementation of laminar flow technology in transportation aligns with broader sustainability goals.

Laminar flow transport systems also contribute to noise pollution reduction. The smoother airflow around vehicles results in less aerodynamic noise, creating quieter transportation options for both urban and rural environments. This decrease in noise pollution can have positive effects on human health and wildlife, particularly in areas near transportation corridors.

Furthermore, the enhanced efficiency of laminar flow vehicles may lead to a reduction in the overall number of vehicles required to meet transportation needs. This could result in less congestion on roads and in the air, potentially decreasing the need for extensive infrastructure expansion and its associated environmental impacts.

The materials and manufacturing processes required for laminar flow transport systems may also have environmental implications. While the production of specialized surfaces or coatings might initially have a higher environmental cost, the long-term benefits in operational efficiency could offset these impacts. Additionally, the development of new, environmentally friendly materials for laminar flow applications could drive innovation in sustainable manufacturing practices.

Water-based transport utilizing laminar flow principles could see significant improvements in energy efficiency and reduced wake formation. This would be particularly beneficial for marine ecosystems, minimizing disturbance to aquatic life and reducing erosion in coastal and riverine environments.

However, it is important to consider potential negative environmental impacts. For instance, the disposal or recycling of specialized materials used in laminar flow transport systems at the end of their lifecycle must be carefully managed to prevent environmental contamination.

In conclusion, while laminar flow transport systems offer promising environmental benefits, particularly in terms of energy efficiency and emissions reduction, a comprehensive lifecycle assessment is necessary to fully understand and optimize their environmental impact. This holistic approach will ensure that the implementation of laminar flow technology in transportation aligns with broader sustainability goals.

Regulatory Framework for Advanced Transport Technologies

The regulatory framework for advanced transport technologies, particularly those involving laminar flow, is a critical aspect of bringing revolutionary change to the transport sector. As these technologies evolve, governments and regulatory bodies must adapt their policies to ensure safety, efficiency, and fair competition while fostering innovation.

At the international level, organizations such as the International Civil Aviation Organization (ICAO) and the International Maritime Organization (IMO) play crucial roles in setting standards for air and sea transport, respectively. These bodies are increasingly focusing on the integration of laminar flow technologies into existing regulatory frameworks. For instance, ICAO has been working on updating its Standards and Recommended Practices (SARPs) to accommodate new aerodynamic designs that utilize laminar flow principles.

National regulatory agencies, such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA), are also adapting their certification processes to evaluate and approve laminar flow-based transport technologies. These agencies are developing new testing protocols and performance standards to ensure that vehicles incorporating laminar flow designs meet stringent safety and efficiency requirements.

Environmental regulations are another key area impacting the development of laminar flow technologies in transport. Many countries have implemented or are considering stricter emissions standards, which incentivize the adoption of more fuel-efficient technologies like laminar flow. The European Union's Emissions Trading System (EU ETS) and the International Maritime Organization's strategy to reduce greenhouse gas emissions are examples of regulatory frameworks that indirectly promote the development of laminar flow technologies.

Intellectual property regulations also play a significant role in the advancement of laminar flow technologies. Patent offices worldwide are seeing an increase in applications related to laminar flow designs and materials. Regulatory bodies are working to strike a balance between protecting inventors' rights and fostering open innovation in this field.

As laminar flow technologies progress from research to commercial application, regulators are also addressing issues related to manufacturing standards and quality control. This includes developing guidelines for the production and maintenance of surfaces that can maintain laminar flow characteristics over extended periods.

The regulatory landscape for advanced transport technologies is dynamic, with agencies continuously updating their frameworks to keep pace with technological advancements. Collaboration between industry stakeholders, research institutions, and regulatory bodies is essential to ensure that the regulatory environment supports rather than hinders the revolutionary potential of laminar flow in transport.

At the international level, organizations such as the International Civil Aviation Organization (ICAO) and the International Maritime Organization (IMO) play crucial roles in setting standards for air and sea transport, respectively. These bodies are increasingly focusing on the integration of laminar flow technologies into existing regulatory frameworks. For instance, ICAO has been working on updating its Standards and Recommended Practices (SARPs) to accommodate new aerodynamic designs that utilize laminar flow principles.

National regulatory agencies, such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA), are also adapting their certification processes to evaluate and approve laminar flow-based transport technologies. These agencies are developing new testing protocols and performance standards to ensure that vehicles incorporating laminar flow designs meet stringent safety and efficiency requirements.

Environmental regulations are another key area impacting the development of laminar flow technologies in transport. Many countries have implemented or are considering stricter emissions standards, which incentivize the adoption of more fuel-efficient technologies like laminar flow. The European Union's Emissions Trading System (EU ETS) and the International Maritime Organization's strategy to reduce greenhouse gas emissions are examples of regulatory frameworks that indirectly promote the development of laminar flow technologies.

Intellectual property regulations also play a significant role in the advancement of laminar flow technologies. Patent offices worldwide are seeing an increase in applications related to laminar flow designs and materials. Regulatory bodies are working to strike a balance between protecting inventors' rights and fostering open innovation in this field.

As laminar flow technologies progress from research to commercial application, regulators are also addressing issues related to manufacturing standards and quality control. This includes developing guidelines for the production and maintenance of surfaces that can maintain laminar flow characteristics over extended periods.

The regulatory landscape for advanced transport technologies is dynamic, with agencies continuously updating their frameworks to keep pace with technological advancements. Collaboration between industry stakeholders, research institutions, and regulatory bodies is essential to ensure that the regulatory environment supports rather than hinders the revolutionary potential of laminar flow in transport.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!