Laminar Flow: Key to Precision in Sensor Technology

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Fundamentals

Laminar flow is a fundamental concept in fluid dynamics, characterized by smooth, predictable fluid motion with minimal mixing between adjacent layers. In the context of sensor technology, understanding and harnessing laminar flow is crucial for achieving high precision and reliability in various applications.

At its core, laminar flow occurs when a fluid moves in parallel layers, with no disruption between the layers. This phenomenon is typically observed at low Reynolds numbers, where viscous forces dominate over inertial forces. The Reynolds number, a dimensionless quantity, is used to predict flow patterns in different fluid flow situations and is critical in determining whether a flow will be laminar or turbulent.

In laminar flow, fluid particles move in orderly paths, maintaining their relative positions within the fluid. This predictable behavior allows for precise control and manipulation of fluids, making it invaluable in sensor technology. The absence of turbulence and mixing between layers enables accurate measurements and consistent fluid behavior, which is essential for many sensing applications.

One of the key advantages of laminar flow in sensor technology is its ability to maintain stable and reproducible conditions. This stability is particularly important in microfluidic devices, where precise control over small volumes of fluid is necessary. Laminar flow allows for the creation of well-defined fluid interfaces, enabling the development of highly sensitive and specific biosensors, chemical sensors, and environmental monitoring devices.

The principles of laminar flow are also applied in flow cytometry, a technique widely used in biomedical research and clinical diagnostics. In this application, laminar flow is used to align and focus particles or cells in a fluid stream, allowing for individual analysis and sorting. This precise control over particle positioning is crucial for accurate measurements and high-throughput analysis.

Understanding the transition from laminar to turbulent flow is equally important in sensor design. As flow rates increase or fluid properties change, the flow may become turbulent, leading to unpredictable behavior and reduced measurement accuracy. Sensor designers must carefully consider these factors to ensure optimal performance across a range of operating conditions.

In conclusion, laminar flow fundamentals form the backbone of many precision sensing technologies. By leveraging the predictable and controllable nature of laminar flow, engineers and scientists can develop highly accurate and reliable sensors for a wide range of applications, from medical diagnostics to environmental monitoring and beyond.

At its core, laminar flow occurs when a fluid moves in parallel layers, with no disruption between the layers. This phenomenon is typically observed at low Reynolds numbers, where viscous forces dominate over inertial forces. The Reynolds number, a dimensionless quantity, is used to predict flow patterns in different fluid flow situations and is critical in determining whether a flow will be laminar or turbulent.

In laminar flow, fluid particles move in orderly paths, maintaining their relative positions within the fluid. This predictable behavior allows for precise control and manipulation of fluids, making it invaluable in sensor technology. The absence of turbulence and mixing between layers enables accurate measurements and consistent fluid behavior, which is essential for many sensing applications.

One of the key advantages of laminar flow in sensor technology is its ability to maintain stable and reproducible conditions. This stability is particularly important in microfluidic devices, where precise control over small volumes of fluid is necessary. Laminar flow allows for the creation of well-defined fluid interfaces, enabling the development of highly sensitive and specific biosensors, chemical sensors, and environmental monitoring devices.

The principles of laminar flow are also applied in flow cytometry, a technique widely used in biomedical research and clinical diagnostics. In this application, laminar flow is used to align and focus particles or cells in a fluid stream, allowing for individual analysis and sorting. This precise control over particle positioning is crucial for accurate measurements and high-throughput analysis.

Understanding the transition from laminar to turbulent flow is equally important in sensor design. As flow rates increase or fluid properties change, the flow may become turbulent, leading to unpredictable behavior and reduced measurement accuracy. Sensor designers must carefully consider these factors to ensure optimal performance across a range of operating conditions.

In conclusion, laminar flow fundamentals form the backbone of many precision sensing technologies. By leveraging the predictable and controllable nature of laminar flow, engineers and scientists can develop highly accurate and reliable sensors for a wide range of applications, from medical diagnostics to environmental monitoring and beyond.

Sensor Market Dynamics

The sensor market has experienced significant growth and transformation in recent years, driven by advancements in technology and increasing demand across various industries. The global sensor market size was valued at $166.69 billion in 2020 and is projected to reach $345.77 billion by 2028, growing at a CAGR of 8.9% from 2021 to 2028. This robust growth is attributed to the rising adoption of sensors in consumer electronics, automotive, healthcare, and industrial applications.

The automotive sector has emerged as a key driver of sensor market growth, with the increasing integration of advanced driver assistance systems (ADAS) and the development of autonomous vehicles. The automotive sensor market alone is expected to grow from $24.5 billion in 2020 to $40.3 billion by 2025, at a CAGR of 10.5%. This growth is fueled by stringent government regulations for vehicle safety and emissions, as well as the growing consumer demand for enhanced driving experiences.

In the consumer electronics segment, the proliferation of smartphones, wearables, and smart home devices has significantly boosted sensor demand. The consumer electronics sensor market is anticipated to reach $29.25 billion by 2025, growing at a CAGR of 12.4% from 2020 to 2025. This growth is driven by the increasing integration of sensors in devices for features such as facial recognition, gesture control, and environmental monitoring.

The industrial sector is another major contributor to sensor market dynamics, with the advent of Industry 4.0 and the Industrial Internet of Things (IIoT). The industrial sensor market is expected to grow from $18.3 billion in 2020 to $29.6 billion by 2025, at a CAGR of 10.1%. This growth is propelled by the increasing adoption of automation and predictive maintenance in manufacturing processes.

Geographically, Asia Pacific dominates the sensor market, accounting for over 40% of the global market share in 2020. This dominance is attributed to the region's strong presence in consumer electronics manufacturing and the rapid industrialization of countries like China and India. North America and Europe follow closely, driven by technological advancements and high adoption rates in automotive and healthcare sectors.

The sensor market is characterized by intense competition and rapid technological advancements. Key players in the market include Texas Instruments, STMicroelectronics, Bosch Sensortec, and TE Connectivity, among others. These companies are focusing on developing innovative sensor technologies to gain a competitive edge and meet the evolving demands of various industries.

The automotive sector has emerged as a key driver of sensor market growth, with the increasing integration of advanced driver assistance systems (ADAS) and the development of autonomous vehicles. The automotive sensor market alone is expected to grow from $24.5 billion in 2020 to $40.3 billion by 2025, at a CAGR of 10.5%. This growth is fueled by stringent government regulations for vehicle safety and emissions, as well as the growing consumer demand for enhanced driving experiences.

In the consumer electronics segment, the proliferation of smartphones, wearables, and smart home devices has significantly boosted sensor demand. The consumer electronics sensor market is anticipated to reach $29.25 billion by 2025, growing at a CAGR of 12.4% from 2020 to 2025. This growth is driven by the increasing integration of sensors in devices for features such as facial recognition, gesture control, and environmental monitoring.

The industrial sector is another major contributor to sensor market dynamics, with the advent of Industry 4.0 and the Industrial Internet of Things (IIoT). The industrial sensor market is expected to grow from $18.3 billion in 2020 to $29.6 billion by 2025, at a CAGR of 10.1%. This growth is propelled by the increasing adoption of automation and predictive maintenance in manufacturing processes.

Geographically, Asia Pacific dominates the sensor market, accounting for over 40% of the global market share in 2020. This dominance is attributed to the region's strong presence in consumer electronics manufacturing and the rapid industrialization of countries like China and India. North America and Europe follow closely, driven by technological advancements and high adoption rates in automotive and healthcare sectors.

The sensor market is characterized by intense competition and rapid technological advancements. Key players in the market include Texas Instruments, STMicroelectronics, Bosch Sensortec, and TE Connectivity, among others. These companies are focusing on developing innovative sensor technologies to gain a competitive edge and meet the evolving demands of various industries.

Laminar Flow Challenges

Laminar flow, while crucial for precision in sensor technology, presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is maintaining stable laminar flow conditions in various environmental settings. Fluctuations in temperature, pressure, and external vibrations can disrupt the delicate balance required for laminar flow, leading to turbulence and compromising sensor accuracy.

The miniaturization of sensors poses another challenge in achieving and sustaining laminar flow. As devices become smaller, the Reynolds number—a key parameter in fluid dynamics—becomes more difficult to control. This can result in unexpected flow behaviors at microscale levels, requiring innovative approaches to ensure laminar flow in confined spaces.

Surface roughness and material properties of sensor components also play a critical role in laminar flow challenges. Even minor imperfections or variations in surface texture can trigger flow separation or induce turbulence, affecting the sensor's performance. Developing materials and manufacturing techniques that can produce ultra-smooth surfaces at micro and nano scales is an ongoing area of research.

Another significant challenge lies in the design of flow channels and geometries that promote laminar flow. Complex sensor structures often require intricate flow paths, which can introduce areas of potential turbulence or flow separation. Engineers must carefully optimize channel designs to maintain laminar flow throughout the entire sensor system, often requiring advanced computational fluid dynamics simulations and iterative prototyping.

The presence of particulates or contaminants in the fluid medium presents yet another hurdle. These impurities can disrupt laminar flow patterns and potentially damage sensitive sensor components. Developing effective filtration systems that do not themselves disturb the laminar flow is a delicate balance that researchers must strike.

Time-dependent flow variations also pose challenges, particularly in applications where rapid changes in flow rate or direction are expected. Maintaining laminar flow during these transitions requires sophisticated control systems and sensor designs that can quickly adapt to changing conditions without introducing turbulence.

Finally, the integration of laminar flow principles with other sensor technologies presents its own set of challenges. For instance, combining laminar flow with optical or electrochemical sensing methods may require novel approaches to ensure that the sensing mechanisms do not interfere with the flow characteristics. This interdisciplinary challenge calls for collaboration between fluid dynamics experts and specialists in various sensing modalities.

The miniaturization of sensors poses another challenge in achieving and sustaining laminar flow. As devices become smaller, the Reynolds number—a key parameter in fluid dynamics—becomes more difficult to control. This can result in unexpected flow behaviors at microscale levels, requiring innovative approaches to ensure laminar flow in confined spaces.

Surface roughness and material properties of sensor components also play a critical role in laminar flow challenges. Even minor imperfections or variations in surface texture can trigger flow separation or induce turbulence, affecting the sensor's performance. Developing materials and manufacturing techniques that can produce ultra-smooth surfaces at micro and nano scales is an ongoing area of research.

Another significant challenge lies in the design of flow channels and geometries that promote laminar flow. Complex sensor structures often require intricate flow paths, which can introduce areas of potential turbulence or flow separation. Engineers must carefully optimize channel designs to maintain laminar flow throughout the entire sensor system, often requiring advanced computational fluid dynamics simulations and iterative prototyping.

The presence of particulates or contaminants in the fluid medium presents yet another hurdle. These impurities can disrupt laminar flow patterns and potentially damage sensitive sensor components. Developing effective filtration systems that do not themselves disturb the laminar flow is a delicate balance that researchers must strike.

Time-dependent flow variations also pose challenges, particularly in applications where rapid changes in flow rate or direction are expected. Maintaining laminar flow during these transitions requires sophisticated control systems and sensor designs that can quickly adapt to changing conditions without introducing turbulence.

Finally, the integration of laminar flow principles with other sensor technologies presents its own set of challenges. For instance, combining laminar flow with optical or electrochemical sensing methods may require novel approaches to ensure that the sensing mechanisms do not interfere with the flow characteristics. This interdisciplinary challenge calls for collaboration between fluid dynamics experts and specialists in various sensing modalities.

Current Laminar Solutions

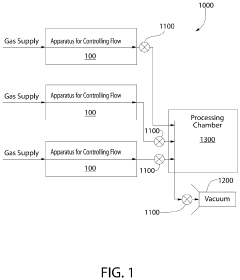

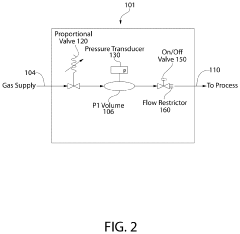

01 Laminar flow control in fluid systems

Techniques for controlling and maintaining laminar flow in fluid systems to enhance precision and efficiency. This includes methods for reducing turbulence, optimizing flow channels, and implementing flow stabilization mechanisms to ensure consistent and predictable fluid behavior.- Laminar flow control in fluid systems: Techniques for controlling and maintaining laminar flow in various fluid systems, including precision flow control devices, flow stabilizers, and laminar flow chambers. These methods enhance the accuracy and consistency of fluid flow, which is crucial for applications requiring high precision.

- Precision measurement and analysis in laminar flow: Advanced methods and devices for precise measurement and analysis of laminar flow characteristics. This includes high-resolution sensors, optical measurement techniques, and data processing algorithms to accurately quantify and analyze laminar flow parameters.

- Laminar flow applications in manufacturing processes: Integration of laminar flow principles in various manufacturing processes to improve precision and quality. This includes applications in coating, printing, and material deposition processes where controlled, uniform flow is essential for achieving high-precision results.

- Laminar flow in microfluidic devices: Design and optimization of microfluidic devices utilizing laminar flow properties for precise fluid handling and manipulation at microscale levels. These devices are crucial in various fields such as biomedical research, chemical analysis, and lab-on-a-chip applications.

- Laminar flow in aerodynamics and fluid dynamics: Exploration of laminar flow principles in aerodynamics and fluid dynamics to enhance precision in various applications. This includes the design of aerodynamic surfaces, flow control in wind tunnels, and optimization of fluid flow in industrial processes for improved efficiency and accuracy.

02 Precision measurement in laminar flow environments

Advanced methods for conducting high-precision measurements within laminar flow conditions. This encompasses the development of sensitive sensors, calibration techniques, and data processing algorithms to accurately quantify fluid properties and flow characteristics in controlled laminar environments.Expand Specific Solutions03 Laminar flow applications in manufacturing processes

Integration of laminar flow principles in various manufacturing processes to improve product quality and consistency. This includes applications in coating, printing, and material deposition where precise control of fluid behavior is crucial for achieving desired outcomes.Expand Specific Solutions04 Laminar flow devices for medical and scientific research

Development of specialized devices and instruments that utilize laminar flow for medical diagnostics, drug delivery, and scientific research. These innovations focus on creating controlled microenvironments for precise manipulation and analysis of biological samples and chemical reactions.Expand Specific Solutions05 Computational modeling and simulation of laminar flow

Advanced computational techniques for modeling and simulating laminar flow behavior in complex systems. This includes the development of algorithms, software tools, and numerical methods to predict and optimize fluid dynamics in various applications, enhancing design and analysis capabilities.Expand Specific Solutions

Key Industry Players

The laminar flow sensor technology market is in a growth phase, with increasing demand across various industries. The market size is expanding due to the technology's critical role in precision measurements and control systems. Technological maturity varies among key players, with established companies like Honeywell International Technologies Ltd. and Rosemount, Inc. leading in innovation and product development. Emerging players such as H2scan Corp. and Ichor Systems, Inc. are also making significant strides. Universities like Tianjin University and Northeastern University contribute to research and development, fostering industry-academia collaborations. The competitive landscape is characterized by a mix of large corporations and specialized firms, driving continuous advancements in sensor accuracy, reliability, and application versatility.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced laminar flow sensors for precision measurements in various applications. Their technology utilizes microfluidic channels with carefully designed geometries to maintain laminar flow conditions. This allows for highly accurate and repeatable measurements of fluid properties and flow rates. Honeywell's sensors incorporate temperature compensation and pressure equalization techniques to minimize external disturbances[1]. The company has also implemented advanced signal processing algorithms to filter out noise and extract clean sensor data. Their laminar flow sensors achieve flow measurement accuracies of up to ±0.5% of reading[2], making them suitable for demanding industrial and aerospace applications.

Strengths: High accuracy, wide range of applications, robust design for industrial use. Weaknesses: Relatively high cost, may require periodic recalibration for maximum precision.

Rosemount, Inc.

Technical Solution: Rosemount, a subsidiary of Emerson, has pioneered laminar flow element (LFE) technology for precise flow measurement. Their LFE design creates a pressure differential directly proportional to flow rate under laminar conditions. Rosemount's sensors utilize a stack of precisely spaced plates to generate multiple laminar flow paths[3]. This multi-channel approach increases the sensor's rangeability and reduces its sensitivity to upstream flow disturbances. The company has also developed proprietary coating technologies to prevent fluid contamination and maintain long-term stability. Rosemount's laminar flow sensors can achieve turndown ratios of up to 100:1 and maintain accuracy over a wide range of fluid viscosities[4].

Strengths: High rangeability, excellent long-term stability, suitable for various fluid types. Weaknesses: May be sensitive to temperature changes, requires clean fluid streams for optimal performance.

Laminar Flow Innovations

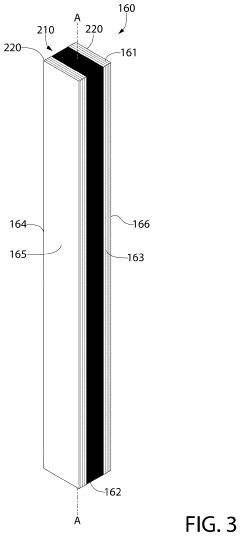

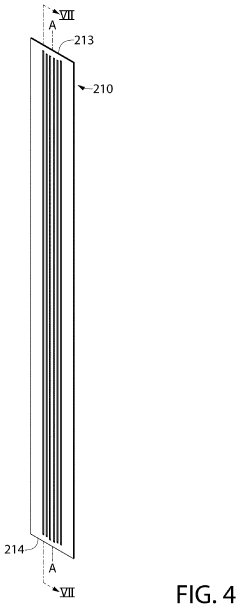

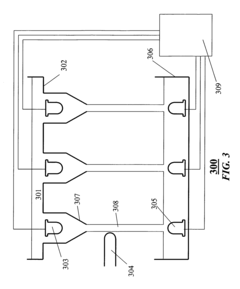

Laminar flow restrictor and seal for same

PatentPendingUS20240026909A1

Innovation

- The development of laminar flow restrictors with multiple layers and seals that form fluid-tight connections to enhance gas flow control, featuring specific apertures and passages for precise impedance and reduced leakage, integrated into mass flow controllers for semiconductor and other industrial processes.

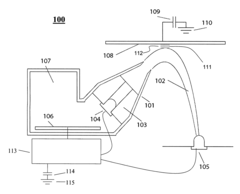

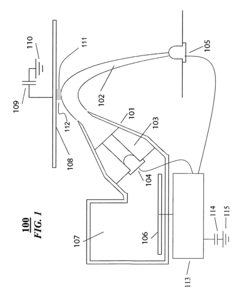

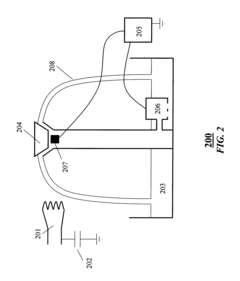

Apparatus and method for sensing objects proximate to fluid flows

PatentInactiveUS20070188178A1

Innovation

- The use of laminar fluid flow as a sensing element, combining optical and capacitive sensing techniques, where the fluid serves as a light pipe for optical detection and an electrode for capacitive measurement, allowing for the determination of object proximity and position along the fluid stream through changes in optical characteristics and impedance.

Regulatory Considerations

The regulatory landscape surrounding laminar flow technology in sensor applications is complex and multifaceted, requiring careful consideration by manufacturers and researchers. Regulatory bodies such as the Food and Drug Administration (FDA) in the United States and the European Medicines Agency (EMA) in Europe play crucial roles in overseeing the development and implementation of sensor technologies that utilize laminar flow principles.

In the medical device sector, sensors employing laminar flow must adhere to stringent quality control and validation processes. The FDA's Quality System Regulation (QSR) and the European Union's Medical Device Regulation (MDR) set forth comprehensive guidelines for the design, manufacture, and post-market surveillance of such devices. These regulations emphasize the importance of risk management, performance evaluation, and clinical evidence in ensuring the safety and efficacy of laminar flow-based sensors.

Environmental monitoring applications of laminar flow sensors are subject to regulations from agencies like the Environmental Protection Agency (EPA) in the US and the European Environment Agency (EEA). These bodies establish standards for air and water quality monitoring, where laminar flow sensors play a critical role in accurate measurement and analysis. Compliance with these standards often requires regular calibration and maintenance of sensors to ensure consistent and reliable performance.

In the automotive industry, laminar flow sensors used in engine management systems and emissions control must meet strict regulatory requirements. The National Highway Traffic Safety Administration (NHTSA) in the US and the European New Car Assessment Programme (Euro NCAP) set standards for vehicle safety and emissions, which directly impact the design and implementation of these sensors. Manufacturers must demonstrate compliance through rigorous testing and certification processes.

Intellectual property considerations also form a significant part of the regulatory landscape. Patent laws and licensing agreements govern the use and development of laminar flow technology in sensors. Companies must navigate these legal frameworks carefully to avoid infringement issues and ensure proper protection of their innovations.

Data privacy and security regulations, such as the General Data Protection Regulation (GDPR) in Europe and the California Consumer Privacy Act (CCPA) in the US, have implications for laminar flow sensors that collect and transmit data. Manufacturers must implement robust data protection measures and ensure transparency in data handling practices to comply with these regulations.

As laminar flow sensor technology continues to advance, regulatory frameworks are likely to evolve. Emerging applications in fields such as nanotechnology and biotechnology may necessitate the development of new regulatory guidelines. Industry stakeholders must stay informed of these changes and actively participate in shaping future regulations to ensure a balance between innovation and public safety.

In the medical device sector, sensors employing laminar flow must adhere to stringent quality control and validation processes. The FDA's Quality System Regulation (QSR) and the European Union's Medical Device Regulation (MDR) set forth comprehensive guidelines for the design, manufacture, and post-market surveillance of such devices. These regulations emphasize the importance of risk management, performance evaluation, and clinical evidence in ensuring the safety and efficacy of laminar flow-based sensors.

Environmental monitoring applications of laminar flow sensors are subject to regulations from agencies like the Environmental Protection Agency (EPA) in the US and the European Environment Agency (EEA). These bodies establish standards for air and water quality monitoring, where laminar flow sensors play a critical role in accurate measurement and analysis. Compliance with these standards often requires regular calibration and maintenance of sensors to ensure consistent and reliable performance.

In the automotive industry, laminar flow sensors used in engine management systems and emissions control must meet strict regulatory requirements. The National Highway Traffic Safety Administration (NHTSA) in the US and the European New Car Assessment Programme (Euro NCAP) set standards for vehicle safety and emissions, which directly impact the design and implementation of these sensors. Manufacturers must demonstrate compliance through rigorous testing and certification processes.

Intellectual property considerations also form a significant part of the regulatory landscape. Patent laws and licensing agreements govern the use and development of laminar flow technology in sensors. Companies must navigate these legal frameworks carefully to avoid infringement issues and ensure proper protection of their innovations.

Data privacy and security regulations, such as the General Data Protection Regulation (GDPR) in Europe and the California Consumer Privacy Act (CCPA) in the US, have implications for laminar flow sensors that collect and transmit data. Manufacturers must implement robust data protection measures and ensure transparency in data handling practices to comply with these regulations.

As laminar flow sensor technology continues to advance, regulatory frameworks are likely to evolve. Emerging applications in fields such as nanotechnology and biotechnology may necessitate the development of new regulatory guidelines. Industry stakeholders must stay informed of these changes and actively participate in shaping future regulations to ensure a balance between innovation and public safety.

Environmental Impact

The environmental impact of laminar flow technology in sensor applications is a critical consideration as industries strive for more sustainable practices. Laminar flow, characterized by smooth and predictable fluid motion, plays a significant role in enhancing sensor precision and efficiency. However, its implementation and utilization also have environmental implications that warrant careful examination.

One of the primary environmental benefits of laminar flow in sensor technology is the potential for reduced energy consumption. By minimizing turbulence and chaotic fluid behavior, laminar flow systems often require less power to maintain optimal operating conditions. This energy efficiency can lead to decreased carbon emissions and a smaller overall environmental footprint for sensor-dependent industries.

Moreover, the improved accuracy and reliability of sensors utilizing laminar flow can contribute to more efficient resource utilization. For instance, in environmental monitoring applications, precise sensors can help detect pollutants or contaminants at lower concentrations, enabling earlier intervention and potentially reducing the scale of environmental remediation efforts.

However, the production and disposal of specialized components required for laminar flow systems may pose environmental challenges. The manufacturing processes for high-precision parts often involve energy-intensive techniques and potentially hazardous materials. As such, the lifecycle assessment of laminar flow sensor technologies must consider these factors to ensure a net positive environmental impact.

In fluid-based sensing applications, the use of laminar flow may necessitate the consumption of specific fluids or gases. The environmental impact of producing, transporting, and disposing of these substances should be carefully evaluated. Additionally, any potential for leaks or emissions during operation must be addressed to prevent unintended environmental consequences.

The application of laminar flow in sensor technology also has indirect environmental implications. By enabling more precise measurements and control in various industrial processes, it can contribute to overall resource optimization and waste reduction. For example, in manufacturing, sensors leveraging laminar flow can help fine-tune production parameters, potentially reducing material waste and improving energy efficiency.

As the demand for high-precision sensors grows across industries such as healthcare, automotive, and environmental monitoring, the widespread adoption of laminar flow technology may lead to cumulative environmental benefits. However, this scaling up also necessitates careful consideration of material sourcing, manufacturing processes, and end-of-life management to ensure sustainable practices throughout the technology's lifecycle.

In conclusion, while laminar flow offers significant potential for enhancing sensor precision and efficiency, its environmental impact is multifaceted. Balancing the benefits of improved accuracy and potential energy savings against the environmental costs of production and operation is crucial for ensuring the sustainable development and implementation of this technology in sensor applications.

One of the primary environmental benefits of laminar flow in sensor technology is the potential for reduced energy consumption. By minimizing turbulence and chaotic fluid behavior, laminar flow systems often require less power to maintain optimal operating conditions. This energy efficiency can lead to decreased carbon emissions and a smaller overall environmental footprint for sensor-dependent industries.

Moreover, the improved accuracy and reliability of sensors utilizing laminar flow can contribute to more efficient resource utilization. For instance, in environmental monitoring applications, precise sensors can help detect pollutants or contaminants at lower concentrations, enabling earlier intervention and potentially reducing the scale of environmental remediation efforts.

However, the production and disposal of specialized components required for laminar flow systems may pose environmental challenges. The manufacturing processes for high-precision parts often involve energy-intensive techniques and potentially hazardous materials. As such, the lifecycle assessment of laminar flow sensor technologies must consider these factors to ensure a net positive environmental impact.

In fluid-based sensing applications, the use of laminar flow may necessitate the consumption of specific fluids or gases. The environmental impact of producing, transporting, and disposing of these substances should be carefully evaluated. Additionally, any potential for leaks or emissions during operation must be addressed to prevent unintended environmental consequences.

The application of laminar flow in sensor technology also has indirect environmental implications. By enabling more precise measurements and control in various industrial processes, it can contribute to overall resource optimization and waste reduction. For example, in manufacturing, sensors leveraging laminar flow can help fine-tune production parameters, potentially reducing material waste and improving energy efficiency.

As the demand for high-precision sensors grows across industries such as healthcare, automotive, and environmental monitoring, the widespread adoption of laminar flow technology may lead to cumulative environmental benefits. However, this scaling up also necessitates careful consideration of material sourcing, manufacturing processes, and end-of-life management to ensure sustainable practices throughout the technology's lifecycle.

In conclusion, while laminar flow offers significant potential for enhancing sensor precision and efficiency, its environmental impact is multifaceted. Balancing the benefits of improved accuracy and potential energy savings against the environmental costs of production and operation is crucial for ensuring the sustainable development and implementation of this technology in sensor applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!