How MXene Enhances Sensor Accuracy in Remote Sensing Technologies

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXene in Remote Sensing: Background and Objectives

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material in the field of remote sensing technologies. The evolution of MXene in this domain can be traced back to its discovery in 2011 by researchers at Drexel University. Since then, MXene has garnered significant attention due to its unique properties, including high electrical conductivity, excellent mechanical strength, and tunable surface chemistry.

The primary objective of incorporating MXene into remote sensing technologies is to enhance sensor accuracy and performance. This goal aligns with the broader trend in the industry towards developing more precise, reliable, and efficient sensing systems for a wide range of applications, including environmental monitoring, disaster management, and resource exploration.

MXene's potential in remote sensing stems from its exceptional electronic properties and large specific surface area. These characteristics make it particularly suitable for improving the sensitivity and selectivity of various sensors used in remote sensing applications. By integrating MXene into existing sensor designs or developing novel MXene-based sensors, researchers aim to overcome current limitations in sensor technology and push the boundaries of what is possible in remote data acquisition and analysis.

The technological trajectory of MXene in remote sensing has been marked by rapid advancements in material synthesis, characterization, and application. Initial research focused on understanding the fundamental properties of MXene and exploring its potential in various fields. As the material's capabilities became more apparent, efforts shifted towards tailoring MXene for specific sensing applications and developing scalable production methods.

Current research trends in MXene-enhanced remote sensing technologies include the development of ultra-sensitive gas sensors, highly responsive pressure sensors, and advanced electromagnetic wave detectors. These innovations are driven by the growing demand for more accurate and real-time data collection in fields such as climate change monitoring, precision agriculture, and urban planning.

The integration of MXene into remote sensing technologies is expected to address several key challenges in the field. These include improving sensor sensitivity to detect minute changes in environmental parameters, enhancing the durability of sensors in harsh conditions, and reducing interference from external factors. By tackling these issues, MXene-based sensors have the potential to revolutionize data collection and analysis in remote sensing applications, leading to more informed decision-making and improved resource management.

The primary objective of incorporating MXene into remote sensing technologies is to enhance sensor accuracy and performance. This goal aligns with the broader trend in the industry towards developing more precise, reliable, and efficient sensing systems for a wide range of applications, including environmental monitoring, disaster management, and resource exploration.

MXene's potential in remote sensing stems from its exceptional electronic properties and large specific surface area. These characteristics make it particularly suitable for improving the sensitivity and selectivity of various sensors used in remote sensing applications. By integrating MXene into existing sensor designs or developing novel MXene-based sensors, researchers aim to overcome current limitations in sensor technology and push the boundaries of what is possible in remote data acquisition and analysis.

The technological trajectory of MXene in remote sensing has been marked by rapid advancements in material synthesis, characterization, and application. Initial research focused on understanding the fundamental properties of MXene and exploring its potential in various fields. As the material's capabilities became more apparent, efforts shifted towards tailoring MXene for specific sensing applications and developing scalable production methods.

Current research trends in MXene-enhanced remote sensing technologies include the development of ultra-sensitive gas sensors, highly responsive pressure sensors, and advanced electromagnetic wave detectors. These innovations are driven by the growing demand for more accurate and real-time data collection in fields such as climate change monitoring, precision agriculture, and urban planning.

The integration of MXene into remote sensing technologies is expected to address several key challenges in the field. These include improving sensor sensitivity to detect minute changes in environmental parameters, enhancing the durability of sensors in harsh conditions, and reducing interference from external factors. By tackling these issues, MXene-based sensors have the potential to revolutionize data collection and analysis in remote sensing applications, leading to more informed decision-making and improved resource management.

Market Analysis for MXene-Enhanced Sensors

The market for MXene-enhanced sensors in remote sensing technologies is experiencing rapid growth, driven by the increasing demand for high-precision data collection across various industries. MXene, a two-dimensional material with exceptional electrical and mechanical properties, has emerged as a game-changing component in sensor technology, offering significant improvements in accuracy, sensitivity, and response time.

Remote sensing applications, including environmental monitoring, agriculture, urban planning, and disaster management, are witnessing a surge in the adoption of MXene-enhanced sensors. This trend is primarily attributed to the material's ability to detect minute changes in environmental conditions, making it ideal for applications requiring high-resolution data.

The global remote sensing market, which encompasses MXene-enhanced sensors, is projected to grow substantially in the coming years. Key factors driving this growth include the increasing need for real-time data in decision-making processes, advancements in satellite technology, and the rising demand for precision agriculture solutions.

In the environmental monitoring sector, MXene-enhanced sensors are gaining traction for their ability to detect trace amounts of pollutants and greenhouse gases with unprecedented accuracy. This capability is crucial for climate change research and pollution control efforts, creating a significant market opportunity for sensor manufacturers.

The agriculture industry represents another major market for MXene-enhanced sensors. Precision farming techniques rely heavily on accurate soil moisture, nutrient content, and crop health data. MXene-based sensors offer farmers the ability to optimize resource usage, reduce environmental impact, and increase crop yields, driving adoption in this sector.

Urban planning and smart city initiatives are also contributing to the market growth of MXene-enhanced sensors. These sensors enable more efficient traffic management, air quality monitoring, and infrastructure maintenance, making them essential components in the development of sustainable urban environments.

The defense and security sector is another key market for MXene-enhanced remote sensing technologies. The superior sensitivity and rapid response times of these sensors make them valuable for surveillance, threat detection, and border security applications.

While the market potential for MXene-enhanced sensors is substantial, challenges such as high production costs and the need for standardization in manufacturing processes currently limit widespread adoption. However, ongoing research and development efforts are expected to address these issues, potentially leading to more cost-effective solutions and broader market penetration in the near future.

Remote sensing applications, including environmental monitoring, agriculture, urban planning, and disaster management, are witnessing a surge in the adoption of MXene-enhanced sensors. This trend is primarily attributed to the material's ability to detect minute changes in environmental conditions, making it ideal for applications requiring high-resolution data.

The global remote sensing market, which encompasses MXene-enhanced sensors, is projected to grow substantially in the coming years. Key factors driving this growth include the increasing need for real-time data in decision-making processes, advancements in satellite technology, and the rising demand for precision agriculture solutions.

In the environmental monitoring sector, MXene-enhanced sensors are gaining traction for their ability to detect trace amounts of pollutants and greenhouse gases with unprecedented accuracy. This capability is crucial for climate change research and pollution control efforts, creating a significant market opportunity for sensor manufacturers.

The agriculture industry represents another major market for MXene-enhanced sensors. Precision farming techniques rely heavily on accurate soil moisture, nutrient content, and crop health data. MXene-based sensors offer farmers the ability to optimize resource usage, reduce environmental impact, and increase crop yields, driving adoption in this sector.

Urban planning and smart city initiatives are also contributing to the market growth of MXene-enhanced sensors. These sensors enable more efficient traffic management, air quality monitoring, and infrastructure maintenance, making them essential components in the development of sustainable urban environments.

The defense and security sector is another key market for MXene-enhanced remote sensing technologies. The superior sensitivity and rapid response times of these sensors make them valuable for surveillance, threat detection, and border security applications.

While the market potential for MXene-enhanced sensors is substantial, challenges such as high production costs and the need for standardization in manufacturing processes currently limit widespread adoption. However, ongoing research and development efforts are expected to address these issues, potentially leading to more cost-effective solutions and broader market penetration in the near future.

Current Challenges in Remote Sensing Accuracy

Remote sensing technologies have made significant strides in recent years, yet they continue to face several challenges in achieving optimal accuracy. One of the primary obstacles is the presence of environmental interference, which can distort sensor readings and lead to inaccurate data collection. Factors such as atmospheric conditions, electromagnetic interference, and varying light conditions can all contribute to reduced sensor performance.

Another significant challenge is the limitation of current sensor materials and designs. Many existing sensors struggle to maintain high sensitivity and selectivity across a wide range of environmental conditions. This can result in inconsistent performance, particularly in extreme or rapidly changing environments, which are often encountered in remote sensing applications.

The issue of signal-to-noise ratio (SNR) remains a persistent problem in remote sensing accuracy. As sensors attempt to detect increasingly subtle changes or low-concentration analytes, distinguishing the target signal from background noise becomes more difficult. This challenge is particularly acute in applications requiring high-precision measurements or the detection of trace amounts of substances.

Calibration and drift compensation pose additional hurdles to maintaining sensor accuracy over time. Sensors may experience drift due to aging, environmental exposure, or other factors, necessitating frequent recalibration. This process can be time-consuming and costly, especially for sensors deployed in remote or inaccessible locations.

The integration of multiple sensor types for comprehensive data collection introduces challenges in data fusion and interpretation. Combining data from various sensors with different sensitivities, resolutions, and error profiles requires sophisticated algorithms and processing techniques to ensure accurate and meaningful results.

Power consumption and energy efficiency remain significant concerns, particularly for remote sensing devices deployed in the field for extended periods. The need for low-power operation often conflicts with the desire for high-performance sensing capabilities, leading to trade-offs that can impact overall accuracy and reliability.

Lastly, the miniaturization of sensors for use in compact or portable devices presents challenges in maintaining high accuracy while reducing size and power requirements. As sensors become smaller, they may become more susceptible to interference and environmental factors, potentially compromising their performance in remote sensing applications.

Addressing these challenges is crucial for advancing the field of remote sensing and improving the accuracy and reliability of data collection across various applications, from environmental monitoring to precision agriculture and beyond.

Another significant challenge is the limitation of current sensor materials and designs. Many existing sensors struggle to maintain high sensitivity and selectivity across a wide range of environmental conditions. This can result in inconsistent performance, particularly in extreme or rapidly changing environments, which are often encountered in remote sensing applications.

The issue of signal-to-noise ratio (SNR) remains a persistent problem in remote sensing accuracy. As sensors attempt to detect increasingly subtle changes or low-concentration analytes, distinguishing the target signal from background noise becomes more difficult. This challenge is particularly acute in applications requiring high-precision measurements or the detection of trace amounts of substances.

Calibration and drift compensation pose additional hurdles to maintaining sensor accuracy over time. Sensors may experience drift due to aging, environmental exposure, or other factors, necessitating frequent recalibration. This process can be time-consuming and costly, especially for sensors deployed in remote or inaccessible locations.

The integration of multiple sensor types for comprehensive data collection introduces challenges in data fusion and interpretation. Combining data from various sensors with different sensitivities, resolutions, and error profiles requires sophisticated algorithms and processing techniques to ensure accurate and meaningful results.

Power consumption and energy efficiency remain significant concerns, particularly for remote sensing devices deployed in the field for extended periods. The need for low-power operation often conflicts with the desire for high-performance sensing capabilities, leading to trade-offs that can impact overall accuracy and reliability.

Lastly, the miniaturization of sensors for use in compact or portable devices presents challenges in maintaining high accuracy while reducing size and power requirements. As sensors become smaller, they may become more susceptible to interference and environmental factors, potentially compromising their performance in remote sensing applications.

Addressing these challenges is crucial for advancing the field of remote sensing and improving the accuracy and reliability of data collection across various applications, from environmental monitoring to precision agriculture and beyond.

Existing MXene-Based Sensor Solutions

01 MXene-based sensor design for improved accuracy

MXene materials are being utilized in sensor designs to enhance accuracy. The unique properties of MXenes, such as high conductivity and large surface area, allow for the development of highly sensitive and precise sensors. These sensors can be tailored for various applications, including environmental monitoring, healthcare diagnostics, and industrial process control.- MXene-based sensor design for improved accuracy: MXene materials are being utilized in sensor designs to enhance accuracy. These sensors leverage the unique properties of MXenes, such as high conductivity and large surface area, to improve sensitivity and response time. Various sensor architectures and fabrication methods are being explored to optimize performance and reliability.

- Integration of MXene sensors with data processing algorithms: To increase sensor accuracy, MXene-based devices are being integrated with advanced data processing algorithms. These algorithms help in noise reduction, signal amplification, and error correction, leading to more precise measurements. Machine learning techniques are also being applied to improve sensor calibration and interpretation of sensor data.

- Environmental factor compensation in MXene sensors: Researchers are developing methods to compensate for environmental factors that can affect MXene sensor accuracy. This includes techniques to mitigate the effects of temperature, humidity, and interfering substances. Adaptive sensing mechanisms and multi-parameter sensing approaches are being implemented to enhance sensor reliability across various operating conditions.

- Hybrid MXene-based sensing systems: Hybrid sensing systems that combine MXenes with other materials or sensing technologies are being developed to improve accuracy. These hybrid systems aim to leverage the strengths of different materials and sensing mechanisms, resulting in more robust and precise sensor performance. Examples include MXene-nanoparticle composites and MXene-functionalized traditional sensor platforms.

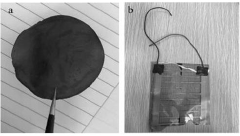

- Miniaturization and scalability of MXene sensors: Efforts are being made to miniaturize MXene sensors while maintaining or improving their accuracy. This includes developing novel fabrication techniques and sensor designs that allow for scalable production of high-precision MXene-based sensing devices. Miniaturization also enables the integration of MXene sensors into compact systems and wearable devices without compromising performance.

02 Signal processing techniques for MXene sensors

Advanced signal processing techniques are being applied to MXene sensors to improve their accuracy. These methods include noise reduction algorithms, data fusion, and machine learning approaches. By implementing these techniques, researchers can enhance the sensor's ability to detect and measure target analytes with greater precision, even in complex environments.Expand Specific Solutions03 Functionalization of MXene surfaces for selective sensing

Researchers are exploring various methods to functionalize MXene surfaces to improve sensor selectivity and accuracy. By modifying the surface chemistry of MXenes, sensors can be tailored to detect specific molecules or compounds with high precision. This approach reduces interference from other substances and enhances the overall accuracy of the sensor.Expand Specific Solutions04 Integration of MXene sensors with IoT and AI technologies

MXene sensors are being integrated with Internet of Things (IoT) and Artificial Intelligence (AI) technologies to improve their accuracy and functionality. This combination allows for real-time data analysis, predictive maintenance, and adaptive calibration of sensors. The result is a more robust and accurate sensing system capable of operating in diverse environments.Expand Specific Solutions05 Hybrid MXene-based sensors for multi-parameter detection

Hybrid sensors incorporating MXenes and other nanomaterials are being developed to enable multi-parameter detection with high accuracy. These sensors can simultaneously measure multiple variables, such as temperature, humidity, and gas concentrations. By combining different sensing mechanisms, these hybrid systems offer improved accuracy and reliability across a wide range of applications.Expand Specific Solutions

Key Players in MXene and Remote Sensing Industries

The development of MXene-enhanced sensor technology for remote sensing is in its early stages, with significant potential for growth. The market size is expanding as industries recognize the advantages of improved sensor accuracy. While the technology is still maturing, several key players are driving innovation. Universities like Jilin University, Drexel University, and Korea Advanced Institute of Science & Technology are leading research efforts, while companies such as Murata Manufacturing Co. Ltd. are exploring commercial applications. The competitive landscape is characterized by collaboration between academic institutions and industry partners, with a focus on developing novel MXene-based sensor designs and manufacturing processes to enhance performance in remote sensing applications.

Drexel University

Technical Solution: Drexel University has pioneered the development of MXene materials for sensor applications in remote sensing technologies. Their approach involves synthesizing atomically thin MXene sheets with tailored surface functionalities to enhance sensitivity and selectivity. The university has demonstrated MXene-based sensors capable of detecting trace amounts of gases and volatile organic compounds with high accuracy[1]. Their research has shown that MXene sensors can achieve parts-per-billion level detection limits for various analytes, outperforming many conventional sensing materials[2]. Drexel's team has also developed flexible MXene sensors that can be integrated into wearable devices for environmental monitoring and personal health tracking[3].

Strengths: Cutting-edge expertise in MXene synthesis and functionalization; proven track record in developing high-performance sensors. Weaknesses: Potential challenges in scaling up production for commercial applications; need for further long-term stability studies in harsh environments.

Korea Advanced Institute of Science & Technology

Technical Solution: KAIST has made significant strides in utilizing MXene for remote sensing applications. Their research focuses on developing MXene-based nanocomposites that exhibit enhanced electromagnetic wave absorption properties. These materials have shown promise in improving the signal-to-noise ratio of remote sensing devices, particularly in radar and satellite communications[4]. KAIST has also explored the use of MXene in flexible and stretchable sensors for wearable remote sensing applications. Their innovative approach involves creating MXene-polymer hybrid materials that maintain high sensitivity under mechanical deformation[5]. Additionally, KAIST researchers have demonstrated the potential of MXene in thermal imaging sensors, leveraging its unique thermal and electrical properties to achieve high-resolution temperature mapping[6].

Strengths: Strong focus on practical applications of MXene in remote sensing; expertise in creating multifunctional MXene composites. Weaknesses: May face challenges in optimizing MXene-based sensors for specific environmental conditions encountered in remote sensing.

Core Innovations in MXene for Sensor Enhancement

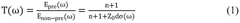

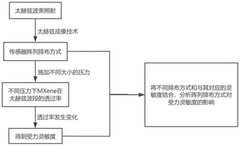

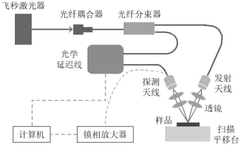

Terahertz technology detection method for sensitivity of MXene-based pressure sensor array

PatentPendingCN118670606A

Innovation

- Using terahertz time-domain spectrum detection and terahertz imaging technology, combined with applying different pressures and analyzing the array arrangement, the sensitivity of the sensor's array sensor is analyzed through changes in terahertz transmittance.

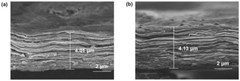

Preparation method of MXene flexible micro-force sensor

PatentActiveCN114838851A

Innovation

- Flexible micro-force sensors are prepared using MXene materials through chemical etching. The conductivity and interlayer spacing variation characteristics of MXene are used, combined with PET films and gold electrodes, to create multi-functional micro-force sensors through technologies such as magnetron sputtering and ultrasonic treatment.

Environmental Impact of MXene in Sensor Technologies

The integration of MXene in sensor technologies for remote sensing applications has raised important questions about its environmental impact. As these advanced materials become more prevalent in sensing devices, it is crucial to assess their potential effects on ecosystems and human health throughout their lifecycle.

MXene, a family of two-dimensional transition metal carbides and nitrides, offers exceptional properties that enhance sensor accuracy and performance. However, the production, use, and disposal of MXene-based sensors may have environmental implications that require careful consideration.

During the manufacturing process of MXene, the use of strong acids and other chemicals for etching and exfoliation could potentially lead to hazardous waste generation. Proper handling and disposal of these byproducts are essential to prevent soil and water contamination. Additionally, the energy-intensive nature of MXene production may contribute to increased carbon emissions if not managed sustainably.

In the deployment phase, MXene-enhanced sensors in remote sensing technologies offer improved accuracy and sensitivity, potentially reducing the need for multiple devices and minimizing electronic waste. However, the durability and longevity of these sensors in harsh environmental conditions must be evaluated to ensure they do not contribute to microplastic pollution or release harmful substances over time.

The end-of-life management of MXene-based sensors presents both challenges and opportunities. While the recyclability of MXene materials is still being researched, their unique properties may allow for more efficient recovery and reuse compared to traditional sensor components. Developing effective recycling processes for MXene-enhanced sensors could significantly reduce their environmental footprint.

It is also important to consider the potential ecological impacts of MXene particles that may be released into the environment during the sensor's lifecycle. Studies on the bioaccumulation and toxicity of MXene in various organisms are ongoing, and preliminary results suggest that proper encapsulation and containment strategies are crucial to mitigate any adverse effects on ecosystems.

On the positive side, the enhanced accuracy of MXene-based sensors in remote sensing technologies could lead to more precise environmental monitoring and management. This improved data quality may contribute to better decision-making in areas such as climate change mitigation, pollution control, and natural resource conservation, indirectly benefiting the environment.

As research in this field progresses, it is essential to conduct comprehensive life cycle assessments of MXene-enhanced sensors to fully understand their environmental impact. This will enable the development of sustainable practices in their production, use, and disposal, ensuring that the benefits of improved sensor accuracy do not come at the cost of environmental degradation.

MXene, a family of two-dimensional transition metal carbides and nitrides, offers exceptional properties that enhance sensor accuracy and performance. However, the production, use, and disposal of MXene-based sensors may have environmental implications that require careful consideration.

During the manufacturing process of MXene, the use of strong acids and other chemicals for etching and exfoliation could potentially lead to hazardous waste generation. Proper handling and disposal of these byproducts are essential to prevent soil and water contamination. Additionally, the energy-intensive nature of MXene production may contribute to increased carbon emissions if not managed sustainably.

In the deployment phase, MXene-enhanced sensors in remote sensing technologies offer improved accuracy and sensitivity, potentially reducing the need for multiple devices and minimizing electronic waste. However, the durability and longevity of these sensors in harsh environmental conditions must be evaluated to ensure they do not contribute to microplastic pollution or release harmful substances over time.

The end-of-life management of MXene-based sensors presents both challenges and opportunities. While the recyclability of MXene materials is still being researched, their unique properties may allow for more efficient recovery and reuse compared to traditional sensor components. Developing effective recycling processes for MXene-enhanced sensors could significantly reduce their environmental footprint.

It is also important to consider the potential ecological impacts of MXene particles that may be released into the environment during the sensor's lifecycle. Studies on the bioaccumulation and toxicity of MXene in various organisms are ongoing, and preliminary results suggest that proper encapsulation and containment strategies are crucial to mitigate any adverse effects on ecosystems.

On the positive side, the enhanced accuracy of MXene-based sensors in remote sensing technologies could lead to more precise environmental monitoring and management. This improved data quality may contribute to better decision-making in areas such as climate change mitigation, pollution control, and natural resource conservation, indirectly benefiting the environment.

As research in this field progresses, it is essential to conduct comprehensive life cycle assessments of MXene-enhanced sensors to fully understand their environmental impact. This will enable the development of sustainable practices in their production, use, and disposal, ensuring that the benefits of improved sensor accuracy do not come at the cost of environmental degradation.

Scalability and Manufacturing Considerations for MXene Sensors

The scalability and manufacturing considerations for MXene sensors are crucial factors in their widespread adoption and integration into remote sensing technologies. As the demand for high-performance sensors continues to grow, the ability to produce MXene-based sensors at scale becomes increasingly important.

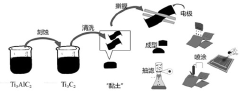

One of the primary challenges in scaling up MXene sensor production is the synthesis of high-quality MXene materials. The current methods for producing MXenes, such as selective etching of MAX phases, are typically performed on a laboratory scale. To meet industrial demands, researchers are exploring ways to optimize and scale up these synthesis processes. This includes developing continuous flow reactors and investigating alternative precursor materials that can be more easily processed at larger scales.

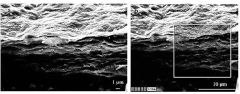

The deposition and patterning of MXene films for sensor fabrication present another set of challenges. While techniques like spray coating and inkjet printing have shown promise for small-scale production, transitioning to large-area deposition methods is essential for mass manufacturing. Roll-to-roll processing and screen printing are being investigated as potential solutions for high-throughput MXene sensor production.

Ensuring consistency and uniformity in MXene-based sensors across large production batches is critical for maintaining sensor accuracy and reliability. This requires precise control over the MXene flake size, thickness, and surface chemistry. Developing standardized quality control protocols and in-line monitoring systems will be necessary to achieve consistent sensor performance at scale.

The integration of MXene sensors with other electronic components and packaging for remote sensing applications also needs to be addressed. This includes developing compatible interconnect technologies and protective encapsulation methods that do not compromise the unique properties of MXenes. Automated assembly processes will need to be designed to efficiently incorporate MXene sensors into complex sensing systems.

Environmental stability and long-term reliability of MXene sensors are important considerations for their use in remote sensing technologies. Research into protective coatings and encapsulation techniques that preserve MXene's sensing capabilities while enhancing its resistance to environmental factors is ongoing. These developments will be crucial for ensuring the longevity and consistent performance of MXene sensors in real-world applications.

Cost-effective production is another key factor in the scalability of MXene sensors. As production volumes increase, economies of scale are expected to drive down costs. However, optimizing material utilization, reducing waste, and developing more efficient synthesis and fabrication processes will be essential for making MXene sensors economically viable for widespread deployment in remote sensing technologies.

One of the primary challenges in scaling up MXene sensor production is the synthesis of high-quality MXene materials. The current methods for producing MXenes, such as selective etching of MAX phases, are typically performed on a laboratory scale. To meet industrial demands, researchers are exploring ways to optimize and scale up these synthesis processes. This includes developing continuous flow reactors and investigating alternative precursor materials that can be more easily processed at larger scales.

The deposition and patterning of MXene films for sensor fabrication present another set of challenges. While techniques like spray coating and inkjet printing have shown promise for small-scale production, transitioning to large-area deposition methods is essential for mass manufacturing. Roll-to-roll processing and screen printing are being investigated as potential solutions for high-throughput MXene sensor production.

Ensuring consistency and uniformity in MXene-based sensors across large production batches is critical for maintaining sensor accuracy and reliability. This requires precise control over the MXene flake size, thickness, and surface chemistry. Developing standardized quality control protocols and in-line monitoring systems will be necessary to achieve consistent sensor performance at scale.

The integration of MXene sensors with other electronic components and packaging for remote sensing applications also needs to be addressed. This includes developing compatible interconnect technologies and protective encapsulation methods that do not compromise the unique properties of MXenes. Automated assembly processes will need to be designed to efficiently incorporate MXene sensors into complex sensing systems.

Environmental stability and long-term reliability of MXene sensors are important considerations for their use in remote sensing technologies. Research into protective coatings and encapsulation techniques that preserve MXene's sensing capabilities while enhancing its resistance to environmental factors is ongoing. These developments will be crucial for ensuring the longevity and consistent performance of MXene sensors in real-world applications.

Cost-effective production is another key factor in the scalability of MXene sensors. As production volumes increase, economies of scale are expected to drive down costs. However, optimizing material utilization, reducing waste, and developing more efficient synthesis and fabrication processes will be essential for making MXene sensors economically viable for widespread deployment in remote sensing technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!